|

Digital Materialization

Digital materialization (DM) can loosely be defined as two-way direct communication or conversion between matter and information that enables people to exactly describe, monitor, manipulate and create any arbitrary real object. DM is a general paradigm alongside a specified framework that is suitable for computer processing and includes: holistic, coherent, volumetric modeling systems; symbolic languages that are able to handle infinite degrees of freedom and detail in a compact format; and the direct interaction and/or fabrication of any object at any spatial resolution without the need for “lossy” or intermediate formats. ''DM'' systems possess the following attributes: * realistic - correct spatial mapping of matter to information * exact - exact language and/or methods for input from and output to matter * infinite - ability to operate at any scale and define infinite detail * symbolic - accessible to individuals for design, creation and modification Such an approach c ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

|

|

Paradigm

In science and philosophy, a paradigm () is a distinct set of concepts or thought patterns, including theories, research methods, postulates, and standards for what constitute legitimate contributions to a field. Etymology ''Paradigm'' comes from Greek παράδειγμα (''paradeigma''), "pattern, example, sample" from the verb παραδείκνυμι (''paradeiknumi''), "exhibit, represent, expose" and that from παρά (''para''), "beside, beyond" and δείκνυμι (''deiknumi''), "to show, to point out". In classical (Greek-based) rhetoric, a paradeigma aims to provide an audience with an illustration of a similar occurrence. This illustration is not meant to take the audience to a conclusion, however it is used to help guide them get there. One way of how a ''paradeigma'' is meant to guide an audience would be exemplified by the role of a personal accountant. It is not the job of a personal accountant to tell a client exactly what (and what not) to spend money ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

|

|

Function Representation

Function Representation (FRep or F-Rep) is used in solid modeling, volume modeling and computer graphics. FRep was introduced in "Function representation in geometric modeling: concepts, implementation and applications" as a uniform representation of multidimensional geometric objects (shapes). An object as a point set in multidimensional space is defined by a single continuous real-valued function f(X) of point coordinates X _1,x_2, ..., x_n/math> which is evaluated at the given point by a procedure traversing a tree structure with primitives in the leaves and operations in the nodes of the tree. The points with f(x_1,x_2, ..., x_n) \ge 0 belong to the object, and the points with f(x_1,x_2, ..., x_n) < 0 are outside of the object. The point set with is called an . Geometric domain The geomet ...[...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

|

|

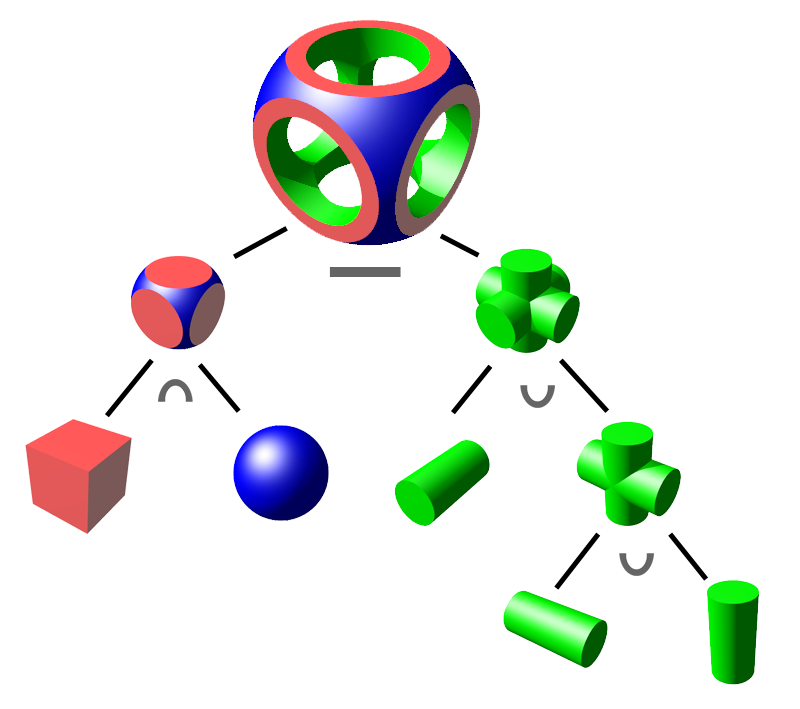

Constructive Solid Geometry

Constructive solid geometry (CSG; formerly called computational binary solid geometry) is a technique used in solid modeling. Constructive solid geometry allows a modeler to create a complex surface or object by using Boolean operators to combine simpler objects,, potentially generating visually complex objects by combining a few primitive ones.. In 3D computer graphics and CAD, CSG is often used in procedural modeling. CSG can also be performed on polygonal meshes, and may or may not be procedural and/or parametric. Contrast CSG with polygon mesh modeling and box modeling. Workings The simplest solid objects used for the representation are called ''geometric primitives''. Typically they are the objects of simple shape: cuboids, cylinders, prisms, pyramids, spheres, cones. The set of allowable primitives is limited by each software package. Some software packages allow CSG on curved objects while other packages do not. An object is ''constructed'' from primitives by mea ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

|

Isosurface

An isosurface is a three-dimensional analog of an isoline. It is a surface that represents points of a constant value (e.g. pressure, temperature, velocity, density) within a volume of space; in other words, it is a level set of a continuous function whose domain is 3-space. The term ''isoline'' is also sometimes used for domains of more than 3 dimensions. Applications Isosurfaces are normally displayed using computer graphics, and are used as data visualization methods in computational fluid dynamics (CFD), allowing engineers to study features of a fluid flow (gas or liquid) around objects, such as aircraft wings. An isosurface may represent an individual shock wave in supersonic flight, or several isosurfaces may be generated showing a sequence of pressure values in the air flowing around a wing. Isosurfaces tend to be a popular form of visualization for volume datasets since they can be rendered by a simple polygonal model, which can be drawn on the screen very q ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

|

Solid Modeling

Solid modeling (or solid modelling) is a consistent set of principles for mathematical and computer modeling of three-dimensional shapes '' (solids)''. Solid modeling is distinguished from related areas of geometric modeling and computer graphics, such as ''3D modeling'', by its emphasis on physical fidelity. Together, the principles of geometric and solid modeling form the foundation of 3D- computer-aided design and in general support the creation, exchange, visualization, animation, interrogation, and annotation of digital models of physical objects. Overview The use of solid modeling techniques allows for the automation process of several difficult engineering calculations that are carried out as a part of the design process. Simulation, planning, and verification of processes such as machining and assembly were one of the main catalysts for the development of solid modeling. More recently, the range of supported manufacturing applications has been greatly expanded to in ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

|

3D Printing

3D printing or additive manufacturing is the construction of a three-dimensional object from a CAD model or a digital 3D model. It can be done in a variety of processes in which material is deposited, joined or solidified under computer control, with material being added together (such as plastics, liquids or powder grains being fused), typically layer by layer. In the 1980s, 3D printing techniques were considered suitable only for the production of functional or aesthetic prototypes, and a more appropriate term for it at the time was rapid prototyping. , the precision, repeatability, and material range of 3D printing have increased to the point that some 3D printing processes are considered viable as an industrial-production technology, whereby the term ''additive manufacturing'' can be used synonymously with ''3D printing''. One of the key advantages of 3D printing is the ability to produce very complex shapes or geometries that would be otherwise impossible to construc ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

|

Rapid Prototyping

Rapid prototyping is a group of techniques used to quickly fabricate a scale model of a physical part or assembly using three-dimensional computer aided design ( CAD) data. Construction of the part or assembly is usually done using 3D printing or " additive layer manufacturing" technology. The first methods for rapid prototyping became available in the mid 1987 and were used to produce models and prototype parts. Today, they are used for a wide range of applications and are used to manufacture production-quality parts in relatively small numbers if desired without the typical unfavorable short-run economics. This economy has encouraged online service bureaus. Historical surveys of RP technology start with discussions of simulacra production techniques used by 19th-century sculptors. Some modern sculptors use the progeny technology to produce exhibitions and various objects. The ability to reproduce designs from a dataset has given rise to issues of rights, as it is now ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

|

Molecular Assembler

A molecular assembler, as defined by K. Eric Drexler, is a "proposed device able to guide chemical reactions by positioning reactive molecules with atomic precision". A molecular assembler is a kind of molecular machine. Some biological molecules such as ribosomes fit this definition. This is because they receive instructions from messenger RNA and then assemble specific sequences of amino acids to construct protein molecules. However, the term "molecular assembler" usually refers to theoretical human-made devices. Beginning in 2007, the British Engineering and Physical Sciences Research Council has funded development of ribosome-like molecular assemblers. Clearly, molecular assemblers are possible in this limited sense. A technology roadmap project, led by the Battelle Memorial Institute and hosted by several U.S. National Laboratories has explored a range of atomically precise fabrication technologies, including both early-generation and longer-term prospects for prog ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

|

|

RepRap

The RepRap project started in England in 2005 as a University of Bath initiative to develop a low-cost 3D printer that can print most of its own components, but it is now made up of hundreds of collaborators worldwide. RepRap is short for rep''licating'' rap''id prototyper''. As an open design, all of the designs produced by the project are released under a free software license, the GNU General Public License. Due to the ability of the machine to make some of its own parts, authors envisioned the possibility of cheap RepRap units, enabling the manufacture of complex products without the need for extensive industrial infrastructure.J.M. Pearce, ''Open-Source Lab: How to Build Your Own Hardware and Reduce Research Costs'', Elsevier, 2014. They intended for the RepRap to demonstrate evolution in this process as well as for it to increase in number exponentially. A preliminary study claimed that using RepRaps to print common products results in economic savings. History RepRap wa ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

|

Engineering Concepts

Engineering is the use of scientific principles to design and build machines, structures, and other items, including bridges, tunnels, roads, vehicles, and buildings. The discipline of engineering encompasses a broad range of more specialized fields of engineering, each with a more specific emphasis on particular areas of applied mathematics, applied science, and types of application. See glossary of engineering. The term ''engineering'' is derived from the Latin ''ingenium'', meaning "cleverness" and ''ingeniare'', meaning "to contrive, devise". Definition The American Engineers' Council for Professional Development (ECPD, the predecessor of ABET) has defined "engineering" as: The creative application of scientific principles to design or develop structures, machines, apparatus, or manufacturing processes, or works utilizing them singly or in combination; or to construct or operate the same with full cognizance of their design; or to forecast their behavior under spec ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

|

Digital Manufacturing

Digital manufacturing is an integrated approach to manufacturing that is centered around a computer system. The transition to digital manufacturing has become more popular with the rise in the quantity and quality of computer systems in manufacturing plants. As more automated tools have become used in manufacturing plants it has become necessary to model, simulate, and analyze all of the machines, tooling, and input materials in order to optimize the manufacturing process. Overall, digital manufacturing can be seen sharing the same goals as computer-integrated manufacturing (CIM), flexible manufacturing, lean manufacturing, and design for manufacturability (DFM). The main difference is that digital manufacturing was evolved for use in the computerized world. As part of Manufacturing USA, Congress and the U.S. Department of Defense establisheMxD(Manufacturing x Digital), the nation's digital manufacturing institute, to speed adoption of these digital tools. Three dimensional modeli ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |