|

Dead Blow Hammer

A dead-blow hammer is a specialized mallet helpful in minimizing damage to the struck surface and in controlling striking force, with minimal rebound from the struck surface. The minimal rebound is helpful in avoiding accidental damage to precision work, especially in tight locations and in applications such as maintenance work on hydraulic cylinders. Description The head of the dead-blow hammer can be solid or hollow (often partially filled with loose steel shot), which distributes the energy of the strike over a longer period of time and reduces rebound. Solid-head dead-blow hammers are usually made of rubber or resilient plastic (such as polyurethane or ultra-high-molecular-weight polyethylene) and rely on the inherent properties of the material to absorb shock and reduce rebound. Composite heads and fiberglass handle models are also available, with optional shock-absorbent rubber grips. A variant design omits the handle entirely; the dead-blow head is gripped directly ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hammer

A hammer is a tool, most often a hand tool, consisting of a weighted "head" fixed to a long handle that is swung to deliver an impact to a small area of an object. This can be, for example, to drive nail (fastener), nails into wood, to shape metal (as with a forge), or to crush Rock (geology), rock. Hammers are used for a wide range of driving, shaping, breaking and non-destructive striking applications. Traditional disciplines include carpentry, blacksmithing, war hammer, warfare, and mallet percussion, percussive musicianship (as with a gong). Hammering is use of a hammer in its strike capacity, as opposed to pry bar, prying with a secondary claw or grappling with a secondary hook. Carpentry and blacksmithing hammers are generally wielded from a stationary stance against a stationary target as gripped and propelled with one arm, in a lengthy downward plane (geometry), planar arc—downward to add kinetic energy to the impact—pivoting mainly around the shoulder and elbo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Mass

Mass is an Intrinsic and extrinsic properties, intrinsic property of a physical body, body. It was traditionally believed to be related to the physical quantity, quantity of matter in a body, until the discovery of the atom and particle physics. It was found that different atoms and different elementary particle, elementary particles, theoretically with the same amount of matter, have nonetheless different masses. Mass in modern physics has multiple Mass in special relativity, definitions which are conceptually distinct, but physically equivalent. Mass can be experimentally defined as a measure (mathematics), measure of the body's inertia, meaning the resistance to acceleration (change of velocity) when a net force is applied. The object's mass also determines the Force, strength of its gravitational attraction to other bodies. The SI base unit of mass is the kilogram (kg). In physics, mass is Mass versus weight, not the same as weight, even though mass is often determined by ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Vise

A vise or vice (British English) is a mechanical apparatus used to secure an object to allow work to be performed on it. Vises have two parallel jaws, one fixed and the other movable, threaded in and out by a screw and lever. The jaws are often flat but may have grooves, adapt to the shape of the workpiece or be custom made. A vise grip is not a vise but a pair of lever-actuated locking pliers. Etymology The etymology of ''vise'' can be tracked via Middle English ''vys'' Anglo-French ''vyz'' from Latin ''vitis'' "vine". The tight grip of the mechanical device was likened to that of the twines of the plant. Types Face A face vise is the standard woodworking vise, always securely attached to a workbench flush with its work surface. Its jaws are made of wood or metal, the latter usually faced with wood, called cheeks, to avoid marring the work. The movable jaw may include a retractable dog to hold work against a bench dog. A "quick-release" woodworker's vise employs a split ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Parallels (engineering)

A parallel is a rectangular block of metal, commonly made from tool steel, stainless steel or cast iron, which has 2, 4 or 6 faces ground or lapped to a precise surface finish. Parallels are used when machining with a mill, drill or any other machining operation that requires work to be held in a vise or with clamps - to keep work parallel or raised evenly such as in a milling vise to give adequate height for the cutting tool/spindle to pass over. Description Parallels come in pairs, which are machined to be the same dimensions as their corresponding faces. They come in a variety of thicknesses and size, allowing them to be stacked up or to support a workpiece which doesn't have a flat profile. Parallels commonly have a series of holes drilled on the 'front' face - allowing them to be used to position a workpiece or secured using t-slot clamps, and a countersink on each side to remove any sharp edges. Generally, workshop parallels have 4 faces that are machined and ground - ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Metalworking

Metalworking is the process of shaping and reshaping metals in order to create useful objects, parts, assemblies, and large scale structures. As a term, it covers a wide and diverse range of processes, skills, and tools for producing objects on every scale: from huge ships, buildings, and bridges, down to precise engine parts and delicate jewellery. The historical roots of metalworking predate recorded history; its use spans cultures, civilizations and millennia. It has evolved from shaping soft, native metals like gold with simple hand tools, through the smelting of ores and hot forging of harder metals like iron, up to and including highly technical modern processes such as machining and welding. It has been used as an industry, a driver of trade, individual hobbies, and in the creation of art; it can be regarded as both a science and a craft. Modern metalworking processes, though diverse and specialized, can be categorized into one of three broad areas known as forming, cutt ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Woodworking

Woodworking is the skill of making items from wood, and includes cabinetry, furniture making, wood carving, joinery, carpentry, and woodturning. History Along with stone, clay and animal parts, wood was one of the first materials worked by early humans. Microwear analysis of the Mousterian stone tools used by the Neanderthals show that many were used to work wood. The development of civilization was closely tied to the development of increasingly greater degrees of skill in working these materials. Among the earlliest finds of woodworking are shaped sticks displaying notches from Kalambo Falls in southen Africa, dating to around 476,000 years ago. The Clacton spearhead from Clacton-on-Sea, England, dating to around 400,000 years ago,Allington-Jones, L., (2015) ''Archaeological Journal'', 172 (2) 273–296 The Clacton Spear – The Last One Hundred Years the Schöningen spears, from Schöningen (Germany) dating around 300,000 years ago and the Lehringen spear from no ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bearing (mechanical)

A ball bearing A bearing is a machine element that constrains relative motion to only the desired motion and reduces friction between moving parts. The design of the bearing may, for example, provide for free linear movement of the moving part or for free rotation around a fixed axis; or, it may prevent a motion by controlling the vectors of normal forces that bear on the moving parts. Most bearings facilitate the desired motion by minimizing friction. Bearings are classified broadly according to the type of operation, the motions allowed, or the directions of the loads (forces) applied to the parts. The term "bearing" is derived from the verb " to bear"; a bearing being a machine element that allows one part to bear (i.e., to support) another. The simplest bearings are bearing surfaces, cut or formed into a part, with varying degrees of control over the form, size, roughness, and location of the surface. Other bearings are separate devices installed into a machine or mach ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Aerospace Engineering

Aerospace engineering is the primary field of engineering concerned with the development of aircraft and spacecraft. It has two major and overlapping branches: aeronautical engineering and astronautical engineering. Avionics engineering is similar, but deals with the electronics side of aerospace engineering. "Aeronautical engineering" was the original term for the field. As flight technology advanced to include vehicles operating in outer space, the broader term "aerospace engineering" has come into use. Aerospace engineering, particularly the astronautics branch, is often colloquially referred to as "rocket science". Overview Flight vehicles are subjected to demanding conditions such as those caused by changes in atmospheric pressure and temperature, with structural loads applied upon vehicle components. Consequently, they are usually the products of various technological and engineering disciplines including aerodynamics, air propulsion, avionics, materials science, st ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

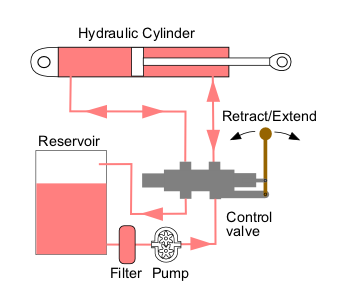

Hydraulic Machinery

Hydraulic machines use liquid fluid power to perform work. Heavy construction vehicles are a common example. In this type of machine, hydraulic fluid is pumped to various hydraulic motors and hydraulic cylinders throughout the machine and becomes pressurized according to the resistance present. The fluid is controlled directly or automatically by control valves and distributed through hoses, tubes, or pipes. Hydraulic systems, like pneumatic systems, are based on Pascal's law which states that any pressure applied to a fluid inside a closed system will transmit that pressure equally everywhere and in all directions. A hydraulic system uses an incompressible liquid as its fluid, rather than a compressible gas. The popularity of hydraulic machinery is due to the large amount of power that can be transferred through small tubes and flexible hoses, the high power density and a wide array of actuators that can make use of this power, and the huge multiplication of forces t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Transmission (mechanical Device)

A transmission (also called a gearbox) is a mechanical device invented by Louis Renault (who founded Renault) which uses a gear set—two or more gears working together—to change the speed, direction of rotation, or torque multiplication/reduction in a machine. Transmissions can have a single fixed-gear ratio, multiple distinct gear ratios, or continuously variable ratios. Variable-ratio transmissions are used in all sorts of machinery, especially vehicles. Applications Early uses Early transmissions included the right-angle drives and other gearing in windmills, horse-powered devices, and steam-powered devices. Applications of these devices included pumps, mills and hoists. Bicycles Bicycles traditionally have used hub gear or Derailleur gear transmissions, but there are other more recent design innovations. Automobiles Since the torque and power output of an internal combustion engine (ICE) varies with its rpm, automobiles powered by ICEs require multi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Internal Combustion Engine

An internal combustion engine (ICE or IC engine) is a heat engine in which the combustion of a fuel occurs with an oxidizer (usually air) in a combustion chamber that is an integral part of the working fluid flow circuit. In an internal combustion engine, the expansion of the high-temperature and high-pressure gases produced by combustion applies direct force to some component of the engine. The force is typically applied to pistons (reciprocating engine, piston engine), turbine blades (gas turbine), a Wankel engine, rotor (Wankel engine), or a propulsive nozzle, nozzle (jet engine). This force moves the component over a distance. This process transforms chemical energy into kinetic energy which is used to propel, move or power whatever the engine is attached to. The first commercially successful internal combustion engines were invented in the mid-19th century. The first modern internal combustion engine, the Otto engine, was designed in 1876 by the German engineer Nicolaus ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hubcap

A hubcap or hub cap is a decorative disk on an automobile wheel that covers at minimum the central portion of the wheel, called the hub. An automobile hubcap is used to cover the wheel hub and the wheel fasteners to reduce the accumulation of dirt and moisture. It also has the function of decorating the car. A hubcap is technically a small cover over the center of the wheel, while a wheel cover is a decorative metal or plastic disk that snaps or bolts onto and covers the entire face of the wheel. Cars with stamped steel wheels often use a full-wheel cover that conceals the entire wheel. Cars with alloy wheels or styled steel wheels generally use smaller hubcaps, sometimes called center caps. Alternatively, a wheel cover or spare tire cover can be an accessory that covers an external rear-mounted spare tire found on some automobiles. History Hubcaps were first used on the Newton Reaction Carriage in 1680. The first hubcaps were more commonly known as dust or grease caps. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |