|

Crosshead Guide

In mechanical engineering, a crosshead is a mechanical joint used as part of the slider-crank linkages of long stroke reciprocating engines (either internal combustion or steam) and reciprocating compressors to eliminate sideways force on the piston. The crosshead also allows the connecting rod to move freely outside the cylinder. Because of the very small bore-to-stroke ratio on such engines, the connecting rod would hit the cylinder walls and block the engine from rotating if the piston were attached directly to the connecting rod as in a trunk engine. Therefore, the longitudinal dimension of the crosshead must be matched to the stroke of the engine. Overview On smaller engines, the connecting rod links the piston and the crankshaft directly, but this transmits sideways forces to the piston, since the crankpin (and thus the direction the force is applied) moves from side to side with the rotary motion of the crank. These transverse forces are tolerable in a relatively small e ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Piston Rod

In a piston engine, a piston rod joins a piston to the crosshead and thus to the connecting rod that drives the crankshaft or (for steam locomotives) the driving wheels. Internal combustion engines, and in particular all current automobile engines, do not generally have piston rods. Instead they use trunk pistons, where the piston and crosshead are combined and so do not need a rod between them. The term ''piston rod'' has been used as a synonym for 'connecting rod' in the context of these engines. Engines with crossheads have piston rods. These include most steam locomotives and some large marine diesel engines. Compressor piston rods are made from various types of steel depending on the stress levels and gas compression. Steam engines The first single-acting beam engines, such as Newcomen's, had a single power stroke acting downwards. Rather than a piston rod, they used an iron chain. This could transmit a tensile force, but not a compression force pushing upwards. Th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bearings (mechanical)

A ball bearing A bearing is a machine element that constrains relative motion to only the desired motion and reduces friction between moving parts. The design of the bearing may, for example, provide for free linear movement of the moving part or for free rotation around a fixed axis; or, it may prevent a motion by controlling the vectors of normal forces that bear on the moving parts. Most bearings facilitate the desired motion by minimizing friction. Bearings are classified broadly according to the type of operation, the motions allowed, or the directions of the loads (forces) applied to the parts. The term "bearing" is derived from the verb " to bear"; a bearing being a machine element that allows one part to bear (i.e., to support) another. The simplest bearings are bearing surfaces, cut or formed into a part, with varying degrees of control over the form, size, roughness, and location of the surface. Other bearings are separate devices installed into a machine or mac ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Engine Technology

An engine or motor is a machine designed to convert one or more forms of energy into mechanical energy. Available energy sources include potential energy (e.g. energy of the Earth's gravitational field as exploited in hydroelectric power generation), heat energy (e.g. geothermal), chemical energy, electric potential and nuclear energy (from nuclear fission or nuclear fusion). Many of these processes generate heat as an intermediate energy form; thus heat engines have special importance. Some natural processes, such as atmospheric convection cells convert environmental heat into motion (e.g. in the form of rising air currents). Mechanical energy is of particular importance in transportation, but also plays a role in many industrial processes such as cutting, grinding, crushing, and mixing. Mechanical heat engines convert heat into work via various thermodynamic processes. The internal combustion engine is perhaps the most common example of a mechanical heat engine in which hea ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Crosshead Piston

A piston is a component of reciprocating engines, reciprocating pumps, gas compressors, hydraulic cylinders and pneumatic cylinders, among other similar mechanisms. It is the moving component that is contained by a cylinder and is made gas-tight by piston rings. In an engine, its purpose is to transfer force from expanding gas in the cylinder to the crankshaft via a piston rod and/or connecting rod. In a pump, the function is reversed and force is transferred from the crankshaft to the piston for the purpose of compressing or ejecting the fluid in the cylinder. In some engines, the piston also acts as a valve by covering and uncovering ports in the cylinder. __TOC__ Piston engines Internal combustion engines An internal combustion engine is acted upon by the pressure of the expanding combustion gases in the combustion chamber space at the top of the cylinder. This force then acts downwards through the connecting rod and onto the crankshaft. The connecting rod is attached t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Side-lever

A marine steam engine is a steam engine that is used to power a ship or boat. This article deals mainly with marine steam engines of the reciprocating type, which were in use from the inception of the steamboat in the early 19th century to their last years of large-scale manufacture during World War II. Reciprocating steam engines were progressively replaced in marine applications during the 20th century by steam turbines and marine diesel engines. History The first commercially successful steam engine was developed by Thomas Newcomen in 1712. The steam engine improvements brought forth by James Watt in the later half of the 18th century greatly improved steam engine efficiency and allowed more compact engine arrangements. Successful adaptation of the steam engine to marine applications in England would have to wait until almost a century after Newcomen, when Scottish engineer William Symington built the world's "first practical steamboat", the '' Charlotte Dundas'', in 1802. Ri ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Steam Locomotive

A steam locomotive is a locomotive that provides the force to move itself and other vehicles by means of the expansion of steam. It is fuelled by burning combustible material (usually coal, Fuel oil, oil or, rarely, Wood fuel, wood) to heat water in the locomotive's Boiler (power generation), boiler to the point where it becomes gaseous and its volume increases 1,700 times. Functionally, it is a steam engine on wheels. In most locomotives, the steam is admitted alternately to each end of its Steam locomotive components, cylinders in which pistons are mechanically connected to the locomotive's main wheels. Fuel and water supplies are usually carried with the locomotive, either on the locomotive itself or in a Tender (rail), tender coupled to it. #Variations, Variations in this general design include electrically powered boilers, turbines in place of pistons, and using steam generated externally. Steam locomotives were first developed in the United Kingdom of Great Britain an ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Planer (metalworking)

A planer is a type of metalworking machine tool that uses linear relative motion between the workpiece and a single-point cutting tool to cut the work piece.Parker, Dana T. ''Building Victory: Aircraft Manufacturing in the Los Angeles Area in World War II,'' p. 73, Cypress, CA, 2013. . A planer is similar to a shaper, but larger, and with workpiece moving, whereas in a shaper the cutting tool moves. Applications Linear planing The most common applications of planers and shapers are linear-toolpath ones, such as: * Generating accurate flat surfaces. (While not as precise as grinding, a planer can remove a tremendous amount of material in one pass with high accuracy.) * Cutting slots (such as keyways). * It is even possible to do work that might now be done by wire EDM in some cases. Starting from a drilled or cored hole, a planer with a boring-bar type tool can cut internal features that do not lend themselves to milling or boring (such as irregularly shaped holes with tight ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Parallel Motion Linkage

In kinematics, the parallel motion linkage is a six-bar mechanical linkage invented by the Scottish engineer James Watt in 1784 for the double-acting Watt steam engine. It allows a rod moving practically straight up and down to transmit motion to a beam moving in an arc, without putting significant sideways strain on the rod. Description In previous engines built by Newcomen and Watt, the piston pulled one end of the walking beam downwards during the power stroke using a chain, and the weight of the pump pulled the other end of the beam downwards during the recovery stroke using a second chain, the alternating forces producing the rocking motion of the beam. In Watt's new double-acting engine, the piston produced power on both the upward and downward strokes, so a chain could not be used to transmit the force to the beam. Watt designed the parallel motion to transmit force in both directions whilst keeping the piston rod very close to vertical. He called it "parallel motion ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

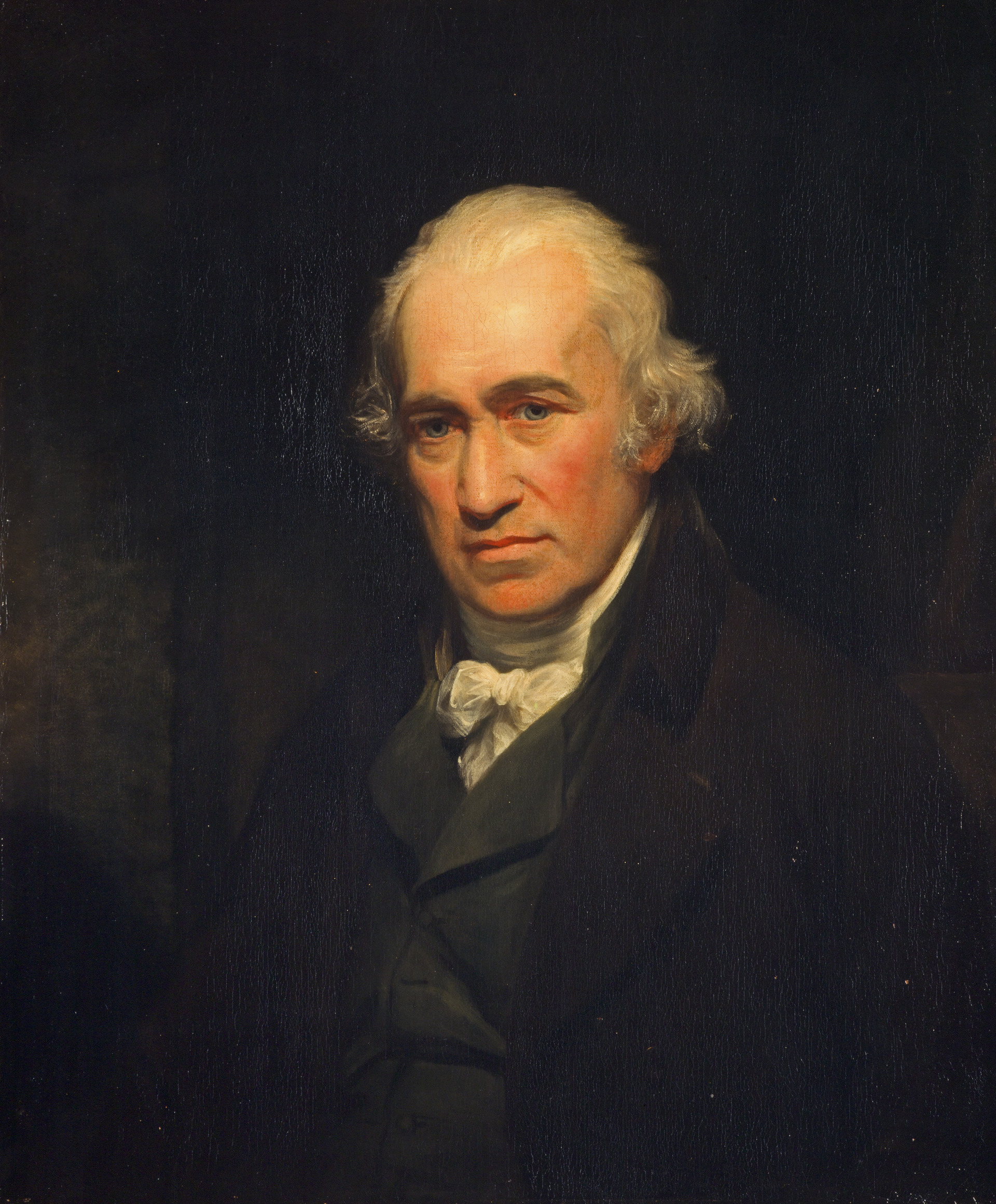

James Watt

James Watt (; 30 January 1736 (19 January 1736 OS) – 25 August 1819) was a Scottish inventor, mechanical engineer, and chemist who improved on Thomas Newcomen's 1712 Newcomen steam engine with his Watt steam engine in 1776, which was fundamental to the changes brought by the Industrial Revolution in both his native Great Britain and the rest of the world. While working as an instrument maker at the University of Glasgow, Watt became interested in the technology of steam engines. At the time engineers such as John Smeaton were aware of the inefficiencies of Newcomen's engine and aimed to improve it. Watt's insight was to realise that contemporary engine designs wasted a great deal of energy by repeatedly cooling and reheating the cylinder. Watt introduced a design enhancement, the separate condenser, which avoided this waste of energy and radically improved the power, efficiency, and cost-effectiveness of steam engines. Eventually, he adapted his engine to produce rot ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Oscillating Cylinder Steam Engine

An oscillating cylinder steam engine (also known as a wobbler in the US) is a simple steam-engine design (proposed by William Murdoch at the end of 18th century) that requires no valve gear. Instead the cylinder rocks, or oscillates, as the crank moves the piston, pivoting in the mounting trunnion so that ports in the cylinder line up with ports in a fixed port face alternately to direct steam into or out of the cylinder. Oscillating cylinder steam engines are now mainly used in toys and models but, in the past, have been used in full-size working engines, mainly on ships and small stationary engines. They have the advantage of simplicity and, therefore, low manufacturing costs. They also tend to be more compact than other types of cylinder of the same capacity, which makes them advantageous for use in ships. Operation alt=oscillating cylinder diagram, Operation of a simple oscillating cylinder steam engine The steam needs to be fed into the end of the cylinder at just the rig ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |