|

Coining (mint)

Minting, coining or coinage is the process of manufacturing coins using a kind of stamping, the process used in both hammered coinage and milled coinage. This "stamping" process is different from the method used in cast coinage. A coin die (archaically spelt dye) is one of the two metallic pieces that are used to strike a coin, one per each side of the coin. A die contains an inverse version of the image to be ''struck'' on the coin. ''Striking'' a coin refers to pressing an image into the blank metal disc, or planchet, and is a term descended from the days when the dies were struck with hammers to deform the metal into the image of the dies. Modern dies made out of hardened steel are capable of producing many hundreds of thousands of coins before they are retired and defaced. Scissel is the scrap produced in the punching of coin blanks from a continuous strip of metal. Ancient coin dies Prior to the modern era, coin dies were manufactured individually by hand by arti ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Mint (coin)

A mint is an industrial facility which manufactures coins that can be used as currency. The history of mints correlates closely with the history of coins. In the beginning, hammered coinage or cast coinage were the chief means of coin minting, with resulting production runs numbering as little as the hundreds or thousands. In modern mints, coin dies are manufactured in large numbers and planchets are made into milled coins by the billions. With the mass production of currency, the production cost is weighed when minting coins. For example, it costs the United States Mint much less than 25 cents to make a quarter (a 25 cent coin), and the difference in production cost and face value (called seigniorage) helps fund the minting body. Conversely, a U.S. penny ($0.01) cost $0.015 to make in 2016. History The first minted coins The first mint was likely established in Lydia in the 7th century BC, for coining gold, silver and electrum. The first coins known to be minted on E ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Grosso Minted By Martino Zaccaria

Grosso may refer to: * Grosso, Piedmont, comune in the Metropolitan City of Turin in the Italian region Piedmont * Grosso (footballer), retired Portuguese footballer * Grosso (surname), an Italian surname * Grosso (coin), name for a silver coin used in various states of the Holy Roman Empire See also * Grasso * Grossi {{dab ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

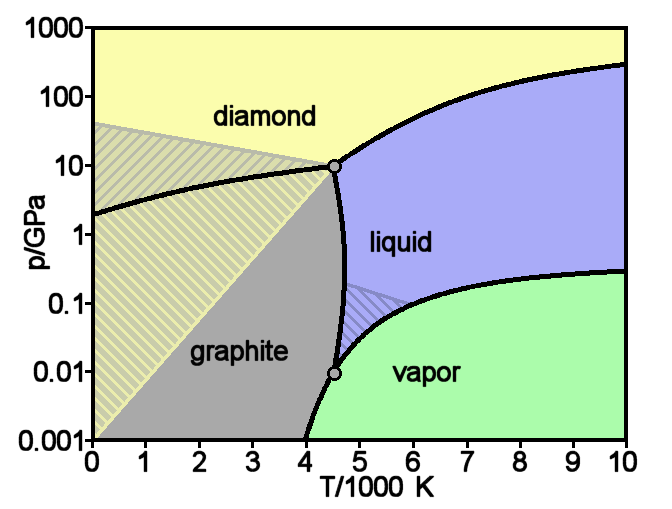

Graphite

Graphite () is a Crystallinity, crystalline allotrope (form) of the element carbon. It consists of many stacked Layered materials, layers of graphene, typically in excess of hundreds of layers. Graphite occurs naturally and is the most stable form of carbon under standard conditions. Synthetic and natural graphite are consumed on a large scale (1.3million metric tons per year in 2022) for uses in many critical industries including refractories (50%), lithium-ion batteries (18%), foundries (10%), and lubricants (5%), among others (17%). Graphite converts to diamond under extremely high pressure and temperature. Graphite's low cost, thermal and chemical inertness and characteristic conductivity of heat and electricity finds numerous applications in high energy and high temperature processes. Types and varieties Graphite can occur naturally or be produced synthetically. Natural graphite is obtained from naturally occurring geologic deposits and synthetic graphite is produced t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Plasticine

Plasticine is a putty-like modelling material made from calcium salts, petroleum jelly and aliphatic acids. Though originally a brand name for the British version of the product, it is now applied generically in English as a product category to other formulations. Plasticine is used for children's play and as a modelling medium for more formal or permanent structures. Because of its non-drying property, it is a material commonly chosen for stop motion animation, including several Academy Award-winning films by Nick Park. History Franz Kolb, owner of a pharmacy in Munich, Germany, invented an oil-based modelling clay in 1880. At the time, the city was a centre for the arts, and among Kolb's circle of friends were sculptors. They complained about how with the clay they were using for modelling, their sculptures would dry too fast and that, particularly in winter, it was too difficult to work with. In order to commercialize his invention, he presented it to the Faber-Caste ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Die Making

Tool and die makers are highly skilled crafters working in the manufacturing industries. Tool and die makers work primarily in toolroom environments—sometimes literally in one room but more often in an environment with flexible, semipermeable boundaries from production work. They are skilled artisans ( craftspeople) who typically learn their trade through a combination of academic coursework and with substantial period of on-the-job training that is functionally an apprenticeship. They make jigs, fixtures, dies, molds, machine tools, cutting tools, gauges, and other tools used in manufacturing processes. Divisions The main divisions of the tool & die industry include: *Die casting * Dies * Fixtures *Forging * Gauges * Jigs *Metal working * Moulding Job description Working from engineering drawings developed by the toolmaker, engineers or technologists, tool makers lay out the design on the raw material (usually metal), then cut it to size and shape using manually control ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Epoxy

Epoxy is the family of basic components or Curing (chemistry), cured end products of epoxy Resin, resins. Epoxy resins, also known as polyepoxides, are a class of reactive prepolymers and polymers which contain epoxide groups. The epoxide functional group is also collectively called ''epoxy''. The IUPAC name for an epoxide group is an oxirane. Epoxy resins may be reacted (cross-linked) either with themselves through catalytic homopolymerisation, or with a wide range of co-reactants including polyfunctional amines, acids (and acid anhydrides), phenols, alcohols and thiols (sometimes called mercaptans). These co-reactants are often referred to as hardeners or curatives, and the cross-linking reaction is commonly referred to as Curing (chemistry), curing. Reaction of polyepoxides with themselves or with polyfunctional hardeners forms a thermosetting polymer, often with favorable mechanical properties and high thermal and chemical resistance. Epoxy has a wide range of application ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Rubber

Rubber, also called India rubber, latex, Amazonian rubber, ''caucho'', or ''caoutchouc'', as initially produced, consists of polymers of the organic compound isoprene, with minor impurities of other organic compounds. Types of polyisoprene that are used as natural rubbers are classified as elastomers. Currently, rubber is harvested mainly in the form of the latex from the Hevea brasiliensis, Pará rubber tree (''Hevea brasiliensis'') or others. The latex is a sticky, milky and white colloid drawn off by making incisions in the bark and collecting the fluid in vessels in a process called "tapping". Manufacturers refine this latex into the rubber that is ready for commercial processing. Natural rubber is used extensively in many applications and products, either alone or in combination with other materials. In most of its useful forms, it has a large stretch ratio and high resilience and also is buoyant and water-proof. Industrial demand for rubber-like materials began to out ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Plaster

Plaster is a building material used for the protective or decorative coating of walls and ceilings and for moulding and casting decorative elements. In English, "plaster" usually means a material used for the interiors of buildings, while "render" commonly refers to external applications. The term stucco refers to plasterwork that is worked in some way to produce relief decoration, rather than flat surfaces. The most common types of plaster mainly contain either gypsum, lime, or cement,Franz Wirsching "Calcium Sulfate" in Ullmann's Encyclopedia of Industrial Chemistry, 2012 Wiley-VCH, Weinheim. but all work in a similar way. The plaster is manufactured as a dry powder and is mixed with water to form a stiff but workable paste immediately before it is applied to the surface. The reaction with water liberates heat through crystallization and the hydrated plaster then hardens. Plaster can be relatively easily worked with metal tools and sandpaper and can be moulded, either on ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Coin Making At Jorvik Viking Centre

A coin is a small object, usually round and flat, used primarily as a medium of exchange or legal tender. They are standardized in weight, and produced in large quantities at a mint in order to facilitate trade. They are most often issued by a government. Coins often have images, numerals, or text on them. The faces of coins or medals are sometimes called the ''obverse'' and the ''reverse'', referring to the front and back sides, respectively. The obverse of a coin is commonly called ''heads'', because it often depicts the head of a prominent person, and the reverse is known as ''tails''. The first metal coins – invented in the ancient Greek world and disseminated during the Hellenistic period – were precious metal–based, and were invented in order to simplify and regularize the task of measuring and weighing bullion (bulk metal) carried around for the purpose of transactions. They carried their value within the coins themselves, but the stampings also induced manipulati ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

The Royal Mint

The Royal Mint is the United Kingdom's official Mint (facility), maker of British coins. It is currently located in Llantrisant, Wales, where it moved in 1968. Operating under the legal name The Royal Mint Limited, it is a limited company that is wholly owned by HM Treasury, His Majesty's Treasury and is under an exclusive contract to supply the nation's coinage. As well as minting circulating coins for the UK and international markets, The Royal Mint is a leading provider of precious metal products. The Royal Mint was historically part of a series of mints that became centralised to produce coins for the Kingdom of England, all of Great Britain, the United Kingdom, and nations across the Commonwealth. The Royal Mint operated within the Tower of London for several hundred years before moving to what is now called Royal Mint Court, where it remained until the 1960s. As Britain followed the rest of the world in Decimalisation, decimalising its currency, the Mint moved from Lond ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Samuel Pepys

Samuel Pepys ( ; 23 February 1633 – 26 May 1703) was an English writer and Tories (British political party), Tory politician. He served as an official in the Navy Board and Member of Parliament (England), Member of Parliament, but is most remembered today for the diary he kept for almost a decade. Though he had no Maritime pilot, maritime experience, Pepys rose to be the Chief Secretary to the Admiralty under both Charles II of England, Charles II and James II of England, James II through patronage, diligence, and his talent for administration. His influence and reforms at the Admiralty (United Kingdom), English Admiralty were important in the early professionalisation of the Royal Navy. The detailed private diary that Pepys kept from 1660 until 1669 was first published in the 19th century and is one of the most important primary sources of the Stuart Restoration. It provides a combination of personal revelation and eyewitness accounts of great events, such as the Grea ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |