|

Carbonitriding

Carbonitriding is a metallurgical surface modification technique that is used to increase the surface hardness of a metal, thereby reducing wear. During the process, atoms of carbon and nitrogen diffuse interstitially into the metal, creating barriers to slip, increasing the hardness and modulus near the surface. Carbonitriding is often applied to inexpensive, easily machined low carbon steel to impart the surface properties of more expensive and difficult to work grades of steel. Surface hardness of carbonitrided parts ranges from 55 to 62 HRC. Certain pre-industrial case hardening processes include not only carbon-rich materials such as charcoal, but nitrogen-rich materials such as urea, which implies that traditional surface hardening techniques were a form of carbonitriding. Process Carbonitriding is similar to gas carburization with the addition of ammonia to the carburizing atmosphere, which provides a source of nitrogen. Nitrogen is absorbed at the surface and dif ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Carburizing

Carburizing, or carburising, is a heat treatment process in which iron or steel absorbs carbon while the metal is heated in the presence of a carbon-bearing material, such as charcoal or carbon monoxide. The intent is to make the metal harder and more wear resistant. Depending on the amount of time and temperature, the affected area can vary in carbon content. Longer carburizing times and higher temperatures typically increase the depth of carbon diffusion. When the iron or steel is cooled rapidly by quenching, the higher carbon content on the outer surface becomes hard due to the transformation from austenite to martensite, while the core remains soft and tough as a ferritic and/or pearlite microstructure. This manufacturing process can be characterized by the following key points: It is applied to low-carbon workpieces; workpieces are in contact with a high-carbon gas, liquid or solid; it produces a hard workpiece surface; workpiece cores largely retain their toughness an ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Computerised Heat Treatment Furnance

*

*

{{disambiguation ...

Computerize or computerization may refer to: * Equipping with a general purpose computer, embedded computer, or computer system * Equipping something with or the usage of software * Business process reengineering that converts a manual process into one done by a computer * Digital transformation of a service or business * Inputting data (computing) into computers * Digitizing information for computers * Creating computer-generated content See also *Automation Automation describes a wide range of technologies that reduce human intervention in processes, mainly by predetermining decision criteria, subprocess relationships, and related actions, as well as embodying those predeterminations in machine ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fatigue (material)

In materials science, fatigue is the initiation and propagation of cracks in a material due to cyclic loading. Once a fatigue crack has initiated, it grows a small amount with each loading cycle, typically producing striations on some parts of the fracture surface. The crack will continue to grow until it reaches a critical size, which occurs when the stress intensity factor of the crack exceeds the fracture toughness of the material, producing rapid propagation and typically complete fracture of the structure. Fatigue has traditionally been associated with the failure of metal components which led to the term metal fatigue. In the nineteenth century, the sudden failing of metal railway axles was thought to be caused by the metal crystallising because of the brittle appearance of the fracture surface, but this has since been disproved. Most materials, such as composites, plastics and ceramics, seem to experience some sort of fatigue-related failure. To aid in predicting the f ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Metal Heat Treatments

A metal () is a material that, when polished or fractured, shows a lustrous appearance, and conducts electricity and heat relatively well. These properties are all associated with having electrons available at the Fermi level, as against nonmetallic materials which do not. Metals are typically ductile (can be drawn into a wire) and malleable (can be shaped via hammering or pressing). A metal may be a chemical element such as iron; an alloy such as stainless steel; or a molecular compound such as polymeric sulfur nitride. The general science of metals is called metallurgy, a subtopic of materials science; aspects of the electronic and thermal properties are also within the scope of condensed matter physics and solid-state chemistry, it is a multidisciplinary topic. In colloquial use materials such as steel alloys are referred to as metals, while others such as polymers, wood or ceramics are nonmetallic materials. A metal conducts electricity at a temperature of absolute zero ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Surface Engineering

Surface engineering is the sub-discipline of materials science which deals with the surface of solid matter. It has applications to chemistry, mechanical engineering, and electrical engineering (particularly in relation to semiconductor manufacturing). Solids are composed of a bulk material covered by a surface. The surface which bounds the bulk material is called the surface phase. It acts as an interface to the surrounding environment. The bulk material in a solid is called the bulk phase. The surface phase of a solid interacts with the surrounding environment. This interaction can degrade the surface phase over time. Environmental degradation of the surface phase over time can be caused by wear, corrosion, fatigue Fatigue is a state of tiredness (which is not sleepiness), exhaustion or loss of energy. It is a signs and symptoms, symptom of any of various diseases; it is not a disease in itself. Fatigue (in the medical sense) is sometimes associated wit ... and creep. Su ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Quench Polish Quench

Quench polish quench (QPQ) is a specialized type of nitrocarburizing case hardening that increases corrosion resistance. It is sometimes known by the brand name of Tufftride, Tenifer or Melonite. Three steps are involved: nitrocarburize ("quench"), polish, and post-oxidize ("quench"). This process is often used when two or more of the following properties are required in a workpiece: * wear resistance * corrosion resistance * fatigue strength Common applications of the process are for piston rods of shock absorbers, cylinders and rods for hydraulic systems, pumps, axles, spindle (tool), spindles, Pistol slide, firearm slides and Barrel (firearm), barrels and valves. Process The process starts with a standard salt bath nitrocarburizing cycle, which produces a layer of ε iron nitride. Next, the workpiece is mechanically polished; typical polishing processes include vibratory finishing, lapping, and centerless grinding. Finally, the workpiece is re-immersed into the salt quench bath ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Nitridization

Nitriding is a heat treating process that diffuses nitrogen into the surface of a metal to create a case-hardened surface. These processes are most commonly used on low-alloy steels. They are also used on titanium, aluminium and molybdenum. Typical applications include gears, crankshafts, camshafts, cam followers, valve parts, extruder screws, die-casting tools, forging dies, extrusion dies, firearm components, injectors and plastic mold tools. Processes The processes are named after the medium used to donate. The three main methods used are: ''gas nitriding'', ''salt bath nitriding'', and ''plasma nitriding''. Gas nitriding In gas nitriding the donor is a nitrogen-rich gas, usually ammonia (NH3), which is why it is sometimes known as ''ammonia nitriding''. When ammonia comes into contact with the heated work piece it dissociates into nitrogen and hydrogen. The nitrogen then diffuses onto the surface of the material creating a nitride layer. This process has existed for near ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Differential Hardening

Differential heat treatment (also called selective heat treatment or local heat treatment) is a technique used during heat treating of steel to harden or soften certain areas of an object, creating a difference in hardness between these areas. There are many techniques for creating a difference in properties, but most can be defined as either ''differential hardening'' or ''differential tempering''. These were common heat treatment techniques used historically in Europe and Asia, with possibly the most widely known example being from Japanese swordsmithing. Some modern varieties were developed in the twentieth century as metallurgical knowledge and technology rapidly increased. Differential hardening is done by either of two methods. One of them is heating the steel evenly to a red-hot temperature and then cooling part of it quickly, turning that part into very hard martensite while the rest cools more slowly and becomes softer pearlite. The other is heating only part of the steel ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Die (manufacturing)

A die is a specialized machine tool used in manufacturing industries to cut and/or Forming (metalworking), form material to a desired shape or profile. ''Stamping (metalworking), Stamping dies'' are used with a machine press, press, as opposed to ''Draw plate, drawing dies'' (used in the manufacture of wire) and ''Die casting, casting dies'' (used in Molding (process), molding) which are not. Like molds, dies are generally customized to the item they are used to create. Products made with dies range from simple paper clips to complex pieces used in advanced technology. Continuous production, Continuous-feed laser cutting may displace the analogous die-based process in the automotive industry, among others. Die stamping Blanking and piercing are two Shearing (manufacturing), die cutting operations, and Bending (metalworking), bending is an example of a die forming operation. Die forming Forming operations work by deforming materials like sheet metal or plastic using force (Compre ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tool

A tool is an Physical object, object that can extend an individual's ability to modify features of the surrounding environment or help them accomplish a particular task. Although many Tool use by animals, animals use simple tools, only human beings, whose use of stone tools dates back hundreds of millennia, have been observed using tools to make other tools. Early human tools, made of such materials as Rock (geology), stone, bone, and wood, were used for the preparation of food, hunting, the manufacture of weapons, and the working of materials to produce clothing and useful Cultural artifact, artifacts and crafts such as pottery, along with the construction of housing, businesses, infrastructure, and transportation. The development of metalworking made additional types of tools possible. Harnessing energy sources, such as Working animal, animal power, wind, or steam, allowed increasingly complex tools to produce an even larger range of items, with the Industrial Revolution markin ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

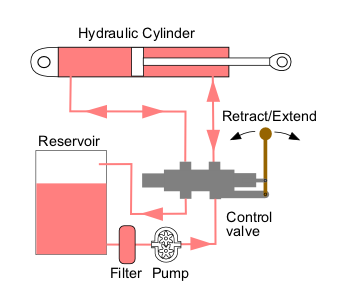

Hydraulic Machinery

Hydraulic machines use liquid fluid power to perform work. Heavy construction vehicles are a common example. In this type of machine, hydraulic fluid is pumped to various hydraulic motors and hydraulic cylinders throughout the machine and becomes pressurized according to the resistance present. The fluid is controlled directly or automatically by control valves and distributed through hoses, tubes, or pipes. Hydraulic systems, like pneumatic systems, are based on Pascal's law which states that any pressure applied to a fluid inside a closed system will transmit that pressure equally everywhere and in all directions. A hydraulic system uses an incompressible liquid as its fluid, rather than a compressible gas. The popularity of hydraulic machinery is due to the large amount of power that can be transferred through small tubes and flexible hoses, the high power density and a wide array of actuators that can make use of this power, and the huge multiplication of forces t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fastener

A fastener (US English) or fastening (UK English) is a hardware device that mechanically joins or affixes two or more objects together. In general, fasteners are used to create non-permanent joints; that is, joints that can be removed or dismantled without damaging the joining components. Steel fasteners are usually made of stainless steel, carbon steel, or alloy steel. Other methods of joining materials, some of which may create permanent joints, include: crimping, welding, soldering, brazing, taping, gluing, cement, or the use of other adhesives. Force may also be used, such as with magnets, vacuum (like suction cups), or even friction (like sticky pads). Some types of woodworking joints make use of separate internal reinforcements, such as dowels or biscuits, which in a sense can be considered fasteners within the scope of the joint system, although on their own they are not general-purpose fasteners. Furniture supplied in flat-pack form often uses cam dowels lock ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |