|

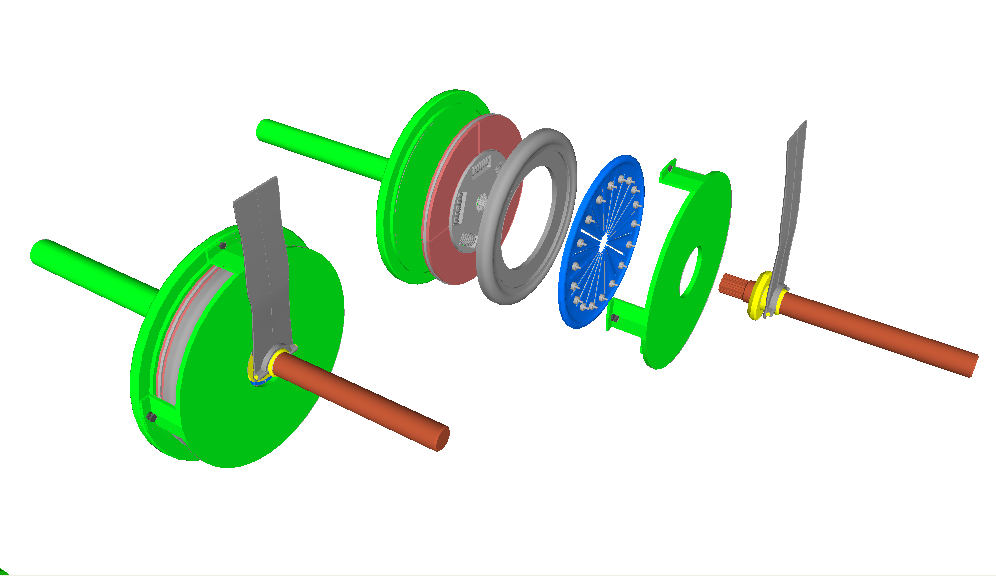

Banjo Bolt

A banjo fitting is actually called a hose connecting bolt, or internally relieved bolt, and a spherical union for fluid transfer. It is typically used to connect a fluid line to a rigid, internally Screw_thread, threaded hydraulic component. The bolt is assembled through the center of the union, usually with face seal, face seals on either side of the union, to create a fluid path between the external ports on the union and bolt. A flexible hose or a rigid Pipe_(fluid_conveyance), pipe may be connected to the union port. The main advantage of the fitting is in high pressure applications (i.e. more than 50 Bar (unit), bar). The name stems from the shape of the fitting, having a large circular section connected to a thinner pipe, generally similar to the shape of a banjo. Compared to pipe fittings that are themselves screw thread, threaded, banjo fittings have the advantage that they do not have to be rotated relative to the host fitting. This avoids damage that can be caused ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Banjo Fitting Example

The banjo is a stringed instrument with a thin membrane stretched over a frame or cavity to form a resonator. The membrane is typically circular, and usually made of plastic, or occasionally animal skin. Early forms of the instrument were fashioned by African Americans in the United States. The banjo is frequently associated with folk music, folk, bluegrass music, bluegrass and country music, and has also been used in some rock music, rock, pop music, pop and hip-hop music, hip-hop. Several Rock n Roll, rock bands, such as Eagles (band), the Eagles, Led Zeppelin, and Grateful Dead, the Grateful Dead, have used the five-string banjo in some of their songs. Historically, the banjo occupied a central place in Black American music, Black American traditional music and the folk culture of rural whites before entering the mainstream via the minstrel shows of the 19th century. Along with the fiddle, the banjo is a mainstay of American styles of music, such as bluegrass and old-time musi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Motor Oil

Motor oil, engine oil, or engine lubricant is any one of various substances used for the lubrication of internal combustion engines. They typically consist of base oils enhanced with various additives, particularly antiwear additives, detergents, dispersants, and, for multi-grade oils, viscosity index improvers. The main function of motor oil is to reduce friction and wear on moving parts and to clean the engine from sludge (one of the functions of dispersants) and varnish (detergents). It also neutralizes acids that originate from fuel and from oxidation of the lubricant (detergents), improves sealing of piston rings, and cools the engine by carrying heat away from moving parts. In addition to the aforementioned basic constituents, almost all lubricating oils contain corrosion and oxidation inhibitors. Motor oil may be composed of only a lubricant base stock in the case of non- detergent oil, or a lubricant base stock plus additives to improve the oil's detergency, ex ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Selective Catalytic Reduction

Selective catalytic reduction (SCR) is a means of converting nitrogen oxides, also referred to as with the aid of a catalyst into diatomic nitrogen (), and water (). A reductant, typically anhydrous ammonia (), aqueous ammonia (), or a urea () solution, is added to a stream of flue or exhaust gas and is reacted onto a catalyst. As the reaction drives toward completion, nitrogen (), and carbon dioxide (), in the case of urea use, are produced. Selective catalytic reduction of using ammonia as the reducing agent was patented in the United States by the Engelhard Corporation in 1957. Development of SCR technology continued in Japan and the US in the early 1960s with research focusing on less expensive and more durable catalyst agents. The first large-scale SCR was installed by the IHI Corporation in 1978.Steam: Its Generation and Uses. Babcock & Wilcox. Commercial selective catalytic reduction systems are typically found on large utility boilers, industrial boilers, a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hydraulic Clutch

A clutch is a mechanical device that engages and disengages power transmission, especially from a drive shaft to a driven shaft. In the simplest application, clutches connect and disconnect two rotating shafts (drive shafts or line shafts). In these devices, one shaft is typically attached to an engine or other power unit (the driving member), while the other shaft (the driven member) provides output power for work. Typically the motions involved are rotary, but linear clutches also exist. In a motor vehicle, the clutch acts as a mechanical linkage between the engine and transmission, and briefly disconnects, or separates the engine from the transmission system. This disconnects the drive wheels whenever the clutch pedal is depressed, allowing the driver to smoothly change gears. In a torque-controlled drill, for instance, one shaft is driven by a motor, and the other drives a drill chuck. The clutch connects the two shafts so they may be locked together and spin at the sa ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

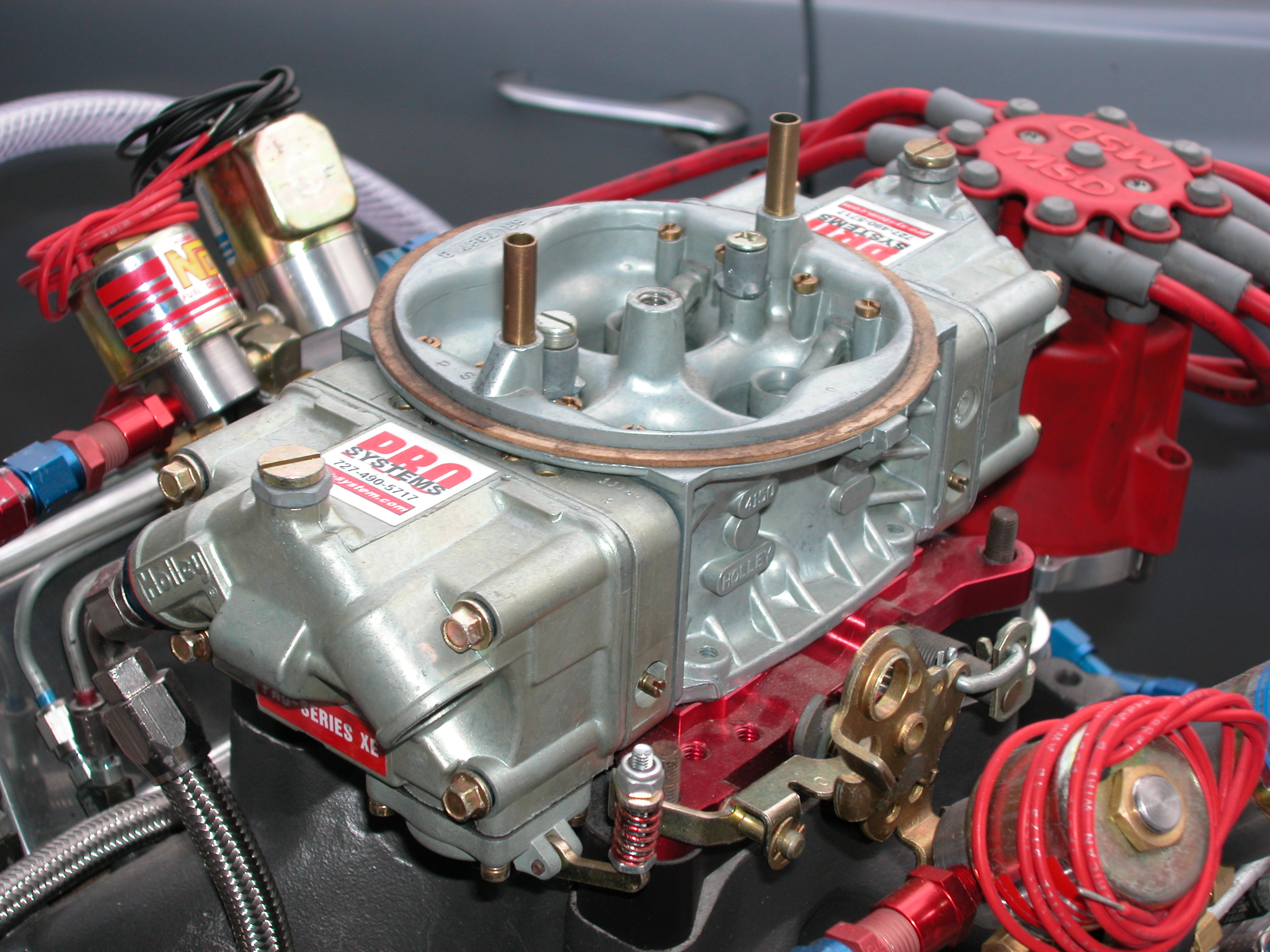

Carburetor

A carburetor (also spelled carburettor) is a device used by an internal combustion engine to control and mix air and fuel entering the engine. The primary method of adding fuel to the intake air is through the venturi tube in the main metering circuit, however various other components are also used to provide extra fuel or air in specific circumstances. Since the 1990s, carburetors have been largely replaced by fuel injection for cars and trucks, however carburetors are still used by some small engines (e.g. lawnmowers, generators and concrete mixers) and motorcycles. Diesel engines have always used fuel injection instead of carburetors. Etymology The name "carburetor" is derived from the verb ''carburet'', which means "to combine with carbon," or in particular, "to enrich a gas by combining it with carbon or hydrocarbons." Thus a carburetor mixes intake air with hydrocarbon-based fuel, such as petrol or autogas (LPG). The name is spelled "carburetor" in American Eng ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fuel Filter

A fuel filter is a filter used to screens out foreign particles or liquids from the fuel. Most internal combustion engines use a fuel filter, in order to protect the components in the fuel system. Filters for foreign particles Unfiltered fuel may contain several kinds of contamination, for example paint chips and dirt that has entered the fuel tank while filling, or rust caused by moisture in a steel tank. If these substances are not removed before the fuel enters the system, they will cause rapid wear and failure of the fuel pump and injectors. The filters are normally made into cartridges containing a filter paper. Fuel filters need to be maintained or replaced at regular intervals. Filters for foreign liquids Some diesel engines use a bowl-like design to collect water in the bottom of the filter (as diesel floats on top of water). The water can then be drained off by opening a valve in the bottom of the bowl and letting it run out, until only the fuel remains. See also ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Turbo Charger

In an internal combustion engine, a turbocharger (often called a turbo) is a forced induction device that is powered by the flow of exhaust gases. It uses this energy to compress the intake gas, forcing more air into the engine in order to produce more power for a given displacement. The current categorisation is that a turbocharger is powered by the kinetic energy of the exhaust gasses, whereas a is mechanically powered (usually by a belt from the engine's crankshaft). However, up until the mid-20th century, a turbocharger was called a "turbosupercharger" and was considered a type of supercharger. History Prior to the invention of the turbocharger, |

Brake Caliper

A disc brake is a type of brake that uses the calipers to squeeze pairs of pads against a disc or a "rotor" to create friction. This action slows the rotation of a shaft, such as a vehicle axle, either to reduce its rotational speed or to hold it stationary. The energy of motion is converted into waste heat which must be dispersed. Hydraulically actuated disc brakes are the most commonly used form of brake for motor vehicles, but the principles of a disc brake are applicable to almost any rotating shaft. The components include the disc, master cylinder, and caliper (which contains a cylinder and two brake pads) on both sides of the disc. Design The development of disc-type brakes began in England in the 1890s. In 1902, the Lanchester Motor Company designed brakes that looked and operated in a similar way to a modern disc-brake system even though the disc was thin and a cable activated the brake pad. Other designs were not practical or widely available in cars for another ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Variable Valve Timing

In internal combustion engines, variable valve timing (VVT) is the process of altering the timing of a valve lift event, and is often used to improve performance, fuel economy or emissions. It is increasingly being used in combination with variable valve lift systems. There are many ways in which this can be achieved, ranging from mechanical devices to electro-hydraulic and camless systems. Increasingly strict emissions regulations are causing many automotive manufacturers to use VVT systems. Two-stroke engines use a power valve system to get similar results to VVT. Background theory The valves within an internal combustion engine are used to control the flow of the intake and exhaust gases into and out of the combustion chamber. The timing, duration and lift of these valve events has a significant impact on engine performance. Without variable valve timing or variable valve lift, the valve timing is the same for all engine speeds and conditions, therefore compromises are neces ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Power Steering

A power steering is a mechanical device equipped on a motor vehicle that helps drivers steer the vehicle by reducing steering effort needed to turn the steering wheel, making it easier for the vehicle to turn or maneuver at lower speeds. Hydraulic or electric actuators add controlled energy to the steering mechanism, so the driver can provide less effort to turn the steered wheels when driving at typical speeds, and reduce considerably the physical effort necessary to turn the wheels when a vehicle is stopped or moving slowly. Power steering can also be engineered to provide some artificial feedback of forces acting on the steered wheels. Hydraulic power steering systems for cars augment steering effort via an actuator, a hydraulic cylinder that is part of a servo system. These systems have a direct mechanical connection between the steering wheel and the linkage that steers the wheels. This means that power-steering system failure (to augment effort) still permits the vehicle to ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fluid Power

Fluid power is the use of fluids under pressure to generate, control, and transmit power. Fluid power is subdivided into hydraulics using a liquid such as mineral oil or water, and pneumatics using a gas such as air or other gases. Compressed-air and water-pressure systems were once used to transmit power from a central source to industrial users over extended geographic areas; fluid power systems today are usually within a single building or mobile machine. Fluid power systems perform work by a pressurized fluid bearing directly on a piston in a cylinder or in a fluid motor. A fluid cylinder produces a force resulting in linear motion, whereas a fluid motor produces torque resulting in rotary motion. Within a fluid power system, cylinders and motors (also called actuators) do the desired work. Control components such as valves regulate the system. Elements A fluid power system has a pump driven by a prime mover (such as an electric motor or internal combustion engine) tha ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

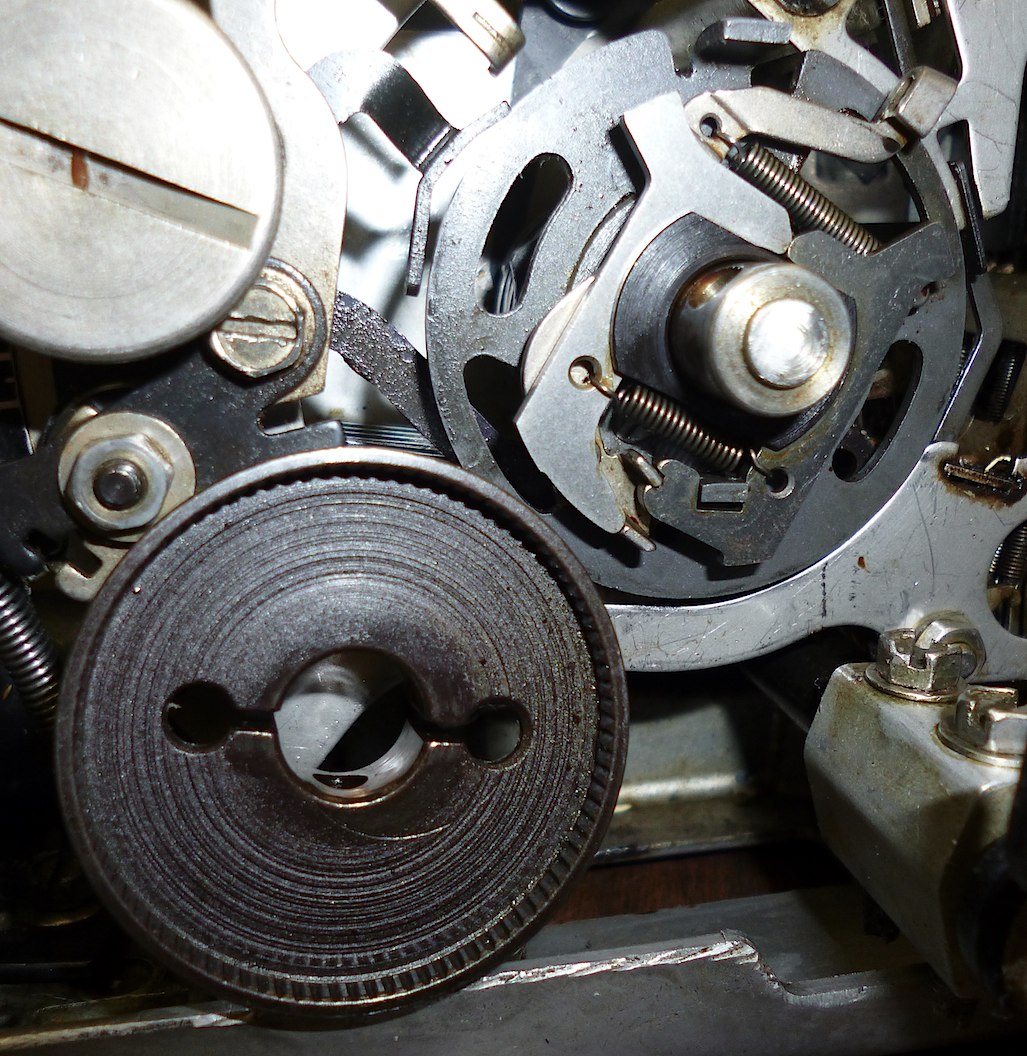

Clutch

A clutch is a mechanical device that engages and disengages power transmission, especially from a drive shaft to a driven shaft. In the simplest application, clutches connect and disconnect two rotating shafts (drive shafts or line shafts). In these devices, one shaft is typically attached to an engine or other power unit (the driving member), while the other shaft (the driven member) provides output power for work. Typically the motions involved are rotary, but linear clutches also exist. In a motor vehicle, the clutch acts as a mechanical linkage between the engine and transmission, and briefly disconnects, or separates the engine from the transmission system. This disconnects the drive wheels whenever the clutch pedal is depressed, allowing the driver to smoothly change gears. In a torque-controlled drill, for instance, one shaft is driven by a motor, and the other drives a drill chuck. The clutch connects the two shafts so they may be locked together and spin at th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |