|

Allotropes Of Iron

At atmospheric pressure, three allotropic forms of iron exist, depending on temperature: alpha iron (α-Fe, ferrite), gamma iron (γ-Fe, austenite), and delta iron (δ-Fe, similar to alpha iron). At very high pressure, a fourth form exists, epsilon iron (ε-Fe, hexaferrum). Some controversial experimental evidence suggests the existence of a fifth high-pressure form that is stable at very high pressures and temperatures. The phases of iron at atmospheric pressure are important because of the differences in solubility of carbon, forming different types of steel. The high-pressure phases of iron are important as models for the solid parts of planetary cores. The inner core of the Earth is generally assumed to consist essentially of a crystalline iron-nickel alloy with ε structure. The outer core surrounding the solid inner core is believed to be composed of liquid iron mixed with nickel and trace amounts of lighter elements. Standard pressure allotropes Alpha iron (α-Fe) ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pure Iron Phase Diagram (EN)

Pure may refer to: Computing * Pure function * PureSystems, a family of computer systems introduced by IBM in 2012 * Pure Software, a company founded in 1991 by Reed Hastings to support the Purify tool * Pure-FTPd, FTP server software * Pure (programming language), functional programming language based on term rewriting * Pure Storage, a company that makes datacenter storage solutions Companies and products * Pure (app), dating app * Pure (company), a British consumer electronics company specialising in digital radios * Pure (restaurant chain), a British fast food chain * Pure Insurance, Privilege Underwriters Reciprocal Exchange * Pure Trading, a Canadian electronic communication network operated by CNQ * Pure Oil, a U.S. chain of gas stations * Propulsion Universelle et Récuperation d'Énergie (PURE), a motorsport engineering company * Pure FM (Portsmouth), a university radio station based in Portsmouth, UK * Pure (Belgian radio station), a former Belgian radio sta ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Chemical Stability

In chemistry, chemical stability is the thermodynamic stability of a chemical system, in particular a chemical compound or a polymer. Colloquially, it may instead refer to kinetic persistence, the shelf-life of a metastable substance or system; that is, the timescale over which it begins to degrade. Thermodynamic stability occurs when a system is in its lowest energy state, or in chemical equilibrium with its environment. This may be a dynamic equilibrium in which individual atoms or molecules change form, but their overall number in a particular form is conserved. This type of chemical thermodynamic equilibrium will persist indefinitely unless the system is changed. Chemical systems might undergo changes in the phase of matter or a set of chemical reactions. State A is said to be more thermodynamically stable than state B if the Gibbs free energy of the change from A to B is positive. Versus reactivity Thermodynamic stability applies to a particular system. The reacti ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Brinell Scale

The Brinell hardness test (pronounced /brəˈnɛl/) measures the indentation hardness of materials. It determines hardness through the scale of penetration of an indenter, loaded on a material test-piece. It is one of several definitions of hardness in materials science. The hardness scale is expressed in terms of a Brinell hardness value, sometimes referred to as the Brinell hardness number but formally expressed as HBW (Hardness Brinell Wolfram – Wolfram being an alternative name for the tungsten carbide ball indenter used during the test). The test was named after Johan August Brinell (1849-1925) who developed the method at the end of the 19th century. History Premiered by Swedish engineer Johan August Brinell at the 1900 Paris Exposition, it was the first widely used and standardised hardness test in engineering and metallurgy. The large size of indentation and thus possible damage to test-pieces limits its usefulness. However, it also had the useful feature that the h ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

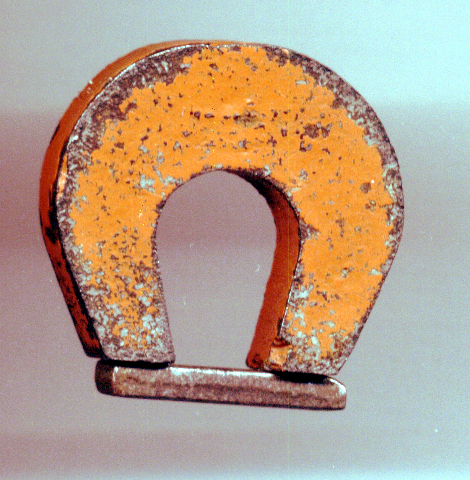

Ferromagnetic

Ferromagnetism is a property of certain materials (such as iron) that results in a significant, observable magnetic permeability, and in many cases, a significant magnetic coercivity, allowing the material to form a permanent magnet. Ferromagnetic materials are noticeably attracted to a magnet, which is a consequence of their substantial magnetic permeability. Magnetic permeability describes the induced magnetization of a material due to the presence of an external magnetic field. For example, this temporary magnetization inside a steel plate accounts for the plate's attraction to a magnet. Whether or not that steel plate then acquires permanent magnetization depends on both the strength of the applied field and on the coercivity of that particular piece of steel (which varies with the steel's chemical composition and any heat treatment it may have undergone). In physics, multiple types of material magnetism have been distinguished. Ferromagnetism (along with the similar effec ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cast Iron

Cast iron is a class of iron–carbon alloys with a carbon content of more than 2% and silicon content around 1–3%. Its usefulness derives from its relatively low melting temperature. The alloying elements determine the form in which its carbon appears: Cast iron#White cast iron, white cast iron has its carbon combined into an iron carbide named cementite, which is very hard, but brittle, as it allows cracks to pass straight through; Grey iron, grey cast iron has graphite flakes which deflect a passing crack and initiate countless new cracks as the material breaks, and Ductile iron, ductile cast iron has spherical graphite "nodules" which stop the crack from further progressing. Carbon (C), ranging from 1.8 to 4 wt%, and silicon (Si), 1–3 wt%, are the main alloying elements of cast iron. Iron alloys with lower carbon content are known as steel. Cast iron tends to be brittle, except for malleable iron, malleable cast irons. With its relatively low melting point, g ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Mild Steel

Carbon steel is a steel with carbon content from about 0.05 up to 2.1 percent by weight. The definition of carbon steel from the American Iron and Steel Institute (AISI) states: * no minimum content is specified or required for chromium, cobalt, molybdenum, nickel, niobium, titanium, tungsten, vanadium, zirconium, or any other element to be added to obtain a desired alloying effect; * the specified minimum for copper does not exceed 0.40%; * or the specified maximum for any of the following elements does not exceed: manganese 1.65%; silicon 0.60%; and copper 0.60%. As the carbon content percentage rises, steel has the ability to become harder and stronger through heat treating; however, it becomes less ductile. Regardless of the heat treatment, a higher carbon content reduces weldability. In carbon steels, the higher carbon content lowers the melting point. The term may be used to reference steel that is not stainless steel; in this use carbon steel may include alloy stee ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Phase (matter)

In the physical sciences, a phase is a region of material that is chemically uniform, physically distinct, and (often) mechanically separable. In a system consisting of ice and water in a glass jar, the ice cubes are one phase, the water is a second phase, and the humid air is a third phase over the ice and water. The glass of the jar is a different material, in its own separate phase. (See .) More precisely, a phase is a region of space (a thermodynamic system), throughout which all physical properties of a material are essentially uniform. Examples of physical properties include density, index of refraction, magnetization and chemical composition. The term ''phase'' is sometimes used as a synonym for state of matter, but there can be several immiscible phases of the same state of matter (as where oil and water separate into distinct phases, both in the liquid state). Types of phases Distinct phases may be described as different states of matter such as gas, liquid ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cementite

Cementite (or iron carbide) is a compound of iron and carbon, more precisely an intermediate transition metal carbide with the formula Fe3C. By weight, it is 6.67% carbon and 93.3% iron. It has an orthorhombic crystal structure. It is a hard, brittle material, normally classified as a ceramic in its pure form, and is a frequently found and important constituent in ferrous metallurgy. While cementite is present in most steels and cast irons, it is produced as a raw material in the iron carbide process, which belongs to the family of alternative ironmaking technologies. The name ''cementite'' originated from the theory of Floris Osmond and J. Werth, in which the structure of solidified steel consists of a kind of cellular tissue, with ferrite as the nucleus and Fe3C the envelope of the cells. The carbide therefore ''cemented'' the iron. Metallurgy In the iron–carbon system (i.e. plain-carbon steels and cast irons) it is a common constituent because ferrite can contain at m ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Eutectoid

A eutectic system or eutectic mixture ( ) is a type of a homogeneous mixture that has a melting point lower than those of the constituents. The lowest possible melting point over all of the mixing ratios of the constituents is called the ''eutectic temperature''. On a phase diagram, the eutectic temperature is seen as the eutectic point (see plot on the right). Non-eutectic mixture ratios have different melting temperatures for their different constituents, since one component's lattice will melt at a lower temperature than the other's. Conversely, as a non-eutectic mixture cools down, each of its components solidifies into a lattice at a different temperature, until the entire mass is solid. A non-eutectic mixture thus does not have a single melting/freezing point temperature at which it changes phase, but rather a temperature at which it changes between liquid and slush (known as the liquidus) and a lower temperature at which it changes between slush and solid (the solidus) ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Heat Treating

Heat treating (or heat treatment) is a group of industrial, thermal and metalworking processes used to alter the physical, and sometimes chemical, properties of a material. The most common application is metallurgical. Heat treatments are also used in the manufacture of many other materials, such as glass. Heat treatment involves the use of heating or chilling, normally to extreme temperatures, to achieve the desired result such as hardening or softening of a material. Heat treatment techniques include annealing, case hardening, precipitation strengthening, tempering, carburizing, normalizing and quenching. Although the term ''heat treatment'' applies only to processes where the heating and cooling are done for the specific purpose of altering properties intentionally, heating and cooling often occur incidentally during other manufacturing processes such as hot forming or welding. Physical processes Photomicrographs of steel. Top: In annealed (slowly cooled) steel, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |