|

Yaw System

The yaw system of wind turbines is the component responsible for the orientation of the wind turbine rotor towards the wind. History The task of orienting the rotor into the wind was a complicated issue already for historical windmills. The first windmills able to rotate in order to "face" the wind appeared in the mid-18th century.Wind Power Plants, R. Gasch and J. Twele, Solarpraxis, Their rotatable nacelles were mounted on the main structure of the windmill using primitive wooden gliding bearings lubricated with animal fat. The necessary yawing torque was created by means of animal power, human power or even wind power (implementation of an auxiliary rotor known as fantail). Vertical-axis wind turbines (VAWTs) do not need a yaw system since their vertical rotors can face the wind from any direction and only their self rotation gives the blades a clear direction of the air flow. Horizontal-axis wind turbines (HAWTs), however, need to orient their rotors into and out of the wi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Wind

Wind is the natural movement of atmosphere of Earth, air or other gases relative to a planetary surface, planet's surface. Winds occur on a range of scales, from thunderstorm flows lasting tens of minutes, to local breezes generated by heating of land surfaces and lasting a few hours, to global winds resulting from the difference in absorption (electromagnetic radiation), absorption of solar energy between the climate zones on Earth. The study of wind is called anemology. The two main causes of large-scale atmospheric circulation are the differential heating between the equator and the poles, and the rotation of the planet (Coriolis effect). Within the tropics and subtropics, thermal low circulations over terrain and high plateaus can drive monsoon circulations. In coastal areas the sea breeze/land breeze cycle can define local winds; in areas that have variable terrain, mountain and valley breezes can prevail. Winds are commonly classified by their scale (spatial), spatial ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Roller Bearing

In mechanical engineering, a rolling-element bearing, also known as a rolling bearing,ISO 15 is a bearing which carries a load by placing rolling elements (such as balls, cylinders, or cones) between two concentric, grooved rings called races. The relative motion of the races causes the rolling elements to roll with very little rolling resistance and with little sliding. One of the earliest and best-known rolling-element bearings is a set of logs laid on the ground with a large stone block on top. As the stone is pulled, the logs roll along the ground with little sliding friction. As each log comes out the back, it is moved to the front where the block then rolls onto it. It is possible to imitate such a bearing by placing several pens or pencils on a table and placing an item on top of them. See " bearings" for more on the historical development of bearings. A rolling element rotary bearing uses a shaft in a much larger hole, and spheres or cylinders called "rollers" tig ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hydraulic Fluid

A hydraulic fluid or hydraulic liquid is the medium by which power is transferred in hydraulic machinery. Common hydraulic fluids are based on mineral oil or water. Examples of equipment that might use hydraulic fluids are excavators and backhoes, hydraulic brakes, power steering systems, automatic transmissions, garbage trucks, aircraft flight control systems, lifts, and industrial machinery. Hydraulic systems like the ones mentioned above will work most efficiently if the hydraulic fluid used has zero compressibility. Functions and properties The primary function of a hydraulic fluid is to convey power. In use, however, there are other important functions of hydraulic fluid such as protection of the hydraulic machine components. The table below lists the major functions of a hydraulic fluid and the properties of a fluid that affect its ability to perform that function: Composition Base stock The original hydraulics fluid, dating back to the time of ancient Egyp ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Reliability Engineering

Reliability engineering is a sub-discipline of systems engineering that emphasizes the ability of equipment to function without failure. Reliability is defined as the probability that a product, system, or service will perform its intended function adequately for a specified period of time, OR will operate in a defined environment without failure. Reliability is closely related to availability, which is typically described as the ability of a component or system to function at a specified moment or interval of time. The ''reliability function'' is theoretically defined as the probability of success. In practice, it is calculated using different techniques, and its value ranges between 0 and 1, where 0 indicates no probability of success while 1 indicates definite success. This probability is estimated from detailed (physics of failure) analysis, previous data sets, or through reliability testing and reliability modeling. Availability, testability, maintainability, and maintenance ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Power-to-weight Ratio

Power-to-weight ratio (PWR, also called specific power, or power-to-mass ratio) is a calculation commonly applied to engines and mobile power sources to enable the comparison of one unit or design to another. Power-to-weight ratio is a measurement of actual performance of any engine or power source. It is also used as a measurement of performance of a vehicle as a whole, with the engine's power output being divided by the weight (or mass) of the vehicle, to give a metric that is independent of the vehicle's size. Power-to-weight is often quoted by manufacturers at the peak value, but the actual value may vary in use and variations will affect performance. The inverse of power-to-weight, weight-to-power ratio (power loading) is a calculation commonly applied to aircraft, cars, and vehicles in general, to enable the comparison of one vehicle's performance to another. Power-to-weight ratio is equal to thrust per unit mass multiplied by the velocity of any vehicle. Power-to-weight ( ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hydraulic Motor

A hydraulic motor is a mechanical actuator that converts hydraulic pressure and flow into torque and angular displacement (rotation). The hydraulic motor is the rotary counterpart of the hydraulic cylinder as a linear actuator. Most broadly, the category of devices called hydraulic motors has sometimes included those that run on hydropower (namely, water engines and water motors) but in today's terminology the name usually refers more specifically to motors that use hydraulic fluid as part of closed hydraulic circuits in modern hydraulic machinery. Conceptually, a hydraulic motor should be interchangeable with a hydraulic pump because it performs the opposite function – similar to the way a DC electric motor is theoretically interchangeable with a DC electrical generator. However, many hydraulic pumps cannot be used as hydraulic motors because they cannot be backdriven. Also, a hydraulic motor is usually designed for working pressure at both sides of the motor, whereas m ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hydraulic Cylinder

A hydraulic cylinder (also called a linear hydraulic motor) is a mechanical actuator that is used to give a unidirectional force through a unidirectional stroke. It has many applications, notably in construction equipment ( engineering vehicles), manufacturing machinery, elevators, and civil engineering. A hydraulic cylinder is a hydraulic actuator that provides linear motion when hydraulic energy is converted into mechanical movement. It can be likened to a muscle in that, when the hydraulic system of a machine is activated, the cylinder is responsible for providing the motion. Operation Hydraulic cylinders get their power from pressurized hydraulic fluid, which is incompressible. Typically oil is used as hydraulic fluid. The hydraulic cylinder consists of a cylinder barrel, in which a piston connected to a piston rod moves back and forth. The barrel is closed on one end by the cylinder bottom (also called the cap) and the other end by the cylinder head (also called th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ratchet (device)

A ratchet (occasionally spelled rachet) is a mechanical device that allows continuous linear or rotary motion in only one direction while preventing motion in the opposite direction. Ratchets are widely used in machinery and tools. The word ''ratchet'' is also used informally to refer to a ratcheting socket wrench. __TOC__ Theory of operation A ratchet consists of a round gear or a linear rack with teeth, and a pivoting, spring-loaded finger called a '' pawl'' (or ''click'', in clocks and watches) that engages the teeth. The teeth are uniform but are usually asymmetrical, with each tooth having a moderate slope on one edge and a much steeper slope on the other edge. When the teeth are moving in the unrestricted (i.e. forward) direction, the pawl easily slides up and over the gently sloped edges of the teeth, with a spring forcing it (often with an audible 'click') into the depression between the teeth as it passes the tip of each tooth. When the teeth move in the oppo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hydraulic Motor

A hydraulic motor is a mechanical actuator that converts hydraulic pressure and flow into torque and angular displacement (rotation). The hydraulic motor is the rotary counterpart of the hydraulic cylinder as a linear actuator. Most broadly, the category of devices called hydraulic motors has sometimes included those that run on hydropower (namely, water engines and water motors) but in today's terminology the name usually refers more specifically to motors that use hydraulic fluid as part of closed hydraulic circuits in modern hydraulic machinery. Conceptually, a hydraulic motor should be interchangeable with a hydraulic pump because it performs the opposite function – similar to the way a DC electric motor is theoretically interchangeable with a DC electrical generator. However, many hydraulic pumps cannot be used as hydraulic motors because they cannot be backdriven. Also, a hydraulic motor is usually designed for working pressure at both sides of the motor, whereas m ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Backlash (engineering)

In mechanical engineering, backlash, sometimes called lash, play, or slop, is a Engineering tolerance, clearance or lost motion in a mechanism caused by gaps between the parts. It can be defined as "the maximum distance or angle through which any part of a mechanical system may be moved in one direction without applying appreciable force or motion to the next part in mechanical sequence."p. 1-8 An example, in the context of gears and gear trains, is the amount of clearance between mated gear teeth. It can be seen when the direction of movement is reversed and the slack or lost motion is taken up before the reversal of motion is complete. It can be heard from the railway couplings when a train reverses direction. Another example is in a valve train with mechanical tappets, where a certain range of lash is necessary for the valves to work properly. Depending on the application, backlash may or may not be desirable. Some amount of backlash is unavoidable in nearly all reversing me ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fatigue (material)

In materials science, fatigue is the initiation and propagation of cracks in a material due to cyclic loading. Once a fatigue crack has initiated, it grows a small amount with each loading cycle, typically producing striations on some parts of the fracture surface. The crack will continue to grow until it reaches a critical size, which occurs when the stress intensity factor of the crack exceeds the fracture toughness of the material, producing rapid propagation and typically complete fracture of the structure. Fatigue has traditionally been associated with the failure of metal components which led to the term metal fatigue. In the nineteenth century, the sudden failing of metal railway axles was thought to be caused by the metal crystallising because of the brittle appearance of the fracture surface, but this has since been disproved. Most materials, such as composites, plastics and ceramics, seem to experience some sort of fatigue-related failure. To aid in predicting the f ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

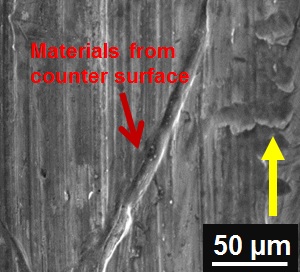

Wear

Wear is the damaging, gradual removal or deformation of material at solid surfaces. Causes of wear can be mechanical (e.g., erosion) or chemical (e.g., corrosion). The study of wear and related processes is referred to as tribology. Wear in machine elements, together with other processes such as fatigue and creep, causes functional surfaces to degrade, eventually leading to material failure or loss of functionality. Thus, wear has large economic relevance as first outlined in the Jost Report. Abrasive wear alone has been estimated to cost 1–4% of the gross national product of industrialized nations. Wear of metals occurs by plastic displacement of surface and near-surface material and by detachment of particles that form wear debris. The particle size may vary from millimeters to nanometers. This process may occur by contact with other metals, nonmetallic solids, flowing liquids, solid particles or liquid droplets entrained in flowing gasses. The wear rate is affected ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |