|

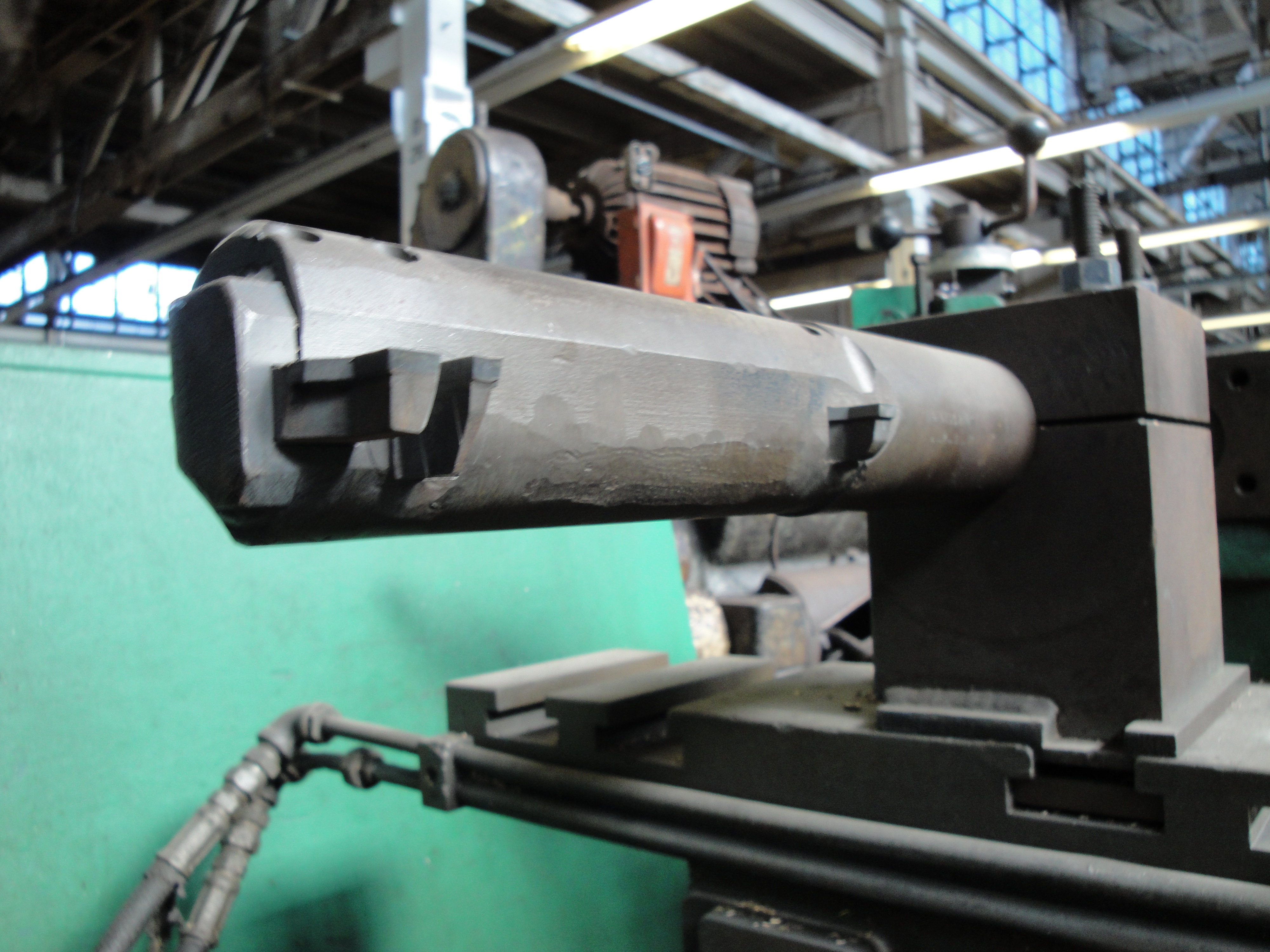

Universal Lathe

A universal lathe or parallel lathe is the most common type of lathe. It differs from other types of lathes in that it has the option of a tailstock, separate mechanisms for longitudinal and transverse feeds (typically via separate handwheels), and an automatic (usually mechanically) driven longitudinal leadscrew for making threads. Description Universal lathes are used for the production of single products or small batches, and are suitable for maintenance and similar minor work in a workshop, as well as anywhere there is a need for tools that should be as versatile as possible. On universal lathes, one can turn longitudinally, transversely, one can turn cylindrical and conical threads, Archimedean spirals, one can also bore, countersink, ream, tap threads with taps and dies, manually polish and file. Extra accessories enables ball turning, copying and grinding. There are even aftermarket accessories for milling; typically by replacing the top slide (compound) with a mi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Boring (manufacturing)

In machining, boring is the process of enlarging a hole that has already been drilled (or casting, cast) by means of a Tool bit, single-point cutting tool (or of a boring head containing several such tools), such as in boring a gun barrel or an cylinder (engine), engine cylinder. Boring is used to achieve greater accuracy of the diameter of a hole, and can be used to cut a tapered hole. Boring can be viewed as the internal-diameter counterpart to turning, which cuts external diameters. There are various types of boring. The boring bar may be supported on both ends (which only works if the existing hole is a through hole), or it may be supported at one end (which works for both, through holes and blind holes). Lineboring (line boring, line-boring) implies the former. Backboring (back boring, back-boring) is the process of reaching through an existing hole and then boring on the "back" side of the workpiece (relative to the machine headstock). Because of the limitatio ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Frontal Lathe

A frontal lathe or face lathe is a type of lathe with a horizontal Headstock (lathe), headstock, and without a tailstock. They are suitable for Workpiece, workpieces with a very large diameter (in some cases over 3 meters), but with a relatively short length. Advantages include their simple and inexpensive construction, good access around the workpiece, and a good overview of the work. Disadvantages include that it can be difficult to clamp the workpiece into place safely, and that the front Bearing (mechanical), bearing on the Spindle (tool), spindle is heavily loaded, which is less favourable for accuracy. Description There are several different designs of frontal lathes. In particular, a distinction is made between lathes where the Way (machine tool element), bedway is parallel to the Axle, axis of the main spindle (similar to a universal lathe), and lathes where the bedway is perpendicular to the axis of the main spindle (similar to the letter T in a floor plan). In industr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Coordinate Table

X-Y tables, also known as cross working tables or coordinate tables, help provide horizontal motion for automated machinery such as assembly robots in manufacturing facilities. Robotic arms and other automated machinery have only a limited range of motion while their bases remain stationary; X-Y tables allow this basis to move horizontally along X and Y axis. Also known as XY stages, XY tables are motorized linear slides with linear motion based in bearings which are driven by a drive mechanism, typically a linear motor. XY tables are built and configured to provide high-performance positioning along multiple axes. Applications Serving industries including general machinery, pharmaceutical, manufacturing and semiconductor, XY tables offer precision-controlled automated movement. XY tables are broadly used in mechanical processes and applications including material handling, industrial automation equipment, machinery building and automated measurement. Construction XY tables are f ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Milling (machining)

Milling is the process of machining using rotary Milling cutter, cutters to remove material by advancing a cutter into a workpiece. This may be done by varying directions on one or several axes, cutter head speed, and pressure. Milling covers a wide variety of different operations and machines, on scales from small individual parts to large, heavy-duty gang milling operations. It is one of the most commonly used processes for machining custom parts to precise tolerances. Milling can be done with a wide range of machine tools. The original class of machine tools for milling was the milling machine (often called a mill). After the advent of computer numerical control (CNC) in the 1960s, milling machines evolved into ''machining centers'': milling machines augmented by automatic tool changers, tool magazines or carousels, CNC capability, coolant systems, and enclosures. Milling centers are generally classified as vertical machining centers (VMCs) or horizontal machining centers (HMCs ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Grinding (abrasive Cutting)

Grinding is a type of abrasive machining process which uses a grinding wheel as cutting tool. A wide variety of machines are used for grinding, best classified as portable or stationary: * Portable power tools such as angle grinders, die grinders and cut-off saws * Stationary power tools such as bench grinders and cut-off saws * Stationary hydro- or hand-powered sharpening stones Milling practice is a large and diverse area of manufacturing and toolmaking. It can produce very fine finishes and very accurate dimensions; yet in mass production contexts, it can also rough out large volumes of metal quite rapidly. It is usually better suited to the machining of very hard materials than is "regular" machining (that is, cutting larger chips with cutting tools such as tool bits or milling cutters), and until recent decades it was the only practical way to machine such materials as hardened steels. Compared to "regular" machining, it is usually better suited to taking very ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Copying Lathe

The copying lathe or duplicating lathe is a lathe that creates shapes identical to the specified pattern. Early inventions Nartov's lathe In early 1700s Russian engineer Andrey Nartov invented a copying lathe for the purpose of ornamental turning, which allowed the operator to make ornaments with the same precision as that of handicraft work of that time.''Nartov and his Theatrum Machinarium'' (translated in 1966 from Russian original Виктор Данилевский (), ''Нартов и Ясное зрелище машин'', 1958); book review: , * It includes Nartovs's biography, his inventions, and illustrations and extended excerpts from Nartov's unpublished manuscript describing various machinery, stored in State Public Library in St.Petersburg, Russia. Nartov's manuscript was extensively annotated by editor A.S.Britkin. The Hermitage Museum, Russia, displays the Nartov's copying lathe used for ornamental turning: making medals and guilloche patterns designed by Nar ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

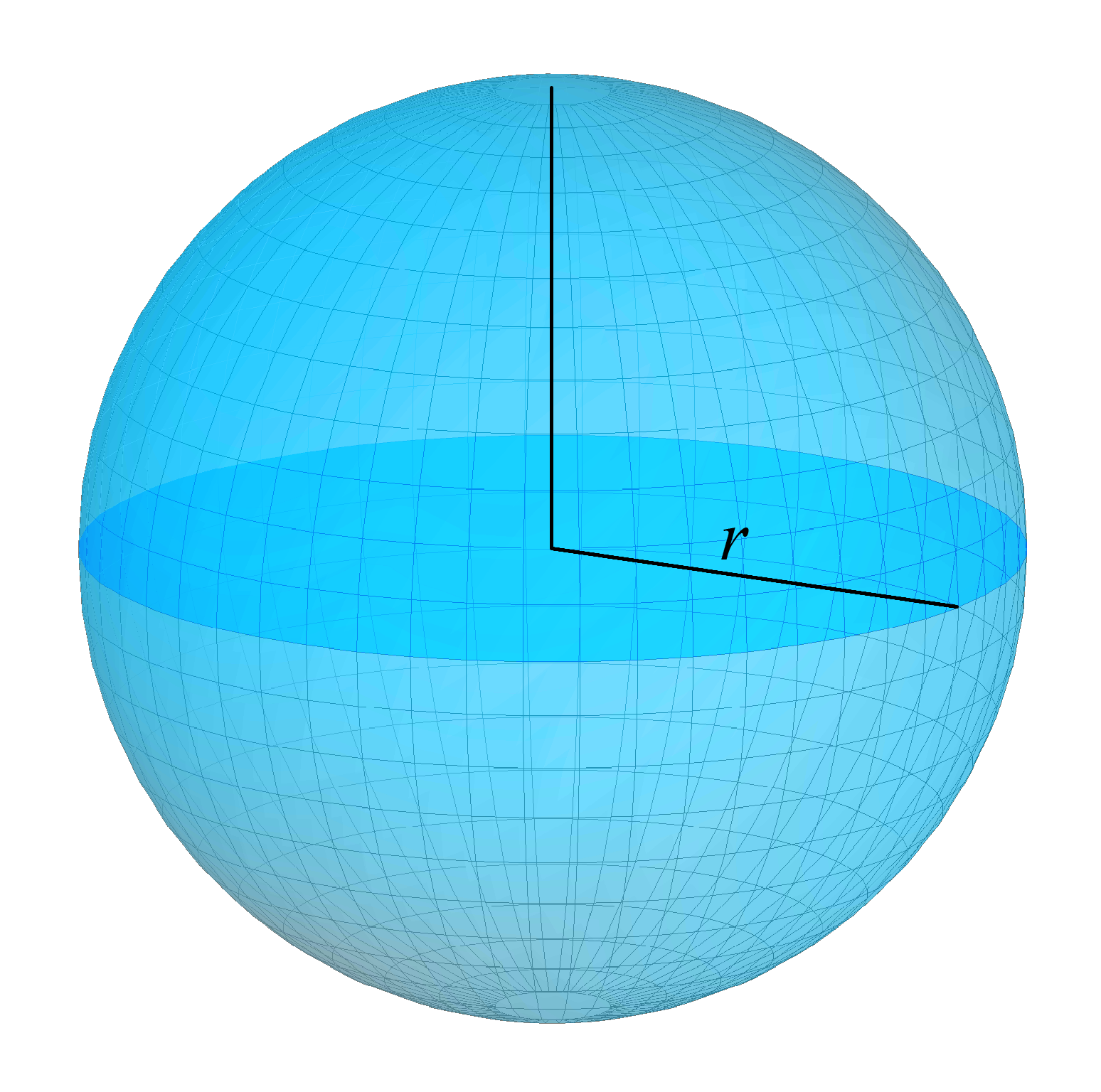

Sphere

A sphere (from Ancient Greek, Greek , ) is a surface (mathematics), surface analogous to the circle, a curve. In solid geometry, a sphere is the Locus (mathematics), set of points that are all at the same distance from a given point in three-dimensional space.. That given point is the center (geometry), ''center'' of the sphere, and the distance is the sphere's ''radius''. The earliest known mentions of spheres appear in the work of the Greek mathematics, ancient Greek mathematicians. The sphere is a fundamental surface in many fields of mathematics. Spheres and nearly-spherical shapes also appear in nature and industry. Bubble (physics), Bubbles such as soap bubbles take a spherical shape in equilibrium. The Earth is spherical Earth, often approximated as a sphere in geography, and the celestial sphere is an important concept in astronomy. Manufactured items including pressure vessels and most curved mirrors and lenses are based on spheres. Spheres rolling, roll smoothly in ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

File (tool)

A file is a tool used to remove fine amounts of material from a workpiece. It is common in woodworking, metalworking, and other similar trade and hobby tasks. Most are hand tools, made of a case hardened steel bar of rectangular, square, triangular, or round cross-section, with one or more surfaces cut with sharp, generally parallel Tine (structural), teeth. A narrow, pointed Tang (tools), tang is common at one end, to which a handle may be fitted.. A rasp is a form of file with distinct, individually cut teeth used for coarsely removing large amounts of material. Files have also been developed with abrasive surfaces, such as natural or synthetic diamond tool, diamond grains or silicon carbide, allowing removal of material that would dull or resist steel files, such as ceramic. History Early filing or rasping has prehistoric roots and grew naturally out of the blending of the twin inspirations of cutting with stone cutting tools (such as hand axes) and abrasive, abrading u ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Polishing (metalworking)

Buffing are finishing processes for smoothing a workpiece's surface using an abrasive and a work wheel or a leather strop. Technically, ''polishing'' refers to processes that uses an abrasive that is glued to the work wheel, while ''buffing'' uses a loose abrasive applied to the work wheel. Polishing is a more aggressive process, while buffing is less harsh, which leads to a smoother, brighter finish.Oberg, p. 1439. A common misconception is that a polished surface has a mirror-bright finish, however, most mirror-bright finishes are actually buffed. Polishing is often used to enhance the appearance of an item, prevent contamination of instruments, remove oxidation, create a reflective surface, or prevent corrosion in pipes. In metallography and metallurgy, polishing is used to create a flat, defect-free surface for examination of a metal's microstructure under a microscope. Silicon-based polishing pads or a diamond solution can be used in the polishing process. Polishing stai ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tap And Die

In the context of threading, taps and dies are the two classes of tools used to create screw threads. Many are cutting tools; others are forming tools. A tap is used to cut or form the female portion of the mating pair (e.g. a nut). A die is used to cut or form the male portion of the mating pair (e.g. a bolt). The process of cutting or forming threads using a tap is called ''tapping'', whereas the process using a die is called ''threading''. Both tools can be used to clean up a thread, which is called ''chasing''. However, using an ordinary tap or die to clean threads generally removes some material, which results in looser, weaker threads. Because of this, machinists generally clean threads with special taps and dies—called '' chasers''—made for that purpose. Chasers are made of softer materials and don't cut new threads. However they still fit tighter than actual fasteners, and are fluted like regular taps and dies so debris can escape. Car mechanics, for example, use ch ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Reamer

A reamer is a type of rotary cutting tool used in metalworking. Precision reamers are designed to enlarge the size of a previously formed hole by a small amount but with a high degree of accuracy to leave smooth sides. There are also non-precision reamers which are used for more basic enlargement of holes or for removing Burr (edge), burrs. The process of enlarging the hole is called reaming. There are many different types of reamer and they may be designed for use as a hand tool or in a machine tool, such as a milling machine or drill press. Construction A typical reamer consists of a set of Parallel (geometry), parallel straight or helical cutting edges along the length of a Cylinder (geometry), cylindrical body. Each cutting edge is ground at a slight angle and with a slight undercut below the cutting edge. Reamers must combine both hardness in the cutting edges, for long life, and toughness, so that the tool does not fail under the normal forces of use. They should only be use ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |