|

Torque Tester

A torque tester is a quality control device to test or calibrate torque-controlled tools. This includes electronic torque wrenches, click torque wrenches, dial torque wrenches, electric screwdrivers, air screwdrivers, pulse tools, cordless screwdrivers, nutrunners, and torque screwdrivers. Advanced torque testers include the ability to measure in clockwise and counter-clockwise directions, and potentially convert to engineering units (such as in·oz, in·lb, ft·lb, N·m, cN·m, kgf·cm, gf·cm, kgf·fm). They can also have different modes of operation (such as peak, 1st peak, track), and may include a certificate from a local regulator (such as NIST). Torque testers measure properties such as torsional strength and stiffness and are used in quality control of various fields including medical devices, metals, and aerospace. Cap torque testers are also frequently used of measure the removal torque of screw caps on bottles and jars.ASTM D3474 Standard Practice for Calibration an ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

|

|

Quality Control

Quality control (QC) is a process by which entities review the quality of all factors involved in production. ISO 9000 defines quality control as "a part of quality management focused on fulfilling quality requirements". This approach places emphasis on three aspects (enshrined in standards such as ISO 9001): # Elements such as controls, job management, defined and well managed processes, performance and integrity criteria, and identification of records # Competence, such as knowledge, skills, experience, and qualifications # Soft elements, such as personnel, integrity, confidence, organizational culture, motivation, team spirit, and quality relationships. Inspection is a major component of quality control, where physical product is examined visually (or the end results of a service are analyzed). Product inspectors will be provided with lists and descriptions of unacceptable product defects such as cracks or surface blemishes for example. History and introductio ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

|

Load Cell

A load cell converts a force such as tension, compression, pressure, or torque into a signal (electrical, pneumatic or hydraulic pressure, or mechanical displacement indicator) that can be measured and standardized. It is a force transducer. As the force applied to the load cell increases, the signal changes proportionally. The most common types of load cells are pneumatic, hydraulic, and strain gauge types for industrial applications. Typical non-electronic bathroom scales are a widespread example of a mechanical displacement indicator where the applied weight (force) is indicated by measuring the deflection of springs supporting the load platform, technically a "load cell". Strain gauge load cell Strain gauge load cells are the kind most often found in industrial settings. It is ideal as it is highly accurate, versatile, and cost-effective. Structurally, a load cell has a metal body to which strain gauges have been secured. The body is usually made of aluminum, alloy steel, or ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

|

Belleville Washer

A Belleville washer, also known as a coned-disc spring, conical spring washer, disc spring, Belleville spring or cupped spring washer, is a conical shell which can be loaded along its axis either statically or dynamically. A Belleville washer is a type of Spring (device), spring shaped like a Washer (mechanical), washer. It is the shape, a cone frustum, that gives the washer its characteristic spring. The "Belleville" name comes from the inventor :Fr:Julien Belleville, Julien Belleville who in Dunkerque, France, in 1867 patented a spring design which already contained the principle of the disc spring. The real inventor of Belleville washers is unknown. Through the years, many profiles for disc springs have been developed. Today the most used are the profiles with or without contact flats, while some other profiles, like disc springs with trapezoidal cross-section, have lost importance. Features and use In the different fields, if they are used as springs or to apply a fle ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

|

|

Algorithm

In mathematics and computer science, an algorithm () is a finite sequence of Rigour#Mathematics, mathematically rigorous instructions, typically used to solve a class of specific Computational problem, problems or to perform a computation. Algorithms are used as specifications for performing calculations and data processing. More advanced algorithms can use Conditional (computer programming), conditionals to divert the code execution through various routes (referred to as automated decision-making) and deduce valid inferences (referred to as automated reasoning). In contrast, a Heuristic (computer science), heuristic is an approach to solving problems without well-defined correct or optimal results.David A. Grossman, Ophir Frieder, ''Information Retrieval: Algorithms and Heuristics'', 2nd edition, 2004, For example, although social media recommender systems are commonly called "algorithms", they actually rely on heuristics as there is no truly "correct" recommendation. As an e ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

|

|

Instrumentation Amplifier

An instrumentation amplifier (sometimes shorthanded as in-amp or InAmp) is a type of differential amplifier that has been outfitted with input buffer amplifiers, which eliminate the need for input impedance matching and thus make the amplifier particularly suitable for use in measurement and test equipment. Additional characteristics include very low DC offset, low drift, low noise, very high open-loop gain, very high common-mode rejection ratio, and very high input impedances. Instrumentation amplifiers are used where great accuracy and stability of the circuit both short- and long-term are required. Although the instrumentation amplifier is usually shown schematically identical to a standard operational amplifier (op-amp), the electronic instrumentation amplifier is almost always internally composed of 3 op-amps. These are arranged so that there is one op-amp to buffer each input (+, −), and one to produce the desired output with adequate impedance matching for the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

|

|

Wheatstone Bridge

A Wheatstone bridge is an electrical circuit used to measure an unknown electrical resistance by balancing two legs of a bridge circuit, one leg of which includes the unknown component. The primary benefit of the circuit is its ability to provide extremely accurate measurements (in contrast with something like a simple voltage divider). Its operation is similar to the original potentiometer. The Wheatstone bridge was invented by Samuel Hunter Christie (sometimes spelled "Christy") in 1833 and improved and popularized by Sir Charles Wheatstone in 1843. One of the Wheatstone bridge's initial uses was for soil analysis and comparison. Operation In the figure, is the fixed, yet unknown, resistance to be measured. , , and are resistors of known resistance and the resistance of is adjustable. The resistance is adjusted until the bridge is "balanced" and no current flows through the galvanometer . At this point, the potential difference between the two midpoints (B and D ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

|

|

Strain (materials Science)

In mechanics, strain is defined as relative deformation, compared to a position configuration. Different equivalent choices may be made for the expression of a strain field depending on whether it is defined with respect to the initial or the final configuration of the body and on whether the metric tensor or its dual is considered. Strain has dimension of a length ratio, with SI base units of meter per meter (m/m). Hence strains are dimensionless and are usually expressed as a decimal fraction or a percentage. Parts-per notation is also used, e.g., parts per million or parts per billion (sometimes called "microstrains" and "nanostrains", respectively), corresponding to μm/m and nm/m. Strain can be formulated as the spatial derivative of displacement: \boldsymbol \doteq \cfrac\left(\mathbf - \mathbf\right) = \boldsymbol'- \boldsymbol, where is the identity tensor. The displacement of a body may be expressed in the form , where is the reference position of ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

|

|

Strain Gauge

A strain gauge (also spelled strain gage) is a device used to measure Deformation (mechanics)#Strain, strain on an object. Invented by Edward E. Simmons and Arthur C. Ruge in 1938, the most common type of strain gauge consists of an Electrical insulation, insulating flexible backing which supports a metallic foil pattern. The gauge is attached to the object by a suitable adhesive, such as cyanoacrylate. As the object is deformed, the foil is deformed, causing its electrical resistance to change. This resistance change, usually measured using a Wheatstone bridge, is related to the strain by the quantity known as the gauge factor. History Edward E. Simmons and Professor Arthur C. Ruge independently invented the strain gauge. Simmons was involved in a research project by Dätwyler and Clark at Caltech between 1936 and 1938. They researched the stress-strain behavior of metals under shock loads. Simmons came up with an original way to measure the force introduced into the sample b ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

|

|

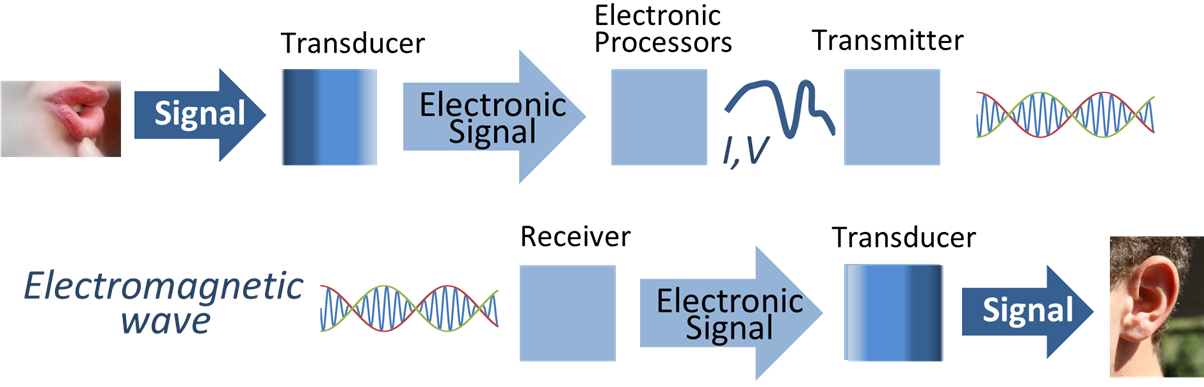

Transducer

A transducer is a device that Energy transformation, converts energy from one form to another. Usually a transducer converts a signal in one form of energy to a signal in another. Transducers are often employed at the boundaries of automation, Measuring instrument, measurement, and control systems, where electrical signals are converted to and from other physical quantities (energy, force, torque, light, motion, position, etc.). The process of converting one form of energy to another is known as transduction. Types * Mechanical transducers convert physical quantities into mechanical outputs or vice versa; * Electrical transducers convert physical quantities into electrical outputs or signals. Examples of these are: ** a thermocouple that changes temperature differences into a small voltage; ** a linear variable differential transformer (LVDT), used to measure displacement (position) changes by means of electrical signals. Sensors, actuators and transceivers Transducers can be ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

|

Torque

In physics and mechanics, torque is the rotational analogue of linear force. It is also referred to as the moment of force (also abbreviated to moment). The symbol for torque is typically \boldsymbol\tau, the lowercase Greek letter ''tau''. When being referred to as moment of force, it is commonly denoted by . Just as a linear force is a push or a pull applied to a body, a torque can be thought of as a twist applied to an object with respect to a chosen point; for example, driving a screw uses torque to force it into an object, which is applied by the screwdriver rotating around its axis to the drives on the head. Historical terminology The term ''torque'' (from Latin , 'to twist') is said to have been suggested by James Thomson and appeared in print in April, 1884. Usage is attested the same year by Silvanus P. Thompson in the first edition of ''Dynamo-Electric Machinery''. Thompson describes his usage of the term as follows: Today, torque is referred to using d ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

|

|

ASTM

ASTM International, formerly known as American Society for Testing and Materials, is a standards organization that develops and publishes voluntary consensus technical international standards for a wide range of materials, products, systems and services. Some 12,575 apply globally. The headquarters is in West Conshohocken, Pennsylvania, about northwest of Philadelphia. It was founded in 1902 as the American Section of the International Association for Testing Materials. In addition to its traditional standards work, ASTM operates several global initiatives advancing additive manufacturing, advanced manufacturing, and emerging technologies, including the Additive Manufacturing Center of Excellence (AM CoE), the acquisition oWohlers Associatesfor market intelligence and advisory services, and the NIST-funded Standardization Center of Excellence (SCOE). History In 1898, a group of scientists and engineers, led by chemist, industry leader, and proponent of standardization Ch ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

|

|

Screw Cap

A screw cap or closure is a common type of closure for bottles, jars, and tubes. History Screw caps had been used in Europe since the 1500s and a British patent was filed in 1810 by Peter Durand acting on behalf of Nicolas Appert. John Landis Mason patented in 1858 a screw-on lid for a jar that became known as the Mason jar. Usage A screw closure is a mechanical device which is screwed on and off of a "finish" on a container. Either continuous threads or lugs are used. It must be engineered to be cost-effective, to provide an effective seal (and barrier), to be compatible with the contents, to be easily opened by the consumer, often to be reclosable, and to comply with product, package, and environmental laws and regulations. Manufacturers may ensure the integrity of a screw cap using a cap torque tester. Some closures need to be tamper resistant and have child-resistant packaging features. A tamper-evident band is a common tamper warning for screw caps of bottles ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |