|

TRIP Steel

TRIP steel are a class of high-strength steel alloys typically used in naval and marine applications and in the automotive industry. TRIP stands for "Transformation induced plasticity," which implies a phase transformation in the material, typically when a stress is applied. These alloys are known to possess an outstanding combination of strength and ductility. Microstructure TRIP steels possess a microstructure consisting of austenite with sufficient thermodynamic instability such that transformation to martensite is achieved during loading or deformation. Many automotive TRIP steels possess retained austenite within a ferrite matrix, which may also contain hard phases like bainite and martensite. In the case of these alloys, the high silicon and carbon content of TRIP steels results in significant volume fractions of retained austenite in the final microstructure. TRIP steels use higher quantities of carbon than dual-phase steels to obtain sufficient carbon content for stabilizi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Steel

Steel is an alloy of iron and carbon that demonstrates improved mechanical properties compared to the pure form of iron. Due to steel's high Young's modulus, elastic modulus, Yield (engineering), yield strength, Fracture, fracture strength and low raw material cost, steel is one of the most commonly manufactured materials in the world. Steel is used in structures (as concrete Rebar, reinforcing rods), in Bridge, bridges, infrastructure, Tool, tools, Ship, ships, Train, trains, Car, cars, Bicycle, bicycles, Machine, machines, Home appliance, electrical appliances, furniture, and Weapon, weapons. Iron is always the main element in steel, but other elements are used to produce various grades of steel demonstrating altered material, mechanical, and microstructural properties. Stainless steels, for example, typically contain 18% chromium and exhibit improved corrosion and Redox, oxidation resistance versus its carbon steel counterpart. Under atmospheric pressures, steels generally ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Strain Hardening

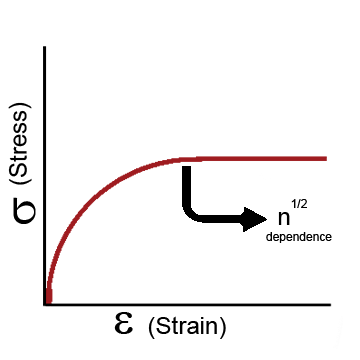

Work hardening, also known as strain hardening, is the process by which a material's load-bearing capacity (strength) increases during plastic (permanent) deformation. This characteristic is what sets ductile materials apart from brittle materials. Work hardening may be desirable, undesirable, or inconsequential, depending on the application. This strengthening occurs because of dislocation movements and dislocation generation within the crystal structure of the material. Many non-brittle metals with a reasonably high melting point as well as several polymers can be strengthened in this fashion. Alloys not amenable to heat treatment, including low-carbon steel, are often work-hardened. Some materials cannot be work-hardened at low temperatures, such as indium, however others can be strengthened only via work hardening, such as pure copper and aluminum. Undesirable work hardening An example of undesirable work hardening is during machining when early passes of a cutting tool (ma ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Stamping (metalworking)

Stamping (also known as pressing) is the process of placing flat sheet metal in either blank or coil form into a stamping press where a tool and Die (manufacturing), die surface forms the metal into a net shape. Stamping includes a variety of sheet-metal forming manufacturing processes, such as punching using a machine press or stamping press, blanking, embossing, bending, flanging, and coining. This could be a single stage operation where every stroke of the press produces the desired form on the sheet metal part, or could occur through a series of stages. The process is usually carried out on sheet metal, but can also be used on other materials, such as polystyrene. Progressive dies are commonly fed from a coil of steel, coil reel for unwinding of coil to a straightener to level the coil and then into a feeder which advances the material into the press and die at a predetermined feed length. Depending on part complexity, the number of stations in the die can be determined. St ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Formability

Formability is the ability of a given metal workpiece to undergo plastic deformation without being damaged. The plastic deformation capacity of metallic materials, however, is limited to a certain extent, at which point, the material could experience tearing or fracture (breakage). Processes affected by the formability of a material include: rolling, extrusion, forging, rollforming, stamping, and hydroforming. Fracture strain A general parameter that indicates the formability and ductility of a material is the fracture strain which is determined by a uniaxial tensile test (see also fracture toughness). The strain identified by this test is defined by elongation with respect to a reference length. For example, a length of is used for the standardized uniaxial test of flat specimens, pursuant to EN 10002. It is important to note that deformation is homogeneous up to uniform elongation. Strain subsequently localizes until fracture occurs. Fracture strain is not an engineering s ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Work Hardening

Work hardening, also known as strain hardening, is the process by which a material's load-bearing capacity (strength) increases during plastic (permanent) deformation. This characteristic is what sets ductile materials apart from brittle materials. Work hardening may be desirable, undesirable, or inconsequential, depending on the application. This strengthening occurs because of dislocation movements and dislocation generation within the crystal structure of the material. Many non-brittle metals with a reasonably high melting point as well as several polymers can be strengthened in this fashion. Alloys not amenable to heat treatment, including low-carbon steel, are often work-hardened. Some materials cannot be work-hardened at low temperatures, such as indium, however others can be strengthened only via work hardening, such as pure copper and aluminum. Undesirable work hardening An example of undesirable work hardening is during machining when early passes of a cutter inadver ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Strain (materials Science)

In mechanics, strain is defined as relative deformation, compared to a position configuration. Different equivalent choices may be made for the expression of a strain field depending on whether it is defined with respect to the initial or the final configuration of the body and on whether the metric tensor or its dual is considered. Strain has dimension of a length ratio, with SI base units of meter per meter (m/m). Hence strains are dimensionless and are usually expressed as a decimal fraction or a percentage. Parts-per notation is also used, e.g., parts per million or parts per billion (sometimes called "microstrains" and "nanostrains", respectively), corresponding to μm/m and nm/m. Strain can be formulated as the spatial derivative of displacement: \boldsymbol \doteq \cfrac\left(\mathbf - \mathbf\right) = \boldsymbol'- \boldsymbol, where is the identity tensor. The displacement of a body may be expressed in the form , where is the reference position of ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Carbon

Carbon () is a chemical element; it has chemical symbol, symbol C and atomic number 6. It is nonmetallic and tetravalence, tetravalent—meaning that its atoms are able to form up to four covalent bonds due to its valence shell exhibiting 4 electrons. It belongs to group 14 of the periodic table. Carbon makes up about 0.025 percent of Earth's crust. Three Isotopes of carbon, isotopes occur naturally, carbon-12, C and carbon-13, C being stable, while carbon-14, C is a radionuclide, decaying with a half-life of 5,700 years. Carbon is one of the timeline of chemical element discoveries#Pre-modern and early modern discoveries, few elements known since antiquity. Carbon is the 15th abundance of elements in Earth's crust, most abundant element in the Earth's crust, and the abundance of the chemical elements, fourth most abundant element in the universe by mass after hydrogen, helium, and oxygen. Carbon's abundance, its unique diversity of organic compounds, and its unusual abi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ductility

Ductility refers to the ability of a material to sustain significant plastic Deformation (engineering), deformation before fracture. Plastic deformation is the permanent distortion of a material under applied stress, as opposed to elastic deformation, which is reversible upon removing the stress. Ductility is a critical mechanical performance indicator, particularly in applications that require materials to bend, stretch, or deform in other ways without breaking. The extent of ductility can be quantitatively assessed using the percent elongation at break, given by the equation: \% \mathrm= \left ( \frac \right )\times100 where l_ is the length of the material after fracture and l_0 is the original length before testing. This formula helps in quantifying how much a material can stretch under tensile stress before failure, providing key insights into its ductile behavior. Ductility is an important consideration in engineering and manufacturing. It defines a material's suitabil ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Carbide

In chemistry, a carbide usually describes a compound composed of carbon and a metal. In metallurgy, carbiding or carburizing is the process for producing carbide coatings on a metal piece. Interstitial / Metallic carbides The carbides of the group 4, 5 and 6 transition metals (with the exception of chromium) are often described as interstitial compounds. These carbides have metallic properties and are refractory. Some exhibit a range of stoichiometries, being a non-stoichiometric mixture of various carbides arising due to crystal defects. Some of them, including titanium carbide and tungsten carbide, are important industrially and are used to coat metals in cutting tools. The long-held view is that the carbon atoms fit into octahedral interstices in a close-packed metal lattice when the metal atom radius is greater than approximately 135 pm: *When the metal atoms are cubic close-packed, (ccp), then filling all of the octahedral interstices with carbon achieves 1:1 ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Microstructure

Microstructure is the very small scale structure of a material, defined as the structure of a prepared surface of material as revealed by an optical microscope above 25× magnification. The microstructure of a material (such as metals, polymers, ceramics or composites) can strongly influence physical properties such as strength, toughness, ductility, hardness, corrosion resistance, high/low temperature behaviour or wear resistance. These properties in turn govern the application of these materials in industrial practice. Microstructure at scales smaller than can be viewed with optical microscopes is often called nanostructure, while the structure in which individual atoms are arranged is known as crystal structure. The nanostructure of biological specimens is referred to as ultrastructure. A microstructure's influence on the mechanical and physical properties of a material is primarily governed by the different defects present or absent of the structure. These defects can ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Aluminium

Aluminium (or aluminum in North American English) is a chemical element; it has chemical symbol, symbol Al and atomic number 13. It has a density lower than that of other common metals, about one-third that of steel. Aluminium has a great affinity towards oxygen, passivation (chemistry), forming a protective layer of aluminium oxide, oxide on the surface when exposed to air. It visually resembles silver, both in its color and in its great ability to reflect light. It is soft, magnetism, nonmagnetic, and ductility, ductile. It has one stable isotope, 27Al, which is highly abundant, making aluminium the abundance of the chemical elements, 12th-most abundant element in the universe. The radioactive decay, radioactivity of aluminium-26, 26Al leads to it being used in radiometric dating. Chemically, aluminium is a post-transition metal in the boron group; as is common for the group, aluminium forms compounds primarily in the +3 oxidation state. The aluminium cation Al3+ ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Silicon

Silicon is a chemical element; it has symbol Si and atomic number 14. It is a hard, brittle crystalline solid with a blue-grey metallic lustre, and is a tetravalent metalloid (sometimes considered a non-metal) and semiconductor. It is a member of group 14 in the periodic table: carbon is above it; and germanium, tin, lead, and flerovium are below it. It is relatively unreactive. Silicon is a significant element that is essential for several physiological and metabolic processes in plants. Silicon is widely regarded as the predominant semiconductor material due to its versatile applications in various electrical devices such as transistors, solar cells, integrated circuits, and others. These may be due to its significant band gap, expansive optical transmission range, extensive absorption spectrum, surface roughening, and effective anti-reflection coating. Because of its high chemical affinity for oxygen, it was not until 1823 that Jöns Jakob Berzelius was first able to p ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |