|

Scotch Key

In mechanical engineering, a key is a machine element used to connect a rotating machine element to a shaft. The key prevents relative rotation between the two parts and may enable torque transmission. For a key to function, the shaft and rotating machine element must have a keyway and a keyseat, which is a slot and pocket in which the key fits. The whole system is called a keyed joint. A keyed joint may allow relative axial movement between the parts. Commonly keyed components include gears, pulleys, couplings, and washers. Types There are five main types of keys: ''sunk'', ''saddle'', ''tangent'', ''round'', and ''spline''. Sunk key Types of sunk keys: ''rectangular'', ''square'', ''parallel sunk'', ''gib-head'', ''feather'', and ''Woodruff''. Parallel keys ''Parallel keys'' are the most widely used. They have a square or rectangular cross-section. Square keys are used for smaller shafts and rectangular faced keys are used for shaft diameters over or when the wall thickness ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Mechanical Engineering

Mechanical engineering is the study of physical machines and mechanism (engineering), mechanisms that may involve force and movement. It is an engineering branch that combines engineering physics and engineering mathematics, mathematics principles with materials science, to design, analyze, manufacture, and maintain mechanical systems. It is one of the oldest and broadest of the List of engineering branches, engineering branches. Mechanical engineering requires an understanding of core areas including mechanics, Analytical dynamics, dynamics, thermodynamics, materials science, design, structural analysis, and electricity. In addition to these core principles, mechanical engineers use tools such as computer-aided design (CAD), computer-aided manufacturing (CAM), computer-aided engineering (CAE), and product lifecycle management to design and analyze manufacturing plants, industrial equipment and industrial machinery, machinery, HVAC, heating and cooling systems, transport systems, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Connecticut

Connecticut ( ) is a U.S. state, state in the New England region of the Northeastern United States. It borders Rhode Island to the east, Massachusetts to the north, New York (state), New York to the west, and Long Island Sound to the south. Its capital is Hartford, Connecticut, Hartford, and its most populous city is Bridgeport, Connecticut, Bridgeport. Connecticut lies between the major hubs of New York City and Boston along the Northeast megalopolis, Northeast Corridor, where the New York metropolitan area, New York-Newark Combined Statistical Area, which includes four of Connecticut's seven largest cities, extends into the southwestern part of the state. Connecticut is the List of U.S. states and territories by area, third-smallest state by area after Rhode Island and Delaware, and the List of U.S. states and territories by population, 29th most populous with more than 3.6 million residents as of 2024, ranking it fourth among the List of states and territories of the Unite ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Vise

A vise or vice (British English) is a mechanical apparatus used to secure an object to allow work to be performed on it. Vises have two parallel jaws, one fixed and the other movable, threaded in and out by a screw and lever. The jaws are often flat but may have grooves, adapt to the shape of the workpiece or be custom made. A vise grip is not a vise but a pair of lever-actuated locking pliers. Etymology The etymology of ''vise'' can be tracked via Middle English ''vys'' Anglo-French ''vyz'' from Latin ''vitis'' "vine". The tight grip of the mechanical device was likened to that of the twines of the plant. Types Face A face vise is the standard woodworking vise, always securely attached to a workbench flush with its work surface. Its jaws are made of wood or metal, the latter usually faced with wood, called cheeks, to avoid marring the work. The movable jaw may include a retractable dog to hold work against a bench dog. A "quick-release" woodworker's vise employs a split ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fixture (tool)

A fixture is a work-holding or support device used in the manufacturing industry. Fixtures are used to securely locate (position in a specific location or orientation) and support the work, ensuring that all parts produced using the fixture will maintain conformity and interchangeability. Using a fixture improves the economy of production by allowing smooth operation and quick transition from part to part, reducing the requirement for skilled labor by simplifying how workpieces are mounted, and increasing conformity across a production run. Compared with a jig A fixture differs from a jig in that when a fixture is used, the tool must move relative to the workpiece; a jig moves the piece while the tool remains stationary. Purpose A fixture's primary purpose is to create a secure mounting point for a workpiece, allowing for support during operation and increased accuracy, precision, reliability, and interchangeability in the finished parts. It also serves to reduce working tim ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cutting Tool

Cutting is the separation or opening of a physical object, into two or more portions, through the application of an acutely directed force. Implements commonly used for cutting are the knife and saw, or in medicine and science the scalpel and microtome. However, any sufficiently sharp object is capable of cutting if it has a hardness sufficiently larger than the object being cut, and if it is applied with sufficient force. Even liquids can be used to cut things when applied with sufficient force (see water jet cutter). Cutting is a compressive and shearing phenomenon, and occurs only when the total stress generated by the cutting implement exceeds the ultimate strength of the material of the object being cut. The simplest applicable equation is: :\text = or \tau=\frac The stress generated by a cutting implement is directly proportional to the force with which it is applied, and inversely proportional to the area of contact. Hence, the smaller the area (i.e., the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Shaper

In machining, a shaper is a type of machine tool that uses linear relative motion between the workpiece and a single-point cutting tool to machine a linear toolpath. Its cut is analogous to that of a lathe, except that it is (archetypally) linear instead of helical. A wood shaper is a functionally different woodworking tool, typically with a powered rotating cutting head and manually fed workpiece, usually known simply as a ''shaper'' in North America and ''spindle moulder'' in the UK. A metalworking shaper is somewhat analogous to a metalworking planer, with the cutter riding a ram that moves relative to a stationary workpiece, rather than the workpiece moving beneath the cutter. The ram is typically actuated by a mechanical crank inside the column, though hydraulically actuated shapers are increasingly used. Adding axes of motion to a shaper can yield helical tool paths, as also done in helical planing. Process A single-point cutting tool is rigidly held in the to ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Maschine002

Maschine ( German for ''machine'') is a hardware/software digital audio workstation developed by Native Instruments. Maschine consists of a controller that connects to the included sequencing software, which can be installed on any compatible computer or laptop. Hardware The Maschine controller is designed like a drum machine, similar to products like the Akai MPC. The controller is powered and connected by USB, with each variation featuring 16 pressure sensitive pads and back-lit buttons. The hardware is not limited for sole use with the Maschine software, but is also compatible with Native Instruments' Traktor DJ software, and music production software such as Ableton Live and FL Studio. There are currently 8 different hardware variations: * Maschine Mk1: The original Maschine featured 16 pressure sensitive pads, 11 rotary knobs, 2 LCD screens, and 41 buttons. Alongside the USB connection, Maschine also featured a MIDI input and output to connect to compatible gear externally. * ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

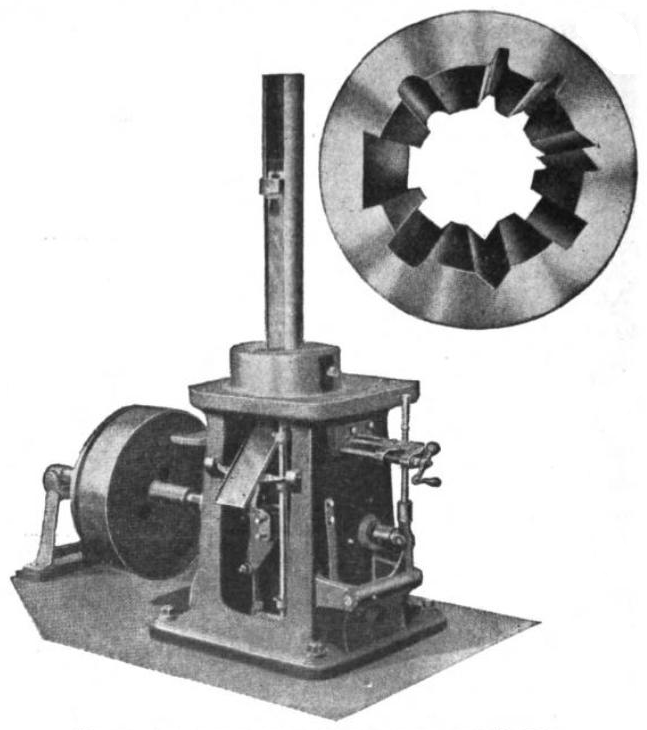

Keyseater And Sample

In mechanical engineering, a key is a machine element used to connect a rotating machine element to a shaft. The key prevents relative rotation between the two parts and may enable torque transmission. For a key to function, the shaft and rotating machine element must have a keyway and a keyseat, which is a slot and pocket in which the key fits. The whole system is called a keyed joint. A keyed joint may allow relative axial movement between the parts. Commonly keyed components include gears, pulleys, couplings, and washers. Types There are five main types of keys: ''sunk'', ''saddle'', ''tangent'', ''round'', and ''spline''. Sunk key Types of sunk keys: ''rectangular'', ''square'', ''parallel sunk'', ''gib-head'', ''feather'', and ''Woodruff''. Parallel keys ''Parallel keys'' are the most widely used. They have a square or rectangular cross-section. Square keys are used for smaller shafts and rectangular faced keys are used for shaft diameters over or when the wall thickness ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Shim (spacer)

A shim is a thin and often tapered or wedge (geometry), wedged piece of material, used to fill small gaps or spaces between objects. Shims are typically used in order to support, adjust for better fit, or provide a level surface. Shims may also be used as spacers to fill gaps between parts subject to wear. Materials Many materials make suitable shim stock (also often styled shimstock), or base material, depending on the context: wood, stone, plastic, metal, or even paper (e.g., when used under a table leg to level the table surface). High quality shim stock such as laminated shims can be bought commercially, but shims are often created ad hoc from whatever material is immediately available. Laminated shim stock is stacked foil (metal), foil that can be peeled off one layer at a time to adjust the thickness of the shim. Applications In automobiles, shims are commonly used to adjust the clearance or space between two parts. For example, shims are inserted into or under bu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Arbor Press

An arbor press is a small hand-operated press. It is typically used to perform smaller jobs, such as staking, riveting A rivet is a permanent mechanical fastener. Before being installed, a rivet consists of a smooth cylindrical shaft with a head on one end. The end opposite the head is called the ''tail''. On installation, the deformed end is called the ''s ..., installing, configuring and removing bearings, and other press fit work. Punches, inserters, or other tools/dies may be added to the end of the ram depending on the desired task. Arbor presses are usually rated by the ideal force that the leverage bar can apply.McMaster-Carr, catalog page 22692269 Typically common are presses with a leverage of one to five tons. This leverage is achieved when a force is applied to the lever arm or wheel. Arbor presses can be mounted on a work bench, wall, or pedestal. The base is usually constructed of cast metal. A ''ram'' provides the force; it may be square or round. The ra ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Broaching (metalworking)

Broaching is a machining process that uses a toothed tool, called a broach, to remove material. There are two main types of broaching: ''linear'' and ''rotary''. In linear broaching, which is the more common process, the broach is run linearly against a surface of the workpiece to produce the cut. Linear broaches are used in a broaching machine, which is also sometimes shortened to ''broach''. In rotary broaching, the broach is rotated and pressed into the workpiece to cut an axisymmetric shape. A rotary broach is used in a lathe or screw machine. In both processes the cut is performed in one pass of the broach, which makes it very efficient. Broaching is used when precision machining is required, especially for odd shapes. Commonly machined surfaces include circular and non-circular holes, splines, keyways, and flat surfaces. Typical workpieces include small to medium-sized castings, forgings, screw machine parts, and stampings. Even though broaches can be expensive, broac ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Spline (mechanical)

A spline is a ridge or tooth on a drive shaft that matches with a groove in a mating piece and transfers torque to it, maintaining the angular correspondence between them. For instance, a gear mounted on a shaft might use a male spline on the shaft that matches the female spline on the gear. Adjacent images in the section below show a transmission input shaft with male splines and a clutch plate with mating female splines in the center hub, where the smooth tip of the axle would be supported in a pilot bearing in the flywheel (not pictured). An alternative to splines is a keyway and key, though splines provide a longer fatigue life, and can carry significantly greater torques for the size. Types There are several types of splines: ;Parallel key spline: where the sides of the equally spaced grooves are parallel in both directions, radial and axial. ;Involute spline: where the sides of the equally spaced grooves are involute, as with an involute gear, but not as tall. The c ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |