|

Rotodynamic Pump

A rotodynamic pump is a kinetic machine in which energy is continuously imparted to the pumped fluid by means of a rotating impeller, propeller, or rotor, in contrast to a positive-displacement pump in which a fluid is moved by trapping a fixed amount of fluid and forcing the trapped volume into the pump's discharge. Examples of rotodynamic pumps include adding kinetic energy to a fluid such as by using a centrifugal pump to increase fluid velocity or pressure. Introduction A pump is a mechanical device generally used for raising liquid from a lower level to higher one. This is achieved by creating a low pressure at the inlet and high pressure at the outlet of the pump. Due to low inlet pressure, the liquid rises from where it is to be stored or supplied. However, work has to be done by a prime mover to enable it to impart mechanical energy to the liquid which ultimately converts into pressure energy. Considering the basic principle of operation, pumps can be classified int ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Impeller

An impeller, or impellor, is a driven rotor used to increase the pressure and flow of a fluid. It is the opposite of a turbine, which extracts energy from, and reduces the pressure of, a flowing fluid. Strictly speaking, propellers are a sub-class of impellers where the flow both enters and leaves axially, but in many contexts the term "impeller" is reserved for ''non''-propeller rotors where the flow enters axially and leaves radially, especially when creating suction in a pump or compressor. In pumps An impeller is a rotating component of a centrifugal pump that accelerates fluid outward from the center of rotation, thus transferring energy from the motor that drives the pump to the fluid being pumped. The acceleration generates output pressure when the outward movement of the fluid is confined by the pump casing. An impeller is usually a short cylinder with an open inlet (called an eye) to accept incoming fluid, vanes to push the fluid radially, and a splined, keyed, or ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pressure

Pressure (symbol: ''p'' or ''P'') is the force applied perpendicular to the surface of an object per unit area over which that force is distributed. Gauge pressure (also spelled ''gage'' pressure)The preferred spelling varies by country and even by industry. Further, both spellings are often used ''within'' a particular industry or country. Industries in British English-speaking countries typically use the "gauge" spelling. is the pressure relative to the ambient pressure. Various #Units, units are used to express pressure. Some of these derive from a unit of force divided by a unit of area; the International System of Units, SI unit of pressure, the Pascal (unit), pascal (Pa), for example, is one newton (unit), newton per square metre (N/m2); similarly, the Pound (force), pound-force per square inch (Pound per square inch, psi, symbol lbf/in2) is the traditional unit of pressure in the imperial units, imperial and United States customary units, US customary systems. Pressure ma ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

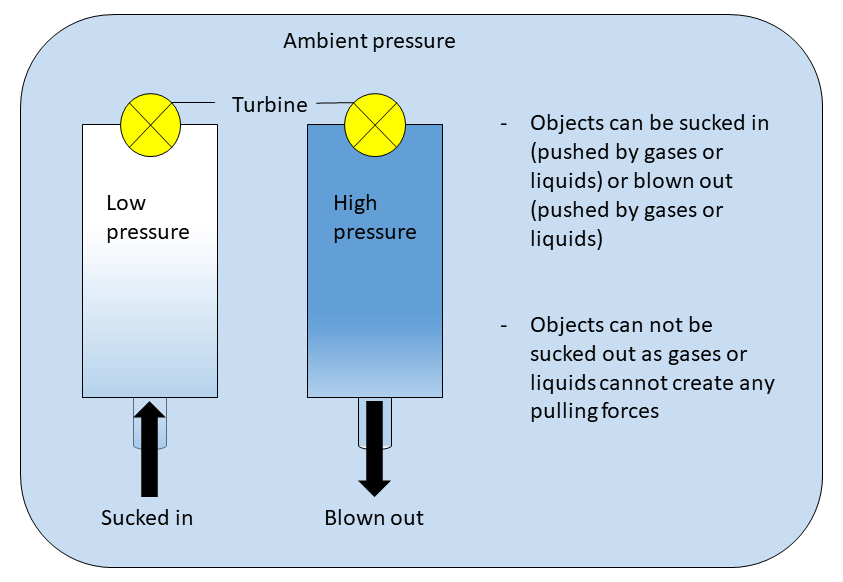

Suction

Suction is the day-to-day term for the movement of gases or liquids along a pressure gradient with the implication that the movement occurs because the lower pressure pulls the gas or liquid. However, the forces acting in this case do not originate from just the lower pressure side, but also from the side of the higher pressure, as a reaction to the pressure difference. When the pressure in one part of a physical system is reduced relative to another, the fluid or gas in the higher pressure region will exert a force relative to the region of lowered pressure, referred to as pressure-gradient force. If all gas or fluid is removed the result is a perfect vacuum in which the pressure is zero. Hence, no negative pressure forces can be generated. Accordingly, from a physics point of view, the objects are not pulled but pushed. Examples Pressure reduction may be static, as in a piston and cylinder arrangement, or dynamic, as in the case of a vacuum cleaner when air flow result ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Volute (pump)

A volute is a curved funnel that increases in area as it approaches the discharge port. The volute of a centrifugal pump is the casing that receives the fluid being pumped by the impeller, maintaining the velocity of the fluid through to the diffuser. As liquid exits the impeller it has high kinetic energy and the volute directs this flow through to the discharge. As the fluid travels along the volute it is joined by more and more fluid exiting the impeller but, as the cross sectional area of the volute increases, the velocity is maintained if the pump is running close to the design point. If the pump has a low flow rate then the velocity will decrease across the volute leading to a pressure rise causing a cross thrust across the impeller that we see as vibration. If the pump flow is higher than design the velocity will increase across the volute and the pressure will decrease according to the first law of thermodynamics. This will cause a side thrust in the opposite direct ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Shaft (mechanical Engineering)

In mechanical engineering, a shaft is a rotating machine element, usually circular in cross section, which is used to transmit power from one part to another, or from a machine which produces power to a machine which absorbs power. Types They are mainly classified into two types. * Transmission shafts are used to transmit power between the source and the machine absorbing power; e.g. counter shafts and line shafts. * Machine shafts are the integral part of the machine itself; e.g. crankshaft. *Axle shaft. *Spindle shaft. Materials The material used for ordinary shafts is mild steel. When high strength is required, an alloy steel such as nickel, nickel-chromium or chromium-vanadium steel is used. Shafts are generally formed by hot rolling and finished to size by cold drawing or turning and grinding. Standard sizes Source:Mahadevan K and Reddy K.Balaveera, (2015), 'Design data hand book', CBS publishers and Distributors (P) ltd., New-Delhi, Machine shafts * Up to 25&nbs ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Roots Blower

The Roots blower is a positive displacement lobe pump which operates by pumping a fluid with a pair of meshing lobes resembling a set of stretched gears. Fluid is trapped in pockets surrounding the lobes and carried from the intake side to the exhaust. The Roots blower design does not incorporate any reduction in volume/increase in pressure as air or other fluid passes through, hence it can best be described as a blower rather than a supercharger unlike some other designs of "supercharger" such as cozette, centric, Shorrock supercharger, Powerplus supercharger and also the axial flow Eaton type supercharger which have internal "compression". The most common application of the Roots-type blower has been the induction device on two-stroke diesel engines, such as those produced by Detroit Diesel and Electro-Motive Diesel. Roots-type blowers are also used to supercharge four-stroke Otto cycle engines, with the blower being driven from the engine's crankshaft via a toot ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Impeller

An impeller, or impellor, is a driven rotor used to increase the pressure and flow of a fluid. It is the opposite of a turbine, which extracts energy from, and reduces the pressure of, a flowing fluid. Strictly speaking, propellers are a sub-class of impellers where the flow both enters and leaves axially, but in many contexts the term "impeller" is reserved for ''non''-propeller rotors where the flow enters axially and leaves radially, especially when creating suction in a pump or compressor. In pumps An impeller is a rotating component of a centrifugal pump that accelerates fluid outward from the center of rotation, thus transferring energy from the motor that drives the pump to the fluid being pumped. The acceleration generates output pressure when the outward movement of the fluid is confined by the pump casing. An impeller is usually a short cylinder with an open inlet (called an eye) to accept incoming fluid, vanes to push the fluid radially, and a splined, keyed, or ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Mill Scale

Mill scale, often shortened to just scale, is the flaky surface of hot rolled steel, consisting of the mixed iron oxides iron(II) oxide (, wüstite), iron(III) oxide (, hematite), and iron(II,III) oxide (, magnetite). Mill scale is formed on the outer surfaces of plates, sheets or profiles when they are produced by passing red hot iron or steel billets through rolling mills. Mill scale is bluish-black in color. It is usually less than thick, and initially adheres to the steel surface and protects it from atmospheric corrosion provided no break occurs in this coating. Because it is electrochemically cathodic to steel, any break in the mill scale coating will cause accelerated corrosion of steel exposed at the break. Mill scale is thus a boon for a while, until its coating breaks due to handling of the steel product or due to any other mechanical cause. Mill scale becomes a nuisance when the steel is to be processed. Any paint applied over it is wasted, since it will come off ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

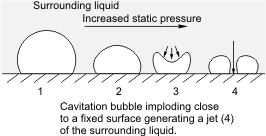

Cavitation

Cavitation in fluid mechanics and engineering normally is the phenomenon in which the static pressure of a liquid reduces to below the liquid's vapor pressure, leading to the formation of small vapor-filled cavities in the liquid. When subjected to higher pressure, these cavities, called "bubbles" or "voids", collapse and can generate shock waves that may damage machinery. These shock waves are strong when they are very close to the imploded bubble, but rapidly weaken as they propagate away from the implosion. Cavitation is a significant cause of wear in some engineering contexts. Collapsing voids that implode near to a metal surface cause cyclic stress through repeated implosion. This results in surface fatigue of the metal, causing a type of wear also called "cavitation". The most common examples of this kind of wear are to pump impellers, and bends where a sudden change in the direction of liquid occurs. Cavitation is usually divided into two classes of behavior. ''In ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Centrifugal Force

Centrifugal force is a fictitious force in Newtonian mechanics (also called an "inertial" or "pseudo" force) that appears to act on all objects when viewed in a rotating frame of reference. It appears to be directed radially away from the axis of rotation of the frame. The magnitude of the centrifugal force ''F'' on an object of mass ''m'' at the perpendicular distance ''ρ'' from the axis of a rotating frame of reference with angular velocity is F = m\omega^2 \rho. This fictitious force is often applied to rotating devices, such as centrifuges, centrifugal pumps, centrifugal governors, and centrifugal clutches, and in centrifugal railways, planetary orbits and banked curves, when they are analyzed in a non–inertial reference frame such as a rotating coordinate system. The term has sometimes also been used for the '' reactive centrifugal force'', a real frame-independent Newtonian force that exists as a reaction to a centripetal force in some scenarios. History F ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Propeller

A propeller (often called a screw if on a ship or an airscrew if on an aircraft) is a device with a rotating hub and radiating blades that are set at a pitch to form a helical spiral which, when rotated, exerts linear thrust upon a working fluid such as water or air. Propellers are used to pump fluid through a pipe or duct, or to create thrust to propel a boat through water or an aircraft through air. The blades are shaped so that their rotational motion through the fluid causes a pressure difference between the two surfaces of the blade by Bernoulli's principle which exerts force on the fluid. Most marine propellers are screw propellers with helical blades rotating on a propeller shaft (ship), propeller shaft with an approximately horizontal axis. History Early developments The principle employed in using a screw propeller is derived from stern sculling. In sculling, a single blade is moved through an arc, from side to side taking care to keep presenting the blade to the wat ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |