|

Rice Polisher

A rice polisher is a machine for buffing (or "polishing") kernels of rice to change their appearance, taste, and texture or for transforming brown rice into white rice. Use Rice polishers are used after the rice has gone through the whitening process. They are abrasive machines that use talc or some other very fine dust to buff the outer surface of rice kernels. In Japanese farming communities, there is often a shared rice polishing machine. The first fully automated rice polishing machine is believed to have been patented by the English engineer and inventor Sampson Moore in 1861. In the 20th century, kitchen appliances for consumers were created that allowed individual cooks to polish rice in their homes. Components The polisher contains cones covered with leather strips and perforated screens. The leather strips on the cones rub the grain of rice over the screen repeatedly. The remaining particles on the rice are removed during this process, giving the grain of rice ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Rice Polisher Japanese

Rice is a cereal grain and in its domesticated form is the staple food of over half of the world's population, particularly in Asia and Africa. Rice is the seed of the grass species ''Oryza sativa'' (Asian rice)—or, much less commonly, '' Oryza glaberrima'' (African rice). Asian rice was domesticated in China some 13,500 to 8,200 years ago; African rice was domesticated in Africa about 3,000 years ago. Rice has become commonplace in many cultures worldwide; in 2023, 800 million tons were produced, placing it third after sugarcane and maize. Only some 8% of rice is traded internationally. China, India, and Indonesia are the largest consumers of rice. A substantial amount of the rice produced in developing nations is lost after harvest through factors such as poor transport and storage. Rice yields can be reduced by pests including insects, rodents, and birds, as well as by weeds, and by List of rice diseases, diseases such as rice blast. Traditional rice polycultures such ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Gloss (optics)

Gloss is an optical property which indicates how well a surface reflects light in a specular (mirror-like) direction. It is one of the important parameters that are used to describe the visual appearance of an object. Other categories of visual appearance related to the perception of regular or diffuse reflection and transmission of light have been organized under the concept of '' cesia'' in an order system with three variables, including gloss among the involved aspects. The factors that affect gloss are the refractive index of the material, the angle of incident light and the surface texture. Apparent gloss depends on the amount of ''specular'' reflection – light reflected from the surface in an equal amount and the symmetrical angle to the one of incoming light – in comparison with ''diffuse'' reflection – the amount of light scattered into other directions. Theory When light illuminates an object, it interacts with it in a number of ways: * Absorbed within it (la ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cookware And Bakeware

Cookware and bakeware is food preparation equipment, such as cooking pots, pans, baking sheets etc. used in kitchens. Cookware is used on a stove or range cooktop, while bakeware is used in an oven. Some utensils are considered both cookware and bakeware. There is a great variety of cookware and bakeware in shape, material, and inside surface. Some materials conduct heat well; some retain heat well. Some surfaces are non-stick; some require seasoning. Some pots and their lids have handles or knobs made of low thermal conductance materials such as bakelite, plastic or wood, which make them easy to pick up without oven gloves. A good cooking pot design has an "overcook edge" which is what the lid lies on. The lid has a dripping edge that prevents condensation fluid from dripping off when handling the lid (taking it off and holding it 45°) or putting it down. History The history of cooking vessels before the development of pottery is minimal due to the limited arch ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Rice Production

Rice is a cereal grain and in its domesticated form is the staple food of over half of the world's population, particularly in Asia and Africa. Rice is the seed of the grass species ''Oryza sativa'' (Asian rice)—or, much less commonly, ''Oryza glaberrima'' (African rice). Asian rice was domesticated in China some 13,500 to 8,200 years ago; African rice was domesticated in Africa about 3,000 years ago. Rice has become commonplace in many cultures worldwide; in 2023, 800 million tons were produced, placing it third after sugarcane and maize. Only some 8% of rice is traded internationally. China, India, and Indonesia are the largest consumers of rice. A substantial amount of the rice produced in developing nations is lost after harvest through factors such as poor transport and storage. Rice yields can be reduced by pests including insects, rodents, and birds, as well as by weeds, and by diseases such as rice blast. Traditional rice polycultures such as rice-duck farming, an ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Rice Huller

A rice huller or rice husker is an agricultural machinery, agricultural machine used to automate the process of removing the chaff (the outer husks) of grains of rice. Throughout history, there have been numerous techniques to hull rice. Traditionally, it would be pounded using some form of mortar and pestle. An early simple machine to do this is a rice pounder. Later even more efficient machinery was developed to hull and polish rice. These machines are most widely developed and used throughout Asia, the most popular modern type in use today is the Engelberg Huller Company, Engelberg huller designed by German Brazilian engineer Evaristo Conrado Engelberg in Brazil and first patented in 1885. The Engelberg huller uses steel rollers to remove the husk. Other types of huller include the disk or ''cono'' huller which uses an abrasive rotating disk to first remove the husk before passing the grain to conical rollers which Rice polisher, polish it to make white rice; this is done r ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Rice Cooker

A rice cooker or rice steamer is an automated kitchen appliance designed to boil or steam rice. It consists of a heat source, a cooking bowl, and a thermostat. The thermostat measures the temperature of the cooking bowl and controls the heat. Complex, high-tech rice cookers may have more sensors and other components, and may be multipurpose. The term ''rice cooker'' formerly applied to non-automated dedicated rice-cooking utensils, which have an ancient history (a ceramic rice steamer dated to 1250 BC is on display in the British Museum). It now applies mostly to automated cookers. Electric rice cookers were developed in Japan, where they are known as ''jp:炊飯器, suihanki'' (, literally, "boil-rice-device"). History The NJ-N1, developed by Mitsubishi Electric in 1923, was the first electric rice cooker, a direct ancestor of today's automatic electric rice cookers. At that time, electricity was not widely used in ordinary households; it was for use on ships. It was a simple ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Emery (rock)

Emery, or corundite, is a dark granular rock used to make an abrasive powder. The rock largely consists of corundum (aluminium oxide), mixed with other minerals. Industrial emery may contain a variety of other minerals and synthetic compounds. Crushed or naturally eroded emery (known as ''black sand'') is used as an abrasive. Turkey and Greece are the main suppliers of the world's emery. Description Emery is a granular rock used to make an abrasive powder. It largely consists of corundum (aluminium oxide), mixed with other minerals such as the iron-bearing spinels, hercynite, and magnetite, and also rutile ( titania). Industrial emery may contain a variety of other minerals and synthetic compounds such as magnesia, mullite, and silica. Emery is black or dark grey in colour, less dense than translucent-brown corundum with a specific gravity of between 3.5 and 3.8. Because it can be a mixture of minerals, no definite Mohs hardness can be assigned: the hardness of corundum is ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Perforation

A perforation is a small hole in a thin material or web. There is usually more than one perforation in an organized fashion, where all of the holes collectively are called a ''perforation''. The process of creating perforations is called perforating, which involves removing bits of the workpiece with a tool. Old-fashioned lick-and-stick postage stamps are perforated. When a tool makes small cuts in the material (without removing anything) it is called 'rouletting', because that tool often resembles a roulette wheel, with blades around the edge. Raffle tickets are a good example of rouletting. Perforations are usually used to allow easy separation of two sections of the material, such as allowing paper to be torn easily along the line. Packaging with perforations in paperboard or plastic film is easy for consumers to open. Other purposes include filtrating fluids, sound deadening, allowing light or fluids to pass through, and to create an aesthetic design. Various applications ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

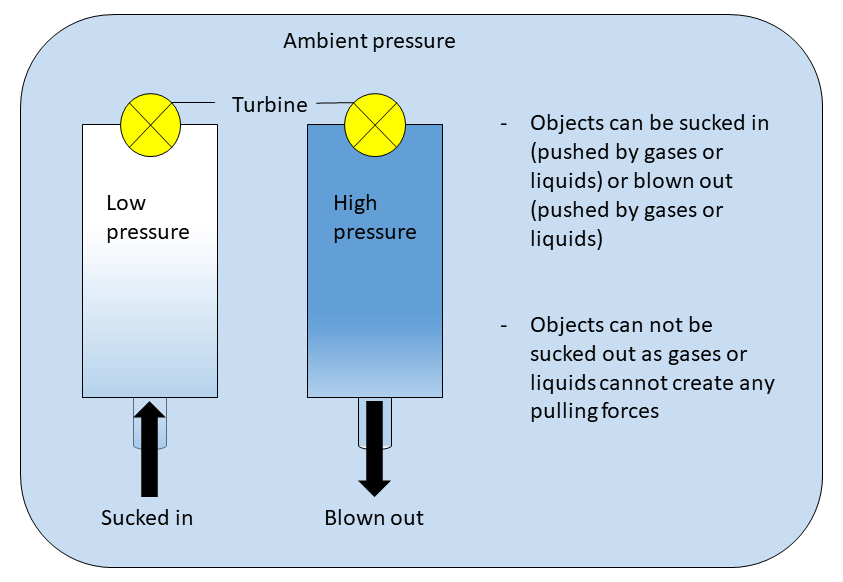

Suction

Suction is the day-to-day term for the movement of gases or liquids along a pressure gradient with the implication that the movement occurs because the lower pressure pulls the gas or liquid. However, the forces acting in this case do not originate from just the lower pressure side, but also from the side of the higher pressure, as a reaction to the pressure difference. When the pressure in one part of a physical system is reduced relative to another, the fluid or gas in the higher pressure region will exert a force relative to the region of lowered pressure, referred to as pressure-gradient force. If all gas or fluid is removed the result is a perfect vacuum in which the pressure is zero. Hence, no negative pressure forces can be generated. Accordingly, from a physics point of view, the objects are not pulled but pushed. Examples Pressure reduction may be static, as in a piston and cylinder arrangement, or dynamic, as in the case of a vacuum cleaner when air flow result ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Perforated

A perforation is a small hole in a thin material or web. There is usually more than one perforation in an organized fashion, where all of the holes collectively are called a ''perforation''. The process of creating perforations is called perforating, which involves removing bits of the workpiece with a tool. Old-fashioned lick-and-stick postage stamps are perforated. When a tool makes small cuts in the material (without removing anything) it is called 'rouletting', because that tool often resembles a roulette wheel, with blades around the edge. Raffle tickets are a good example of rouletting. Perforations are usually used to allow easy separation of two sections of the material, such as allowing paper to be torn easily along the line. Packaging with perforations in paperboard or plastic film is easy for consumers to open. Other purposes include filtrating fluids, sound deadening, allowing light or fluids to pass through, and to create an aesthetic design. Various applications ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Buffing

Buffing are finishing processes for smoothing a workpiece's surface using an abrasive and a work wheel or a leather strop. Technically, ''polishing'' refers to processes that uses an abrasive that is glued to the work wheel, while ''buffing'' uses a loose abrasive applied to the work wheel. Polishing is a more aggressive process, while buffing is less harsh, which leads to a smoother, brighter finish.Oberg, p. 1439. A common misconception is that a polished surface has a mirror-bright finish, however, most mirror-bright finishes are actually buffed. Polishing is often used to enhance the appearance of an item, prevent contamination of instruments, remove oxidation, create a reflective surface, or prevent corrosion in pipes. In metallography and metallurgy, polishing is used to create a flat, defect-free surface for examination of a metal's microstructure under a microscope. Silicon-based polishing pads or a diamond solution can be used in the polishing process. Polishing stainl ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |