|

RF Welding

Radio-frequency welding, also known as dielectric welding and high-frequency welding, is a plastic welding process that utilizes Radio spectrum, high-frequency electric fields to induce heating and melting of thermoplastic base materials. The electric field is applied by a pair of electrodes after the parts being joined are clamped together. The clamping force is maintained until the joint solidifies. Advantages of this process are fast cycle times (on the order of a few seconds), automation, repeatability, and good weld appearance. Only plastics which have Chemical polarity, dipoles can be heated using radio waves and therefore not all plastics are able to be welded using this process. Also, this process is not well suited for thick or overly complex joints. The most common use of this process is lap joints or seals on thin plastic sheets or parts. Heating mechanism Four types of polarization can occur in materials subjected to high-frequency alternating electric fields: * ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Plastic Welding

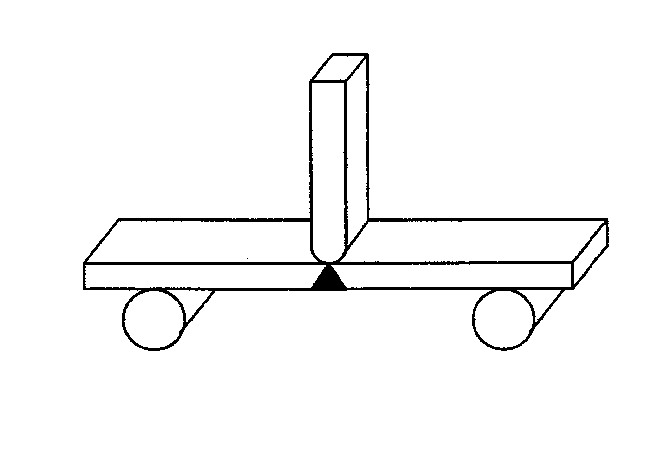

Plastic welding is welding for semi-finished plastic materials, and is described in ISO 472 as a process of uniting softened surfaces of materials, generally with the aid of heat (except for Solvent bonding, solvent welding). Welding of thermoplastics is accomplished in three sequential stages, namely surface preparation, application of heat and pressure, and cooling. Numerous welding methods have been developed for the joining of semi-finished plastic materials. Based on the mechanism of heat generation at the welding interface, welding methods for thermoplastics can be classified as external and internal heating methods, as shown in Fig 1. Production of a good quality weld does not only depend on the welding methods, but also weldability of base materials. Therefore, the evaluation of weldability is of higher importance than the welding operation (see rheological weldability) for plastics. Welding techniques A number of techniques are used for welding of semi-finished plasti ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Chlorinated Polyvinyl Chloride

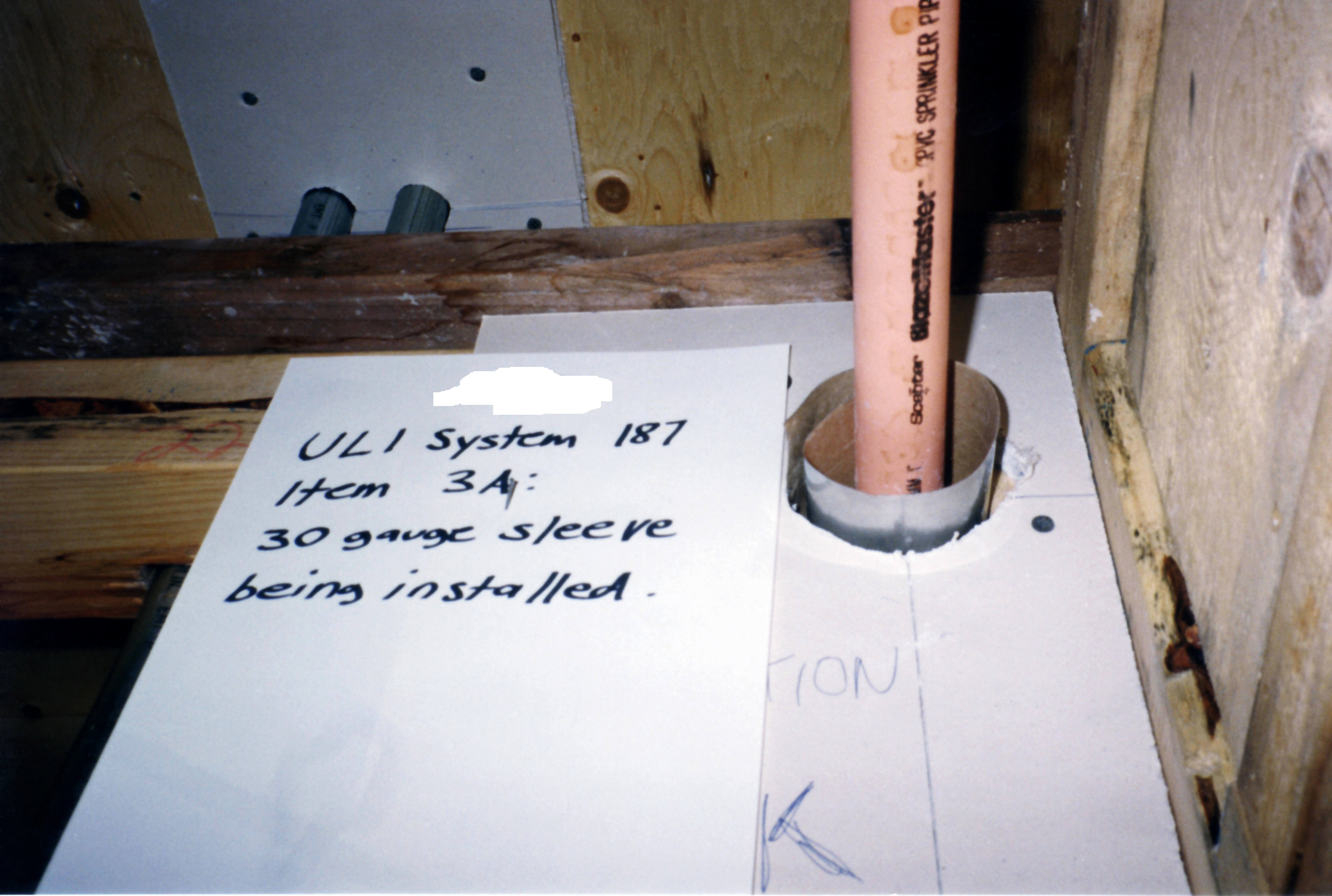

Chlorinated polyvinyl chloride (CPVC) is a thermoplastic produced by chlorination of polyvinyl chloride (PVC) resin. CPVC is significantly more flexible than PVC, and can also withstand higher temperatures. Uses include hot and cold water delivery pipes and industrial liquid handling. CPVC, like PVC, is deemed safe for the transport and use of potable water. History Genova Products located in Michigan initially created the first CPVC tubing and fittings for hot- and cold-water distribution systems in the early 1960s. The original tetrahydrofuran (THF) / methyl ethyl ketone (MEK) formulas for CPVC cements were developed by Genova in conjunction with the B.F. Goodrich Company, the original developer of the CPVC resin. Production process Chlorinated polyvinyl chloride (CPVC) is PVC that has been chlorinated via a free radical chlorination reaction. This reaction is typically initiated by application of thermal or UV energy utilizing various approaches. In the process, chlorine ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Plastic Welding

Plastic welding is welding for semi-finished plastic materials, and is described in ISO 472 as a process of uniting softened surfaces of materials, generally with the aid of heat (except for Solvent bonding, solvent welding). Welding of thermoplastics is accomplished in three sequential stages, namely surface preparation, application of heat and pressure, and cooling. Numerous welding methods have been developed for the joining of semi-finished plastic materials. Based on the mechanism of heat generation at the welding interface, welding methods for thermoplastics can be classified as external and internal heating methods, as shown in Fig 1. Production of a good quality weld does not only depend on the welding methods, but also weldability of base materials. Therefore, the evaluation of weldability is of higher importance than the welding operation (see rheological weldability) for plastics. Welding techniques A number of techniques are used for welding of semi-finished plasti ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Microwave Welding

Microwave welding is a plastic welding process that utilizes alternating electromagnetic fields in the microwave band to join thermoplastic base materials that are melted by the phenomenon of dielectric heating. See also * Dielectric heating * Plastic welding Plastic welding is welding for semi-finished plastic materials, and is described in ISO 472 as a process of uniting softened surfaces of materials, generally with the aid of heat (except for Solvent bonding, solvent welding). Welding of thermopl ... * Radio-frequency welding References {{Metalworking navbox/weld Welding Radio technology ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Dielectric Heating

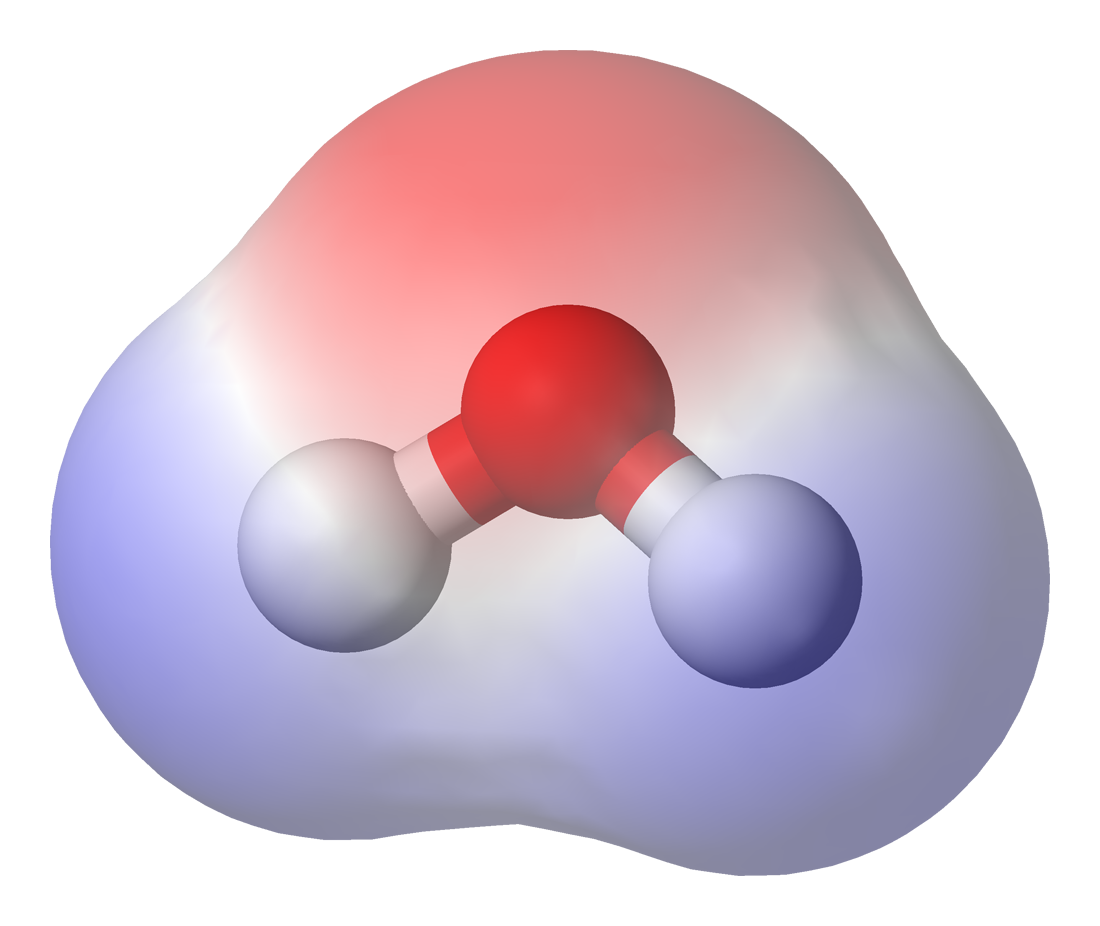

Dielectric heating, also known as electronic heating, radio frequency heating, and high-frequency heating, is the process in which a radio frequency (RF) alternating electric field, or radio wave or microwave electromagnetic radiation heats a dielectric material. At higher frequencies, this heating is caused by molecular dipole rotation within the dielectric. Mechanism Molecular rotation occurs in materials containing polar molecules having an electrical dipole moment, with the consequence that they will align themselves in an electromagnetic field. If the field is oscillating, as in an electromagnetic wave or a rapidly oscillating electric field, these molecules rotate continuously by aligning with it. This is called dipole rotation or dipolar polarisation. As the field alternates, the molecules reverse direction. Rotating molecules push, pull, and collide with other molecules (through electrical forces), distributing the energy to adjacent molecules and atoms in the materia ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Polar Plastic

Polar may refer to: Geography * Geographical pole, either of the two points on Earth where its axis of rotation intersects its surface ** Polar climate, the climate common in polar regions ** Polar regions of Earth, locations within the polar circles, referred to as the Arctic and Antarctic Places * Polar, Wisconsin, town in Langlade County, Wisconsin, United States ** Polar (community), Wisconsin, unincorporated community in Langlade County, Wisconsin, United States Arts, entertainment and media * ''Polar'' (webcomic), a webcomic and series of graphic novels by Víctor Santos * ''Polar'' (film), a 2019 Netflix film adaption of the above comic series * ''Polar'', a 2002 novel by T. R. Pearson Music * Polar Music, a record label * Polar Studios, music studio of ABBA in Sweden * ''Polar'' (album), second album by the High Water Marks * ''Polars'' (album), an album by the Dutch metal band, Textures Brands and enterprises * Polar Air Cargo, an American airline * Polar Airline ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Polyethylene Terephthalate

Polyethylene terephthalate (or poly(ethylene terephthalate), PET, PETE, or the obsolete PETP or PET-P), is the most common thermoplastic polymer resin of the polyester family and is used in synthetic fibre, fibres for clothing, packaging, containers for liquids and foods, and thermoforming for manufacturing, and in combination with glass fibre for engineering resins. In 2016, annual production of PET was 56 million tons. The biggest application is in fibres (in excess of 60%), with bottle production accounting for about 30% of global demand. In the context of textile applications, PET is referred to by its common name, polyester, whereas the acronym ''PET'' is generally used in relation to packaging. PET used in non-fiber applications (i.e. for packaging) makes up about 6% of world polymer production by mass. Accounting for the >60% fraction of polyethylene terephthalate produced for use as polyester fibers, PET is the fourth-most-produced polymer after polyethylene (PE), polypr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Polyvinylidene Chloride

Polyvinylidene chloride, or polyvinylidene dichloride (PVDC), is a homopolymer of vinylidene chloride. History Ralph Wiley accidentally discovered polyvinylidene chloride polymer in 1933. At the time he was a college student who worked part-time at Dow Chemical lab as a dishwasher. While cleaning laboratory glassware, he came across a vial he could not scrub clean. Dow researchers made this material into a greasy, dark green film, first called "Eonite" and then " Saran". Ralph Wiley went on to become one of Dow Chemical's research scientists and invent and develop many plastics, chemicals and production machines. The military sprayed Saran on fighter planes to guard against salty sea spray, and carmakers used it for upholstery. Dow later devised a formulation of polyvinylidene chloride free of unpleasant odour and green colour. The most well known use of polyvinylidene chloride came in 1953, when Saran Wrap, a plastic food wrap, was introduced. In 2004, however, the formul ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ethylene-vinyl Acetate

Ethylene-vinyl acetate (EVA), also known as poly(ethylene-vinyl acetate) (PEVA), is a copolymer of ethylene and vinyl acetate. The weight percent of vinyl acetate usually varies from 10 to 50%, with the remainder being ethylene. There are three different types of EVA copolymer, which differ in the vinyl acetate (VA) content and the way the materials are used. The EVA copolymer which is based on a low proportion of VA (approximately up to 4%) may be referred to as vinyl acetate modified polyethylene. It is a copolymer and is processed as a thermoplastic material – just like low-density polyethylene. It has some of the properties of a low-density polyethylene but increased gloss (useful for film), softness and flexibility. The material is generally considered non-toxic. The EVA copolymer which is based on a medium proportion of VA (approximately 4 to 30%) is referred to as thermoplastic ethylene-vinyl acetate copolymer and is a thermoplastic elastomer material. It is not vulca ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cellulose Acetate

In biochemistry, cellulose acetate refers to any acetate ester of cellulose, usually cellulose diacetate. It was first prepared in 1865. A bioplastic, cellulose acetate is used as a film base in photography, as a component in some coatings, and as a frame material for eyeglasses; it is also used as a synthetic fiber in the manufacture of Cigarette filter, cigarette filters and Playing card, playing cards. In cellulose acetate film, photographic film, cellulose acetate film replaced nitrate film in the 1950s, being far less flammable and cheaper to produce. Water-soluble cellulose acetate (WSCA) has been used as a Prebiotic (nutrition), dietary fiber (prebiotic), in relation with weight loss and Akkermansia muciniphila. History In 1865, French chemist Paul Schützenberger discovered that cellulose reacts with acetic anhydride to form cellulose acetate. The German chemists Arthur Eichengrün and Theodore Becker invented the first soluble forms of cellulose acetate in 1903. In 190 ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Nylon

Nylon is a family of synthetic polymers characterised by amide linkages, typically connecting aliphatic or Polyamide#Classification, semi-aromatic groups. Nylons are generally brownish in color and can possess a soft texture, with some varieties exhibiting a silk-like appearance. As Thermoplastic, thermoplastics, nylons can be melt-processed into fibres, Thin film, films, and diverse shapes. The properties of nylons are often modified by blending with a variety of additives. Numerous types of nylon are available. One family, designated nylon-XY, is derived from diamines and dicarboxylic acids of carbon chain lengths X and Y, respectively. An important example is nylon-6,6 (). Another family, designated nylon-Z, is derived from amino acid, aminocarboxylic acids with carbon chain length Z. An example is nylon-[6]. Nylon polymers have extensive commercial applications, including uses in textiles and fibres (such as apparel, flooring and rubber reinforcement), molded components fo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |