|

Nanosphere Lithography

Nanosphere lithography (NSL) is an economical technique for generating single-layer hexagonally close packed or similar patterns of nanoscale features. Generally, NSL applies planar ordered arrays of nanometer-sized latex or silica spheres as lithography masks to fabricate nanoparticle arrays. NSL uses self-assembled monolayers of spheres (typically made of polystyrene, often available commercially as an aqueous suspension) as evaporation masks. These spheres can be deposited using multiple methods including Langmuir-Blodgett, dip coating, spin coating, solvent evaporation, force-assembly, and air-water interface. This method has been used to fabricate arrays of various nanopatterns, including gold nanodots with precisely controlled spacings. Nanosphere monolayer preparation Monolayers of nanospheres, to be used as lithography masks can be created using multiple methods: Langmuir-Blodgett is a deposition method in which the nanoparticles are placed in a Langmuir-Blodgett Tro ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Nanoscopic Scale

The nanoscopic scale (or nanoscale) usually refers to structures with a length scale applicable to nanotechnology, usually cited as 1–100 nanometers (nm). A nanometer is a billionth of a meter. The nanoscopic scale is (roughly speaking) a lower bound to the mesoscopic scale for most solids. For technical purposes, the nanoscopic scale is the size at which fluctuations in the averaged properties (due to the motion and behavior of individual particles) begin to have a significant effect (often a few percent) on the behavior of a system, and must be taken into account in its analysis. The nanoscopic scale is sometimes marked as the point where the properties of a material change; above this point, the properties of a material are caused by 'bulk' or 'volume' effects, namely which atoms are present, how they are bonded, and in what ratios. Below this point, the properties of a material change, and while the type of atoms present and their relative orientations are still importa ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Self-assembled Monolayers

Self-assembled monolayers (SAM) of organic molecules are molecular assemblies formed spontaneously on surfaces by adsorption and are organized into more or less large ordered domains. In some cases molecules that form the monolayer do not interact strongly with the substrate. This is the case for instance of the two-dimensional supramolecular networks of e.g. perylenetetracarboxylic dianhydride ( PTCDA) on gold or of e.g. porphyrins on highly oriented pyrolitic graphite (HOPG). In other cases the molecules possess a head group that has a strong affinity to the substrate and anchors the molecule to it. Such a SAM consisting of a head group, tail and functional end group is depicted in Figure 1. Common head groups include thiols, silanes, phosphonates, etc. SAMs are created by the chemisorption of "head groups" onto a substrate from either the vapor or liquid phase followed by a slow organization of "tail groups". Initially, at small molecular density on the surface, adsorba ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

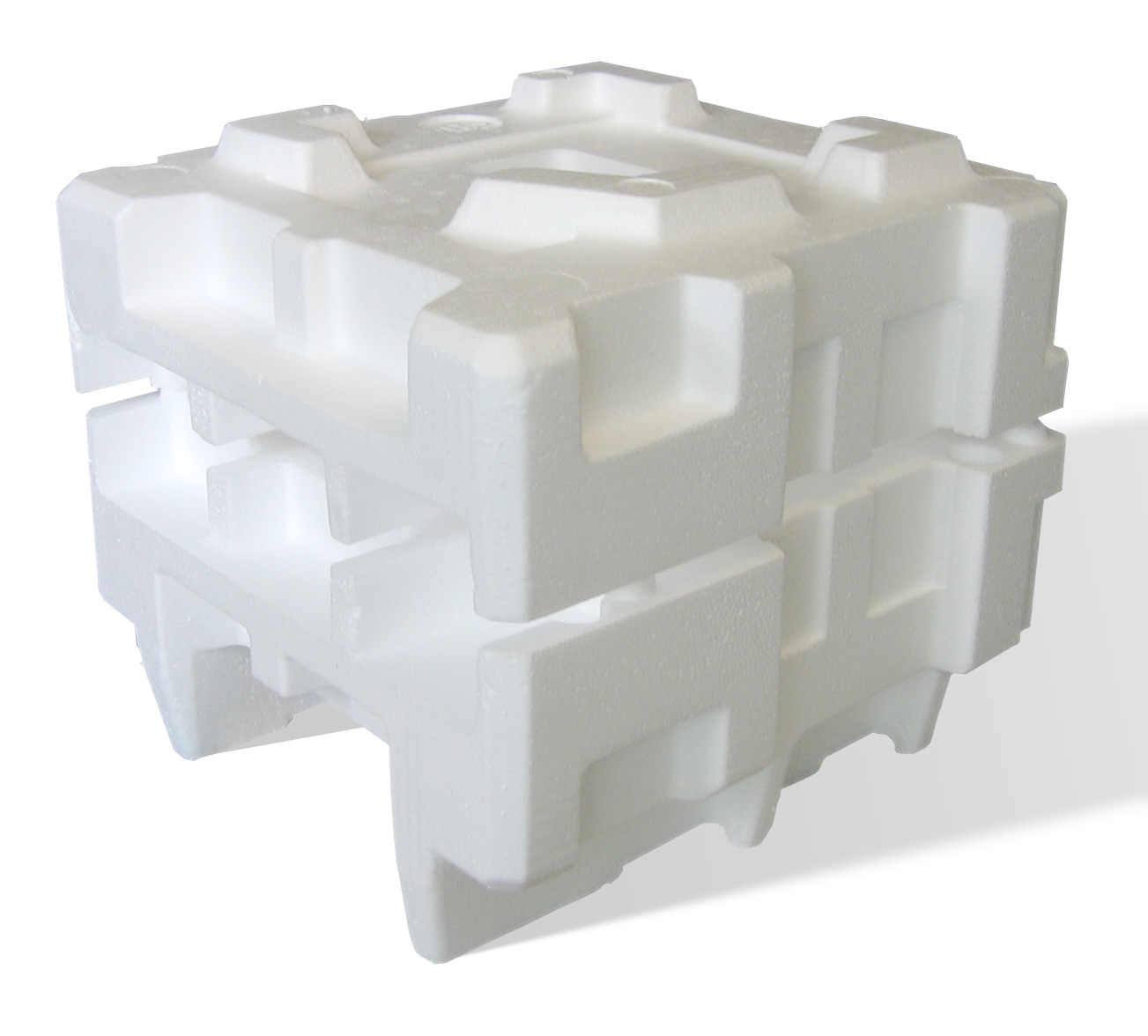

Polystyrene

Polystyrene (PS) is a synthetic polymer made from monomers of the aromatic hydrocarbon styrene. Polystyrene can be solid or foamed. General-purpose polystyrene is clear, hard, and brittle. It is an inexpensive resin per unit weight. It is a poor barrier to oxygen and water vapour and has a relatively low melting point. Polystyrene is one of the most widely used plastics, the scale of its production being several million tonnes per year. Polystyrene can be naturally transparent, but can be colored with colorants. Uses include protective packaging (such as packing peanuts and in the jewel cases used for storage of optical discs such as CDs and occasionally DVDs), containers, lids, bottles, trays, tumblers, disposable cutlery, in the making of models, and as an alternative material for phonograph records. As a thermoplastic polymer, polystyrene is in a solid (glassy) state at room temperature but flows if heated above about 100 °C, its glass transition temperature ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

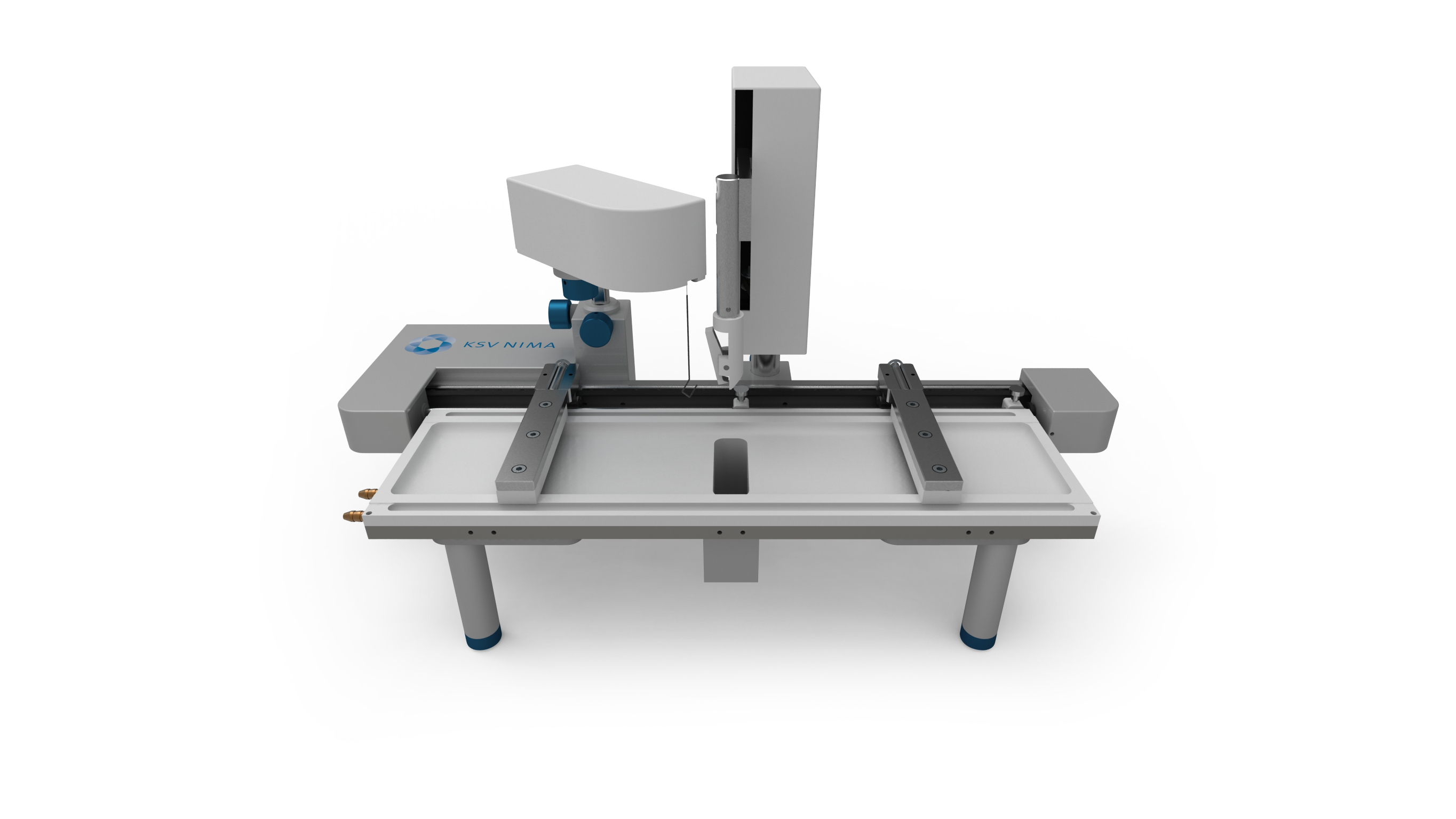

Langmuir–Blodgett Trough

A Langmuir–Blodgett trough (LB trough) is a laboratory apparatus that is used to compress monolayers of molecules on the surface of a given subphase (usually water) and measures surface phenomena due to this compression. It can also be used to deposit single or multiple monolayers on a solid substrate. Description Overview The idea of a Langmuir–Blodgett (LB) film was first proven feasible in 1917 when Irving Langmuir (Langmuir, 1917) showed that single water-surface monolayers could be transferred to solid substrates. 18 years later, Katharine Blodgett made an important scientific advance when she discovered that several of these single monolayer films could be stacked on top of one another to make multilayer films (Blodgett 1935). Since then, LB films (and subsequently the troughs to make them) have been used for a wide variety of scientific experimentation, ranging from 2D crystallization of proteins to Brewster angle microscopy. The LB trough's general objective is to st ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Dip-coating

image:Dip coating.svg, A schematic of the continuous dip coating process. Roll of coarse cloth Cloth Bath Liquid material Rollers Oven Scrapers Excess liquid falls back A coating remains on the fabric cloth. Dip coating is an industrial coating process which is used, for example, to manufacture bulk products such as coated fabrics and condoms and specialised coatings for example in the biomedical field. Dip coating is also commonly used in academic research, where many chemical and nano material engineering research projects use the dip coating technique to create thin-film coatings. The earliest dip-coated products may have been candles. For flexible laminar substrates such as fabrics, dip coating may be performed as a continuous roll-to-roll process. For coating a 3D object, it may simply be inserted and removed from the bath of coating. For condom-making, a former is dipped into the coating. For some products, such as early methods of making candles, the process is re ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Spin Coating

Spin coating is a procedure used to deposit uniform thin films onto flat substrates. Usually a small amount of coating material is applied on the center of the substrate, which is either spinning at low speed or not spinning at all. The substrate is then rotated at speed up to 10,000 rpm to spread the coating material by centrifugal force. A machine used for spin coating is called a spin coater, or simply spinner. Rotation is continued while the fluid spins off the edges of the substrate, until the desired thickness of the film is achieved. The applied solvent is usually volatile, and simultaneously evaporates. The higher the angular speed of spinning, the thinner the film. The thickness of the film also depends on the viscosity and concentration of the solution, and the solvent. Pioneering theoretical analysis of spin coating was undertaken by Emslie et al., and has been extended by many subsequent authors (including Wilson et al., who studied the rate of spreading in spin coat ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Nanoparticle Coating

A nanoparticle or ultrafine particle is usually defined as a particle of matter that is between 1 and 100 nanometres (nm) in diameter. The term is sometimes used for larger particles, up to 500 nm, or fibers and tubes that are less than 100 nm in only two directions. At the lowest range, metal particles smaller than 1 nm are usually called atom clusters instead. Nanoparticles are usually distinguished from microparticles (1-1000 µm), "fine particles" (sized between 100 and 2500 nm), and "coarse particles" (ranging from 2500 to 10,000 nm), because their smaller size drives very different physical or chemical properties, like colloidal properties and ultrafast optical effects or electric properties. Being more subject to the brownian motion, they usually do not sediment, like colloidal particles that conversely are usually understood to range from 1 to 1000 nm. Being much smaller than the wavelengths of visible light (400-700 nm), nanop ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Polydimethylsiloxane

Polydimethylsiloxane (PDMS), also known as dimethylpolysiloxane or dimethicone, belongs to a group of polymeric organosilicon compounds that are commonly referred to as silicones. PDMS is the most widely used silicon-based organic polymer, as its versatility and properties lead to many applications. It is particularly known for its unusual rheological (or flow) properties. PDMS is optically clear and, in general, inert, non-toxic, and non-flammable. It is one of several types of silicone oil (polymerized siloxane). Its applications range from contact lenses and medical devices to elastomers; it is also present in shampoos (as it makes hair shiny and slippery), food ( antifoaming agent), caulk, lubricants and heat-resistant tiles. Structure The chemical formula of PDMS is , where ''n'' is the number of repeating monomer units.Mark, J. E.; Allcock, H. R.; West, R. “Inorganic Polymers” Prentice Hall, Englewood, NJ: 1992. . Industrial synthesis can begin from dimethy ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Colloidal Lithography Steps

A colloid is a mixture in which one substance consisting of microscopically dispersed insoluble particles is suspended throughout another substance. Some definitions specify that the particles must be dispersed in a liquid, while others extend the definition to include substances like aerosols and gels. The term colloidal suspension refers unambiguously to the overall mixture (although a narrower sense of the word '' suspension'' is distinguished from colloids by larger particle size). A colloid has a dispersed phase (the suspended particles) and a continuous phase (the medium of suspension). The dispersed phase particles have a diameter of approximately 1 nanometre to 1 micrometre. Some colloids are translucent because of the Tyndall effect, which is the scattering of light by particles in the colloid. Other colloids may be opaque or have a slight color. Colloidal suspensions are the subject of interface and colloid science. This field of study was introduced in 1845 by It ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Solar Cell

A solar cell, or photovoltaic cell, is an electronic device that converts the energy of light directly into electricity by the photovoltaic effect, which is a physical and chemical phenomenon.Solar Cells chemistryexplained.com It is a form of photoelectric cell, defined as a device whose electrical characteristics, such as current, voltage, or , vary when exposed to light. Individual solar cell devices are often the electrical building blocks of [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Self-cleaning Surfaces

Self-cleaning surfaces are a class of materials with the inherent ability to remove any debris or bacteria from their surfaces in a variety of ways. The self-cleaning functionality of these surfaces are commonly inspired by natural phenomena observed in lotus leaves, gecko feet, and water striders to name a few. The majority of self-cleaning surfaces can be placed into three categories: # superhydrophobic # superhydrophilic # photocatalytic. History The first instance of a self-cleaning surface was created in 1995. Paz et al. created a transparent titanium dioxide (TiO2) film that was used to coat glass and provide the ability for the glass to self-clean. The first commercial application of this self-cleaning surface, Pilkington Activ, was developed by Pilkington glass in 2001. This product implements a two-stage cleaning process. The first stage consists of photocatalysis of any fouling matter on the glass. This stage is followed by the glass becoming superhydrophilic and allowi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Nanolithography

Nanolithography (NL) is a growing field of techniques within nanotechnology dealing with the engineering (patterning e.g. etching, depositing, writing, printing etc) of nanometer-scale structures on various materials. The modern term reflects on a design of structures built in range of 10−9 to 10−6 meters, i.e. nanometer scale. Essentially, the field is a derivative of lithography, only covering very small structures. All NL methods can be categorized into four groups: photo lithography, scanning lithography, soft lithography and other miscellaneous techniques. History The NL has evolved from the need to increase the number of sub-micrometer features (e.g. transistors, capacitors etc.) in an integrated circuit in order to keep up with Moore's Law. While lithographic techniques have been around since the late 18th century, none were applied to nanoscale structures until the mid-1950s. With evolution of the semiconductor industry, demand for techniques capable of producing ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |