|

Molybdenum Disilicide

Molybdenum disilicide (MoSi2, or molybdenum silicide), an intermetallic compound, a silicide of molybdenum, is a refractory ceramic with primary use in heating elements. It has moderate density, melting point 2030 °C, and is electrically conductive. At high temperatures it forms a passivation layer of silicon dioxide, protecting it from further oxidation. The thermal stability of MoSi2 alongside its high emissivity make this material, alongside WSi2 attractive for applications as a high emissivity coatings in heat shields for atmospheric entry. MoSi2 is a gray metallic-looking material with tetragonal crystal structure (alpha-modification); its beta-modification is hexagonal and unstable. It is insoluble in most acids but soluble in nitric acid and hydrofluoric acid. While MoSi2 has excellent resistance to oxidation and high Young's modulus at temperatures above 1000 °C, it is brittle in lower temperatures. Also, at above 1200 °C it loses creep resista ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tetragonal

In crystallography, the tetragonal crystal system is one of the 7 crystal systems. Tetragonal crystal lattices result from stretching a cubic lattice along one of its lattice vectors, so that the Cube (geometry), cube becomes a rectangular Prism (geometry), prism with a square base (''a'' by ''a'') and height (''c'', which is different from ''a''). Bravais lattices There are two tetragonal Bravais lattices: the primitive tetragonal and the body-centered tetragonal. The body-centered tetragonal lattice is equivalent to the primitive tetragonal lattice with a smaller unit cell, while the face-centered tetragonal lattice is equivalent to the body-centered tetragonal lattice with a smaller unit cell. Crystal classes The point groups that fall under this crystal system are listed below, followed by their representations in international notation, Schoenflies notation, orbifold notation, Coxeter notation and mineral examples.Hurlbut, Cornelius S.; Klein, Cornelis, 1985, ''Ma ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Atmospheric Entry

Atmospheric entry (sometimes listed as Vimpact or Ventry) is the movement of an object from outer space into and through the gases of an atmosphere of a planet, dwarf planet, or natural satellite. Atmospheric entry may be ''uncontrolled entry,'' as in the entry of astronomical objects, space debris, or bolides. It may be ''controlled entry'' (or ''reentry'') of a spacecraft that can be navigated or follow a predetermined course. Methods for controlled atmospheric ''entry, descent, and landing'' of spacecraft are collectively termed as ''EDL''. Objects entering an atmosphere experience atmospheric drag, which puts mechanical stress on the object, and aerodynamic heating—caused mostly by compression of the air in front of the object, but also by drag. These forces can cause loss of mass ( ablation) or even complete disintegration of smaller objects, and objects with lower compressive strength can explode. Objects have reentered with speeds ranging from 7.8 km/s for ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Industrial Furnace

An industrial furnace is a device used to provide heat for an industrial process, typically operating at temperatures above 400 degrees Celsius. These furnaces generate heat by combusting fuel with air or oxygen, or through Electricity, electrical energy, and are used across various industries for applications such as chemical reactions, cremation, Oil refinery, oil refining, and Glass melting furnace, glasswork. The residual heat is expelled as flue gas. While the term industrial furnace encompasses a wide range of high-temperature equipment, one specific type is the direct fired heater, also known as a direct fired furnace or process furnace. Direct fired heaters are primarily used in refinery and petrochemical applications to efficiently transfer heat to process fluids by means of combustion. Unlike other industrial furnaces used in metallurgical furnace, metallurgy or batch ovens, direct fired heaters are optimized for precise temperature control and high thermal efficiency ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Plasma Spraying

Thermal spraying techniques are coating processes in which melted (or heated) materials are sprayed onto a surface. The "feedstock" (coating precursor) is heated by electrical (plasma or arc) or chemical means (combustion flame). Thermal spraying can provide thick coatings (approx. thickness range is 20 microns to several mm, depending on the process and feedstock), over a large area at high deposition rate as compared to other coating processes such as electroplating, physical and chemical vapor deposition. Coating materials available for thermal spraying include metals, alloys, ceramics, plastics and composites. They are fed in powder or wire form, heated to a molten or semimolten state and accelerated towards substrates in the form of micrometer-size particles. Combustion or electrical arc discharge is usually used as the source of energy for thermal spraying. Resulting coatings are made by the accumulation of numerous sprayed particles. The surface may not heat up significan ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sintering

Sintering or frittage is the process of compacting and forming a solid mass of material by pressure or heat without melting it to the point of liquefaction. Sintering happens as part of a manufacturing process used with metals, ceramics, plastics, and other materials. The atoms/molecules in the sintered material diffuse across the boundaries of the particles, fusing the particles together and creating a solid piece. Since the sintering temperature does not have to reach the melting point of the material, sintering is often chosen as the shaping process for materials with extremely high melting points, such as tungsten and molybdenum. The study of sintering in metallurgy, metallurgical powder-related processes is known as powder metallurgy. An example of sintering can be observed when ice cubes in a glass of water adhere to each other, which is driven by the temperature difference between the water and the ice. Examples of pressure-driven sintering are the compacting of snowfa ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Composite Material

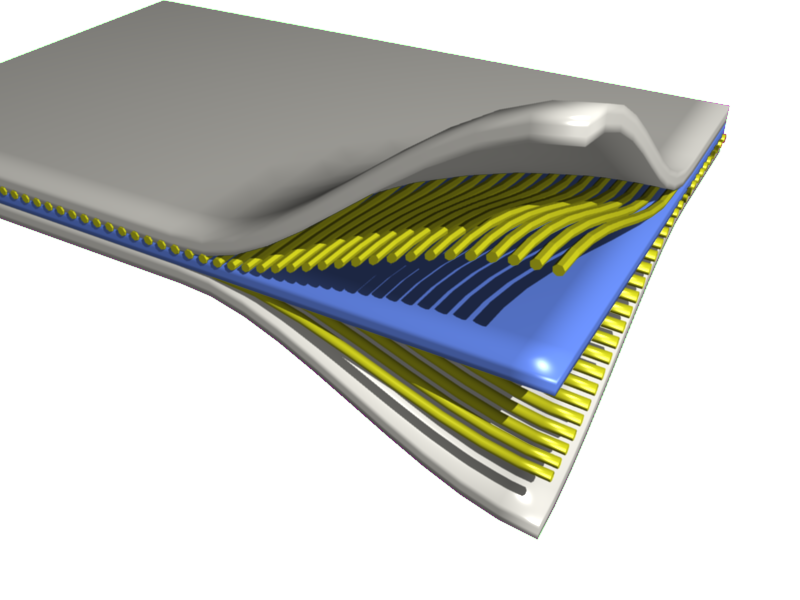

A composite or composite material (also composition material) is a material which is produced from two or more constituent materials. These constituent materials have notably dissimilar chemical or physical properties and are merged to create a material with properties unlike the individual elements. Within the finished structure, the individual elements remain separate and distinct, distinguishing composites from mixtures and solid solutions. Composite materials with more than one distinct layer are called ''composite laminates''. Typical engineered composite materials are made up of a binding agent forming the ''matrix'' and a Filler (materials), filler material (particulates or fibres) giving ''substance'', e.g.: * Concrete, reinforced concrete and masonry with cement, lime or Mortar (masonry), mortar (which is itself a composite material) as a binder * Composite wood such as glulam and plywood with wood glue as a binder * Reinforced plastics, such as fiberglass and fibre-rein ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Structural Material

Structural engineering depends on the knowledge of materials and their properties, in order to understand how different materials resist and support loads. Common structural materials are: Iron Wrought iron Wrought iron is the simplest form of iron, and is almost pure iron (typically less than 0.15% carbon). It usually contains some slag. Its uses are almost entirely obsolete, and it is no longer commercially produced. Wrought iron is very poor in fires. It is ductile, malleable and tough. It does not corrode as easily as steel. Cast iron Cast iron is a brittle form of iron which is weaker in tension than in compression. It has a relatively low melting point, good fluidity, castability, excellent machinability and wear resistance. Though almost entirely replaced by steel in building structures, cast irons have become an engineering material with a wide range of applications, including pipes, machine and car parts. Cast iron retains high strength in fires, despite its low ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Creep (deformation)

In materials science, creep (sometimes called cold flow) is the tendency of a solid material to undergo slow deformation while subject to persistent mechanical stresses. It can occur as a result of long-term exposure to high levels of stress that are still below the yield strength of the material. Creep is more severe in materials that are subjected to heat for long periods and generally increases as they near their melting point. The rate of deformation is a function of the material's properties, exposure time, exposure temperature and the applied structural load. Depending on the magnitude of the applied stress and its duration, the deformation may become so large that a component can no longer perform its function – for example creep of a turbine blade could cause the blade to contact the casing, resulting in the failure of the blade. Creep is usually of concern to engineers and metallurgists when evaluating components that operate under high stresses or high temperatures ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Brittle

A material is brittle if, when subjected to stress, it fractures with little elastic deformation and without significant plastic deformation. Brittle materials absorb relatively little energy prior to fracture, even those of high strength. Breaking is often accompanied by a sharp snapping sound. When used in materials science, it is generally applied to materials that fail when there is little or no plastic deformation before failure. One proof is to match the broken halves, which should fit exactly since no plastic deformation has occurred. Brittleness in different materials Polymers Mechanical characteristics of polymers can be sensitive to temperature changes near room temperatures. For example, poly(methyl methacrylate) is extremely brittle at temperature 4˚C, but experiences increased ductility with increased temperature. Amorphous polymers are polymers that can behave differently at different temperatures. They may behave like a glass at low temperatures (the gla ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Young's Modulus

Young's modulus (or the Young modulus) is a mechanical property of solid materials that measures the tensile or compressive stiffness when the force is applied lengthwise. It is the modulus of elasticity for tension or axial compression. Young's modulus is defined as the ratio of the stress (force per unit area) applied to the object and the resulting axial strain (displacement or deformation) in the linear elastic region of the material. Although Young's modulus is named after the 19th-century British scientist Thomas Young, the concept was developed in 1727 by Leonhard Euler. The first experiments that used the concept of Young's modulus in its modern form were performed by the Italian scientist Giordano Riccati in 1782, pre-dating Young's work by 25 years. The term modulus is derived from the Latin root term '' modus'', which means ''measure''. Definition Young's modulus, E, quantifies the relationship between tensile or compressive stress \sigma (force per unit ar ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hydrofluoric Acid

Hydrofluoric acid is a solution of hydrogen fluoride (HF) in water. Solutions of HF are colorless, acidic and highly corrosive. A common concentration is 49% (48–52%) but there are also stronger solutions (e.g. 70%) and pure HF has a boiling point near room temperature. It is used to make most organofluorine compounds; examples include the commonly used pharmaceutical antidepressant medication fluoxetine (Prozac) and the material PTFE (Teflon). Elemental fluorine is produced from it. It is commonly used to etch glass and silicon wafers. Uses Production of organofluorine compounds The principal use of hydrofluoric acid is in organofluorine chemistry. Many organofluorine compounds are prepared using HF as the fluorine source, including Teflon, fluoropolymers, fluorocarbons, and refrigerants such as freon. Many pharmaceuticals contain fluorine. Production of inorganic fluorides Most high-volume inorganic fluoride compounds are prepared from hydrofluoric acid. Foremost ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Nitric Acid

Nitric acid is an inorganic compound with the formula . It is a highly corrosive mineral acid. The compound is colorless, but samples tend to acquire a yellow cast over time due to decomposition into nitrogen oxide, oxides of nitrogen. Most commercially available nitric acid has a concentration of 68% in water. When the solution contains more than 86% , it is referred to as ''fuming nitric acid''. Depending on the amount of nitrogen dioxide present, fuming nitric acid is further characterized as red fuming nitric acid at concentrations above 86%, or white fuming nitric acid at concentrations above 95%. Nitric acid is the primary reagent used for nitration – the addition of a nitro group, typically to an organic molecule. While some resulting nitro compounds are shock- and thermally-sensitive explosives, a few are stable enough to be used in munitions and demolition, while others are still more stable and used as synthetic dyes and medicines (e.g. metronidazole). Nitric acid is ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |