|

Metal Injection Molding

Metal injection molding (MIM) is a metalworking process in which finely-powdered metal is mixed with binder material to create a "feedstock" that is then shaped and solidified using injection molding. Metal injection molding combines the most useful characteristics of powder metallurgy and plastic injection molding to facilitate the production of small, complex-shaped metal components with outstanding mechanical properties. The molding process allows high volume, complex parts to be shaped in a single step. After molding, the part undergoes conditioning operations to remove the binder (debinding) and densify the powders. Finished products are small components used in many industries and applications. The behavior of MIM feedstock is governed by rheology, the study of sludges, suspensions, and other non-Newtonian fluids. Due to current injection molding equipment limitations, products must be molded using quantities of 100 grams or less per "shot" into the mold. This sho ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Carburizing

Carburizing, or carburising, is a heat treatment process in which iron or steel absorbs carbon while the metal is heated in the presence of a carbon-bearing material, such as charcoal or carbon monoxide. The intent is to make the metal harder and more wear resistant. Depending on the amount of time and temperature, the affected area can vary in carbon content. Longer carburizing times and higher temperatures typically increase the depth of carbon diffusion. When the iron or steel is cooled rapidly by quenching, the higher carbon content on the outer surface becomes hard due to the transformation from austenite to martensite, while the core remains soft and tough as a ferritic and/or pearlite microstructure. This manufacturing process can be characterized by the following key points: It is applied to low-carbon workpieces; workpieces are in contact with a high-carbon gas, liquid or solid; it produces a hard workpiece surface; workpiece cores largely retain their toughness an ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

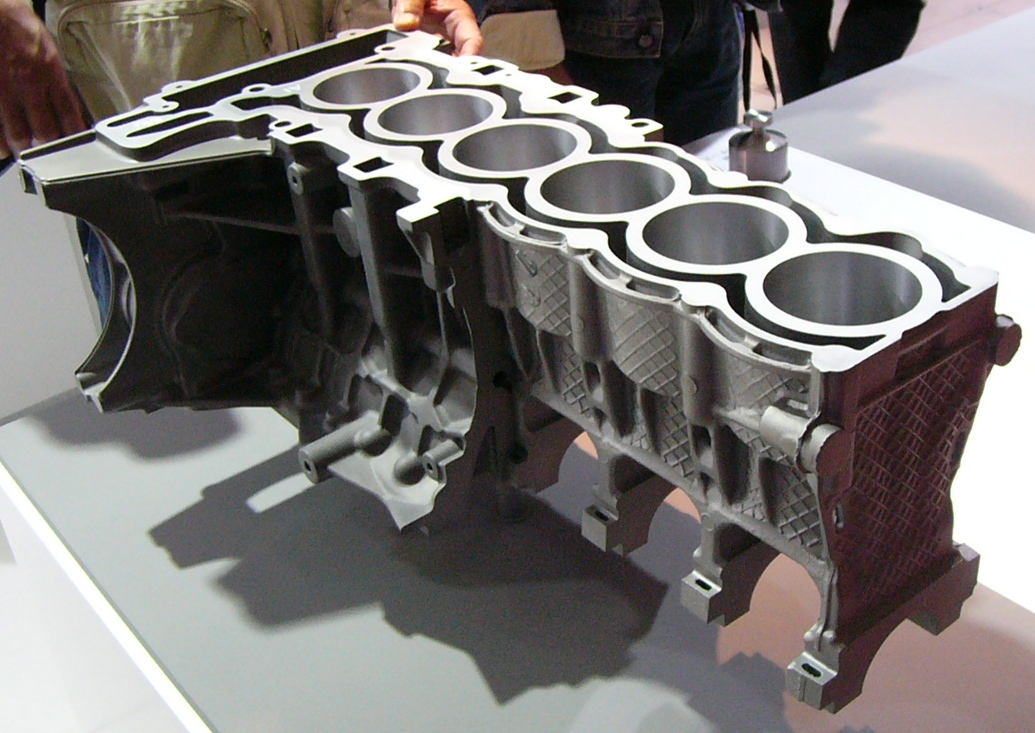

Die Casting

Die casting is a casting (metalworking), metal casting process that is characterized by forcing molten metal under high pressure into a mold cavity. The mold cavity is created using two hardened tool steel die (manufacturing), dies which have been machined into shape and work similarly to an injection molding, injection mold during the process. Most die castings are made from non-ferrous metals, specifically zinc, copper, aluminium, magnesium, lead, pewter, and tin-based alloys. Depending on the type of metal being cast, a hot- or cold-chamber machine is used. The casting equipment and the metal dies represent large capital costs and this tends to limit the process to high-volume production. Manufacture of parts using die casting is relatively simple, involving only four main steps, which keeps the incremental cost per item low. It is especially suited for a large quantity of small- to medium-sized castings, which is why die casting produces more castings than any other casting proc ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

ASTM

ASTM International, formerly known as American Society for Testing and Materials, is a standards organization that develops and publishes voluntary consensus technical international standards for a wide range of materials, products, systems and services. Some 12,575 apply globally. The headquarters is in West Conshohocken, Pennsylvania, about northwest of Philadelphia. It was founded in 1902 as the American Section of the International Association for Testing Materials. In addition to its traditional standards work, ASTM operates several global initiatives advancing additive manufacturing, advanced manufacturing, and emerging technologies, including the Additive Manufacturing Center of Excellence (AM CoE), the acquisition oWohlers Associatesfor market intelligence and advisory services, and the NIST-funded Standardization Center of Excellence (SCOE). History In 1898, a group of scientists and engineers, led by chemist, industry leader, and proponent of standardization Ch ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

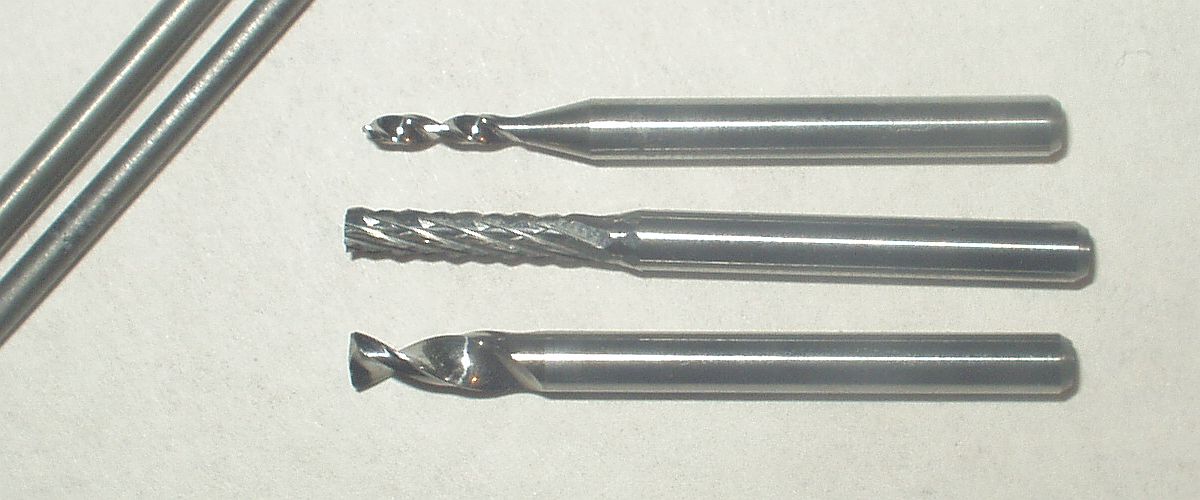

Tungsten Carbide

Tungsten carbide (chemical formula: ) is a carbide containing equal parts of tungsten and carbon atoms. In its most basic form, tungsten carbide is a fine gray powder, but it can be pressed and formed into shapes through sintering for use in industrial machinery, engineering facilities, molding blocks, cutting tools, chisels, abrasives, armor-piercing bullets and jewelry. Tungsten carbide is approximately three times as stiff as steel, with a Young's modulus of approximately 530–700 GPa, and is twice as dense as steel. It is comparable with corundum (α- ) in hardness, approaching that of a diamond, and can be polished and finished only with abrasives of superior hardness such as cubic boron nitride and diamond. Tungsten carbide tools can be operated at cutting speeds much higher than high-speed steel (a special steel blend for cutting tools). Tungsten carbide powder was first synthesized by H. Moissan in 1893, and the industrial production of the cemented form starte ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Stainless Steel

Stainless steel, also known as inox, corrosion-resistant steel (CRES), or rustless steel, is an iron-based alloy that contains chromium, making it resistant to rust and corrosion. Stainless steel's resistance to corrosion comes from its chromium content of 11% or more, which forms a Passivation (chemistry), passive film that protects the material and can self-healing material, self-heal when exposed to oxygen. It can be further alloyed with elements like molybdenum, carbon, nickel and nitrogen to enhance specific properties for various applications. The alloy's properties, such as luster and resistance to corrosion, are useful in many applications. Stainless steel can be rolled into Sheet metal, sheets, plates, bars, wire, and tubing. These can be used in cookware, cutlery, surgical instruments, major appliances, vehicles, construction material in large buildings, industrial equipment (e.g., in paper mills, chemical plants, water treatment), and storage tanks and tankers for ch ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

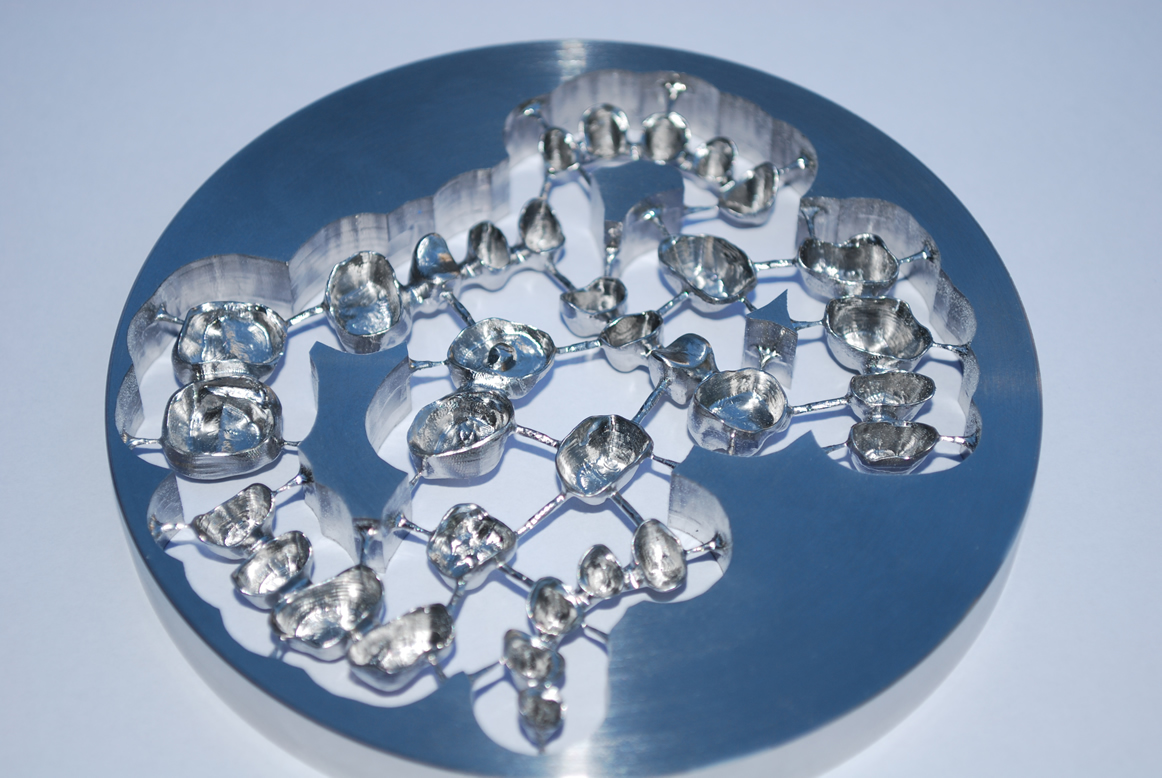

Cobalt-chrome

Cobalt-chrome or cobalt-chromium (CoCr) is a metal alloy of cobalt and chromium. Cobalt-chrome has a very high specific strength and is commonly used in gas turbines, dental implants, and orthopedic implants.ARCAM ASTM F75 CoCr Alloy History Co-Cr alloy was first discovered by Elwood Haynes in the early 1900s by fusing cobalt and chromium. The alloy was first discovered with many other elements such as and |

Aerospace

Aerospace is a term used to collectively refer to the atmosphere and outer space. Aerospace activity is very diverse, with a multitude of commercial, industrial, and military applications. Aerospace engineering consists of aeronautics and astronautics. Aerospace organizations research, design, manufacture, operate, maintain, and repair both aircraft and spacecraft. The border between space and the atmosphere has been proposed as above the ground according to the physical explanation that the air density is too low for a lifting body to generate meaningful lift force without exceeding orbital velocity. This border has been called the Kármán line. Overview In most industrial countries, the aerospace industry is a co-operation of the public and private sectors. For example, several states have a civilian space program funded by the government, such as NASA, National Aeronautics and Space Administration in the United States, European Space Agency in Europe, the Canadian Space A ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Nitriding

Nitriding is a heat treating process that diffusion, diffuses nitrogen into the surface of a metal to create a case-hardening, case-hardened surface. These processes are most commonly used on low-alloy steels. They are also used on titanium, aluminium and molybdenum. Typical applications include gears, crankshafts, camshafts, cam followers, valve parts, extruder screws, die-casting tools, forging dies, extrusion dies, firearm components, injectors and plastic molding (process), mold tools. Processes The processes are named after the medium used to donate. The three main methods used are: ''gas nitriding'', ''salt bath nitriding'', and ''plasma nitriding''. Gas nitriding In gas nitriding the donor is a nitrogen-rich gas, usually ammonia (NH3), which is why it is sometimes known as ''ammonia nitriding''. When ammonia comes into contact with the heated work piece it dissociates into nitrogen and hydrogen. The nitrogen then diffuses onto the surface of the material creating a nitrid ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |