|

Melt Blowing

Melt blowing is a conventional fabrication method of micro- and nanofibers where a polymer melt is extruded through small nozzles surrounded by high speed blowing gas. The randomly deposited fibers form a Nonwoven fabric, nonwoven sheet product applicable for filtration, sorbents, apparels and drug delivery systems. The substantial benefits of melt blowing are simplicity, high specific productivity and solvent-free operation. Choosing an appropriate combination of polymers with optimized rheological and surface properties, scientists have been able to produce melt-blown fibers with an average diameter as small as 36 nm. History During volcanic activity a fibrous material may be drawn by vigorous wind from molten basaltic magma called Pele's hair. The same phenomenon applies for melt blowing of polymers. The first research on melt blowing was a naval attempt in the US to produce fine filtration materials for radiation measurements on drone aircraft in the 1950s. Later on, Ex ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Polyamides

A polyamide is a polymer with repeating units linked by amide bonds. Polyamides occur both naturally and artificially. Examples of naturally occurring polyamides are proteins, such as wool and silk. Artificially made polyamides can be made through step-growth polymerization or solid-phase synthesis yielding materials such as nylons, aramids, and sodium polyaspartate. Synthetic polyamides are commonly used in textiles, automotive industry, carpets, kitchen utensils and sportswear due to their high durability and strength. The transportation manufacturing industry is the major consumer, accounting for 35% of polyamide (PA) consumption. Classification Polymers of amino acids are known as polypeptides or proteins. According to the composition of their main chain, synthetic polyamides are classified as follows: All polyamides are made by the formation of an amide function to link two molecules of monomer together. The monomers can be amides themselves (usually in the form of a cy ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Drug Delivery

Drug delivery involves various methods and technologies designed to transport pharmaceutical compounds to their target sites helping therapeutic effect. It involves principles related to drug preparation, route of administration, site-specific targeting, metabolism, and toxicity all aimed to optimize efficacy and safety, while improving patient convenience and compliance. A key goal of drug delivery is to modify a drug's pharmacokinetics and specificity by combining it with different excipients, drug carriers, and medical devices designed to control its distribution and activity in the body. Enhancing bioavailability and prolonging duration of action are essential strategies for improving therapeutic outcomes, particularly in chronic disease management. Additionally, some research emphasizes on improving safety for the individuals administering the medication. For example, microneedle patches have been developed for vaccines and drug delivery to minimize the risk of ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Thermal Insulation

Thermal insulation is the reduction of heat transfer (i.e., the transfer of thermal energy between objects of differing temperature) between objects in thermal contact or in range of radiative influence. Thermal insulation can be achieved with specially engineered methods or processes, as well as with suitable object shapes and materials. Heat flow is an inevitable consequence of contact between objects of different temperature. Thermal insulation provides a region of insulation in which thermal conduction is reduced, creating a thermal break or thermal barrier, or thermal radiation is reflected rather than absorbed by the lower-temperature body. The insulating capability of a material is measured as the inverse of thermal conductivity, thermal conductivity (k). Low thermal conductivity is equivalent to high insulating capability (R-value (insulation), resistance value). In thermal engineering, other important properties of insulating materials are product density, density (ρ) ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Polycarbonate

Polycarbonates (PC) are a group of thermoplastic polymers containing carbonate ester, carbonate groups in their chemical structures. Polycarbonates used in engineering are strong, toughness, tough materials, and some grades are optically transparent. They are easily worked, injection molding, molded, and thermoforming, thermoformed. Because of these properties, polycarbonates find many applications. Polycarbonates do not have a unique resin identification code, resin identification code (RIC) and are identified as "Other", 7 on the RIC list. Products made from polycarbonate can contain the precursor monomer bisphenol A (BPA). Structure Carbonate esters have planar OC(OC)2 cores, which confer rigidity. The unique O=C bond is short (1.173 Å in the depicted example), while the C-O bonds are more ether-like (the bond distances of 1.326 Å for the example depicted). Polycarbonates received their name because they are polymers containing carbonate ester, carbonate groups (−O−( ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

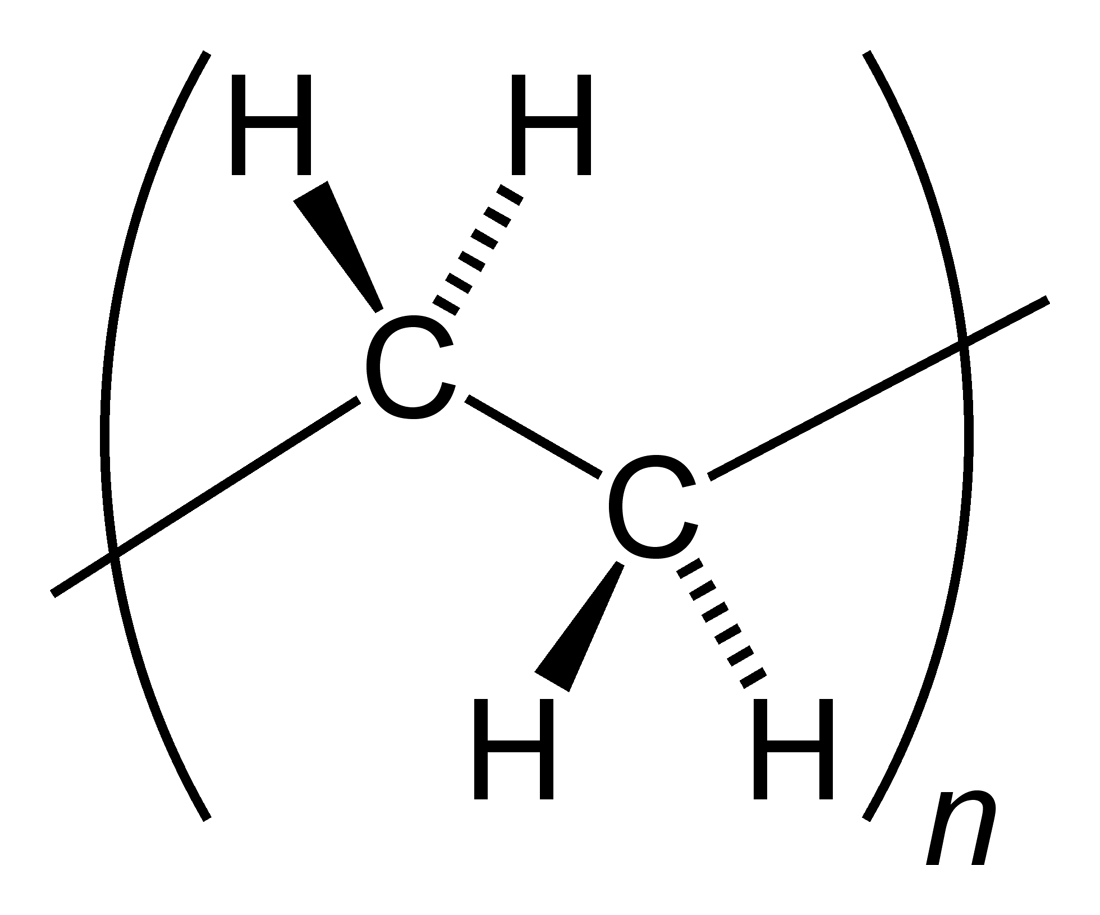

Polyethylene

Polyethylene or polythene (abbreviated PE; IUPAC name polyethene or poly(methylene)) is the most commonly produced plastic. It is a polymer, primarily used for packaging (plastic bags, plastic films, geomembranes and containers including bottles, cups, jars, etc.). , over 100 million tonnes of polyethylene resins are being produced annually, accounting for 34% of the total plastics market. Many kinds of polyethylene are known, with most having the chemical formula (C2H4)''n''. PE is usually a mixture of similar polymers of ethylene, with various values of ''n''. It can be ''low-density'' or ''high-density'' and many variations thereof. Its properties can be modified further by crosslinking or copolymerization. All forms are nontoxic as well as chemically resilient, contributing to polyethylene's popularity as a multi-use plastic. However, polyethylene's chemical resilience also makes it a long-lived and decomposition-resistant pollutant when disposed of improperly. Being a h ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Nylon

Nylon is a family of synthetic polymers characterised by amide linkages, typically connecting aliphatic or Polyamide#Classification, semi-aromatic groups. Nylons are generally brownish in color and can possess a soft texture, with some varieties exhibiting a silk-like appearance. As Thermoplastic, thermoplastics, nylons can be melt-processed into fibres, Thin film, films, and diverse shapes. The properties of nylons are often modified by blending with a variety of additives. Numerous types of nylon are available. One family, designated nylon-XY, is derived from diamines and dicarboxylic acids of carbon chain lengths X and Y, respectively. An important example is nylon-6,6 (). Another family, designated nylon-Z, is derived from amino acid, aminocarboxylic acids with carbon chain length Z. An example is nylon-[6]. Nylon polymers have extensive commercial applications, including uses in textiles and fibres (such as apparel, flooring and rubber reinforcement), molded components fo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Polyurethane

Polyurethane (; often abbreviated PUR and PU) is a class of polymers composed of organic chemistry, organic units joined by carbamate (urethane) links. In contrast to other common polymers such as polyethylene and polystyrene, polyurethane term does not refer to the single type of polymer but a group of polymers. Unlike polyethylene and polystyrene, polyurethanes can be produced from a wide range of starting materials resulting in various polymers within the same group. This chemical variety produces polyurethanes with different chemical structures leading to many List of polyurethane applications, different applications. These include rigid and flexible foams, and coatings, adhesives, Potting (electronics), electrical potting compounds, and fibers such as spandex and polyurethane laminate (PUL). Foams are the largest application accounting for 67% of all polyurethane produced in 2016. A polyurethane is typically produced by reacting a polymeric isocyanate with a polyol. Since a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Nonwoven Fabric

Nonwoven fabric or non-woven fabric is a fabric-like material made from staple fibre (short) and long fibres (continuous long), bonded together by chemical, mechanical, heat or solvent treatment. The term is used in the textile manufacturing industry to denote fabrics, such as felt, which are neither woven nor knitted. Some non-woven materials lack sufficient strength unless densified or reinforced by a backing. In recent years, non-wovens have become an alternative to polyurethane foam. Applications Because nonwoven fabrics do not require the intermediate step of converting fibres to yarn, they have more flexibility in materials usage. Nonwoven fabrics may be single-use, have a limited life, or be very durable. Nonwoven fabrics are sometimes designed to provide specific functions such as absorbency, liquid repellence, resilience, stretch, softness, strength, flame retardancy, washability, cushioning, thermal insulation, acoustic insulation, filtration, use as a bacterial ba ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Polyesters

Polyester is a category of polymers that contain one or two ester linkages in every repeat unit of their main chain. As a specific material, it most commonly refers to a type called polyethylene terephthalate (PET). Polyesters include some naturally occurring chemicals, such as those found in plants and insects. Natural polyesters and a few synthetic ones are biodegradable, but most synthetic polyesters are not. Synthetic polyesters are used extensively in clothing. Polyester fibers are sometimes spun together with natural fibers to produce a cloth with blended properties. Cotton-polyester blends can be strong, wrinkle- and tear-resistant, and reduce shrinking. Synthetic fibers using polyester have high water, wind, and environmental resistance compared to plant-derived fibers. They are less Fireproofing, fire-resistant and can melt when ignited. Liquid crystalline polyesters are among the first industrially used liquid crystal polymers. They are used for their mechanical propert ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

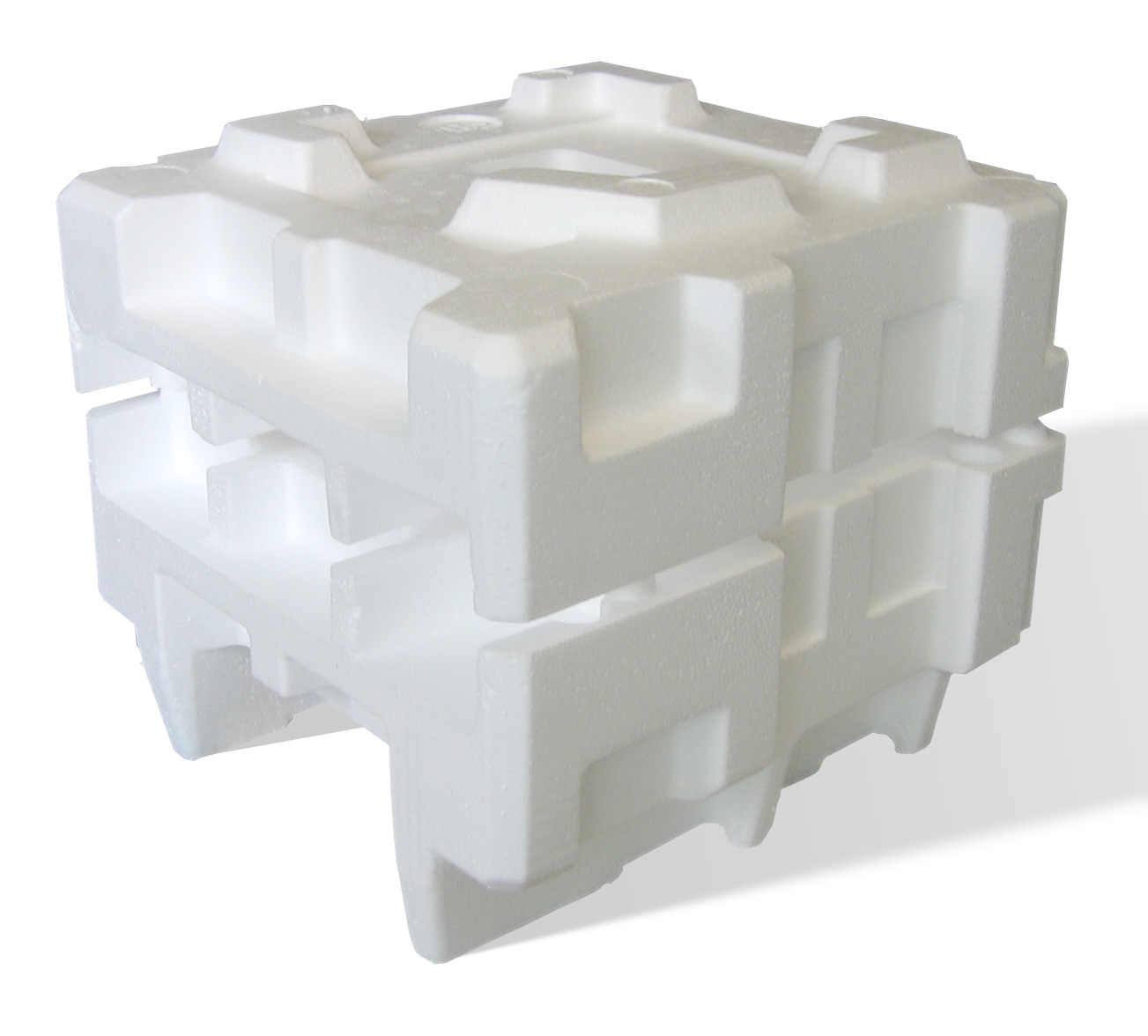

Polystyrene

Polystyrene (PS) is a synthetic polymer made from monomers of the aromatic hydrocarbon styrene. Polystyrene can be solid or foamed. General-purpose polystyrene is clear, hard, and brittle. It is an inexpensive resin per unit weight. It is a poor barrier to air and water vapor and has a relatively low melting point. Polystyrene is one of the most widely used plastics, with the scale of its production being several million tonnes per year. Polystyrene is naturally transparent to visible light, but can be colored with colorants. Uses include protective packaging (such as packing peanuts and optical disc jewel cases), containers, lids, bottles, trays, tumblers, disposable cutlery, in the making of models, and as an alternative material for phonograph records. As a thermoplastic polymer, polystyrene is in a solid (glassy) state at room temperature but flows if heated above about 100 °C, its glass transition temperature. It becomes rigid again when cooled. This te ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |