|

Lug (bicycle Part)

Lugged steel frame construction is a method of building bicycle frames using steel tubing mated with socket-like sleeves, called lugs. For most of the bicycle's history, steel has been the primary material for bicycle frames, with lugged construction the primary assembling method. Steel continues in use by builders of high-quality steel frames, though its dominance as a frame material has waned since the mid-1990s displaced largely by aluminum and carbon fiber; lugging has been displaced by TIG welding. Method of construction Lugged steel construction uses standard cylindrical steel tubes which are connected with lugs, external fittings made of pieces of steel (sometimes stainless steel) which fit over the ends of the tubing. Before assembly, the builder cuts the tubes to the desired length and precisely mitres their ends, providing a tight fit. The end of the tubes are inserted into the lugs and subsequently brazed with a silver or brass filler metal. The lug greatly i ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Seat Tube

A bicycle frame is the main component of a bicycle, onto which wheels and other components are fitted. The modern and most common frame design for an upright bicycle is based on the safety bicycle, and consists of two triangles: a main triangle and a paired rear triangle. This is known as the ''diamond frame''. Frames are required to be strong, stiff and light, which they do by combining different materials and shapes. A frameset consists of the frame and fork of a bicycle and sometimes includes the headset and seat post. Frame builders will often produce the frame and fork together as a paired set. Variations Besides the ubiquitous diamond frame, many different frame types have been developed for the bicycle, several of which are still in common use today. Diamond In the diamond frame, the main "triangle" is not actually a triangle because it consists of four tubes: the head tube, top tube, down tube and seat tube. The rear triangle consists of the seat tube joined by pair ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bicycle Touring

Bicycle touring is the taking of self-contained cycling trips for pleasure, adventure or autonomy rather than sport, commuting or exercise. Bicycle touring can range from single-day trips to extended travels spanning weeks or months. Tours may be planned by the participant or organized by a tourism business, local club or organization, or a charity as a fund-raising venture. Origins Historian James McGurn speaks of bets being taken in London in the 19th century for riders of hobby-horses – machines pushed by the feet rather than pedaled – outspeeding stagecoaches. "One practitioner beat a four-horse coach to Brighton by half an hour," he says.McGurn, James (1987), On Your Bicycle, John Murray, UK "There are various accounts of 15 to 17-year-olds '' draisienne''-touring around France in the 1820s. On 17 February 1869 John Mayall, Charles Spencer and Rowley Turner rode from Trafalgar Square, London, to Brighton in 15 hours for 53 miles. ''The Times'', which had sent a re ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

TIG Welding

Gas tungsten arc welding (GTAW, also known as tungsten inert gas welding or TIG, tungsten argon gas welding or TAG, and heliarc welding when helium is used) is an arc welding process that uses a non-consumable tungsten electrode to produce the weld. The weld area and electrode are protected from oxidation or other atmospheric contamination by an inert shielding gas (argon or helium). A filler metal is normally used, though some welds, known as ' autogenous welds', or ' fusion welds' do not require it. A constant-current welding power supply produces electrical energy, which is conducted across the arc through a column of highly ionized gas and metal vapors known as a plasma. The process grants the operator greater control over the weld than competing processes such as shielded metal arc welding and gas metal arc welding, allowing stronger, higher-quality welds. However, TIG welding is comparatively more complex and difficult to master, and furthermore, it is significantly slo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Mig Welding

Mig, MiG, or MIG may refer to: Business * MiG, a Russian aircraft corporation **Any of the MiG aircraft *Marfin Investment Group MIG Holdings S.A. (also known as MIG) is a Greece, Greek investment company. It has acquired several companies and has changed name several times since. In 2004 it took the name ''Marfin Financial Group'' following the triple merger of ''Comm G ..., Greek private equity company * Atlas Arteria, formerly Macquarie Infrastructure Group, toll roads company * Mortgage indemnity guarantee Other uses * Mig33 mobile social networking, Australian digital media company * Luton Town MIGs, English football hooligans * Monokine Induced by Gamma interferon, or CXCL9 * IATA code for Mianyang Nanjiao Airport, China * Mig Ayesa, an Australian singer-songwriter ** ''MiG'' (album), a 2007 album by Mig Ayesa * Metal inert gas welding or MIG welding {{disambig ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

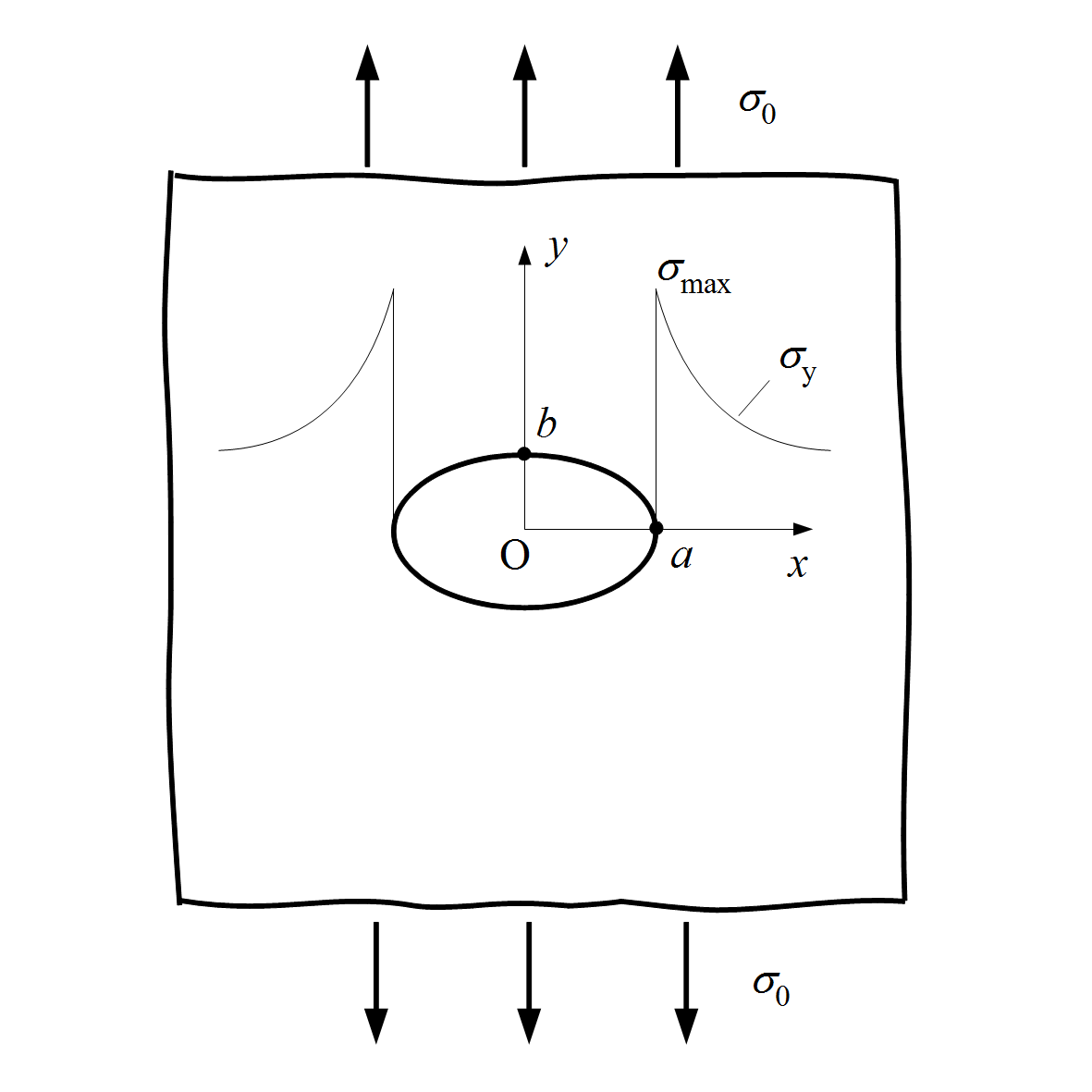

Stress Concentration

In solid mechanics, a stress concentration (also called a stress raiser or a stress riser or notch sensitivity) is a location in an object where the stress (mechanics), stress is significantly greater than the surrounding region. Stress concentrations occur when there are irregularities in the geometry or material of a structural component that cause an interruption to the flow of stress. This arises from such details as holes, Groove (engineering), grooves, Notch (engineering), notches and Fillet (mechanics), fillets. Stress concentrations may also occur from accidental damage such as nicks and scratches. The degree of concentration of a discontinuity under typically Tension (physics), tensile loads can be expressed as a non-dimensional stress concentration factor K_t, which is the ratio of the highest stress to the nominal far field stress. For a circular hole in an infinite plate, K_t = 3. The stress concentration factor should not be confused with the stress intensity factor, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bicycle Fork

A bicycle fork is the part of a bicycle that holds the front wheel. A fork typically consists of two ''blades'' which are joined at the top by a fork ''crown.'' The crown is often at the front. Most suspension forks have an arch connecting the two side of the lowers (the part connected to the axle.) It is often in front of the stanchions (shaft the lowers slide on) but not always. Above the crown, a ''steerer tube'' attaches the fork to the bicycle and the Bicycle handlebar, handlebars (via a Stem (bike), stem) allowing the rider to steer the bicycle. The steerer tube of the fork interfaces with the Bicycle frame, frame via Bearing (mechanical), bearings called a headset (bicycle part), headset mounted in the head tube. At the bottom of the fork, ''fork ends'' hold the wheel. Usually, either the axle is bolted to the fork, or a ''quick release skewer'' passes through a hollow axle, clamping the axle to the fork. A bicycle dropout (drop out, frame end, or fork end), is a slot in ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bicycle Wheel

A bicycle wheel is a wheel, most commonly a wire wheel, designed for a bicycle. A pair is often called a wheelset, especially in the context of ready built "off the shelf" performance-oriented wheels. Bicycle wheels are typically designed to fit into the bicycle frame, frame and bicycle fork, fork via Dropout (bicycle part), dropouts, and hold bicycle tires. Invention The first wheel to use the tension in wire wheel, metal spokes was invented by George Cayley, Sir George Cayley to achieve lightness in his 1853 glider. Construction The first bicycle wheels followed the traditions of carriage building: a wooden hub, a fixed steel axle (the bearings were located in the fork ends), wooden spokes and a shrink fitted iron tire. A typical modern wheel has a metal hub, wire tension spokes and a metal or carbon fiber rim which holds a pneumatic rubber tire. Hub A hub is the center part of a bicycle wheel. It consists of an axle, bearing (mechanical), bearings and a hub shell. The ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

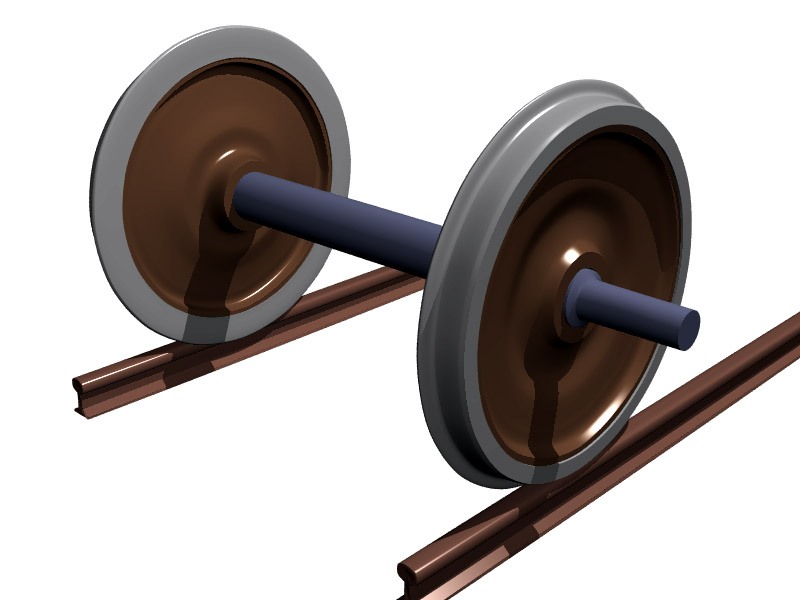

Axle

An axle or axletree is a central shaft for a rotation, rotating wheel and axle, wheel or gear. On wheeled vehicles, the axle may be fixed to the wheels, rotating with them, or fixed to the vehicle, with the wheels rotating around the axle. In the former case, bearing (mechanical), bearings or Bushing (bearing), bushings are provided at the mounting points where the axle is supported. In the latter case, a bearing or bushing sits inside a central hole in the wheel to allow the wheel or gear to rotate around the axle. Sometimes, especially on bicycles, the latter type of axle is referred to as a ''spindle (tool), spindle''. Terminology On cars and trucks, several senses of the word ''axle'' occur in casual usage, referring to the shaft itself, its housing, or simply any transverse pair of wheels. Strictly speaking, a shaft that rotates with the wheel, being either Bolt (fastener), bolted or rotating spline, splined in fixed relation to it, is called an ''axle'' or ''axle shaft ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Dropout (bicycle Part)

A fork end, fork-end, or forkend is a slot in a bicycle frame or bicycle fork where the axle of a bicycle wheel is attached. A dropout is a type of fork end that allows the rear wheel to be removed without first derailing the chain. Track bicycle frames have track fork ends, on which the opening faces rearwards. Because they do not have dropouts, the chain must be derailed from the sprocket before the rear wheel can be removed from a typical track bike. Some single-speed bicycles intended for street or trail use are also equipped with track fork ends instead of dropouts. On bicycles that do not have a derailleur or other chain tensioning device, rear ''horizontal dropouts'' allow adjustment of chain tension, and can accommodate a range of chain lengths or cog sizes. They were standard on most older derailleur bicycles from before the 1990s. An older derailleur-equipped bicycle with horizontal dropouts can be readily converted into singlespeed, fixed gear or to use an internally ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Head Tube

The head tube is the part of a cycle's tubular frame within which the front fork steerer tube is mounted. On a motorcycle, the "head tube" is normally called the steering head. On bicycles the manufacturer's brand located on the head tube is known as a head badge. Bearings The head tube holds the bearings which allow the front fork steerer tube to pivot freely. * In bicycles, these bearings are collectively called the headset. These are usually ball bearings, although some headsets use needle bearings. * In motorcycles, these bearings are also referred to as headset, or ''steering head bearings'' or ''steering neck bearings''. These are usually tapered roller bearings. Caster angle The steering axis angle, also called caster angle, is the angle that the head tube and hence the steering axis makes with the horizontal or vertical, depending on convention. The steering axis is the axis about which the steering mechanism (fork, handlebars, front wheel, etc.) pivots. * In bic ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |