|

Kaldo Converter

A Kaldo converter (using the ''Kaldo process'' or ''Stora-Kaldo process'') is a rotary vessel oxygen based metal refining method. Originally applied to the refining of iron into steel, with most installations in the 1960s, the process is (2014) used primarily to refine non ferrous metals, typically copper. In that field, it is often named TBRC, or Top Blown Rotary Converter. History and description Steel production file:Affinage convertisseur Kaldo.svg, lang=en, upright=1.8, Evolution of chemical composition and temperature of the liquid steel, during the blowing in a Kaldo converter. The iron content is linked with the slag composition, the others elements are taken in the metal. The name "Kaldo" is derived from Prof. Bo Kalling, and from the Domnarvets Jernverk (''Stora Kopparbergs Bergslag'' subsidiary) both key in the development of the process. Research into the use of a stirring to promote mixing, and therefore rate of conversion was investigated from the 1940s, and invest ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

ECSC Financial Report 1983 Sérémange Convertisseur Kaldo

ECSC may stand for: *European Coal and Steel Community, a forerunner of the European Union *Eastern Colleges Science Conference, an undergraduate research conference in the northeastern United States *Eastern Caribbean Supreme Court, a Caribbean court system established under the Organisation of Eastern Caribbean States *East Coast Surfing Championships, one of the United States Surfing Federation's major amateur events *Expedia CruiseShipCenters *European Cybersecurity Challenge, a CTF competition at a European level {{disambiguation ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cockerill-Ougrée-Providence à Marchienne-au-Pont

Forges de la Providence () was a Belgian steel producing company based in the Hainaut (province), Hainaut region around Charleroi. Founded as ''Société Anonyme des laminoirs, forges, fonderies et usines de la Providence'' the company had three steel production sites at Marchienne-au-Pont in Belgium, and Réhon and Hautmont in France. The company was independent until 1966 when it became part of the Cockerill-Ougrée, briefly being absorbed into ''Thy-Marcinelle et Monceau'' before becoming part of Cockerill-Sambre. In the 1980s the French steel plants closed, the Belgian plant continued to operate until 2008, becoming part of the Duferco group as Carsid at the beginning of the 21st century. Coke and blast furnace production CARSID plant closed in 2008 due to an economic downturn, and did not restart - the plant was closed in 2012. Company history In 1836 the Englishman Thomas Bonehill built Puddling (metallurgy), puddling furnaces for the Puissant and Licot de Nîmes families; ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Lead

Lead () is a chemical element; it has Chemical symbol, symbol Pb (from Latin ) and atomic number 82. It is a Heavy metal (elements), heavy metal that is density, denser than most common materials. Lead is Mohs scale, soft and Ductility, malleable, and also has a relatively low melting point. When freshly cut, lead is a shiny gray with a hint of blue. It tarnishes to a dull gray color when exposed to air. Lead has the highest atomic number of any stable nuclide, stable element and three of its isotopes are endpoints of major nuclear decay chains of heavier elements. Lead is a relatively unreactive post-transition metal. Its weak metallic character is illustrated by its Amphoterism, amphoteric nature; lead and lead oxides react with acids and base (chemistry), bases, and it tends to form covalent bonds. Lead compounds, Compounds of lead are usually found in the +2 oxidation state rather than the +4 state common with lighter members of the carbon group. Exceptions are mostly limited ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Copper

Copper is a chemical element; it has symbol Cu (from Latin ) and atomic number 29. It is a soft, malleable, and ductile metal with very high thermal and electrical conductivity. A freshly exposed surface of pure copper has a pinkish-orange color. Copper is used as a conductor of heat and electricity, as a building material, and as a constituent of various metal alloys, such as sterling silver used in jewelry, cupronickel used to make marine hardware and coins, and constantan used in strain gauges and thermocouples for temperature measurement. Copper is one of the few metals that can occur in nature in a directly usable, unalloyed metallic form. This means that copper is a native metal. This led to very early human use in several regions, from . Thousands of years later, it was the first metal to be smelted from sulfide ores, ; the first metal to be cast into a shape in a mold, ; and the first metal to be purposely alloyed with another metal, tin, to create bronze, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Smelting

Smelting is a process of applying heat and a chemical reducing agent to an ore to extract a desired base metal product. It is a form of extractive metallurgy that is used to obtain many metals such as iron-making, iron, copper extraction, copper, silver mining#Ore processing, silver, tin, lead smelting, lead and zinc smelting, zinc. Smelting uses heat and a chemical reducing agent to decompose the ore, driving off other elements as gases or slag and leaving the metal behind. The reducing agent is commonly a fossil-fuel source of carbon, such as carbon monoxide from incomplete combustion of coke (fuel), coke—or, in earlier times, of charcoal. The oxygen in the ore binds to carbon at high temperatures, as the Chemical energy, chemical potential energy of the bonds in carbon dioxide () is lower than that of the bonds in the ore. Sulfide ores such as those commonly used to obtain copper, zinc or lead, are roasting (metallurgy), roasted before smelting in order to convert the sulfid ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Non-ferrous Metal

In metallurgy, non-ferrous metals are metals or alloys that do not contain iron ( allotropes of iron, ferrite, and so on) in appreciable amounts. Generally more costly than ferrous metals, non-ferrous metals are used because of desirable properties such as low weight (e.g. aluminium), higher conductivity (e.g. copper), non- magnetic properties or resistance to corrosion (e.g. zinc). Some non-ferrous materials are also used in the iron and steel industries. For example, bauxite is used as flux for blast furnaces, while others such as wolframite, pyrolusite, and chromite are used in making ferrous alloys. Important non-ferrous metals include aluminium, copper, lead, tin, titanium, and zinc, and alloys such as brass. Precious metals such as gold, silver, and platinum and exotic or rare metals such as mercury, tungsten, beryllium, bismuth, cerium, cadmium, niobium, indium, gallium, germanium, lithium, selenium, tantalum, tellurium, vanadium, and zirconium ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Copper Smelting

Smelting is a process of applying heat and a chemical reducing agent to an ore to extract a desired base metal product. It is a form of extractive metallurgy that is used to obtain many metals such as iron, copper, silver, tin, lead and zinc. Smelting uses heat and a chemical reducing agent to decompose the ore, driving off other elements as gases or slag and leaving the metal behind. The reducing agent is commonly a fossil-fuel source of carbon, such as carbon monoxide from incomplete combustion of coke—or, in earlier times, of charcoal. The oxygen in the ore binds to carbon at high temperatures, as the chemical potential energy of the bonds in carbon dioxide () is lower than that of the bonds in the ore. Sulfide ores such as those commonly used to obtain copper, zinc or lead, are roasted before smelting in order to convert the sulfides to oxides, which are more readily reduced to the metal. Roasting heats the ore in the presence of oxygen from air, oxidizing the ore and li ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Metallo-Chimique

Metallo-Chimique International N.V., based in Beerse, Belgium, also described simply as Metallo, is a privately held metals and mining company. The company was incorporated in 1919. Metallo now specializes in the recycling and refining of metalliferous materials (e.g. copper, tin, lead, zinc, as well as cable, waste from the electronics sector, car catalysts, and the like), to produce pure tin and lead, electrolytic copper, copper anodes and solder from a wide variety of scrap Scrap consists of recyclable materials, usually metals, left over from product manufacturing and consumption, such as parts of vehicles, building supplies, and surplus materials. Unlike waste, scrap can have monetary value, especially recover ... and residues. The company produces approximately 10,000 tons of cu-anodes, 1,500 tons of lead-ingots and 800 tons of tin-ingots per month. It is the leading producer of pure tin in Europe. All Metallo-Chimique final products are made out of scrap and by-pro ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Inco

Vale Canada Limited (formerly Vale Inco, CVRD Inco and Inco Limited; for corporate branding purposes simply known as "Vale" and pronounced in English) is a wholly owned subsidiary of the Brazilian mining company Vale. Vale's nickel mining and metals division is headquartered in Toronto, Ontario, Canada. It produces nickel, copper, cobalt, platinum, rhodium, ruthenium, iridium, gold, and silver. Prior to being purchased by CVRD (now Vale) in 2006, Inco was the world's second largest producer of nickel, and the third largest mining company outside South Africa and Russia of platinum group metals. It was also a charter member of the 30-stock Dow Jones Industrial Average formed on October 1, 1928. History Founding of Inco The company was founded following the discovery by blacksmith Tom Flanagan in Copper Cliff, Ontario of chalcopyrite deposits, while the Canadian Pacific Railway was being built in 1883; the township of Sudbury soon followed in 1884 when JL Morris, provincial ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Matte (metallurgy)

Matte is a term used in the field of pyrometallurgy given to the molten metal sulfide phases typically formed during smelting of copper, nickel, and other base metals. Typically, a matte is the phase in which the principal metal being extracted is recovered prior to a final reduction process (usually converting) to produce blister copper. The matte may also collect some valuable minor constituents such as noble metals, minor base metals, selenium or tellurium. Mattes may also be used to collect impurities from a metal phase, such as in the case of antimony smelting. Molten mattes are insoluble in both slag The general term slag may be a by-product or co-product of smelting (pyrometallurgical) ores and recycled metals depending on the type of material being produced. Slag is mainly a mixture of metal oxides and silicon dioxide. Broadly, it can be c ... and metal phases. This insolubility, combined with differences in specific gravities between mattes, slags, and metals, allows ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

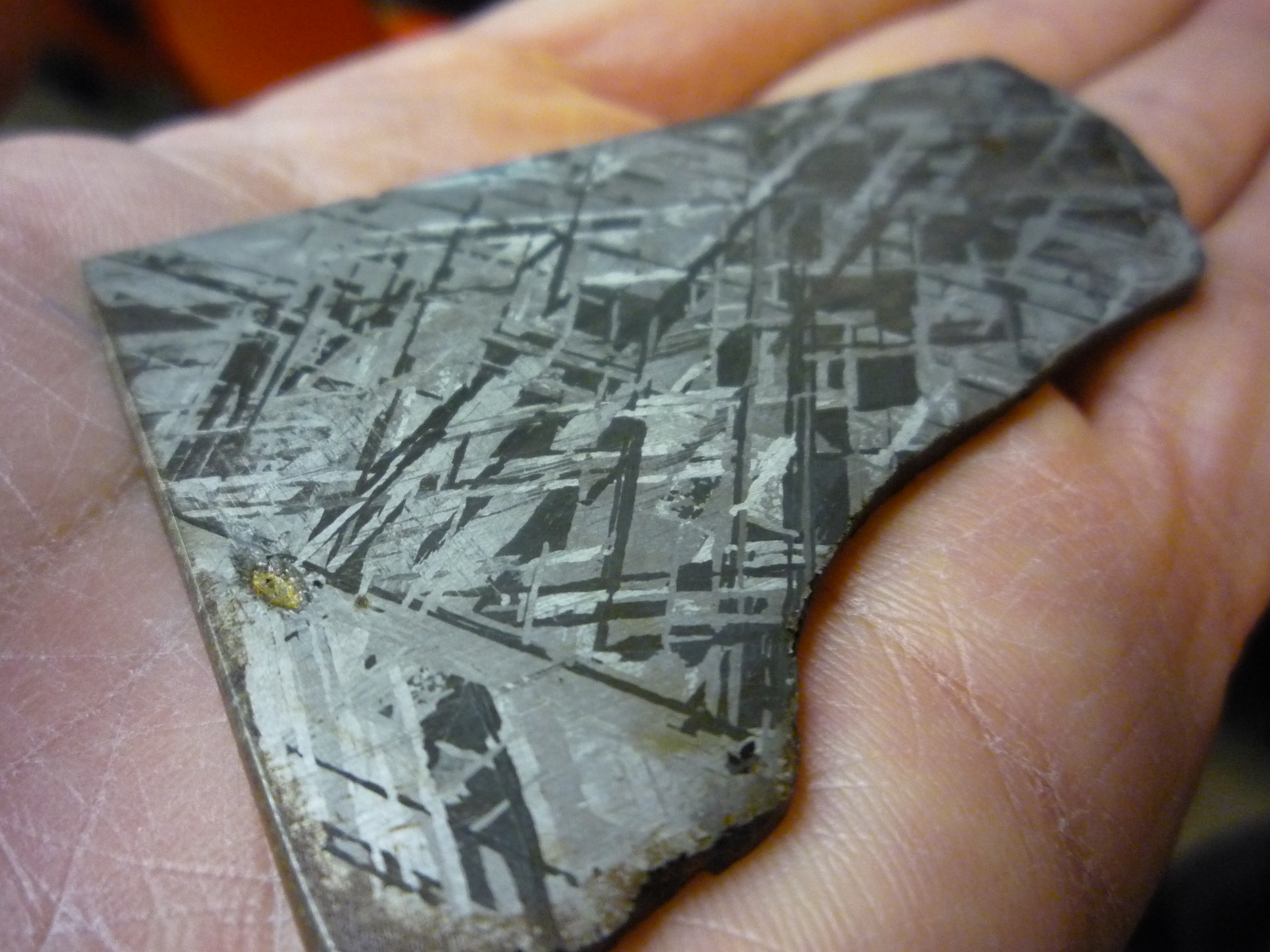

Nickel

Nickel is a chemical element; it has symbol Ni and atomic number 28. It is a silvery-white lustrous metal with a slight golden tinge. Nickel is a hard and ductile transition metal. Pure nickel is chemically reactive, but large pieces are slow to react with air under standard conditions because a passivation layer of nickel oxide forms on the surface that prevents further corrosion. Even so, pure native nickel is found in Earth's crust only in tiny amounts, usually in ultramafic rocks, and in the interiors of larger nickel–iron meteorites that were not exposed to oxygen when outside Earth's atmosphere. Meteoric nickel is found in combination with iron, a reflection of the origin of those elements as major end products of supernova nucleosynthesis. An iron–nickel mixture is thought to compose Earth's outer and inner cores. Use of nickel (as natural meteoric nickel–iron alloy) has been traced as far back as 3500 BCE. Nickel was first isolated and classifie ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Lorraine

Lorraine, also , ; ; Lorrain: ''Louréne''; Lorraine Franconian: ''Lottringe''; ; ; is a cultural and historical region in Eastern France, now located in the administrative region of Grand Est. Its name stems from the medieval kingdom of Lotharingia (855–959 AD), which in turn was named after either Emperor Lothair I or King Lothair II. Lorraine, originally the southern or "upper" part of this kingdom, came to be ruled by the Holy Roman Empire as the Duchy of Lorraine before the Kingdom of France annexed it in 1766. From 1982 until January 2016, Lorraine was an administrative region of France. In 2016, under a reorganisation, it became part of the new region Grand Est. As a region in modern France, Lorraine consisted of the four departments Meurthe-et-Moselle, Meuse, Moselle and Vosges (from a historical point of view the Haute-Marne department is also located in the region), containing 2,337 communes. Metz is the regional prefecture. The largest metropolitan area ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |