|

Interference Fit

An interference fit, also known as a pressed fit or friction fit, is a form of fastening between two tightfitting mating parts that produces a joint which is held together by friction after the parts are pushed together. Depending on the amount of interference, parts may be joined using a tap from a hammer or forced together using a hydraulic press. Critical components that must not sustain damage during joining may also be cooled significantly below room temperature to shrink one of the components before fitting. This method allows the components to be joined without force and produces a shrink fit interference when the component returns to normal temperature. Interference fits are commonly used with aircraft fasteners to improve the fatigue life of a joint. These fits, though applicable to shaft and hole assembly, are more often used for bearing-housing or bearing-shaft assembly. This is referred to as a 'press-in' mounting. Tightness of fit The tightness of fit is contr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

|

|

Fit (manufacturing)

In precision mechanics, fit refers to the degree of 'looseness' with which a Shaft (mechanical engineering), shaft is inserted into a Boring (manufacturing), bored hole. This coupling is related to the Engineering tolerance, tolerance or allowance of both parts' dimensions. The shaft and the orifice must be of a similar diameter, otherwise there will not be a correct adjustment. With this in mind, measurements have been internationally standardised according to International Organization for Standardization, ISO regulation to ensure the interchangeable parts, interchangeability of items and their mass production. Tolerance values are designated with a capital letter in the case of orifices and lower case letters in the case of shafts. The lower the value the higher the machining costs, as a greater precision is required. Maximum and minimum clearance The maximum clearance of a fit is the difference between the upper bound of the orifice diameter and the lower bound of the shaf ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

|

|

Rack And Pinion

rack and pinion is a type of linear actuator that comprises a circular gear (the '' pinion'') engaging a linear gear (the ''rack''). Together, they convert between rotational motion and linear motion: rotating the pinion causes the rack to be driven in a line. Conversely, moving the rack linearly will cause the pinion to rotate. The rack and pinion mechanism is used in rack railways, where the pinion mounted on a locomotive or a railroad car engages a rack usually placed between the rails, and helps to move the train up a steep gradient. It is also used in arbor presses and drill presses, where the pinion is connected to a lever and displaces a vertical rack (the ram). In pipelines and other industrial piping systems, a rack displaced by a linear actuator turns a pinion to open or close a valve. Stairlifts, lock gates, electric gates, and the mechanical steering mechanism of cars are other notable applications. The term "rack and pinion" may be used also when the rac ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

|

|

Metalworking Terminology

This article is a list of terms commonly used in the practice of metalworking – the science, art, industry, and craft of shaping metal. Processes The following is a categorical list of metalworking processes: operations, procedures, techniques, and other actions performed that pertain to or consist of metalworking. Casting Casting is the process of creating objects by filling a mold with molten metal and allowing it to cool. *Centrifugal casting (industrial), Centrifugal *Continuous casting, Continuous *Die casting, Die *Evaporative-pattern casting, Evaporative-pattern **Full-mold casting, Full-mold **Lost-foam casting, Lost-foam *Investment casting, Investment ** in art: Lost-wax casting, Lost-wax *Permanent mold casting, Permanent mold *Plaster mold casting, Plaster mold *Sand casting, Sand *Semi-solid metal casting, Semi-solid metal *Ceramic mold casting#Shaw process, Shaw process *Shell molding *Spin casting, Spin Related terms *Foundry *Crucible *Molding sand *Refracto ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

|

|

Mechanical Engineering

Mechanical engineering is the study of physical machines and mechanism (engineering), mechanisms that may involve force and movement. It is an engineering branch that combines engineering physics and engineering mathematics, mathematics principles with materials science, to design, analyze, manufacture, and maintain mechanical systems. It is one of the oldest and broadest of the List of engineering branches, engineering branches. Mechanical engineering requires an understanding of core areas including mechanics, Analytical dynamics, dynamics, thermodynamics, materials science, design, structural analysis, and electricity. In addition to these core principles, mechanical engineers use tools such as computer-aided design (CAD), computer-aided manufacturing (CAM), computer-aided engineering (CAE), and product lifecycle management to design and analyze manufacturing plants, industrial equipment and industrial machinery, machinery, HVAC, heating and cooling systems, transport systems, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

|

Tempering (metallurgy)

Tempering is a process of heat treating, which is used to increase the toughness of iron-based alloys. Tempering is usually performed after Hardening (metallurgy), hardening, to reduce some of the excess hardness, and is done by heating the metal to some temperature below the critical point (thermodynamics), critical point for a certain period of time, then allowing it to cool in still air. The exact temperature determines the amount of hardness removed, and depends on both the specific composition of the alloy and on the desired properties in the finished product. For instance, very hard tools are often tempered at low temperatures, while spring (device), springs are tempered at much higher temperatures. Introduction Tempering is a heat treatment technique applied to ferrous alloys, such as steel or cast iron, to achieve greater toughness by decreasing the hardness of the alloy. The reduction in hardness is usually accompanied by an increase in ductility, thereby decreasing the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

|

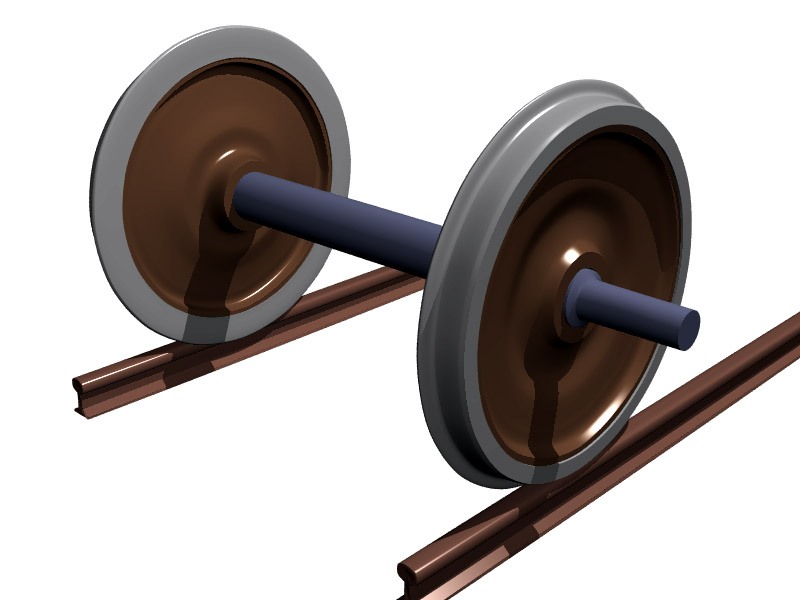

Railway Tire

The steel wheel of a steam locomotive and other older types of rolling stock were usually fitted with a steel tire (American English) or tyre (in British English, Australian English and others) to provide a replaceable wearing element on a costly wheel. Installation Replacing a whole wheel because of a worn contact surface was expensive, so older types of railway wheels were fitted with a replaceable steel tire. The tire is a hoop of steel that is fitted around the steel wheel centre. The tire is machined with a shoulder on its outer face to locate it on the wheel centre, and a groove on the inside diameter of the flange face. The inside diameter of the tire is machined to be slightly less than the diameter of the wheel centre on which it is mounted, to give an interference fit. The tire is fitted by heating to a controlled temperature, avoiding overheating. This causes the tire to expand. The wheel centre, usually already mounted on the axle, is lowered into the tire which i ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

|

|

Shrink-fitting

Shrink-fitting is a technique in which an interference fit is achieved by a relative size change after assembly. This is usually achieved by heating or cooling one component before assembly and allowing it to return to the ambient temperature after assembly, employing the phenomenon of thermal expansion to make a joint. For example, the thermal expansion of a piece of a metallic drainpipe allows a builder to fit the cooler piece to it. As the adjoined pieces reach the same temperature, the joint becomes strained and stronger. Other examples are the fitting of a wrought iron tyre around the rim of a wooden cart wheel by a wheelwright, or of a steel tyre to the wheel of a railway engine or rolling stock. In both cases the tyre will be heated and expands to slightly greater than the wheel's diameter, and is fitted around it. After cooling, the tyre contracts, binding tightly in place. The bombard Mons Meg was assembled from longitudinal staves of iron held in place by shrink-fitted ir ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

|

|

Heat

In thermodynamics, heat is energy in transfer between a thermodynamic system and its surroundings by such mechanisms as thermal conduction, electromagnetic radiation, and friction, which are microscopic in nature, involving sub-atomic, atomic, or molecular particles, or small surface irregularities, as distinct from the macroscopic modes of energy transfer, which are thermodynamic work and transfer of matter. For a closed system (transfer of matter excluded), the heat involved in a process is the difference in internal energy between the final and initial states of a system, after subtracting the work done in the process. For a closed system, this is the formulation of the first law of thermodynamics. Calorimetry is measurement of quantity of energy transferred as heat by its effect on the states of interacting bodies, for example, by the amount of ice melted or by change in temperature of a body. In the International System of Units (SI), the unit of measurement for he ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

|

Axle

An axle or axletree is a central shaft for a rotation, rotating wheel and axle, wheel or gear. On wheeled vehicles, the axle may be fixed to the wheels, rotating with them, or fixed to the vehicle, with the wheels rotating around the axle. In the former case, bearing (mechanical), bearings or Bushing (bearing), bushings are provided at the mounting points where the axle is supported. In the latter case, a bearing or bushing sits inside a central hole in the wheel to allow the wheel or gear to rotate around the axle. Sometimes, especially on bicycles, the latter type of axle is referred to as a ''spindle (tool), spindle''. Terminology On cars and trucks, several senses of the word ''axle'' occur in casual usage, referring to the shaft itself, its housing, or simply any transverse pair of wheels. Strictly speaking, a shaft that rotates with the wheel, being either Bolt (fastener), bolted or rotating spline, splined in fixed relation to it, is called an ''axle'' or ''axle shaft ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

|

Train Wheel

A train wheel or rail wheel is a type of wheel specially designed for use on railway tracks. The wheel acts as a rolling component, typically press fitted on to an axle and mounted directly on a railway carriage or locomotive, or indirectly on a bogie () or truck (). The powered wheels under the locomotive are called driving wheels. Wheels are initially cast or forged and then heat-treated to have a specific hardness. New wheels are machined using a lathe to a standardised shape, called a profile. All wheel profiles are regularly checked to ensure proper interaction between the wheel and the rail. Incorrectly profiled wheels and worn wheels can increase rolling resistance, reduce energy efficiency and may even cause a derailment. The International Union of Railways has defined a standard wheel diameter of , although smaller sizes are used in some rapid transit railway systems and on ro-ro carriages. Wheel geometry and flange The running surface ("tread" or "rim ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

|

Wheelset (rail Transport)

A wheelset is a pair of railroad car, railroad vehicle Train wheel, wheels mounted rigidly on an Axle#Vehicle axles, axle. Wheelsets are often mounted in a bogie ("List of railroad truck parts, truck" in North America) – a pivoted frame assembly holding at least two wheelsets – at each end of the vehicle. Most modern goods wagon, freight cars and Railroad car#Passenger cars, passenger cars have bogies each with two wheelsets, but three wheelsets (or more) are used in bogies of freight cars that carry heavy loads, and three-wheelset bogies are under some passenger cars. Four-wheeled goods wagons that were once near-universal in Europe and Great Britain and their colonies have only two wheelsets; in recent decades such vehicles have become less common as trainloads have become heavier. Conical wheel-tread Most train wheels have a cone (mathematics), conical taper of about 1 in 20 to enable the wheelset to follow Civil engineering#Surveying, curves with less ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

|

Chamfer

A chamfer ( ) is a transitional edge between two faces of an object. Sometimes defined as a form of bevel, it is often created at a 45° angle between two adjoining right-angled faces. Chamfers are frequently used in machining, carpentry, furniture, concrete formwork, mirrors, and to facilitate assembly of many mechanical engineering designs. Terminology In materials and manufacturing, a ''chamfer'' is used to "ease" otherwise sharp edges, both for safety and to prevent damage to the edges; it may also be a primarily decorative feature. In general terms it may be regarded as a type of ''bevel'', and the terms are often used interchangeably. However, in machining, only the term chamfer is used for the specific technique, practice, and result. In carpentry, a lark's tongue is a chamfer which ends short of the end of a piece in a gradual outward curve, leaving the remainder of the edge as a right angle. Chamfers may be formed in either inside or outside adjoining faces of an ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |