|

Impedance Pump

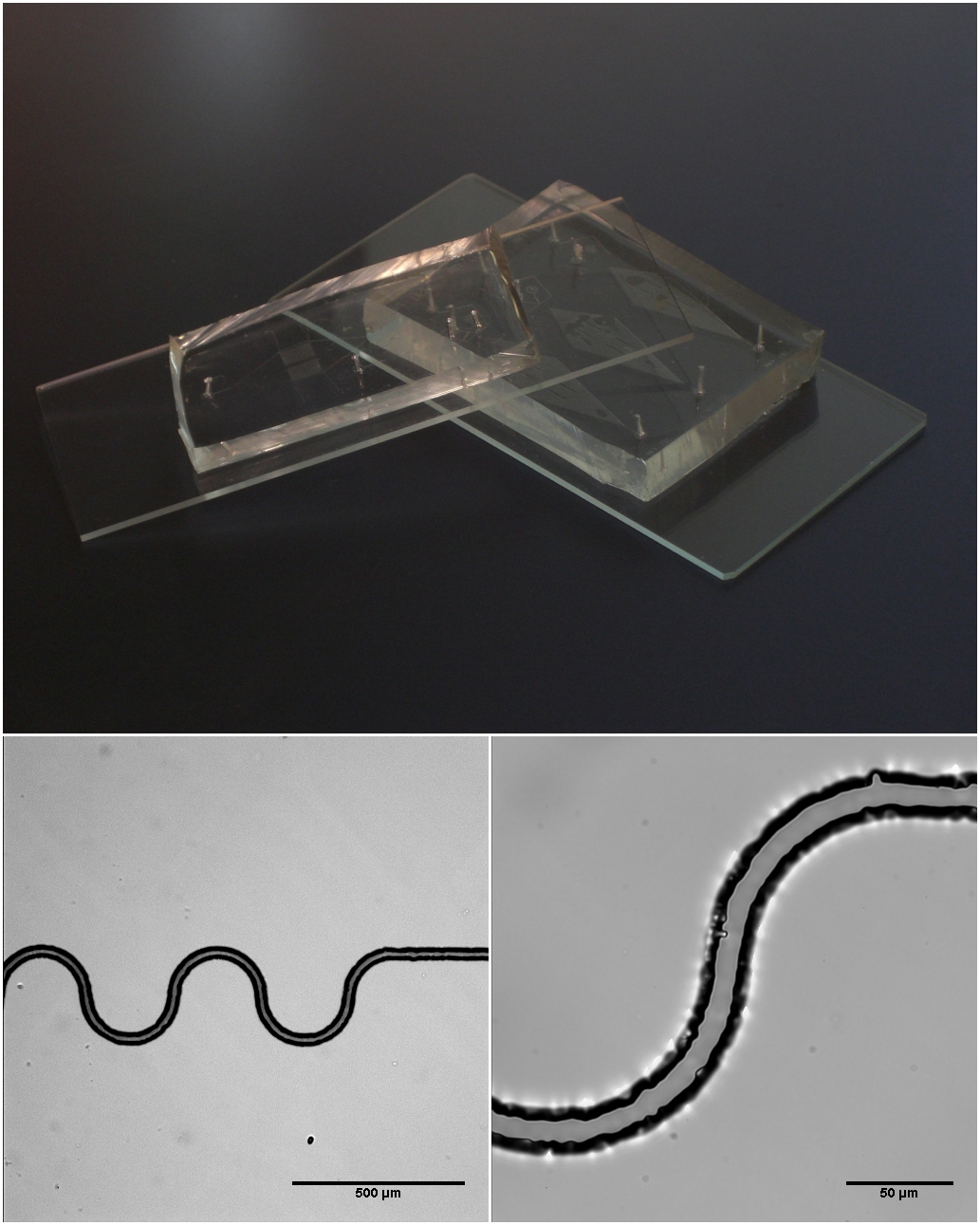

An impedance pump is a valveless pump consisting of an elastic tube connected on both ends to an inelastic tube. Tapping the end of a tube will cause flow of liquid inside the system. Very small versions of an impedance pump -- a micro impedance pump -- can be used as a micropump for lab-on-a-chip active microfluidics Microfluidics refers to a system that manipulates a small amount of fluids (10−9 to 10−18 liters) using small channels with sizes of ten to hundreds of micrometres. It is a multidisciplinary field that involves molecular analysis, molecular bi .... Rinderknecht, Derek Gresham (2008). "Development of a microimpedance pump for pulsatile flow transport : Part 1: Flow characteristics of the microimpedance pump. Part 2: A systematic study of steady and pulsatile transport in microscale cavities.". Dissertation (Ph.D.), California Institute of Technology say ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pump

A pump is a device that moves fluids (liquids or gases), or sometimes Slurry, slurries, by mechanical action, typically converted from electrical energy into hydraulic or pneumatic energy. Mechanical pumps serve in a wide range of applications such as Water well pump, pumping water from wells, aquarium filtering, pond filtering and Water aeration, aeration, in the car industry for Water cooling, water-cooling and fuel injection, in the energy industry for Pumping (oil well), pumping oil and natural gas or for operating cooling towers and other components of heating, ventilation and air conditioning systems. In the medical industry, pumps are used for biochemical processes in developing and manufacturing medicine, and as artificial replacements for body parts, in particular the artificial heart and Penile implant, penile prosthesis. When a pump contains two or more pump mechanisms with fluid being directed to flow through them in series, it is called a ''multi-stage pump''. T ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Elastomer

An elastomer is a polymer with viscoelasticity (i.e. both viscosity and elasticity) and with weak intermolecular forces, generally low Young's modulus (E) and high failure strain compared with other materials. The term, a portmanteau of ''elastic polymer'', is often used interchangeably with ''rubber'', although the latter is preferred when referring to vulcanisates. Each of the monomers which link to form the polymer is usually a compound of several elements among carbon, hydrogen, oxygen and silicon. Elastomers are amorphous polymers maintained above their glass transition temperature, so that considerable molecular reconformation is feasible without breaking of covalent bonds. Rubber-like solids with elastic properties are called elastomers. Polymer chains are held together in these materials by relatively weak intermolecular bonds, which permit the polymers to stretch in response to macroscopic stresses. Elastomers are usually thermosets (requiring vulcanization ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tube (fluid Conveyance)

A tube, or tubing, is a long hollow cylinder used for moving fluids (liquids or gases) or to protect electrical or optical cables and wires. The terms "Pipe (fluid conveyance), pipe" and "tube" are almost interchangeable, although minor distinctions exist — generally, a tube has tighter engineering requirements than a pipe. Both pipe and tube imply a level of rigidity and permanence, whereas a Hose (tubing), hose is usually portable and flexible. A tube and pipe may be specified by standard pipe size designations, ''e.g.'', nominal pipe size, or by nominal (value), nominal outside or inside diameter and/or wall thickness. The actual dimensions of pipe are usually not the nominal dimensions: A 1-inch pipe will not actually measure 1 inch in either outside or inside diameter, whereas many types of tubing are specified by actual inside diameter, outside diameter, or wall thickness. Manufacture There are three classes of manufactured tubing: seamless, as-welded ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Liquid

Liquid is a state of matter with a definite volume but no fixed shape. Liquids adapt to the shape of their container and are nearly incompressible, maintaining their volume even under pressure. The density of a liquid is usually close to that of a solid, and much higher than that of a gas. Therefore, liquid and solid are classified as condensed matter. Meanwhile, since both liquids and gases can flow, they are categorized as fluids. A liquid is composed of atoms or molecules held together by intermolecular bonds of intermediate strength. These forces allow the particles to move around one another while remaining closely packed. In contrast, solids have particles that are tightly bound by strong intermolecular forces, limiting their movement to small vibrations in fixed positions. Gases, on the other hand, consist of widely spaced, freely moving particles with only weak intermolecular forces. As temperature increases, the molecules in a liquid vibrate more intensely, causi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Micropump

Micropumps are devices that can control and manipulate small fluid volumes. Although any kind of small pump is often referred to as a micropump, a more accurate definition restricts this term to pumps with functional dimensions in the micrometer range. Such pumps are of special interest in microfluidic research, and have become available for industrial product integration in recent years. Their miniaturized overall size, potential cost and improved dosing accuracy compared to existing miniature pumps fuel the growing interest for this innovative kind of pump. Note that the below text is very incomplete in terms of providing a good overview of the different micropump types and applications, and therefore please refer to good review articles on the topic. Introduction and history First true micropumps were reported in the mid-1970s, but attracted interest only in the 1980s, when Jan Smits and Harald Van Lintel developed Microelectromechanical systems, MEMS micropumps. Most of th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Lab-on-a-chip

A lab-on-a-chip (LOC) is a device that integrates one or several laboratory functions on a single integrated circuit (commonly called a "chip") of only millimeters to a few square centimeters to achieve automation and high-throughput screening. LOCs can handle extremely small fluid volumes down to less than pico-liters. Lab-on-a-chip devices are a subset of microelectromechanical systems (MEMS) devices and sometimes called "micro total analysis systems" (μTAS). LOCs may use microfluidics, the physics, manipulation and study of minute amounts of fluids. However, strictly regarded "lab-on-a-chip" indicates generally the scaling of single or multiple lab processes down to chip-format, whereas "μTAS" is dedicated to the integration of the total sequence of lab processes to perform chemical analysis. History After the invention of microtechnology (≈1954) for realizing integrated semiconductor structures for microelectronic chips, these lithography-based technologies were soon ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Microfluidics

Microfluidics refers to a system that manipulates a small amount of fluids (10−9 to 10−18 liters) using small channels with sizes of ten to hundreds of micrometres. It is a multidisciplinary field that involves molecular analysis, molecular biology, and microelectronics. It has practical applications in the design of systems that process low volumes of fluids to achieve multiplexing, automation, and high-throughput screening. Microfluidics emerged in the beginning of the 1980s and is used in the development of inkjet printheads, DNA chips, lab-on-a-chip technology, micro-propulsion, and micro-thermal technologies. Typically, micro means one of the following features: * Small volumes (μL, nL, pL, fL) * Small size * Low energy consumption * Microdomain effects Typically microfluidic systems transport, mix, separate, or otherwise process fluids. Various applications rely on passive fluid control using capillary forces, in the form of capillary flow modifying elements, akin to f ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |