|

Idle Air Control Actuator

An idle air control actuator or idle air control valve (IAC actuator/valve) is a device commonly used in fuel-injected vehicles to control the engine's idling rotational speed (RPM). In carburetted vehicles a similar device known as an ''idle speed control actuator'' is used. Description The IAC actuator is an electrically controlled device, which gets its input from the vehicle's engine control unit (ECU). The actuator is fitted such that it either bypasses the throttle or operates the throttle butterfly valve directly. The actuator consists of a linear servo actuator servomotor that controls a plunger which varies air flow through the throttle body. The position of the servomotor and hence the amount of air bypass is controlled digitally by the engine ECU. This allows the engine's idle speed to be maintained constant. The linear servo is most commonly a combination of a DC motor, lead screw A leadscrew (or lead screw), also known as a power screw or translation screw,Bha ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fuel Injection

Fuel injection is the introduction of fuel in an internal combustion engine, most commonly automotive engines, by the means of a fuel injector. This article focuses on fuel injection in reciprocating piston and Wankel rotary engines. All compression-ignition engines (e.g. diesel engines), and many spark-ignition engines (i.e. petrol (gasoline) engines, such as Otto or Wankel), use fuel injection of one kind or another. Mass-produced diesel engines for passenger cars (such as the Mercedes-Benz OM 138) became available in the late 1930s and early 1940s, being the first fuel-injected engines for passenger car use. In passenger car petrol engines, fuel injection was introduced in the early 1950s and gradually gained prevalence until it had largely replaced carburetors by the early 1990s. The primary difference between carburetion and fuel injection is that fuel injection atomizes the fuel through a small nozzle under high pressure, while carburetion relies on suction crea ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Rotational Speed

Rotational frequency, also known as rotational speed or rate of rotation (symbols ''ν'', lowercase Greek nu, and also ''n''), is the frequency of rotation of an object around an axis. Its SI unit is the reciprocal seconds (s−1); other common units of measurement include the hertz (Hz), cycles per second (cps), and revolutions per minute (rpm). Rotational frequency can be obtained dividing ''angular frequency'', ω, by a full turn (2 π radians): ''ν''ω/(2πrad). It can also be formulated as the instantaneous rate of change of the number of rotations, ''N'', with respect to time, ''t'': ''n''d''N''/d''t'' (as per International System of Quantities). (11 pages) Similar to ordinary period (physics), period ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Carburettor

A carburetor (also spelled carburettor or carburetter) is a device used by a gasoline internal combustion engine to control and mix air and fuel entering the engine. The primary method of adding fuel to the intake air is through the Venturi effect or Bernoulli's principle or with a Pitot tube in the main metering circuit, though various other components are also used to provide extra fuel or air in specific circumstances. Since the 1990s, carburetors have been largely replaced by fuel injection for cars and trucks, but carburetors are still used by some small engines (e.g. lawnmowers, generators, and concrete mixers) and motorcycles. In addition, they are still widely used on piston-engine–driven aircraft. Diesel engines have always used fuel injection instead of carburetors, as the compression-based combustion of diesel requires the greater precision and pressure of fuel injection. Etymology The term ''carburetor'' is derived from the verb ''carburet'', which means ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Actuator

An actuator is a machine element, component of a machine that produces force, torque, or Displacement (geometry), displacement, when an electrical, Pneumatics, pneumatic or Hydraulic fluid, hydraulic input is supplied to it in a system (called an actuating system). The effect is usually produced in a controlled way. An actuator translates such an input signal into the required form of mechanical energy. It is a type of transducer. In simple terms, it is a "mover". An actuator requires a control device (which provides control signal) and a source of energy. The control signal is relatively low in energy and may be voltage, electric current, Compressed air, pneumatic, or hydraulic fluid pressure, or even human power. In the electric, hydraulic, and pneumatic sense, it is a form of automation, automation or automatic control. The displacement achieved is commonly linear or rotational, as exemplified by linear motors and rotary motors, respectively. Rotary motion is more natural for s ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Engine Control Unit

An engine control unit (ECU), also called an engine control module (ECM), is a device that controls various subsystems of an internal combustion engine. Systems commonly controlled by an ECU include the fuel injection and ignition systems. The earliest ECUs (used by aircraft engines in the late 1930s) were mechanical-hydraulic units; however, most 21st-century ECUs operate using digital electronics. Functions The main functions of the ECU are typically: * Fuel injection system * Ignition system * Idle speed control (typically either via an idle air control valve or the electronic throttle system) * Variable valve timing and/or variable valve lift systems The sensors used by the ECU include: * accelerator pedal position sensor * camshaft position sensor * coolant temperature sensor * crankshaft position sensor * knock sensors * inlet manifold pressure sensor ( MAP sensor) * intake air temperature * intake air mass flow rate sensor ( MAF sensor) * oxygen (lambda) s ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Throttle

A throttle is a mechanism by which fluid flow is managed by construction or obstruction. An engine's power can be increased or decreased by the restriction of inlet gases (by the use of a throttle), but usually decreased. The term ''throttle'' has come to refer, informally, to any mechanism by which the power or speed of an engine is regulated, such as a car's accelerator pedal. What is often termed a ''throttle'' (in an aviation context) is also called a thrust lever, particularly for jet engine powered aircraft. For a steam locomotive, the valve which controls the steam is known as the regulator. Internal combustion engines In an internal combustion engine, the throttle is a means of controlling an engine's power by regulating the amount of fuel or air entering the engine. In a motor vehicle the control used by the driver to regulate power is sometimes called the throttle, accelerator, or gas pedal. For a gasoline engine, the throttle most commonly regulates the amount of ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

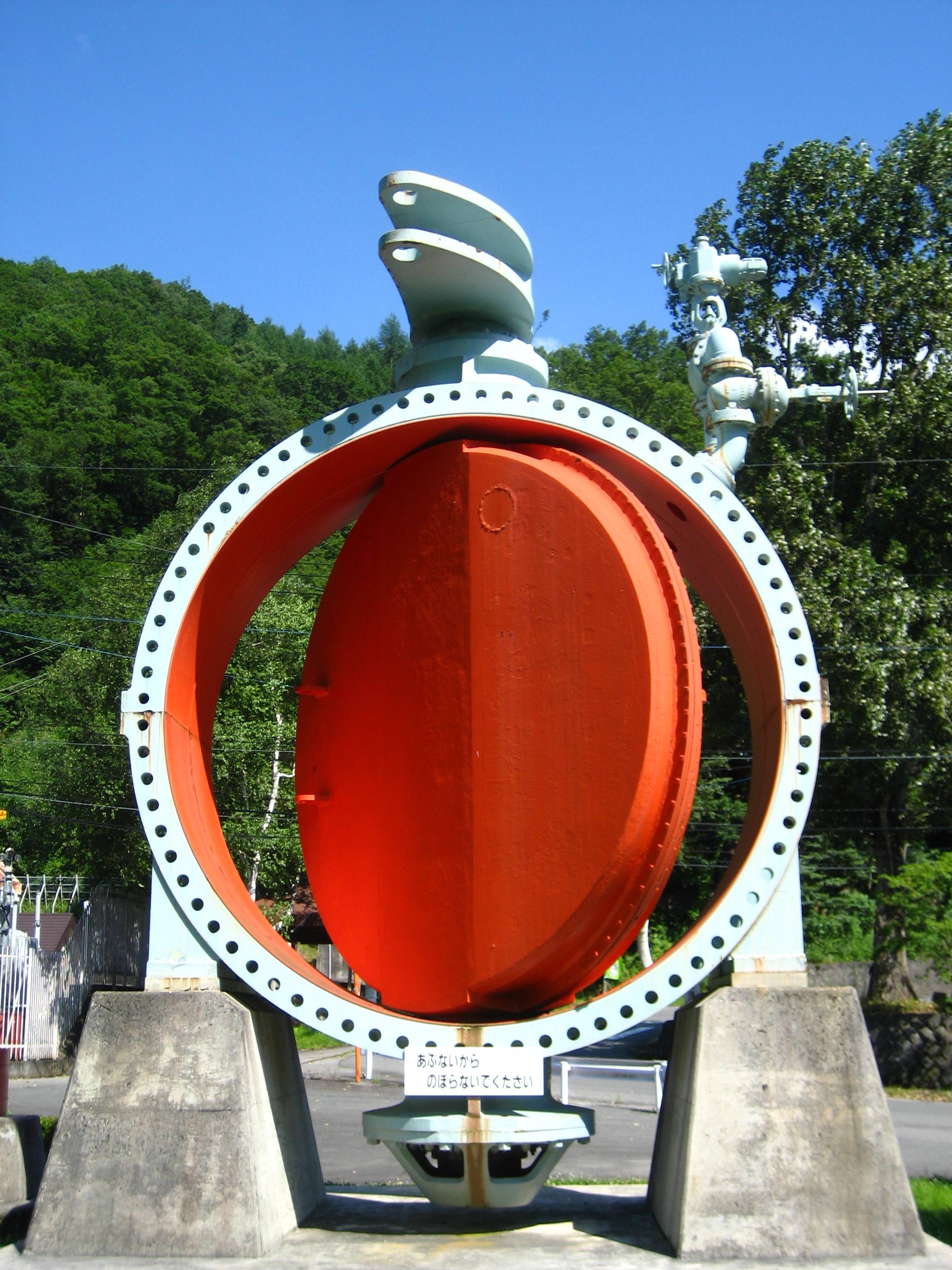

Butterfly Valve

A butterfly valve is a valve that isolates or regulates the flow of a fluid. The closing mechanism is a disk that rotates. Principle of operation Operation is similar to that of a ball valve, which allows for quick shut off. Butterfly valves are generally favored because they cost less than other valve designs, and are lighter weight so they need less support. The disc is positioned in the center of the pipe. A rod passes through the disc to an actuator on the outside of the valve. Rotating the actuator turns the disc either parallel or perpendicular to the flow. Unlike a ball valve, the disc is always present within the flow, so it induces a pressure drop, even when open. A butterfly valve is from a family of valves called quarter-turn valves. In operation, the valve is fully open or closed when the disc is rotated a quarter turn. The "butterfly" is a metal disc mounted on a rod. When the valve is closed, the disc is turned so that it completely blocks off the passageway. Wh ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Servomotor

A servomotor (or servo motor or simply servo) is a rotary or linear actuator that allows for precise control of angular or linear position, velocity, and acceleration in a mechanical system. It constitutes part of a servomechanism, and consists of a suitable motor coupled to a sensor for position feedback and a controller (often a dedicated module designed specifically for servomotors). Servomotors are not a specific class of motor, although the term ''servomotor'' is often used to refer to a motor suitable for use in a closed-loop control system. Servomotors are used in applications such as robotics, CNC machinery, and automated manufacturing. Mechanism A servomotor is a closed-loop servomechanism that uses position feedback (either linear or rotational position) to control its motion and final position. The input to its control is a signal (either analog or digital) representing the desired position of the output shaft. The motor is paired with some type of positio ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

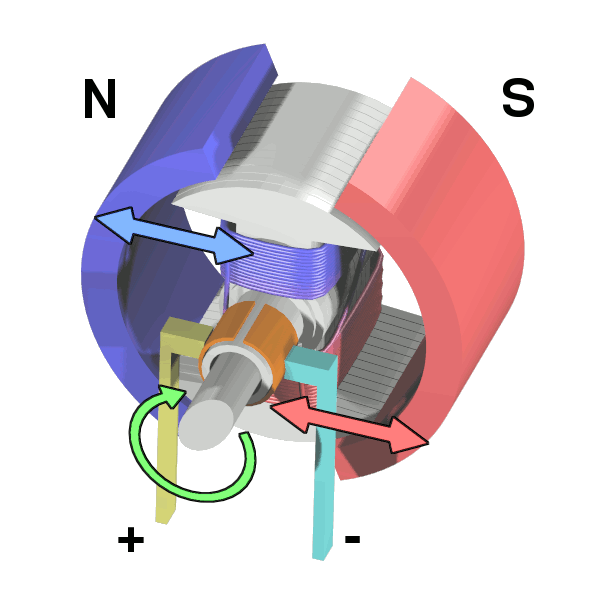

DC Motor

A DC motor is an electrical motor that uses direct current (DC) to produce mechanical force. The most common types rely on magnetic forces produced by currents in the coils. Nearly all types of DC motors have some internal mechanism, either electromechanical or electronic, to periodically change the direction of current in part of the motor. DC motors were the first form of motors to be widely used, as they could be powered from existing direct-current lighting power distribution systems. A DC motor's speed can be controlled over a wide range, using either a variable supply voltage or by changing the strength of current in its field windings. Small DC motors are used in tools, toys, and appliances. The universal motor, a lightweight brushed motor used for portable power tools and appliances can operate on direct current and alternating current. Larger DC motors are currently used in propulsion of electric vehicles, elevator and hoists, and in drives for steel rolling mills. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Lead Screw

A leadscrew (or lead screw), also known as a power screw or translation screw,Bhandari, p. 202. is a screw (simple machine), screw used as a linkage (mechanical), linkage in a machine, to translate rotation, turning motion into linear motion. Because of the large area of sliding contact between their gender of connectors and fasteners, male and female members, screw threads have larger frictional energy losses compared to other linkages. They are not typically used to carry high power, but more for intermittent use in low power actuator and positioner mechanisms. Leadscrews are commonly used in linear actuators, machine slides (such as in machine tools), vise (tool), vises, mechanical press, presses, and jack (device), jacks.Shigley, p. 400. Leadscrews are a common component in electric linear actuators. Leadscrews are manufactured in the same way as other thread forms: they may be threading (manufacturing), rolled, cut, or ground. A lead screw is sometimes used with a spli ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Optical Encoder

A rotary encoder, also called a shaft encoder, is an electro-mechanical device that converts the angular position or motion of a shaft or axle to analog or digital output signals. There are two main types of rotary encoder: absolute and incremental. The output of an absolute encoder indicates the current shaft position, making it an angle transducer. The output of an incremental encoder provides information about the ''motion'' of the shaft, which typically is processed elsewhere into information such as position, speed and distance. Rotary encoders are used in a wide range of applications that require monitoring or control, or both, of mechanical systems, including industrial controls, robotics, photographic lenses, computer input devices such as optomechanical mice and trackballs, controlled stress rheometers, and rotating radar platforms. Technologies * Mechanical: Also known as conductive encoders. A series of circumferential copper tracks etched onto a PCB is used to ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Anti-stall (engine)

A stall is the slowing or stopping of a process, and, in the case of an engine, refers to a sudden stopping of the engine turning, usually brought about accidentally. It is commonly applied to the phenomenon whereby an engine abruptly ceases operating and stops turning. It might be due to not getting enough air, energy, fuel, or electric spark, fuel starvation, a mechanical failure, or in response to a sudden increase in engine load. This increase in engine load is common in vehicles with a manual transmission when the clutch is released too suddenly. The ways in which a car can stall are usually down to the driver, especially with a manual transmission. For instance, if a driver takes their foot off the clutch too quickly while stationary then the car will stall; taking the foot off the clutch slowly will stop this from happening. Stalling also happens when the driver forgets to depress the clutch and/or change to neutral while coming to a stop. Stalling can be dangerous, especia ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |