|

Hydraulically-actuated

A hydraulic cylinder (also called a linear hydraulic motor) is a mechanical actuator that is used to give a unidirectional force through a unidirectional stroke. It has many applications, notably in construction equipment (engineering vehicles), manufacturing machinery, elevators, and civil engineering. A hydraulic cylinder is a hydraulic actuator that provides linear motion when hydraulic energy is converted into mechanical movement. It can be likened to a muscle in that, when the hydraulic system of a machine is activated, the cylinder is responsible for providing the motion. Operation Hydraulic cylinders get their power from pressurized hydraulic fluid, which is incompressible. Typically oil is used as hydraulic fluid. The hydraulic cylinder consists of a cylinder barrel, in which a piston connected to a piston rod moves back and forth. The barrel is closed on one end by the cylinder bottom (also called the cap) and the other end by the cylinder head (also called the gland ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Trunnion

A trunnion () is a cylinder, cylindrical Boss (engineering), protrusion used as a mounting or pivoting point. First associated with cannons, they are an important military development. In mechanical engineering (see the Trunnion#Trunnion bearings, trunnion bearing section below), it is one part of a rotating joint where a shaft (the trunnion) is inserted into (and turns inside) a full or partial cylinder. Medieval history In a cannon, the trunnions are two projections cast just forward of the center of mass of the cannon and fixed to a two-wheeled movable gun carriage. With the creation of larger and more powerful siege guns in the early 15th century, a new way of mounting them became necessary. Stouter gun carriages were created with reinforced wheels, axles, and “trails” which extended behind the gun. Guns were now as long as in length and they were capable of shooting iron projectiles weighing from . When discharged, these wrought iron balls were comparable in range ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Nitrile Rubber

Nitrile rubber, also known as nitrile butadiene rubber, NBR, Buna-N, and acrylonitrile butadiene rubber, is a synthetic rubber derived from acrylonitrile (ACN) and butadiene. Trade names include Perbunan, Nipol, Krynac and Europrene. This rubber is unusual in being resistant to oil, fuel, and other chemicals. NBR is used in the automotive and aeronautical industry to make fuel and oil handling hoses, seals, grommets, and self-sealing fuel tanks. It is also used in the food service, medical, and nuclear industries to make protective gloves. NBR's stability at temperatures from makes it an ideal material for aeronautical applications. Nitrile butadiene is also used to produce moulded goods, footwear, adhesives, sealants, sponges, expanded foams, and floor mats. Its Resilience_(materials_science), resilience makes NBR a useful material for disposable lab, cleaning, and examination gloves. Nitrile rubber is more resistant than natural rubber to oils and acids, and has superior streng ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Operating Temperature

An operating temperature is the allowable temperature range of the local ambient environment at which an electrical or mechanical device operates. The device will operate effectively within a specified temperature range which varies based on the device function and application context, and ranges from the minimum operating temperature to the maximum operating temperature (or peak operating temperature). Outside this range of safe operating temperatures the device may fail. It is one component of reliability engineering. Similarly, biological systems have a viable temperature range, which might be referred to as an "operating temperature". Ranges Most semiconductor devices are manufactured in several temperature grades. Broadly accepted grades are: *Commercial: 0 °C to 70 °C () *Industrial: −40 °C to 85 °C () *Military: −55 °C to 125 °C () Nevertheless, each manufacturer defines its own temperature grades so designers must pay attention to ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Elastomer

An elastomer is a polymer with viscoelasticity (i.e. both viscosity and elasticity) and with weak intermolecular forces, generally low Young's modulus (E) and high failure strain compared with other materials. The term, a portmanteau of ''elastic polymer'', is often used interchangeably with ''rubber'', although the latter is preferred when referring to vulcanisates. Each of the monomers which link to form the polymer is usually a compound of several elements among carbon, hydrogen, oxygen and silicon. Elastomers are amorphous polymers maintained above their glass transition temperature, so that considerable molecular reconformation is feasible without breaking of covalent bonds. Rubber-like solids with elastic properties are called elastomers. Polymer chains are held together in these materials by relatively weak intermolecular bonds, which permit the polymers to stretch in response to macroscopic stresses. Elastomers are usually thermosets (requiring vulcanization ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

O-ring

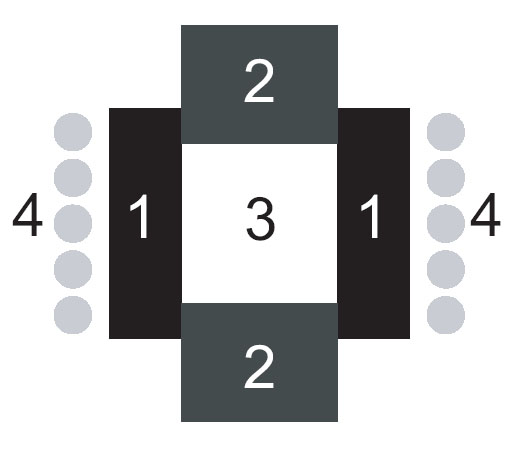

An O-ring, also known as a packing or a toric joint, is a mechanical gasket in the shape of a torus; it is a loop of elastomer with a round cross section (geometry), cross-section, designed to be seated in a groove and compressed during assembly between two or more parts, forming a seal (mechanical), seal at the interface. The O-ring may be used in static applications or in dynamic applications where there is relative motion between the parts and the O-ring. Dynamic examples include rotating pump shafts and hydraulic cylinder pistons. Static applications of O-rings may include fluid or gas sealing applications in which: (1) the O-ring is compressed resulting in zero clearance, (2) the O-ring material is vulcanized solid such that it is permeation, impermeable to the fluid or gas, and (3) the O-ring material is resistant to degradation by the fluid or gas. The wide range of potential liquids and gases that need to be sealed has necessitated the development of a wide range of O-r ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Skiving (metalworking)

Skiving or scarfing is the process of cutting material off in slices, usually metal, but also Skiving (leathercraft), leather or laminates. Skiving can be used instead of rolling (metalworking), rolling the material to shape when the material must not be work hardening, work hardened, or must not shed minute slivers of metal later which is common in cold rolling processes. It can also be used to create fins on a block of metal, not shaving the part entirely off. In metalworking, skiving can be used to remove a thin dimension of material or to create thin slices in an existing material, such as heat sinks where a large amount of surface area is required relative to the volume of the piece of metal. The process involves moving the material past precision-profiled tools made to an exact shape, or past plain cutting tools. The tools are typically made of tungsten carbide-based compounds. It requires a minimum material feed rate to cut successfully. At speeds below those of metal plan ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Honing (metalworking)

Honing is an abrasive machining process that produces a surface integrity, precision surface on a metal workpiece by scrubbing an abrasive grinding stone or grinding wheel against it along a controlled path. Honing is primarily used to improve the geometric form of a surface, but can also improve the surface finish. Typical applications are the finishing of cylinder (engine), cylinders for internal combustion engines, air bearing spindle (tool), spindles and gears. There are many types of hones, but all consist of one or more abrasive stones that are held under pressure against the surface they are working on. Other similar processes are lapping and superfinishing. Honing machines A honing machine is a precision tool used in machining to improve the surface finish and dimensional accuracy of component. It operates by using abrasive honing tools, which rotate and reciprocate inside the components, typically a cylinder or bore. This process enhances the internal surface quality ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hot Pressing

Hot pressing is a high-pressure, low-strain-rate powder metallurgy process for forming of a powder or powder compact at a temperature high enough to induce sintering and creep processes. This is achieved by the simultaneous application of heat and pressure. Hot pressing is mainly used to fabricate hard and brittle materials. One large use is in the consolidation of diamond-metal composite cutting tools and technical ceramics. The densification works through particle rearrangement and plastic flow at the particle contacts. The loose powder or the pre-compacted part is in most of the cases filled to a graphite mould that allows induction or resistance heating up to temperatures of typically . Pressures of up to can be applied. Other great use is in the pressing of different types of polymers, but this is done with lower temperatures and pressures such as those found in the open source hot press. Within hot pressing technology, three distinctly different types of heating can be f ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Plywood

Plywood is a composite material manufactured from thin layers, or "plies", of wood veneer that have been stacked and glued together. It is an engineered wood from the family of manufactured boards, which include plywood, medium-density fibreboard (MDF), oriented strand board (OSB), and particle board (or chipboard). All plywoods bind resin and wood fibre sheets (cellulose cells are long, strong and thin) to form a composite material. The sheets of wood are stacked such that each layer has its grain set typically (see below) perpendicular to its adjacent layers. This alternation of the grain is called ''cross-graining'' and has several important benefits: it reduces the tendency of wood to split when nailed at the edges; it reduces thickness swelling and shrinkage, providing improved dimensional stability; and it makes the strength of the panel consistent across all directions. There is usually an odd number of plies, so that the sheet is balanced, that is, the surface layers ha ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Particle Board

Particle board, also known as particleboard or chipboard, is an engineered wood product, belonging to the wood-based panels, manufactured from wood chips and a synthetic, mostly formaldehyde-based resin or other suitable binder, which is pressed under a hot press, batch- or continuous- type, and produced. Particle board is often confused with oriented strand board (OSB, also known as flakeboard, or waferboard), a different type of fiberboard that uses machined wood flakes and offers more strength. Characteristics Particle board is cheaper, denser, and more uniform than conventional wood and plywood and is substituted for them when cost is more important than strength and appearance. Particleboard can be made more appealing by painting or the use of wood veneers on visible surfaces. Though it is denser than conventional wood, it is the lightest and weakest type of fiberboard, except for insulation board. Medium-density fibreboard and hardboard, also called high-density fibe ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hydraulic Bending Machine

Hydraulics () is a technology and applied science using engineering, chemistry, and other sciences involving the mechanical properties and use of liquids. At a very basic level, hydraulics is the liquid counterpart of pneumatics, which concerns gases. Fluid mechanics provides the theoretical foundation for hydraulics, which focuses on applied engineering using the properties of fluids. In its fluid power applications, hydraulics is used for the generation, control, and transmission of power by the use of pressurized liquids. Hydraulic topics range through some parts of science and most of engineering modules, and they cover concepts such as pipe flow, dam design, fluidics, and fluid control circuitry. The principles of hydraulics are in use naturally in the human body within the vascular system and erectile tissue. ''Free surface hydraulics'' is the branch of hydraulics dealing with free surface flow, such as occurring in rivers, canals, lakes, estuaries, and seas. Its sub-fi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |