|

Hot Air Leveling

HASL or HAL (for hot air (solder) leveling) is a type of finish used on printed circuit boards (PCBs). The PCB is typically dipped into a bath of molten solder so that all exposed copper surfaces are covered by solder. Excess solder is removed by passing the PCB between hot air knives. HASL can be applied with or without lead (Pb), but only lead-free HASL is RoHS compliant. Advantages of HASL * Excellent wetting during component soldering. * Avoids copper corrosion. Disadvantages of HASL * Low planarity on vertical levelers may make this surface finish unsuitable for use with fine pitch components. Improved planarity can be achieved using a horizontal leveler. * High thermal stress during the process may introduce defects into PCB. See also * Electroless Nickel Immersion Gold (ENIG) * Immersion Silver (IAg) * Organic Solderability Preservative (OSP) * Reflow soldering * Wave soldering Wave soldering is a bulk soldering process used in printed circuit board manu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Printed Circuit Board

A printed circuit board (PCB), also called printed wiring board (PWB), is a Lamination, laminated sandwich structure of electrical conduction, conductive and Insulator (electricity), insulating layers, each with a pattern of traces, planes and other features (similar to wires on a flat surface) Chemical milling, etched from one or more sheet layers of copper laminated onto or between sheet layers of a non-conductive substrate. PCBs are used to connect or Electrical wiring, "wire" Electronic component, components to one another in an electronic circuit. Electrical components may be fixed to conductive pads on the outer layers, generally by soldering, which both electrically connects and mechanically fastens the components to the board. Another manufacturing process adds Via (electronics), vias, metal-lined drilled holes that enable electrical interconnections between conductive layers, to boards with more than a single side. Printed circuit boards are used in nearly all e ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Solder

Solder (; North American English, NA: ) is a fusible alloy, fusible metal alloy used to create a permanent bond between metal workpieces. Solder is melted in order to wet the parts of the joint, where it adheres to and connects the pieces after cooling. Metals or alloys suitable for use as solder should have a lower melting point than the pieces to be joined. The solder should also be resistant to oxidative and corrosive effects that would degrade the joint over time. Solder used in making electrical connections also needs to have favorable electrical characteristics. Soft solder typically has a melting point range of , and is commonly used in electronics, plumbing, and sheet metal work. Alloys that melt between are the most commonly used. Soldering performed using alloys with a melting point above is called "hard soldering", "silver soldering", or brazing. In specific proportions, some alloys are eutectic — that is, the alloy's melting point is the lowest possible for a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Copper

Copper is a chemical element; it has symbol Cu (from Latin ) and atomic number 29. It is a soft, malleable, and ductile metal with very high thermal and electrical conductivity. A freshly exposed surface of pure copper has a pinkish-orange color. Copper is used as a conductor of heat and electricity, as a building material, and as a constituent of various metal alloys, such as sterling silver used in jewelry, cupronickel used to make marine hardware and coins, and constantan used in strain gauges and thermocouples for temperature measurement. Copper is one of the few metals that can occur in nature in a directly usable, unalloyed metallic form. This means that copper is a native metal. This led to very early human use in several regions, from . Thousands of years later, it was the first metal to be smelted from sulfide ores, ; the first metal to be cast into a shape in a mold, ; and the first metal to be purposely alloyed with another metal, tin, to create bronze, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Air Knife

An air knife is a tool used to blow off liquid or debris from products as they travel on conveyors. Air knives are normally used in manufacturing or as the first step in a recursive recycling process to separate lighter or smaller particles from other components for use in later or subsequent steps, post manufacturing parts drying and conveyor cleaning, part of component cleaning. The knife consists of a high-intensity, uniform sheet of laminar airflow sometimes known as streamline flow. An industrial air knife is a pressurized air plenum containing a series of holes or continuous slots through which pressurized air exits in a laminar flow pattern. The exit air velocity then creates an impact air velocity onto the surface of whatever object the air is directed. This impact air velocity can range from a gentle breeze to greater than Mach 0.6 (40,000 ft/min) to alter the surface of a product without mechanical contact. Air knives remove liquids, control the thickness of li ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Lead

Lead () is a chemical element; it has Chemical symbol, symbol Pb (from Latin ) and atomic number 82. It is a Heavy metal (elements), heavy metal that is density, denser than most common materials. Lead is Mohs scale, soft and Ductility, malleable, and also has a relatively low melting point. When freshly cut, lead is a shiny gray with a hint of blue. It tarnishes to a dull gray color when exposed to air. Lead has the highest atomic number of any stable nuclide, stable element and three of its isotopes are endpoints of major nuclear decay chains of heavier elements. Lead is a relatively unreactive post-transition metal. Its weak metallic character is illustrated by its Amphoterism, amphoteric nature; lead and lead oxides react with acids and base (chemistry), bases, and it tends to form covalent bonds. Lead compounds, Compounds of lead are usually found in the +2 oxidation state rather than the +4 state common with lighter members of the carbon group. Exceptions are mostly limited ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Lead-free

The Restriction of Hazardous Substances Directive 2002/95/EC (RoHS 1), short for Directive on the restriction of the use of certain hazardous substances in electrical and electronic equipment, was adopted in February 2003 by the European Union. The initiative was to limit the amount of hazardous chemicals in electronics. The RoHS 1 directive took effect on 1 July 2006, and is required to be enforced and became a law in each member state. This directive restricts (with exceptions) the use of ten hazardous materials in the manufacture of various types of electronic and electrical equipment. In addition to the exceptions, there are exclusions for products such as solar panels. It is closely linked with the Waste Electrical and Electronic Equipment Directive (WEEE) 2002/96/EC (now superseded) which sets collection, recycling and recovery targets for electrical goods and is part of a legislative initiative to solve the problem of huge amounts of toxic electronic waste. In sp ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Wetting

Wetting is the ability of a liquid to displace gas to maintain contact with a solid surface, resulting from intermolecular interactions when the two are brought together. These interactions occur in the presence of either a gaseous phase or another liquid phase not miscible with the wetting liquid. The degree of wetting (wettability) is determined by a force balance between adhesive and cohesive forces. There are two types of wetting: non-reactive wetting and reactive wetting. Wetting is important in the bonding or adherence of two materials. The wetting power of a liquid, and surface forces which control wetting, are also responsible for related effects, including capillary effects. Surfactants can be used to increase the wetting power of liquids such as water. Wetting has gained increasing attention in nanotechnology and nanoscience research, following the development of nanomaterials over the past two decades (i.e., graphene, carbon nanotube, boron nitride nanomesh). ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Electroless Nickel Immersion Gold

Electroless nickel immersion gold (ENIG or ENi/IAu), also known as immersion gold (Au), chemical Ni/Au or soft gold, is a metal plating process used in the manufacture of printed circuit boards (PCBs), to avoid oxidation and improve the solderability of copper contacts and plated through-holes. It consists of an electroless nickel plating, covered with a thin layer of gold, which protects the nickel from oxidation. The gold is typically applied by quick immersion in a solution containing gold salts such as gold sulfites with an example being Na3Au(SO3)2 or potassium gold cyanide (KAu(CN)2), with a complexing agent and a stabilizer. The bath needs to be replaced after a certain number of uses and the composition of the gold bath may be patented. Some of the nickel is oxidized to while the gold is reduced to metallic state. A variant of this process adds a thin layer of electroless palladium over the nickel, a process known by the acronym ENEPIG. ENIG can be applied before or aft ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Organic Solderability Preservative

Organic solderability preservative or OSP is a method for coating of printed circuit boards. It uses a water-based organic compound that selectively bonds to copper and protects the copper until soldering. Compared to the traditional HASL process, the OSP process is widely used in the electronics manufacturing industry because it does not require high-temperature treatment and significantly reduces the risk of metal corrosion, environmental impact and damage to electronic components. The basic principle of SP to form a protective layer against oxidation and corrosion by applying a layer consisting of a mixture of organic acids and nitrogen compounds, etc. The OSP process involves delicate steps designed to ensure the uniformity and quality of the protective layer. Although environmentally friendly and suitable for microelectronic manufacturing, the complexity of the process requires strict control of the composition and quality of the coating agent to guarantee consistent board pe ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Reflow Soldering

Reflow soldering is a process in which a solder paste (a sticky mixture of powdered solder and flux (metallurgy), flux) is used to temporarily attach anywhere from one to thousands of tiny electrical components to their contact pads, after which the entire assembly is subjected to controlled heat. The solder paste reflows in a molten state, creating permanent solder joints. Heating may be accomplished by passing the assembly through a reflow oven, under an Infrared heater, infrared lamp, or (mainly for prototyping) by soldering individual joints with a hot air pencil. Reflow soldering with long industrial convection ovens is the preferred method of soldering surface mount technology (SMT) components to a printed circuit board (PCB). Each segment of the oven has a regulated temperature, according to the specific thermal requirements of each assembly. Reflow ovens meant specifically for the soldering of surface mount components may also be used for Through-hole technology, throu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

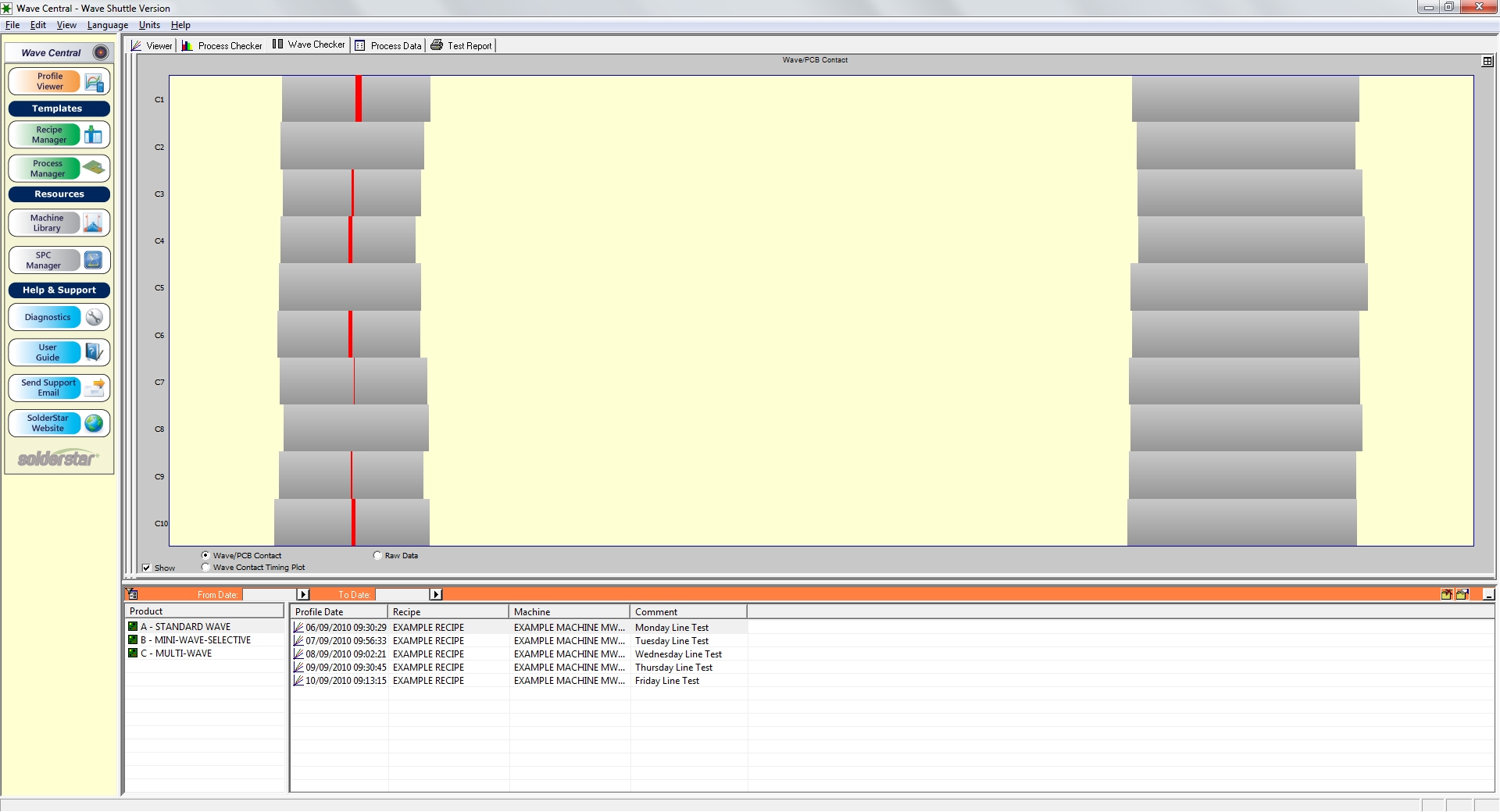

Wave Soldering

Wave soldering is a bulk soldering process used in printed circuit board manufacturing. The circuit board is passed over a pan of molten solder in which a pump produces an upwelling of solder that looks like a standing wave. As the circuit board makes contact with this wave, the components become soldered to the board. Wave soldering is used for both through-hole printed circuit assemblies, and surface mount. In the latter case, the components are glued onto the surface of a printed circuit board (PCB) by placement equipment, before being run through the molten solder wave. Wave soldering is mainly used in soldering of through hole components. As through-hole components have been largely replaced by surface mount components, wave soldering has been supplanted by reflow soldering methods in many large-scale electronics applications. However, there is still significant wave soldering where surface-mount technology (SMT) is not suitable (e.g., large power devices and high pi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |