|

Heat Sink

A heat sink (also commonly spelled heatsink) is a passive heat exchanger that transfers the heat generated by an electronic or a mechanical device to a fluid medium, often air or a liquid coolant, where it is thermal management (electronics), dissipated away from the device, thereby allowing regulation of the device's temperature. In computers, heat sinks computer cooling, are used to cool central processing unit, CPUs, graphics processing unit, GPUs, and some chipsets and RAM modules. Heat sinks are used with other high-power semiconductor devices such as Transistor#Other transistor types, power transistors and optoelectronics such as lasers and light-emitting diodes (LEDs), where the heat dissipation ability of the component itself is insufficient to moderate its temperature. A heat sink is designed to maximize its surface area in contact with the cooling medium surrounding it, such as the air. Air velocity, choice of material, protrusion design and surface treatment are fact ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

AMD Heatsink And Fan

Advanced Micro Devices, Inc. (AMD) is an American multinational corporation and technology company headquartered in Santa Clara, California and maintains significant operations in Austin, Texas. AMD is a Information technology, hardware and Fabless manufacturing, fabless company that designs and develops List of AMD processors, central processing units (CPUs), List of AMD graphics processing units, graphics processing units (GPUs), field-programmable gate arrays (FPGAs), System on a chip, system-on-chip (SoC), and high-performance computing, high-performance computer solutions. AMD serves a wide range of business and consumer markets, including gaming, data centers, artificial intelligence (AI), and embedded systems. AMD's main products include List of AMD microprocessors, microprocessors, motherboard chipsets, embedded processors, and List of AMD graphics processing units, graphics processors for Server (computing), servers, workstations, personal computers, and embedded syst ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Heat Reservoir

A thermal reservoir, also thermal energy reservoir or thermal bath, is a thermodynamic system with a heat capacity so large that the temperature of the reservoir changes relatively little when a significant amount of heat is added or extracted. As a conceptual simplification, it effectively functions as an infinite pool of thermal energy at a given, constant temperature. Since it can act as an inertial source and sink of heat, it is often also referred to as a heat reservoir or heat bath. Lakes, oceans and rivers often serve as thermal reservoirs in geophysical processes, such as the weather. In atmospheric science, large air mass In meteorology, an air mass is a volume of air defined by its temperature and humidity. Air masses cover many hundreds or thousands of square miles, and adapt to the characteristics of the surface below them. They are classified according to ...es in the atmosphere often function as thermal reservoirs. Since the temperature of a thermal rese ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tempering (metallurgy)

Tempering is a process of heat treating, which is used to increase the toughness of iron-based alloys. Tempering is usually performed after Hardening (metallurgy), hardening, to reduce some of the excess hardness, and is done by heating the metal to some temperature below the critical point (thermodynamics), critical point for a certain period of time, then allowing it to cool in still air. The exact temperature determines the amount of hardness removed, and depends on both the specific composition of the alloy and on the desired properties in the finished product. For instance, very hard tools are often tempered at low temperatures, while spring (device), springs are tempered at much higher temperatures. Introduction Tempering is a heat treatment technique applied to ferrous alloys, such as steel or cast iron, to achieve greater toughness by decreasing the hardness of the alloy. The reduction in hardness is usually accompanied by an increase in ductility, thereby decreasing the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

6063 Aluminium Alloy

AA 6063 is an aluminium alloy, with magnesium and silicon as the alloying elements. The standard controlling its composition is maintained by The Aluminum Association. It has generally good mechanical properties and is heat treatable and weldable. It is similar to the British aluminium alloy HE9. 6063 is the most common alloy used for aluminium extrusion. It allows complex shapes to be formed with very smooth surfaces fit for anodizing and is popular for visible architectural applications such as window frames, door frames, roofs, and sign frames. Applications requiring higher strength typically use 6061 or 6082 instead. Chemical composition The alloy composition of 6063 is: Mechanical properties The mechanical properties of 6063 depend greatly on the temper, or heat treatment, of the material. 6063-O Un-heat-treated 6063 has maximum tensile strength no more than , and no specified maximum yield strength In materials science and engineering, the yield point ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

6061 Aluminium Alloy

6061 aluminium alloy ( Unified Numbering System (UNS) designation A96061) is a precipitation-hardened aluminium alloy, containing magnesium and silicon as its major alloying elements. Originally called "Alloy 61S", it was developed in 1935. It has good mechanical properties, exhibits good weldability, and is very commonly extruded (second in popularity only to 6063). It is one of the most common alloys of aluminium for general-purpose use. It is commonly available in pre-tempered grades such as 6061-O (annealed), tempered grades such as 6061-T6 (solutionized and artificially aged) and 6061-T651 (solutionized, stress-relieved stretched and artificially aged). Chemical composition 6061 Aluminium alloy composition by mass: Properties The mechanical properties of 6061 greatly depend on the temper, or heat treatment, of the material. [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

1050 Aluminium Alloy

1050 aluminium alloy is an aluminium-based alloy in the "commercially pure" wrought family (1000 or 1xxx series ). As a wrought alloy, it is not used in castings. Instead, it is usually formed by extrusion or rolling. It is commonly used in the electrical and chemical industries, on account of having high electrical conductivity, corrosion resistance, and workability. 1050 alloy is also sometimes used for the manufacture of heat sinks, since it has a higher thermal conductivity than other alloys. It has low mechanical strength compared to more significantly alloyed metals. It can be strengthened by cold working, but not by heat treatment.Marks' Standard handbook for Mechanical Engineers, 8th Ed., McGraw Hill, p. 6-50 Alternate names and designations include Al99.5, 3.0255, and A91050. It is described in the following standards: [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Aluminium Alloys

An aluminium alloy (British English, UK/International Union of Pure and Applied Chemistry, IUPAC) or aluminum alloy (North American English, NA; see American and British English spelling differences, spelling differences) is an alloy in which aluminium (Al) is the predominant metal. The typical alloying elements are copper, magnesium, manganese, silicon, tin, nickel and zinc. There are two principal classifications, namely casting alloys and wrought alloys, both of which are further subdivided into the categories Heat treating, heat-treatable and non-heat-treatable. About 85% of aluminium is used for wrought products, for example rolled plate, foils and extrusions. Cast aluminium alloys yield cost-effective products due to their low melting points, although they generally have lower Ultimate tensile strength, tensile strengths than wrought alloys. The most important cast aluminium alloy system is Silumin, Al–Si, where the high levels of silicon (4–13%) contribute to give good ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

2N3055

The 2N3055 is a silicon NPN power transistor intended for general purpose applications. It was introduced in the early 1960s by RCA using a hometaxial power transistor process, transitioned to an epitaxial base in the mid-1970s. Its numbering follows the JEDEC standard. It is a transistor type of enduring popularity. Specifications The exact performance characteristics depend on the manufacturer and date; before the move to the epitaxial base version in the mid-1970s the fT could be as low as 0.8 MHz, for example. Packaged in a TO-3 case style, it is a 15 amp, 60 volt (or more, see below), 115 watt power transistor with a β (forward current gain) of 20 to 70 at a collector current of 4 A (this may be over 100 when testing at lower currents). It often has a transition frequency of around 3.0 MHz and 6 MHz is typical for the 2N3055A; at this frequency the calculated current gain (beta) drops to 1, indicating the transistor can no longer provide us ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

TO-92

The TO-92 is a widely used style of semiconductor package mainly used for transistors. The case is often made of epoxy or plastic, and offers compact size at a very low cost. History and origin The JEDEC TO-92 descriptor is derived from the original full name for the package: Transistor Outline Package, Case Style 92. The package is also known by the designation Small-outline transistor#SOT54, SOT54. By 1966 the package was being used by Motorola for their 2N3904 devices among others. Construction and orientation The case is molded around the transistor elements in two parts; the face is flat, usually bearing a machine-printed part number (some early examples had the part number printed on the top surface instead). The back is semi-circularly-shaped. A line of moulding flash from the injection-moulding process can be seen around the case. The leads protrude from the bottom of the case. When looking at the face of the transistor, the leads are commonly configured from left-to- ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

TO-3

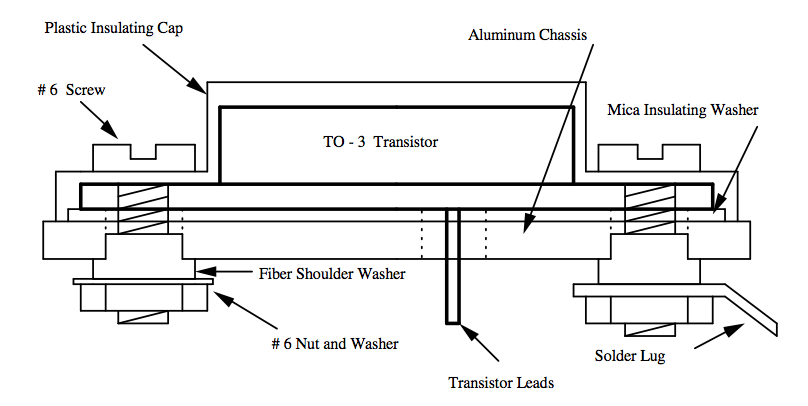

In electronics, TO-3 is a designation for a standardized metal semiconductor package used for power semiconductors, including transistors, silicon controlled rectifiers, and, integrated circuits. ''TO'' stands for "Transistor Outline" and relates to a series of technical drawings produced by JEDEC. The TO-3 case has a flat surface which can be attached to a heatsink, normally via a thermally conductive but electrically insulating washer. The design originated at Motorola around 1955 from a group headed by Virgil E. Bottom, Dr. Virgil E. Bottom. who was director of research of the Motorola Semiconductor Division. The first use of this design was for the germanium alloy-junction transistor, alloy-junction power transistor 2N176 – the first power transistor to be put into quantity production. The lead spacing was originally intended to allow plugging the device into a then-common tube socket. Typical applications The metal package can be attached to a heat sink, making it suitabl ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Thermal Resistance

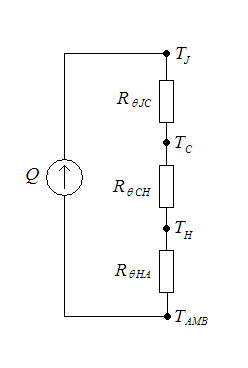

In heat transfer, thermal engineering, and thermodynamics, thermal conductance and thermal resistance are fundamental concepts that describe the ability of materials or systems to conduct heat and the opposition they offer to the heat current. The ability to manipulate these properties allows engineers to control temperature gradient, prevent thermal shock, and maximize the efficiency of thermal systems. Furthermore, these principles find applications in a multitude of fields, including materials science, mechanical engineering, electronics, and energy management. Knowledge of these principles is crucial in various scientific, engineering, and everyday applications, from designing efficient temperature control, thermal insulation, and thermal management in industrial processes to optimizing the performance of electronic devices. Thermal conductance (''G'') measures the ability of a material or system to conduct heat. It provides insights into the ease with which heat can pa ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Power Transistor Heat Sinks

Power may refer to: Common meanings * Power (physics), meaning "rate of doing work" ** Engine power, the power put out by an engine ** Electric power, a type of energy * Power (social and political), the ability to influence people or events Mathematics, science and technology Computing * IBM POWER (software), an IBM operating system enhancement package * IBM POWER architecture, a RISC instruction set architecture * Power ISA, a RISC instruction set architecture derived from PowerPC * IBM Power microprocessors, made by IBM, which implement those RISC architectures * Power.org, a predecessor to the OpenPOWER Foundation Mathematics * Exponentiation, "''x'' to the power of ''y''" * Power function * Power of a point * Statistical power Physics * Magnification, the factor by which an optical system enlarges an image * Optical power, the degree to which a lens converges or diverges light Social sciences and politics * Economic power, encompassing several concepts that economists use ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |