|

Glass Cutter

A glass cutter is a tool used to make a shallow score in one surface of a piece of glass (normally a flat one) that is to be broken in two pieces, for example to fit a window. The scoring makes a split in the surface of the glass which encourages the glass to break along the score. This is not to be confused with the tools used to make cut glass objects. Regular, annealed glass can be broken apart this way but not tempered glass as the latter tends to shatter rather than breaking cleanly into two pieces. History In the Middle Ages, glass was cut with a heated and sharply pointed iron rod. The red hot point was drawn along the moistened surface of the glass causing it to snap apart. Fractures created in this way were not very accurate and the rough pieces had to be chipped or "grozed" down to more exact shapes with a hooked tool called a grozing iron. Between the 14th and 16th centuries, starting in Italy, a diamond-tipped cutter became prevalent which allowed for more precis ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Glass

Glass is an amorphous (non-crystalline solid, non-crystalline) solid. Because it is often transparency and translucency, transparent and chemically inert, glass has found widespread practical, technological, and decorative use in window panes, tableware, and optics. Some common objects made of glass are named after the material, e.g., a Tumbler (glass), "glass" for drinking, "glasses" for vision correction, and a "magnifying glass". Glass is most often formed by rapid cooling (quenching) of the Melting, molten form. Some glasses such as volcanic glass are naturally occurring, and obsidian has been used to make arrowheads and knives since the Stone Age. Archaeological evidence suggests glassmaking dates back to at least 3600 BC in Mesopotamia, Ancient Egypt, Egypt, or Syria. The earliest known glass objects were beads, perhaps created accidentally during metalworking or the production of faience, which is a form of pottery using lead glazes. Due to its ease of formability int ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cut Glass

Cut glass or cut-glass is a technique and a style of decorating glass. For some time the style has often been produced by other techniques such as the use of Molding (process), moulding, but the original technique of cutting glass on an abrasive wheel is still used in luxury products. On glassware vessels, the style typically consists of furrowed faces at angles to each other in complicated patterns, while for lighting fixtures, the style consists of flat or curved facets on small hanging pieces, often all over. Historically, cut glass was shaped using "coldwork" techniques of grinding or drilling, applied as a secondary stage to a piece of glass made by conventional processes such as glassblowing. Today, the glass is often mostly or entirely shaped in the initial process by using a mould (pressed glass), or imitated in clear plastic. Traditional hand-cutting continues, but gives a much more expensive product. Lead glass has long been misleadingly called "crystal" by the indu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Annealed Glass

Annealing is a process of slowly cooling hot glass objects after they have been formed, to relieve residual internal stresses introduced during manufacture. Especially for smaller, simpler objects, annealing may be incidental to the process of manufacture, but in larger or more complex products it commonly demands a special process of annealing in a temperature-controlled kiln known as a lehr. Annealing of glass is critical to its durability. Glass that has not been properly annealed retains thermal stresses caused by quenching, which will indefinitely decrease the strength and reliability of the product. Inadequately annealed glass is likely to crack or shatter when subjected to relatively small temperature changes or to mechanical shock or stress. It even may fail spontaneously. To anneal glass, it is necessary to heat it to its annealing temperature, at which its viscosity, η, drops to 1013 Poise (1013 dyne-second/cm2). For most kinds of glass, this annealing temperature i ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tempered Glass

Tempered or toughened glass is a type of safety glass processed by controlled heat treatment, thermal or chemical treatments to increase its strength compared with normal glass. Tempering puts the outer surfaces into Compression (physics), compression and the interior into Tension (physics), tension. Such stresses cause the glass, when broken, to shatter into small granular chunks instead of splintering into large jagged shards as ordinary annealing (glass), annealed glass does. These smaller, granular chunks are less likely to cause deep penetration when forced into the surface of an object (e.g. by gravity, by wind, by falling onto them, etc.) compared to larger, jagged shards because the reduction in both the mass and the maximum dimension of a glass fragment corresponds with a reduction in both the momentum and the penetration depth of the glass fragment. Tempered glass is used for its safety and strength in a variety of applications, including passenger vehicle windows (ap ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Middle Ages

In the history of Europe, the Middle Ages or medieval period lasted approximately from the 5th to the late 15th centuries, similarly to the post-classical period of global history. It began with the fall of the Western Roman Empire and transitioned into the Renaissance and the Age of Discovery. The Middle Ages is the middle period of the three traditional divisions of Western history: classical antiquity, the medieval period, and the modern period. The medieval period is itself subdivided into the Early, High, and Late Middle Ages. Population decline, counterurbanisation, the collapse of centralised authority, invasions, and mass migrations of tribes, which had begun in late antiquity, continued into the Early Middle Ages. The large-scale movements of the Migration Period, including various Germanic peoples, formed new kingdoms in what remained of the Western Roman Empire. In the 7th century, North Africa and the Middle East—once part of the Byzantine Empire� ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

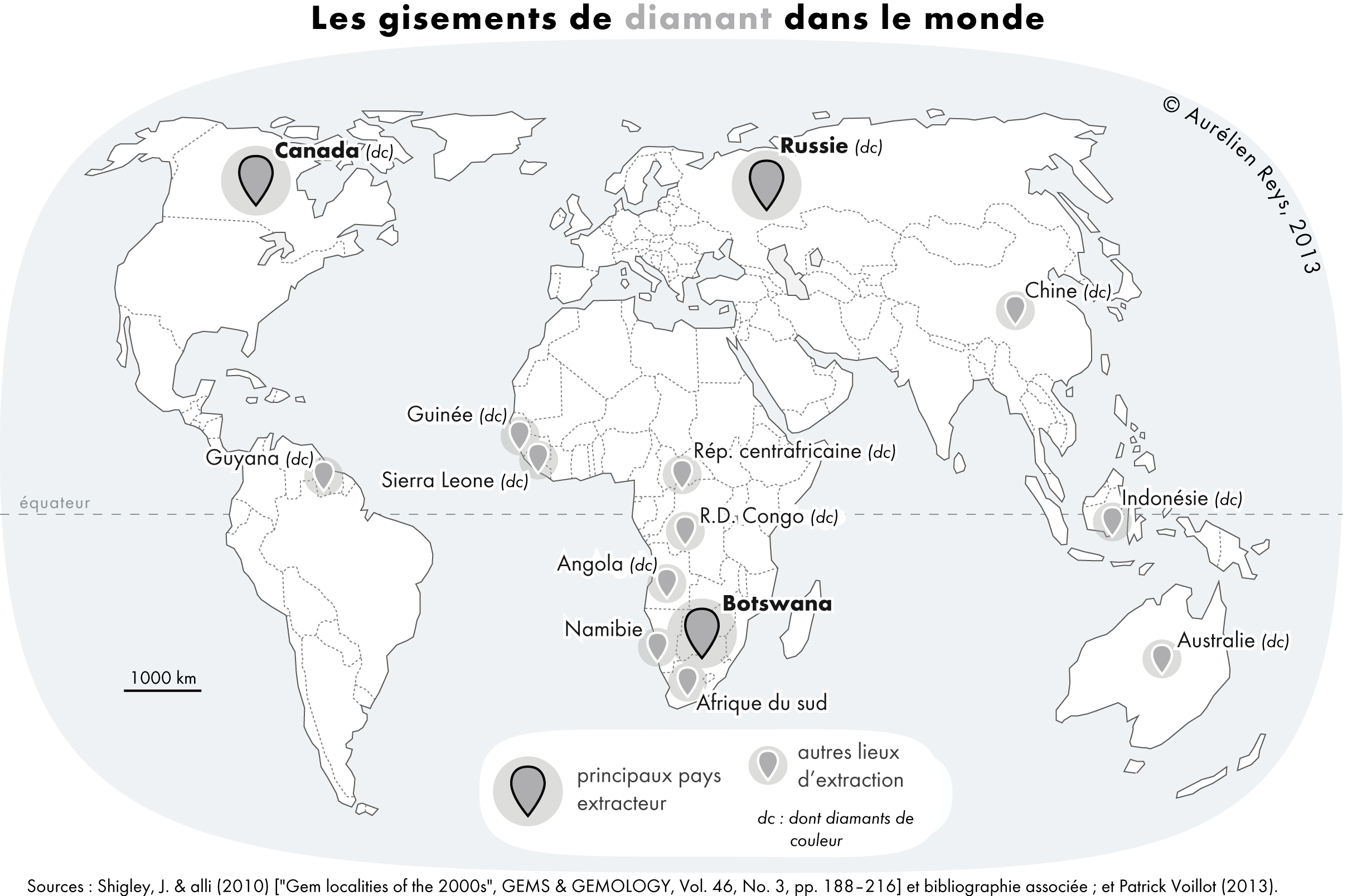

Diamond

Diamond is a Allotropes of carbon, solid form of the element carbon with its atoms arranged in a crystal structure called diamond cubic. Diamond is tasteless, odourless, strong, brittle solid, colourless in pure form, a poor conductor of electricity, and insoluble in water. Another solid form of carbon known as graphite is the Chemical stability, chemically stable form of carbon at Standard temperature and pressure, room temperature and pressure, but diamond is metastable and converts to it at a negligible rate under those conditions. Diamond has the highest Scratch hardness, hardness and thermal conductivity of any natural material, properties that are used in major industrial applications such as cutting and polishing tools. Because the arrangement of atoms in diamond is extremely rigid, few types of impurity can contaminate it (two exceptions are boron and nitrogen). Small numbers of lattice defect, defects or impurities (about one per million of lattice atoms) can color ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hardened Steel

The term hardened steel is often used for a plain-carbon steel, medium or high carbon steel that has been given heat treatment and then quenching followed by tempering (metallurgy), tempering. The quenching results in the formation of metastable martensite, the fraction of which is reduced to the desired amount during tempering. This is the most common state for finished articles such as tools and machine parts. In contrast, the same steel composition in annealing (metallurgy), annealed state is softer, as required for forming and machining. Depending on the temperature and composition of the steel, it can be hardened or softened. To make steel harder, it must be heated to very high temperatures. The final result of exactly how hard the steel becomes depends on the amount of carbon present in the metal. Only steel that is high in carbon can be hardened and tempered. If a metal does not contain the necessary quantity of carbon, then its crystalline structure cannot be broken, and the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

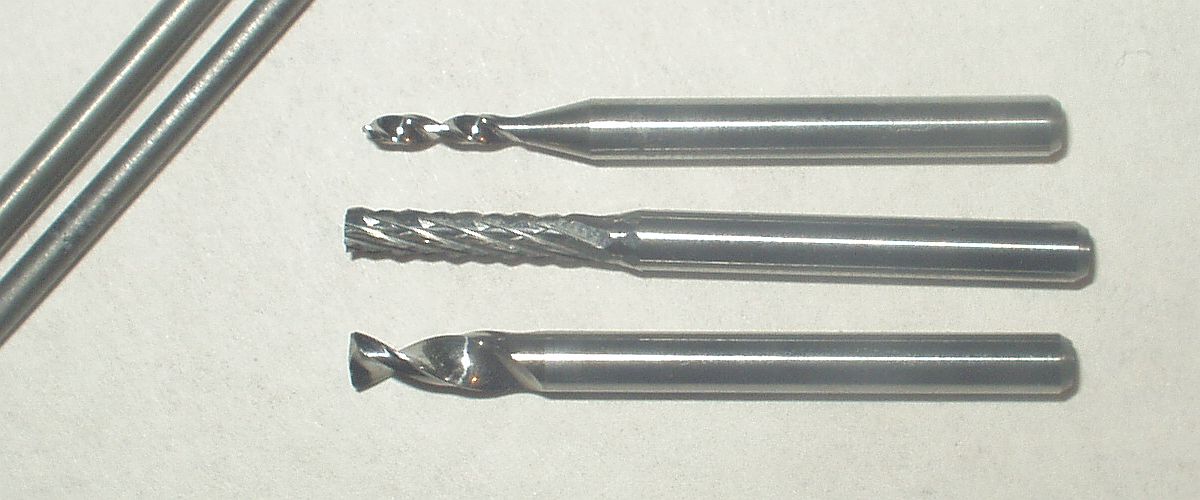

Tungsten Carbide

Tungsten carbide (chemical formula: ) is a carbide containing equal parts of tungsten and carbon atoms. In its most basic form, tungsten carbide is a fine gray powder, but it can be pressed and formed into shapes through sintering for use in industrial machinery, engineering facilities, molding blocks, cutting tools, chisels, abrasives, armor-piercing bullets and jewelry. Tungsten carbide is approximately three times as stiff as steel, with a Young's modulus of approximately 530–700 GPa, and is twice as dense as steel. It is comparable with corundum (α- ) in hardness, approaching that of a diamond, and can be polished and finished only with abrasives of superior hardness such as cubic boron nitride and diamond. Tungsten carbide tools can be operated at cutting speeds much higher than high-speed steel (a special steel blend for cutting tools). Tungsten carbide powder was first synthesized by H. Moissan in 1893, and the industrial production of the cemented form starte ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Float Glass

Float glass is a sheet of glass made by floating molten glass on a bed of molten metal of a low melting point, typically tin, although lead was used for the process in the past. This method gives the sheet uniform thickness and a very flat surface. The float glass process is also known as the Pilkington process, named after the British glass manufacturer Pilkington, which pioneered the technique in the 1950s at their production site in St Helens, Merseyside. Modern windows are usually made from float glass, though Corning Incorporated uses the overflow downdraw method. Most float glass is soda–lime glass, although relatively minor quantities of specialty borosilicate and flat panel display glass are also produced using the float glass process. History Until the 16th century, window glass or other flat glass was generally cut from large discs (or rondels) of crown glass. Larger sheets of glass were made by blowing large cylinders which were cut open and flattened, t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cutting

Cutting is the separation or opening of a physical object, into two or more portions, through the application of an acutely directed force. Implements commonly used for wikt:cut, cutting are the knife and saw, or in medicine and science the scalpel and microtome. However, any sufficiently sharp object is capable of cutting if it has a hardness sufficiently larger than the object being cut, and if it is applied with sufficient force. Even liquids can be used to cut things when applied with sufficient force (see water jet cutter). Cutting is a compression (physical), compressive and shearing (physics), shearing phenomenon, and occurs only when the total stress (physics), stress generated by the cutting implement exceeds the ultimate Strength of materials, strength of the material of the object being cut. The simplest applicable equation is: :\text = or \tau=\frac The stress generated by a cutting implement is directly proportional to the force with which it is applied, and ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Water Jet Cutter

A water jet cutter, also known as a water jet or waterjet, is an industrial tool capable of cutting a wide variety of materials using an extremely high-pressure jet of water, or a mixture of water and an abrasive substance. The term abrasive jet refers specifically to the use of a mixture of water and an abrasive to cut hard materials such as metal, stone or glass, while the terms pure waterjet and water-only cutting refer to waterjet cutting without the use of added abrasives, often used for softer materials such as wood or rubber. Waterjet cutting is often used during the fabrication of machine parts. It is the preferred method when the materials being cut are sensitive to the high temperatures generated by other methods; examples of such materials include plastic and aluminium. Waterjet cutting is used in various industries, including mining and aerospace, for cutting, shaping, and reamer, reaming. History Waterjet While using high-pressure water for erosion dates bac ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |