|

Fuel Line

A fuel line is a hose or pipe used to transfer fuel from one point in a vehicle to another. The United States Environmental Protection Agency defines a fuel line as "all hoses or tubing designed to contain liquid fuel or fuel vapor. This includes all hoses or tubing for the filler neck, for connections between dual fuel tanks, and for connecting a carbon canister to the fuel tank. This does not include hoses or tubing for routing crankcase vapors to the engine's intake or any other hoses or tubing that are open to the atmosphere." Materials Rubber Most vehicles have rubber fuel hoses connecting the fuel pipes on the chassis to the fuel pump or carburetor on the engine. Rubber hoses are flexible and can be cut to length as required, but they have a tendency to perish over time and can rub through if not properly secured. Plastic More modern vehicles may be fitted with fuel lines made of plastic, typically nylon. Plastic fuel lines do not perish and are lighter than metal ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fuel Line A340 To APU

A fuel is any material that can be made to react with other substances so that it releases energy as thermal energy or to be used for work. The concept was originally applied solely to those materials capable of releasing chemical energy but has since also been applied to other sources of heat energy, such as nuclear energy (via nuclear fission and nuclear fusion). The heat energy released by reactions of fuels can be converted into mechanical energy via a heat engine. Other times, the heat itself is valued for warmth, cooking, or industrial processes, as well as the illumination that accompanies combustion. Fuels are also used in the cells of organisms in a process known as cellular respiration, where organic molecules are oxidized to release usable energy. Hydrocarbons and related organic molecules are by far the most common source of fuel used by humans, but other substances, including radioactive metals, are also utilized. Fuels are contrasted with other substances or de ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Carburetor

A carburetor (also spelled carburettor or carburetter) is a device used by a gasoline internal combustion engine to control and mix air and fuel entering the engine. The primary method of adding fuel to the intake air is through the Venturi effect or Bernoulli's principle or with a Pitot tube in the main metering circuit, though various other components are also used to provide extra fuel or air in specific circumstances. Since the 1990s, carburetors have been largely replaced by fuel injection for cars and trucks, but carburetors are still used by some small engines (e.g. lawnmowers, generators, and concrete mixers) and motorcycles. In addition, they are still widely used on piston-engine–driven aircraft. Diesel engines have always used fuel injection instead of carburetors, as the compression-based combustion of diesel requires the greater precision and pressure of fuel injection. Etymology The term ''carburetor'' is derived from the verb ''carburet'', which means "to ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

List Of Auto Parts

This is a list of auto parts, which are manufactured components of automobiles. This list reflects both fossil-fueled cars (using internal combustion engine An internal combustion engine (ICE or IC engine) is a heat engine in which the combustion of a fuel occurs with an oxidizer (usually air) in a combustion chamber that is an integral part of the working fluid flow circuit. In an internal comb ...s) and electric vehicles; the list is not exhaustive. Many of these parts are also used on other motor vehicles such as trucks and buses. Car body and main parts Body components, including trim Vehicle door, Doors Windows Low voltage/auxiliary electrical system and electronics Audio/video devices Cameras Low voltage electrical supply system Gauge (instrument), Gauges and meters Ignition system Automotive lighting, Lighting and signaling system Sensors Starting system Electrical switches Wiring harnesses Miscellaneous ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

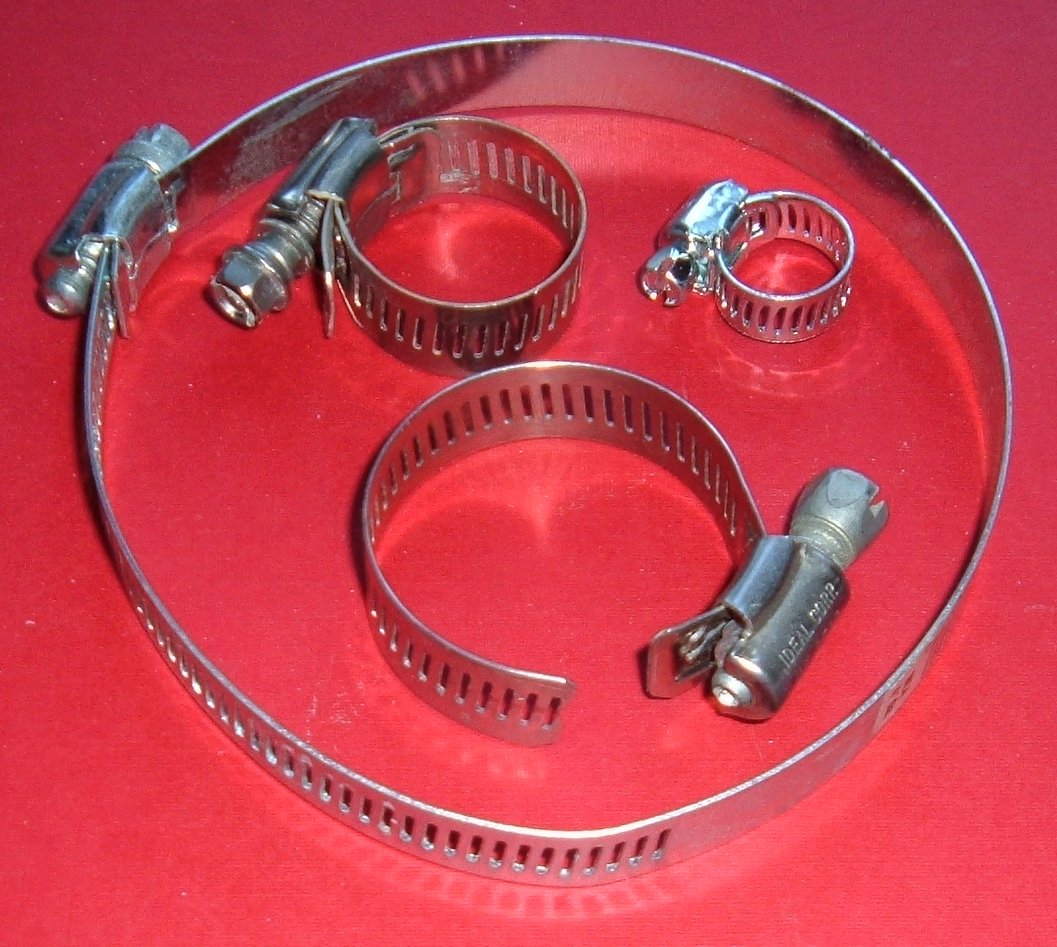

Hose Clamp

A hose clamp is a device used to attach and seal a hose (tubing), hose onto a fitting such as a barb (hose), barb or nipple (plumbing), nipple. Materials The core range of hose clamps on the open market are made from materials like stainless steel, which come in varying standards such as 304 (W4), 316 (W5) and 430 (W3). Stainless steel is classified into various grades based on its composition and properties, which are crucial for applications such as hose clamps. Hose clamps also come in W1 (zinc-plated steel) and mixed materials like zinc-plated & 430SS (W5). More modern iterations of the hose clamp include sees them being manufactured from polymer, which includes materials specifications such as nylon 66 (PA66) or polypropylene (PP) and nylon 12 (PA12). Types Many types are available, including : Screw/band (worm gear) clamps Screw clamps consist of a band, often galvanization, galvanized or stainless steel, into which a screw thread pattern has been cut or pressed. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Compression Fitting

A compression fitting is a fitting used in plumbing and electrical conduit systems to join two tubes or thin-walled pipes together. In instances where two pipes made of dissimilar materials are to be joined (most commonly PVC and copper), the fittings will be made of one or more compatible materials appropriate for the connection. Compression fittings for attaching tubing (piping) commonly have compression rings, called ''ferrules'' (American English) or ''olives'' (British English), in them, and are sometimes referred to as flareless fittings. There are also flare fittings that do not require ferrules/olives. Compression fittings are used extensively in hydraulic, gas, and water systems to enable the connection of tubing to threaded components like valves and tools. Compression fittings are suited to a variety of applications, such as plumbing systems in confined spaces where copper pipe would be difficult to solder without creating a fire hazard, and extensively in hydrau ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Front-engine, Rear-wheel-drive Layout

A front-engine, rear-wheel-drive layout (FR), also called Système Panhard is a powertrain layout with an engine in front and rear-wheel-drive, connected via a drive shaft. This arrangement, with the engine straddling the front axle, was the traditional automobile layout for most of the pre-1950s automotive mechanical projects. It is also used in trucks, pickups, and high-floor buses and school buses. Front mid-engine, rear-wheel-drive layout A front mid-engine, rear-wheel-drive layout (FMR) places the engine in the front half of the vehicle but ''behind'' the front axle, which likewise drives the rear wheels via a driveshaft. Shifting the engine's center of mass rearward aids in front/rear weight distribution and reduces the moment of inertia, both of which improve a vehicle's handling. FMR cars are often characterized by a long hood and front wheels that are pushed forward to the corners of the vehicle, close to the front bumper. 2+2-style grand tourers often have FMR l ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Front-engine, Front-wheel-drive Layout

In automotive design, a front-engine, front-wheel-drive (FWD) layout, or FF layout, places both the internal combustion engine and driven roadwheels at the front of the vehicle. Usage implications Historically, this designation was used regardless of whether the entire engine was behind the front axle line. In recent times, the manufacturers of some cars have added to the designation with the term ''Front mid-engine, front-wheel-drive layout, front-mid'' which describes a car in which the engine is in front of the passenger compartment but behind the front axle. The engine positions of most pre–World War II, World-War-II cars are ''front-mid'' or on the front axle. This layout is the most traditional form and remains a popular, practical design. The engine, which takes up a great deal of space, is packaged in a location passengers and luggage typically would not use. The main deficit is weight distribution—the heaviest component is at one end of the vehicle. Car handling ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Nylon

Nylon is a family of synthetic polymers characterised by amide linkages, typically connecting aliphatic or Polyamide#Classification, semi-aromatic groups. Nylons are generally brownish in color and can possess a soft texture, with some varieties exhibiting a silk-like appearance. As Thermoplastic, thermoplastics, nylons can be melt-processed into fibres, Thin film, films, and diverse shapes. The properties of nylons are often modified by blending with a variety of additives. Numerous types of nylon are available. One family, designated nylon-XY, is derived from diamines and dicarboxylic acids of carbon chain lengths X and Y, respectively. An important example is nylon-6,6 (). Another family, designated nylon-Z, is derived from amino acid, aminocarboxylic acids with carbon chain length Z. An example is nylon-[6]. Nylon polymers have extensive commercial applications, including uses in textiles and fibres (such as apparel, flooring and rubber reinforcement), molded components fo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Thermoplastic

A thermoplastic, or thermosoftening plastic, is any plastic polymer material that becomes pliable or moldable at a certain elevated temperature and solidifies upon cooling. Most thermoplastics have a high molecular weight. The polymer chains associate by intermolecular forces, which weaken rapidly with increased temperature, yielding a viscous liquid. In this state, thermoplastics may be reshaped, and are typically used to produce parts by various polymer processing techniques such as injection molding, compression molding, calendering, and extrusion. Thermoplastics differ from thermosetting polymers (or "thermosets"), which form irreversible chemical bonds during the curing process. Thermosets do not melt when heated, but typically decompose and do not reform upon cooling. Above its glass transition temperature and below its melting point, the physical properties of a thermoplastic change drastically without an associated phase change. Some thermoplastics do not fully ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Internal Combustion Engine

An internal combustion engine (ICE or IC engine) is a heat engine in which the combustion of a fuel occurs with an oxidizer (usually air) in a combustion chamber that is an integral part of the working fluid flow circuit. In an internal combustion engine, the expansion of the high-temperature and high-pressure gases produced by combustion applies direct force to some component of the engine. The force is typically applied to pistons (reciprocating engine, piston engine), turbine blades (gas turbine), a Wankel engine, rotor (Wankel engine), or a propulsive nozzle, nozzle (jet engine). This force moves the component over a distance. This process transforms chemical energy into kinetic energy which is used to propel, move or power whatever the engine is attached to. The first commercially successful internal combustion engines were invented in the mid-19th century. The first modern internal combustion engine, the Otto engine, was designed in 1876 by the German engineer Nicolaus ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fuel Pump

A Fuel pump is a component used in many liquid-fuelled engines (such as petrol/gasoline or diesel engines) to transfer the fuel from the fuel tank to the device where it is mixed with the intake air (such as the carburetor or fuel injector). Carbureted engines often use low-pressure mechanical pumps that are mounted on the engine. Fuel injected engines use either electric fuel pumps mounted inside the fuel tank (for lower pressure manifold injection systems) or high-pressure mechanical pumps mounted on the engine (for high-pressure direct injection systems). Some engines do not use any fuel pump at all. A low-pressure fuel supply used by a carbureted engine can be achieved through a gravity feed system, i.e. by simply mounting the tank higher than the carburetor. This method is commonly used in carbureted motorcycles, where the tank is usually directly above the engine. Low-pressure mechanical pumps On engines that use a carburetor (e.g. in older cars, lawnmowers a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hose

A hose is a flexible hollow tube or pipe designed to carry fluids from one location to another, often from a faucet or hydrant. Early hoses were made of leather, although modern hoses are typically made of rubber, canvas, and helically wound wire. Hoses may also be made from plastics such as polyvinyl chloride, polytetrafluoroethylene, and polyethylene terephthalate, or from metals such as stainless steel. See also * *Heated hose Heated hoses are hoses used for transporting liquids or molten materials where integral heat is needed for temperature control. Heated hoses are suitable for environments from -40°C to 80°C and can be used in explosion proof, explosion-proof zo ... References Further reading * Hydraulics {{tool-stub ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |