|

Fritted Glass

Fritted glass is finely porous glass through which gas or liquid may pass, made by sintering together glass particles into a solid but porous body. This porous glass body can also be called a frit. Applications in laboratory glassware include use in fritted glass filter items, scrubbers, or spargers. Other laboratory applications of fritted glass include packing in chromatography columns and resin beds for special chemical synthesis. In a fritted glass filter, a disc or pane of fritted glass is used to filter out solid particles, precipitate, or residue from a fluid, similar to a piece of filter paper. The fluid can go through the pores in the fritted glass, but the frit will often stop a solid from going through. A fritted filter is often part of a glassware item, so fritted glass funnels and fritted glass crucibles are available. Laboratory scale spargers (also known as gas diffusing stones or diffusors) as well as scrubber Scrubber systems (e.g. chemical scrubbe ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sintered Glass Funnel-02

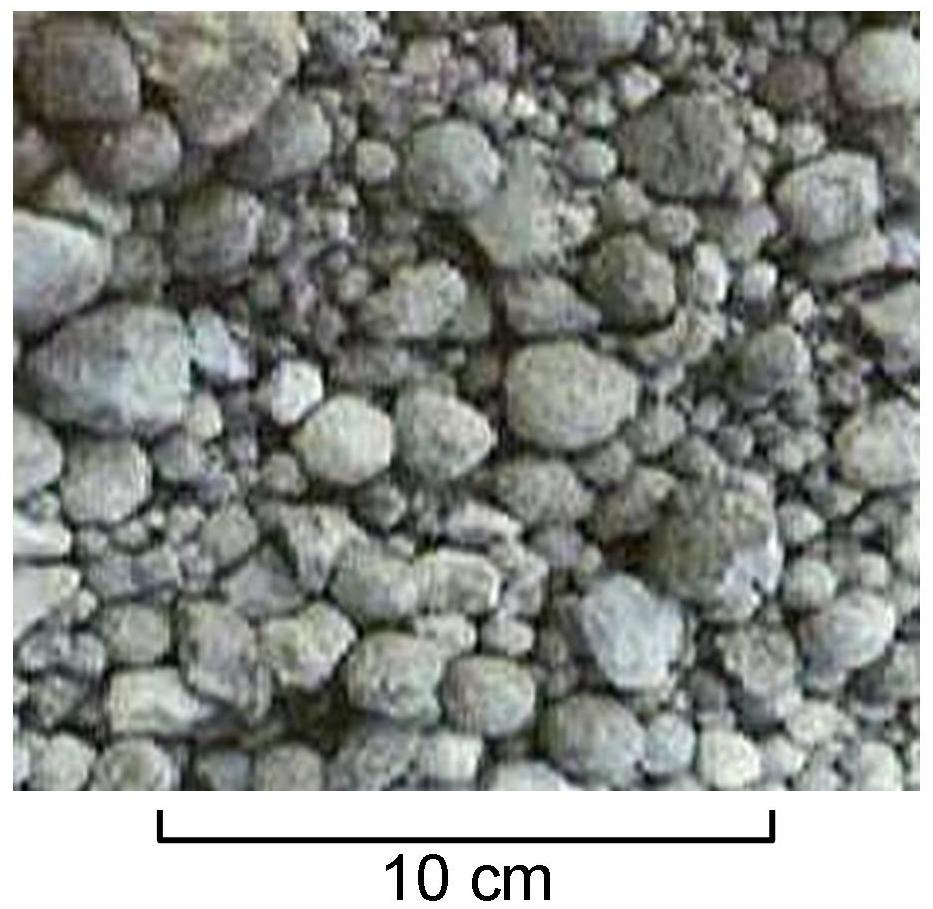

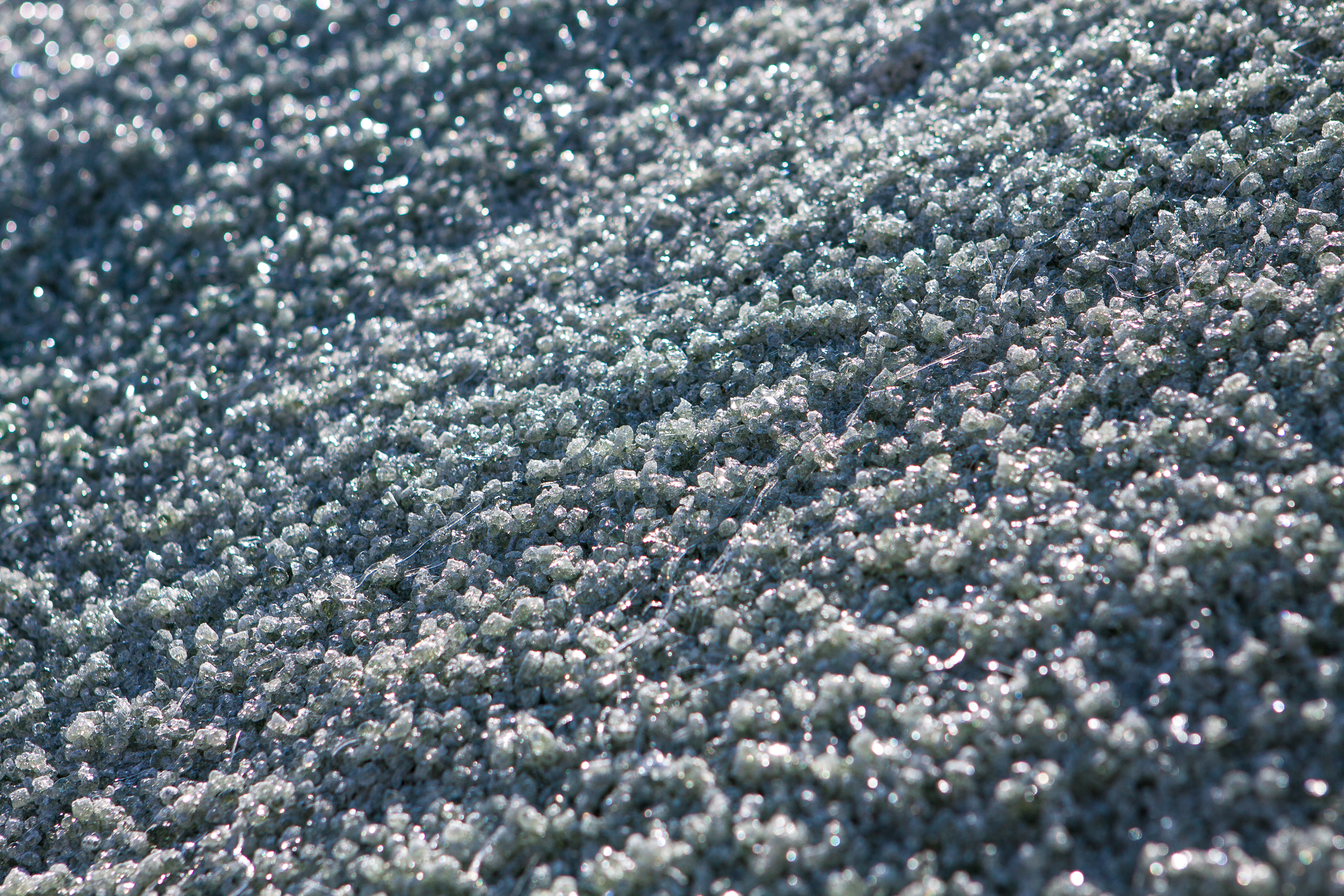

Sintering or frittage is the process of compacting and forming a solid mass of material by pressure or heat without melting it to the point of liquefaction. Sintering happens as part of a manufacturing process used with metals, ceramics, plastics, and other materials. The atoms/molecules in the sintered material diffuse across the boundaries of the particles, fusing the particles together and creating a solid piece. Since the sintering temperature does not have to reach the melting point of the material, sintering is often chosen as the shaping process for materials with extremely high melting points, such as tungsten and molybdenum. The study of sintering in metallurgical powder-related processes is known as powder metallurgy. An example of sintering can be observed when ice cubes in a glass of water adhere to each other, which is driven by the temperature difference between the water and the ice. Examples of pressure-driven sintering are the compacting of snowfall to a glac ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Porous Glass

Porous glass is glass that includes pores, usually in the nanometre- or micrometre-range, commonly prepared by one of the following processes: through metastable phase separation in borosilicate glasses (such as in their system SiO2-B2O3-Na2O), followed by liquid extraction of one of the formed phases; through the sol-gel process; or simply by sintering glass powder. The specific properties and commercial availability of porous glass make it one of the most extensively researched and characterized amorphous solids. Due to the possibility of modeling the microstructure, porous glasses have a high potential as a model system. They show a high chemical, thermal and mechanical resistance, which results from a rigid and incompressible silica network. They can be produced in high quality and with pore sizes ranging from 1 nm up to any desired value. An easy functionalization of the inner surface opens a wide field of applications for porous glasses. A further special advantage of ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Liquid

Liquid is a state of matter with a definite volume but no fixed shape. Liquids adapt to the shape of their container and are nearly incompressible, maintaining their volume even under pressure. The density of a liquid is usually close to that of a solid, and much higher than that of a gas. Therefore, liquid and solid are classified as condensed matter. Meanwhile, since both liquids and gases can flow, they are categorized as fluids. A liquid is composed of atoms or molecules held together by intermolecular bonds of intermediate strength. These forces allow the particles to move around one another while remaining closely packed. In contrast, solids have particles that are tightly bound by strong intermolecular forces, limiting their movement to small vibrations in fixed positions. Gases, on the other hand, consist of widely spaced, freely moving particles with only weak intermolecular forces. As temperature increases, the molecules in a liquid vibrate more intensely, causi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sintering

Sintering or frittage is the process of compacting and forming a solid mass of material by pressure or heat without melting it to the point of liquefaction. Sintering happens as part of a manufacturing process used with metals, ceramics, plastics, and other materials. The atoms/molecules in the sintered material diffuse across the boundaries of the particles, fusing the particles together and creating a solid piece. Since the sintering temperature does not have to reach the melting point of the material, sintering is often chosen as the shaping process for materials with extremely high melting points, such as tungsten and molybdenum. The study of sintering in metallurgy, metallurgical powder-related processes is known as powder metallurgy. An example of sintering can be observed when ice cubes in a glass of water adhere to each other, which is driven by the temperature difference between the water and the ice. Examples of pressure-driven sintering are the compacting of snowfa ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Frit

A frit is a ceramic composition that has been fused, quenched, and granulated. Frits form an important part of the batches used in compounding enamels and ceramic glazes; the purpose of this pre-fusion is to render any soluble and/or toxic components insoluble by causing them to combine with silica and other added oxides.''Dictionary of Ceramics'' (3rd Edition) Edited by Dodd, A. Murfin, D. Institute of Materials. 1994. However, not all glass that is fused and quenched in water is frit, as this method of cooling down very hot glass is also widely used in glass manufacture. According to the '' OED'', the origin of the word "frit" dates back to 1662 and is "a calcinated mixture of sand and fluxes ready to be melted in a crucible to make glass". Nowadays, the unheated raw materials of glass making are more commonly called "glass batch". In antiquity, frit could be crushed to make pigments or shaped to create objects. It may also have served as an intermediate material in the manu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Laboratory Glassware

Laboratory glassware is a variety of equipment used in science, scientific work, traditionally made of glass. Glass may be blown, bent, cut, molded, or formed into many sizes and shapes. It is commonly used in chemistry, biology, and analytical laboratory, laboratories. Many laboratories have training programs to demonstrate how glassware is used and to alert first–time users to the Laboratory safety#Safety hazards, safety hazards involved with using glassware. History Ancient era The history of glassware dates back to the Phoenicians who fused obsidian together in campfires, making the first glassware. Glassware evolved as other ancient civilizations including the Syrians, Egyptians, and Romans refined the art of glassmaking. Mary the Jewess, an alchemist in Alexandria during the 1st century AD, is credited for the creation of some of the first glassware for chemical such as the ''kerotakis'' which was used for the collection of fumes from a heated material. Despite thes ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Filter (chemistry)

Filtration is a physical separation process that separates solid matter and fluid from a mixture using a ''filter medium'' that has a complex structure through which only the fluid can pass. Solid particles that cannot pass through the filter medium are described as ''oversize'' and the fluid that passes through is called the ''filtrate''. Oversize particles may form a filter cake on top of the filter and may also block the filter lattice, preventing the fluid phase from crossing the filter, known as ''blinding''. The size of the largest particles that can successfully pass through a filter is called the effective ''pore size'' of that filter. The separation of solid and fluid is imperfect; solids will be contaminated with some fluid and filtrate will contain fine particles (depending on the pore size, filter thickness and biological activity). Filtration occurs both in nature and in engineering, engineered systems; there are biology, biological, geology, geological, and Indust ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sparger

In chemistry, sparging, also known as gas flushing in metallurgy, is a technique in which a gas is bubbled through a liquid in order to remove ''other'' dissolved gas(es) and/or dissolved volatile liquid(s) from that liquid. It is a method of degassing. According to Henry's law, the concentration of each gas in a liquid is proportional to the partial pressure of that gas (in the gaseous state) in contact with the liquid. Sparging introduces a gas that has little or no partial pressure of the gas(es) to be removed, and increases the area of the gas-liquid interface, which encourages some of the dissolved gas(es) to diffuse into the sparging gas before the sparging gas escapes from the liquid. Many sparging processes, such as solvent removal, use air as the sparging gas. To remove oxygen, or for sensitive solutions or reactive molten metals, a chemically inert gas such as nitrogen, argon, or helium is used. Liquid chromatography Solvents used in high-performance liquid chromatogra ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Chromatography Column

A chromatography column is a device used in chromatography for the separation of chemical compounds. A chromatography column contains the stationary phase, allowing the mobile phase to pass through it. Materials Chromatography columns of different types are used in both gas and liquid chromatography: * Liquid chromatography: Traditional chromatography columns were made of glass. Modern columns are mostly made of borosilicate glass, acrylic glass or stainless steel. To prevent the stationary phase from leaking out of the column interior a polymer, stainless steel or ceramic net is usually applied. Depending on the application material- and size-requirements may change. * Gas chromatography (GC): Older columns were made of glass or metal packed with particles of a solid stationary phase. More recently, narrower diameter (capillary) columns have been made using fused silica coated on the inside with a film of the stationary phase material. GC columns are typically very long to ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Resin Bed

A resin is a solid or highly viscous liquid that can be converted into a polymer. Resins may be biological or synthetic in origin, but are typically harvested from plants. Resins are mixtures of organic compounds, predominantly terpenes. Common resins include amber, hashish, frankincense, myrrh and the animal-derived resin, shellac. Resins are used in varnishes, adhesives, food additives, incenses and perfumes. Resins protect plants from insects and pathogens, and are secreted in response to injury. Resins repel herbivores, insects, and pathogens, while the volatile phenolic compounds may attract benefactors such as predators of insects that attack the plant. Composition Most plant resins are composed of terpenes. Specific components are alpha-pinene, beta-pinene, delta-3 carene, and sabinene, the monocyclic terpenes limonene and terpinolene, and smaller amounts of the tricyclic sesquiterpenes, longifolene, caryophyllene, and delta-cadinene. Some resins also contain a h ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Scrubber

Scrubber systems (e.g. chemical scrubbers, gas scrubbers) are a diverse group of air pollution control devices that can be used to remove some particulates and/or gases from industrial exhaust streams. An early application of a carbon dioxide scrubber was in the submarine the ''Ictíneo I'', in 1859; a role for which they continue to be used today. Traditionally, the term "scrubber" has referred to pollution control devices that use liquid to wash unwanted pollutants from a gas stream. Recently, the term has also been used to describe systems that inject a dry reagent or slurry into a dirty exhaust stream to "wash out" acid gases. Scrubbers are one of the primary devices that control gaseous emissions, especially acid gases. Scrubbers can also be used for heat recovery from hot gases by flue-gas condensation.On Flue gas Condensat ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |