|

Forging

Forging is a manufacturing process involving the shaping of metal using localized compression (physics), compressive forces. The blows are delivered with a hammer (often a power hammer) or a die (manufacturing), die. Forging is often classified according to the temperature at which it is performed: cold forging (a type of cold working), warm forging, or hot forging (a type of hot working). For the latter two, the metal is heated, usually in a forge. Forged parts can range in weight from less than a kilogram to hundreds of metric tons.Degarmo, p. 389 Forging has been done by metalsmith, smiths for millennia; the traditional products were kitchenware, household hardware, hardware, hand tools, edged weapons, cymbals, and jewellery. Since the Industrial Revolution, forged parts are widely used in mechanism (engineering), mechanisms and machines wherever a component requires high strength of materials, strength; such forgings usually require further processing (such as machining) ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Blacksmith

A blacksmith is a metalsmith who creates objects primarily from wrought iron or steel, but sometimes from #Other metals, other metals, by forging the metal, using tools to hammer, bend, and cut (cf. tinsmith). Blacksmiths produce objects such as gates, grilles, railings, light fixtures, furniture, sculpture, tools, agricultural implements, decorative and religious items, cooking utensils, and weapons. There was a historical distinction between the heavy work of the blacksmith and the more delicate operations of a whitesmith, who usually worked in Goldsmith, gold, Silversmith, silver, pewter, or the finishing steps of fine steel. The place where a blacksmith works is variously called a smithy, a forge, or a blacksmith's shop. While there are many professions who work with metal, such as farriers, wheelwrights, and Armourer, armorers, in former times the blacksmith had a general knowledge of how to make and repair many things, from the most complex of weapons and armor to simple ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Forge

A forge is a type of hearth used for heating metals, or the workplace (smithy) where such a hearth is located. The forge is used by the smith to heat a piece of metal to a temperature at which it becomes easier to shape by forging, or to the point at which work hardening no longer occurs. The metal (known as the "workpiece") is transported to and from the forge using tongs, which are also used to hold the workpiece on the smithy's anvil while the smith works it with a hammer. Sometimes, such as when hardening steel or cooling the work so that it may be handled with bare hands, the workpiece is transported to the slack tub, which rapidly cools the workpiece in a large body of water. However, depending on the metal type, it may require an oil quench or a salt brine instead; many metals require more than plain water hardening. The slack tub also provides water to control the fire in the forge. Types Coal/coke/charcoal forge A forge typically uses bituminous coal, indus ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Swage

Swaging () is a forging process in which the dimensions of an item are altered using dies into which the item is forced. Swaging is usually a cold working process, but also may be hot worked. The term swage may apply to the process (verb) or to a die or tool (noun) used in that process. Origin The term "swage" comes from the Old French term , meaning "decorative groove" or "ornamental moulding". Swages were originally tools used by blacksmiths to form metal into various shapes too intricate to make with a hammer alone. These have handles for holding or pegs for attaching to an anvil, and often a flat head for striking with a hammer. Swage blocks are anvil-like dies with various shapes forged into them, which are also used for forming metal. Swages called " fullers" are specific to making grooves in swords and knives. ''Swage'' is most often pronounced ( AHD format: swāj). Another (less common) pronunciation sometimes heard in the metalworking industries is (AHD forma ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Metalworking

Metalworking is the process of shaping and reshaping metals in order to create useful objects, parts, assemblies, and large scale structures. As a term, it covers a wide and diverse range of processes, skills, and tools for producing objects on every scale: from huge ships, buildings, and bridges, down to precise engine parts and delicate jewellery. The historical roots of metalworking predate recorded history; its use spans cultures, civilizations and millennia. It has evolved from shaping soft, native metals like gold with simple hand tools, through the smelting of ores and hot forging of harder metals like iron, up to and including highly technical modern processes such as machining and welding. It has been used as an industry, a driver of trade, individual hobbies, and in the creation of art; it can be regarded as both a science and a craft. Modern metalworking processes, though diverse and specialized, can be categorized into one of three broad areas known as forming, cutt ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Power Hammer

Power hammers are mechanical forging hammers that use an electrical power source or steam to raise the hammer preparatory to striking, and accelerate it onto the work being hammered. They are also called open die power forging hammers. They have been used by blacksmiths, bladesmiths, metalworkers, and manufacturers since the late 1880s, having replaced trip hammers. Design and operation A typical power hammer consists of a frame, an anvil, and a reciprocating ram holding a hammer head or die. The workpiece is placed on the lower anvil or die and the head or upper die strikes the workpiece. The power hammer is a direct descendant of the trip hammer, differing in that the power hammer stores potential energy in an arrangement of mechanical linkages and springs, in compressed air, or steam, and by the fact that it accelerates the ram on the downward stroke. This provides more force than simply allowing the weight to fall. Predecessors like trip hammers, steam drop hammers, b ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Machine Press

A forming press, commonly shortened to press, is a machine tool that changes the shape of a work-piece by the application of pressure. The operator of a forming press is known as a press-tool setter, often shortened to tool-setter. Presses can be classified according to * their mechanism: Hydraulic press, hydraulic, Machine (mechanical) , mechanical, Pneumatics, pneumatic; * their function: forging presses, stamping presses, press brakes, punch press, etc. * their structure, e.g. Knuckle-joint press, screw press, Expeller pressing, Expeller press * their controllability: conventional vs. Servo press, servo-presses Shop Press Typically consisting of a simple rectangular frame, often fabrication (metal), fabricated from Structural channel, C-channel or tubing, containing a Jack (device)#Bottle jack, bottle jack or hydraulic cylinder to apply pressure via a ram to a work-piece. Often used for general-purpose forming work in the auto mechanic shop, machine shop, garage or basem ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Anvil

An anvil is a metalworking tool consisting of a large block of metal (usually Forging, forged or Steel casting, cast steel), with a flattened top surface, upon which another object is struck (or "worked"). Anvils are massive because the higher their inertia, the more efficiently they cause the energy of striking tools to be transferred to the work piece. In most cases the anvil is used as a forge, forging tool. Before the advent of modern welding technology, it was the primary tool of metal workers. The great majority of modern anvils are made of cast steel that has been heat treated by either Case-hardening, flame or Induction_hardening, electric induction. Inexpensive anvils have been made of cast iron and low-quality steel, but are considered unsuitable for serious use, as they deform and lack rebound when struck. The largest single piece tool steel anvil that is heat treated is 1600 pounds. This anvil was made in 2023 by Oak Lawn Blacksmith. There are larger anvils tha ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Metalsmith

A metalsmith or simply smith is a craftsperson fashioning useful items (for example, tools, kitchenware, tableware, jewelry, armor and weapons) out of various metals. Smithing is one of the oldest list of metalworking occupations, metalworking occupations. Shaping metal with a hammer (forging) is the archetypical component of smithing. Often the hammering is done while the metal is hot, having been heated in a forge. Smithing can also involve the other aspects of metalworking, such as refining metals from their ores (traditionally done by smelting), casting it into shapes (foundry, founding), and file (tool), filing to shape and size. The prevalence of metalworking in the culture of recent centuries has led ''Smith (surname), Smith'' and its equivalents in various languages to be a common surname#Occupational name, occupational surname (German Schmidt (surname), Schmidt or Schmied, Portuguese Ferreiro, Ferreira (surname), Ferreira, French Lefèvre, Spanish Herrero, Italian Fabbri ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Machining

Machining is a manufacturing process where a desired shape or part is created using the controlled removal of material, most often metal, from a larger piece of raw material by cutting. Machining is a form of subtractive manufacturing, which utilizes machine tools, in contrast to ''additive manufacturing'' (e.g. 3D printing processes, 3D printing), which uses controlled addition of material. Machining is a major process of the manufacture of many metal products, but it can also be used on other materials such as wood, plastic, ceramic, and composite material, composites. A person who specializes in machining is called a machinist. As a commercial venture, machining is generally performed in a machine shop, which consists of one or more workrooms containing primary machine tools. Although a machine shop can be a standalone operation, many businesses maintain internal machine shops or tool rooms that support their specialized needs. Much modern-day machining uses Numerical control, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hot Working

In metallurgy, hot working refers to processes where metals are plastically deformed above their recrystallization temperature. Being above the recrystallization temperature allows the material to recrystallize during deformation. This is important because recrystallization keeps the materials from strain hardening, which ultimately keeps the yield strength and hardness low and ductility high.Degarmo, p. 373. This contrasts with cold working. Many kinds of working, including rolling, forging, extrusion, and drawing, can be done with hot metal. Temperature The lower limit of the hot working temperature is determined by its recrystallization temperature. As a guideline, the lower limit of the hot working temperature of a material is 60% its melting temperature (on an absolute temperature scale). The upper limit for hot working is determined by various factors, such as: excessive oxidation, grain growth, or an undesirable phase transformation. In practice materials are usua ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

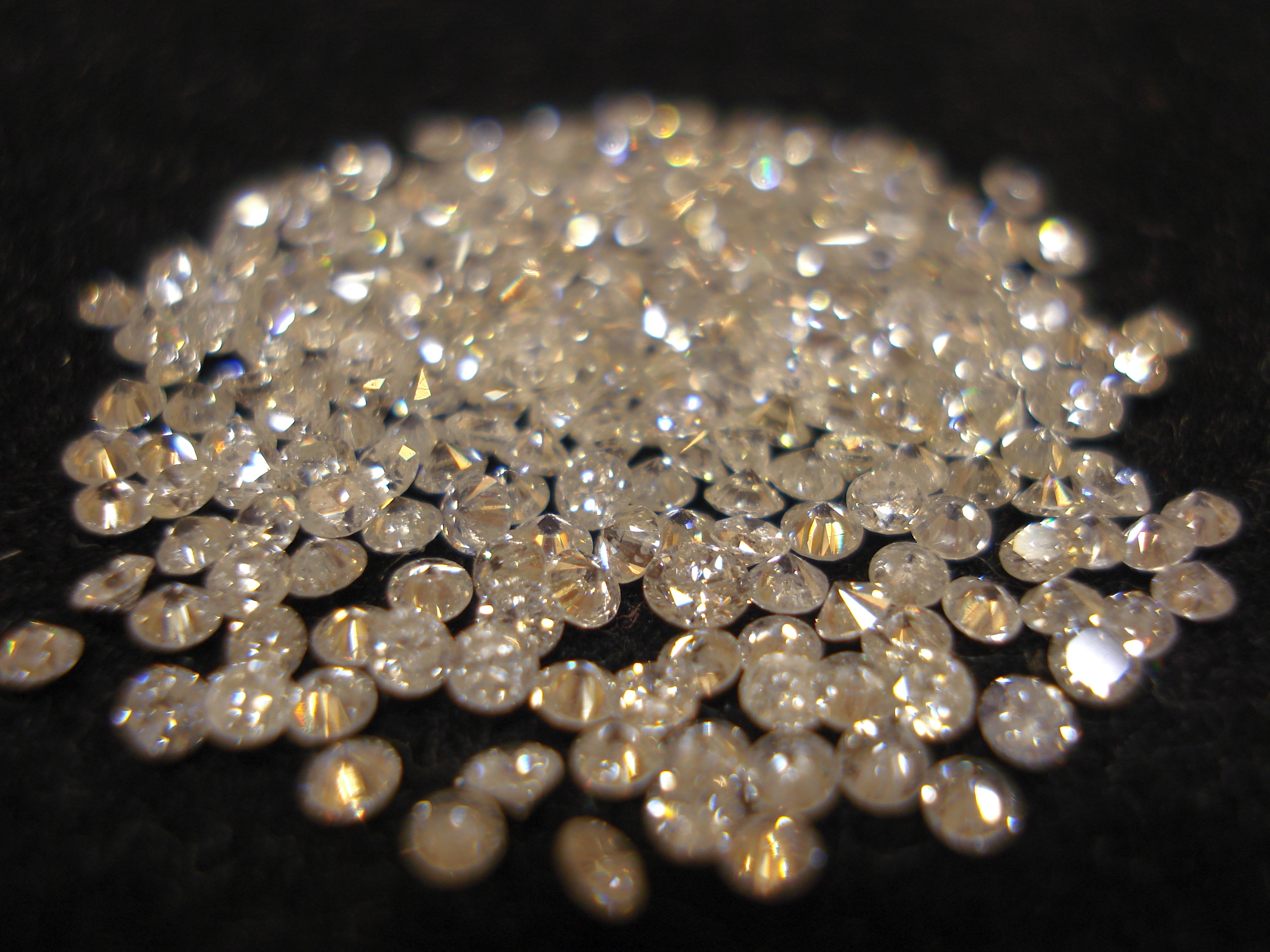

Jewellery

Jewellery (or jewelry in American English) consists of decorative items worn for personal adornment such as brooches, ring (jewellery), rings, necklaces, earrings, pendants, bracelets, and cufflinks. Jewellery may be attached to the body or the clothes. From a western perspective, the term is restricted to durable Ornament (art), ornaments, excluding flowers for example. For many centuries metal such as gold often combined with gemstones, has been the normal material for jewellery, but other materials such as glass, shells and other plant materials may be used. Jewellery is one of the oldest types of archaeological artefact – with 100,000-year-old beads made from ''Nassarius'' shells thought to be the oldest known jewellery. The basic forms of jewellery vary between cultures but are often extremely long-lived; in European cultures the most common forms of jewellery listed above have persisted since ancient times, while other forms such as adornments for the nose or ankle, impo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |