|

FeFET Memory

A ferroelectric field-effect transistor (Fe FET) is a type of field-effect transistor that includes a ferroelectric material sandwiched between the gate electrode and source-drain conduction region of the device (the Channel (semiconductor), channel). Permanent electrical field polarisation in the ferroelectric causes this type of device to retain the transistor's state (on or off) in the absence of any electrical bias. FeFET based devices are used in FeFET memory - a type of single transistor non-volatile memory. Description In 1955, Ian Munro Ross filed a patent for a FeFET or MFSFET. Its structure was like that of a modern inversion channel MOSFET, but ferroelectric material was used as a dielectric/insulator instead of oxide. Use of a ferroelectric (triglycine sulfate) in a solid state memory was proposed by Moll and Tarui in 1963 using a thin film transistor. Further research occurred in the 1960s, but the retention characteristics of the thin film based devices was unsati ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Field-effect Transistor

The field-effect transistor (FET) is a type of transistor that uses an electric field to control the current through a semiconductor. It comes in two types: junction FET (JFET) and metal-oxide-semiconductor FET (MOSFET). FETs have three terminals: ''source'', ''gate'', and ''drain''. FETs control the current by the application of a voltage to the gate, which in turn alters the conductivity between the drain and source. FETs are also known as unipolar transistors since they involve single-carrier-type operation. That is, FETs use either electrons (n-channel) or holes (p-channel) as charge carriers in their operation, but not both. Many different types of field effect transistors exist. Field effect transistors generally display very high input impedance at low frequencies. The most widely used field-effect transistor is the MOSFET (metal–oxide–semiconductor field-effect transistor). History The concept of a field-effect transistor (FET) was first patented by the Austr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

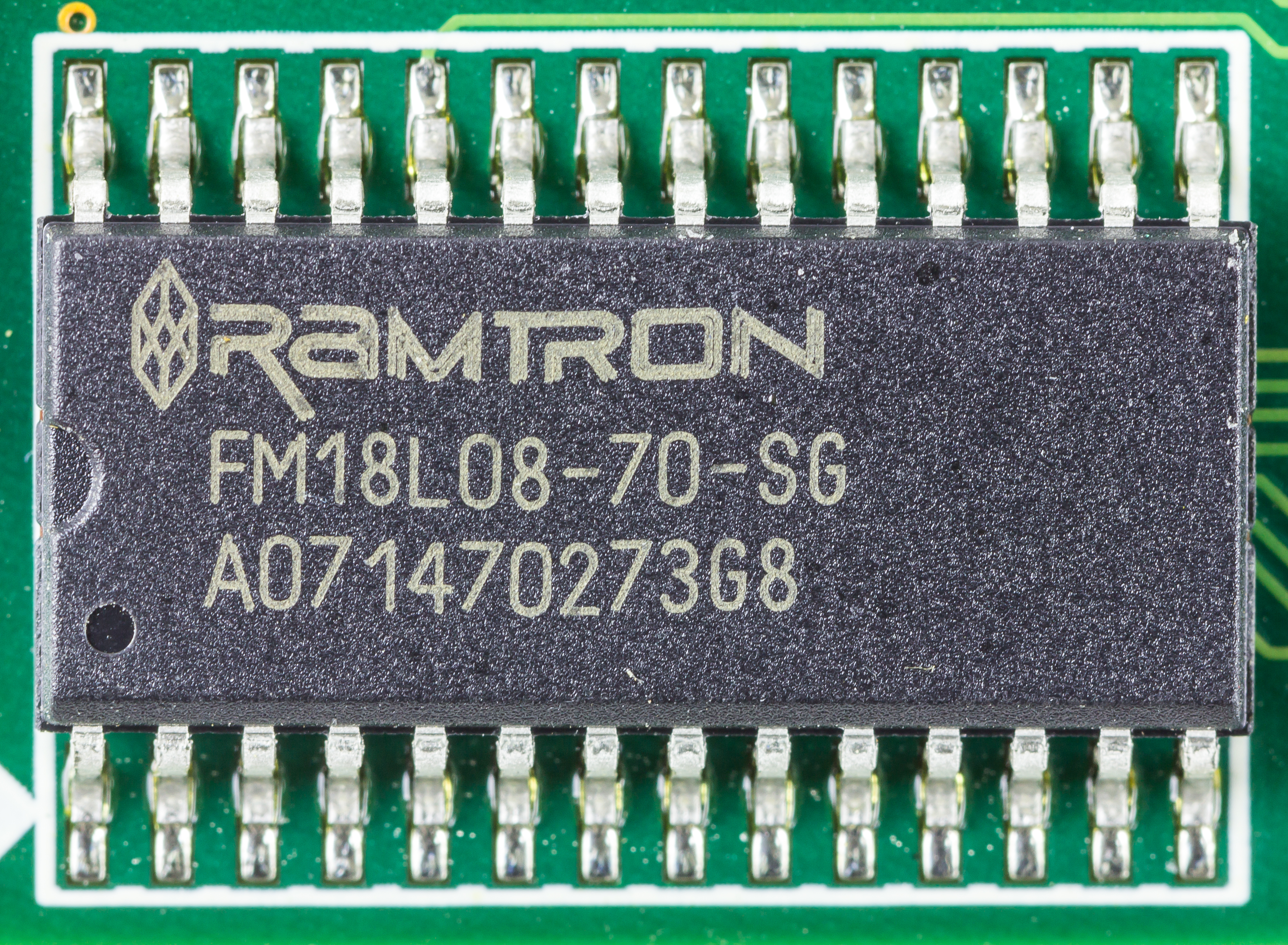

Ferroelectric RAM

Ferroelectric RAM (FeRAM, F-RAM or FRAM) is a random-access memory similar in construction to DRAM but using a ferroelectric layer instead of a dielectric layer to achieve non-volatility. FeRAM is one of a growing number of alternative non-volatile random-access memory technologies that offer the same functionality as flash memory. An FeRAM chip contains a thin film of ferroelectric material, often lead zirconate titanate, commonly referred to as PZT. The atoms in the PZT layer change polarity in an electric field, thereby producing a power-efficient binary switch. However, the most important aspect of the PZT is that it is not affected by power disruption or magnetic interference, making FeRAM a reliable nonvolatile memory. FeRAM's advantages over Flash include: lower power usage, faster write speeds and a much greater maximum read/write endurance (about 1010 to 1015 cycles). FeRAMs have data retention times of more than 10 years at +85 °C (up to many decades at lower ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Non-volatile Memory

Non-volatile memory (NVM) or non-volatile storage is a type of computer memory that can retain stored information even after power is removed. In contrast, volatile memory needs constant power in order to retain data. Non-volatile memory typically refers to storage in memory chips, which store data in floating-gate memory cells consisting of floating-gate MOSFETs ( metal–oxide–semiconductor field-effect transistors), including flash memory storage such as NAND flash and solid-state drives (SSD). Other examples of non-volatile memory include read-only memory (ROM), EPROM (erasable programmable ROM) and EEPROM (electrically erasable programmable ROM), ferroelectric RAM, most types of computer data storage devices (e.g. disk storage, hard disk drives, optical discs, floppy disks, and magnetic tape), and early computer storage methods such as punched tape and cards. Overview Non-volatile memory is typically used for the task of secondary storage or long-term per ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Process Node

Semiconductor device fabrication is the process used to manufacture semiconductor devices, typically integrated circuits (ICs) such as microprocessors, microcontrollers, and memories (such as RAM and flash memory). It is a multiple-step photolithographic and physico-chemical process (with steps such as thermal oxidation, thin-film deposition, ion-implantation, etching) during which electronic circuits are gradually created on a wafer, typically made of pure single-crystal semiconducting material. Silicon is almost always used, but various compound semiconductors are used for specialized applications. This article focuses on the manufacture of integrated circuits, however steps such as etching and photolithography can be used to manufacture other devices such as LCD and OLED displays. The fabrication process is performed in highly specialized semiconductor fabrication plants, also called foundries or "fabs", with the central part being the "clean room". In more advanced semiconduc ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hafnium Dioxide

Hafnium is a chemical element; it has symbol Hf and atomic number 72. A lustrous, silvery gray, tetravalent transition metal, hafnium chemically resembles zirconium and is found in many zirconium minerals. Its existence was predicted by Dmitri Mendeleev in 1869, though it was not identified until 1922, by Dirk Coster and George de Hevesy. Hafnium is named after , the Latin name for Copenhagen, where it was discovered. Hafnium is used in filaments and electrodes. Some semiconductor fabrication processes use its oxide for integrated circuits at 45 nanometers and smaller feature lengths. Some superalloys used for special applications contain hafnium in combination with niobium, titanium, or tungsten. Hafnium's large neutron capture cross section makes it a good material for neutron absorption in control rods in nuclear power plants, but at the same time requires that it be removed from the neutron-transparent corrosion-resistant zirconium alloys used in nuclear reactors. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Silicon On Insulator

In semiconductor manufacturing, silicon on insulator (SOI) technology is fabrication of silicon semiconductor devices in a layered silicon–insulator–silicon substrate, to reduce parasitic capacitance within the device, thereby improving performance. SOI-based devices differ from conventional silicon-built devices in that the silicon junction is above an electrical insulator, typically silicon dioxide or sapphire (these types of devices are called silicon on sapphire, or SOS). The choice of insulator depends largely on intended application, with sapphire being used for high-performance radio frequency (RF) and radiation-sensitive applications, and silicon dioxide for diminished short-channel effects in other microelectronics devices. The insulating layer and topmost silicon layer also vary widely with application. Industry need SOI technology is one of several manufacturing strategies to allow the continued miniaturization of microelectronic devices, colloquially referred to ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

22nm

The "22 nm" node is the process step following 32 nm process, 32 nm in CMOS MOSFET semiconductor device fabrication. It was first demonstrated by Semiconductor company, semiconductor companies for use in Random-access memory, RAM in 2008. In 2010, Toshiba began shipping 24 nm flash memory chips, and Samsung Electronics began mass-producing 20 nm flash memory chips. The first consumer-level central processing unit, CPU deliveries using a 22 nm process started in April 2012 with the Intel Ivy Bridge (microarchitecture), Ivy Bridge processors. Since at least 1997, "process nodes" have been named purely on a marketing basis, and have no relation to the dimensions on the integrated circuit; neither gate length, metal pitch or gate pitch on a "22nm" device is twenty-two nanometers. The International Technology Roadmap for Semiconductors, ITRS 2006 Front End Process Update indicates that equivalent physical oxide thickness will not scale below 0.5 nm (about twice th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

PLZT

Lead zirconate titanate, also called lead zirconium titanate and commonly abbreviated as PZT, is an inorganic compound with the chemical formula . It is a ceramic perovskite material that shows a marked piezoelectric effect, meaning that the compound changes shape when an electric field is applied. It is used in a number of practical applications such as ultrasonic transducers and piezoelectric resonators. It is a white to off-white solid. Lead zirconium titanate was first developed around 1952 at the Tokyo Institute of Technology. Compared to barium titanate, a previously discovered metallic-oxide-based piezoelectric material, lead zirconium titanate exhibits greater sensitivity and has a higher operating temperature. Piezoelectric ceramics are chosen for applications because of their physical strength, chemical inertness and their relatively low manufacturing cost. PZT ceramic is the most commonly used piezoelectric ceramic because it has an even greater sensitivity and higher ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |