|

Equilibrium Catalyst

Equilibrium catalyst usually refers to the catalyst mix use in fluid catalytic cracking (FCC), but includes other petrochemical processes that use large amounts (many tons) of catalysts. The catalyst is a zeolite. During the FCC, the catalyst "inventory" is regularly removed from operation and reactivated by combusting the accumulated coke, which is a catalyst poison. Some of the catalyst is irreversibly deactivated by metal contaminants and by degradation of the alumino silicate backbone of the zeolite. To compensate for these changes, some inventory is removed and some fresh catalyst is added. Thus, the inventory consists of a catalytic particles with a range of activities. This mixture is referred to as the equilibrium catalyst. In addition to FCC, equilibrium catalyst concept applies to hydroprocessing and hydrocracking. Spent catalyst disposal The disposal of spent catalyst is gaining importance, particularly because of strict environmental regulations and high prices of ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Catalyst

Catalysis () is the increase in rate of a chemical reaction due to an added substance known as a catalyst (). Catalysts are not consumed by the reaction and remain unchanged after it. If the reaction is rapid and the catalyst recycles quickly, very small amounts of catalyst often suffice; mixing, surface area, and temperature are important factors in reaction rate. Catalysts generally react with one or more reactants to form intermediates that subsequently give the final reaction product, in the process of regenerating the catalyst. The rate increase occurs because the catalyst allows the reaction to occur by an alternative mechanism which may be much faster than the noncatalyzed mechanism. However the noncatalyzed mechanism does remain possible, so that the total rate (catalyzed plus noncatalyzed) can only increase in the presence of the catalyst and never decrease. Catalysis may be classified as either homogeneous, whose components are dispersed in the same phase (usual ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fluid Catalytic Cracking

Fluid catalytic cracking (FCC) is the conversion process used in petroleum refineries to convert the high-boiling point, high-molecular weight hydrocarbon fractions of petroleum (crude oils) into gasoline, alkene gases, and other petroleum products. The cracking of petroleum hydrocarbons was originally done by thermal cracking, now virtually replaced by catalytic cracking, which yields greater volumes of high octane rating gasoline; and produces by-product gases, with more carbon-carbon double bonds (i.e. alkenes), that are of greater economic value than the gases produced by thermal cracking. The feedstock to the FCC conversion process usually is heavy gas oil (HGO), which is that portion of the petroleum (crude oil) that has an initial boiling-point temperature of or higher, at atmospheric pressure, and that has an average molecular weight that ranges from about 200 to 600 or higher; heavy gas oil also is known as "heavy vacuum gas oil" (HVGO). In the fluid catalytic cracking ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Zeolite

Zeolites are a group of several microporous, crystalline aluminosilicate minerals commonly used as commercial adsorbents and catalysts. They mainly consist of silicon, aluminium, oxygen, and have the general formula ・y where is either a metal ion or H+. The term was originally coined in 1756 by Swedish mineralogist Axel Fredrik Cronstedt, who observed that rapidly heating a material, believed to have been stilbite, produced large amounts of steam from water that had been adsorbed by the material. Based on this, he called the material ''zeolite'', from the Greek , meaning "to boil" and , meaning "stone". Zeolites occur naturally, but are also produced industrially on a large scale. , 253 unique zeolite frameworks have been identified, and over 40 naturally occurring zeolite frameworks are known. Every new zeolite structure that is obtained is examined by the International Zeolite Association Structure Commission (IZA-SC) and receives a three-letter designation. Character ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Catalyst Poison

Catalysis () is the increase in rate of a chemical reaction due to an added substance known as a catalyst (). Catalysts are not consumed by the reaction and remain unchanged after it. If the reaction is rapid and the catalyst recycles quickly, very small amounts of catalyst often suffice; mixing, surface area, and temperature are important factors in reaction rate. Catalysts generally react with one or more reactants to form intermediates that subsequently give the final reaction product, in the process of regenerating the catalyst. The rate increase occurs because the catalyst allows the reaction to occur by an alternative mechanism which may be much faster than the noncatalyzed mechanism. However the noncatalyzed mechanism does remain possible, so that the total rate (catalyzed plus noncatalyzed) can only increase in the presence of the catalyst and never decrease. Catalysis may be classified as either homogeneous, whose components are dispersed in the same phase (usuall ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hydroprocessing

Hydroprocessing is a catalytic term relating to the processes of hydrocracking and hydrotreating. These process are for the removal of sulfur, oxygen, nitrogen and metals from crude oil, this is done in the refining of fuel A fuel is any material that can be made to react with other substances so that it releases energy as thermal energy or to be used for work (physics), work. The concept was originally applied solely to those materials capable of releasing chem ... to enable lower sulfur levels in fuels. References Catalysis Oil refining {{Catalysis-stub ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hydrocracking

In petrochemistry, petroleum geology and organic chemistry, cracking is the process whereby complex organic molecules such as kerogens or long-chain hydrocarbons are broken down into simpler molecules such as light hydrocarbons, by the breaking of carbon–carbon bonds in the precursors. The rate of cracking and the end products are strongly dependent on the temperature and presence of catalysts. Cracking is the breakdown of large hydrocarbons into smaller, more useful alkanes and alkenes. Simply put, hydrocarbon cracking is the process of breaking long-chain hydrocarbons into short ones. This process requires high temperatures. More loosely, outside the field of petroleum chemistry, the term "cracking" is used to describe any type of splitting of molecules under the influence of heat, catalysts and solvents, such as in processes of destructive distillation or pyrolysis. Fluid catalytic cracking produces a high yield of petrol and LPG, while hydrocracking is a major source of ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Landfill

A landfill is a site for the disposal of waste materials. It is the oldest and most common form of waste disposal, although the systematic burial of waste with daily, intermediate and final covers only began in the 1940s. In the past, waste was simply left in piles or thrown into pits (known in Archaeology, archeology as middens). Landfills take up a lot of land and pose environmental risks. Some landfill sites are used for waste management purposes, such as temporary storage, consolidation and transfer, or for various stages of processing waste material, such as sorting, treatment, or recycling. Unless they are stabilized, landfills may undergo severe shaking or soil liquefaction of the ground during an earthquake. Once full, the area over a landfill site may be Landfill restoration, reclaimed for other uses. Both active and restored landfill sites can have significant environmental impacts which can persist for many years. These include the release of gases that contribute to ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Nickel

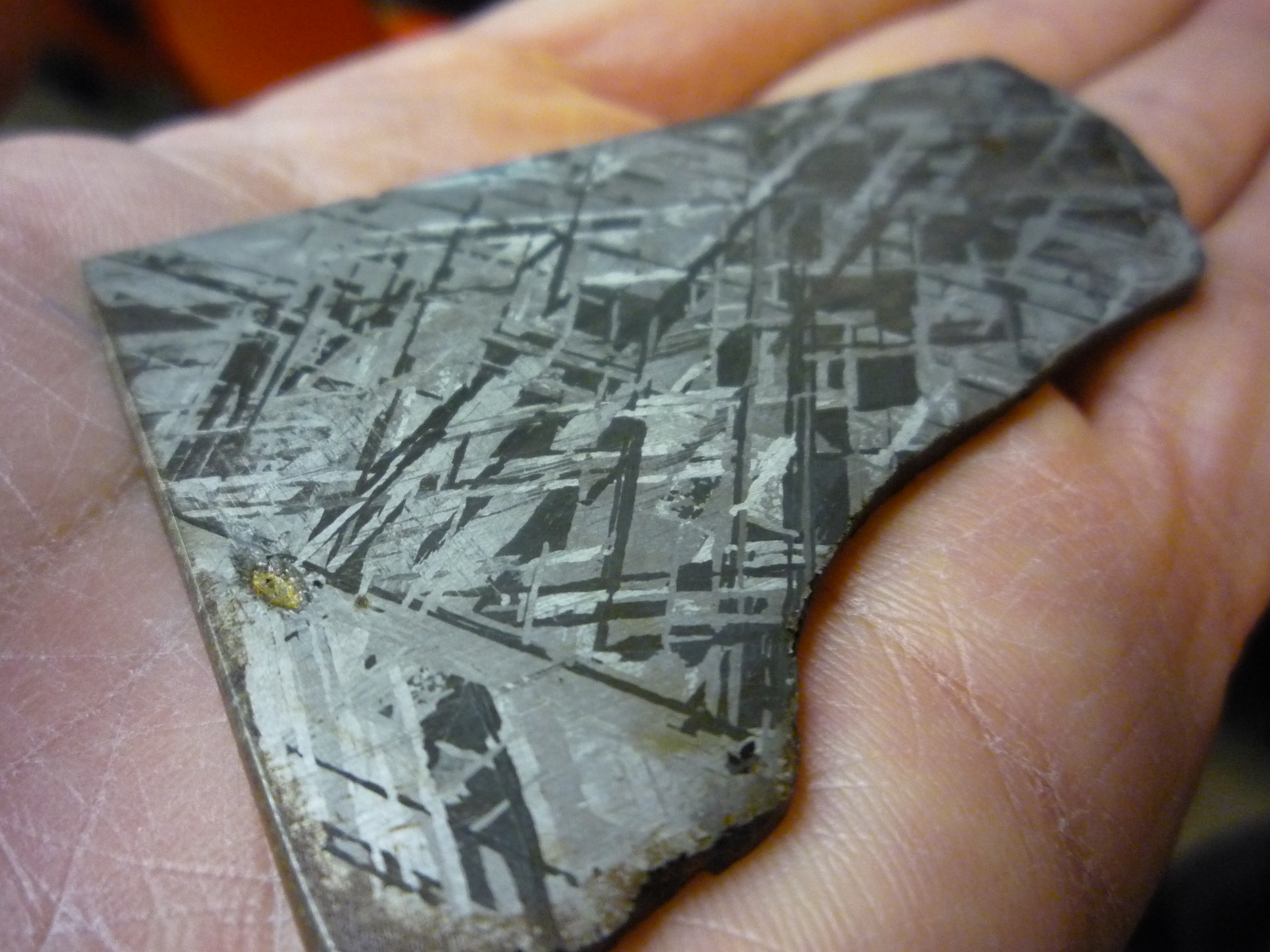

Nickel is a chemical element; it has symbol Ni and atomic number 28. It is a silvery-white lustrous metal with a slight golden tinge. Nickel is a hard and ductile transition metal. Pure nickel is chemically reactive, but large pieces are slow to react with air under standard conditions because a passivation layer of nickel oxide forms on the surface that prevents further corrosion. Even so, pure native nickel is found in Earth's crust only in tiny amounts, usually in ultramafic rocks, and in the interiors of larger nickel–iron meteorites that were not exposed to oxygen when outside Earth's atmosphere. Meteoric nickel is found in combination with iron, a reflection of the origin of those elements as major end products of supernova nucleosynthesis. An iron–nickel mixture is thought to compose Earth's outer and inner cores. Use of nickel (as natural meteoric nickel–iron alloy) has been traced as far back as 3500 BCE. Nickel was first isolated and classifie ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Vanadium

Vanadium is a chemical element; it has Symbol (chemistry), symbol V and atomic number 23. It is a hard, silvery-grey, malleable transition metal. The elemental metal is rarely found in nature, but once isolated artificially, the formation of an oxide layer (passivation (chemistry), passivation) somewhat stabilizes the free metal against further oxidation. Spain, Spanish-Mexico, Mexican scientist Andrés Manuel del Río discovered compounds of vanadium in 1801 by analyzing a new lead-bearing mineral he called "brown lead". Though he initially presumed its qualities were due to the presence of a new element, he was later erroneously convinced by French chemist Hippolyte Victor Collet-Descotils that the element was just chromium. Then in 1830, Nils Gabriel Sefström generated chlorides of vanadium, thus proving there was a new element, and named it "vanadium" after the Scandinavian goddess of beauty and fertility, Vanadís (Freyja). The name was based on the wide range of colors fo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Molybdenum

Molybdenum is a chemical element; it has Symbol (chemistry), symbol Mo (from Neo-Latin ''molybdaenum'') and atomic number 42. The name derived from Ancient Greek ', meaning lead, since its ores were confused with lead ores. Molybdenum minerals have been known throughout history, but the element was discovered (in the sense of differentiating it as a new entity from the mineral salts of other metals) in 1778 by Carl Wilhelm Scheele. The metal was first isolated in 1781 by Peter Jacob Hjelm. Molybdenum does not occur naturally as a Native metal, free metal on Earth; in its minerals, it is found only in oxidation state, oxidized states. The free element, a silvery metal with a grey cast, has the List of elements by melting point, sixth-highest melting point of any element. It readily forms hard, stable carbides in alloys, and for this reason most of the world production of the element (about 80%) is used in steel alloys, including high-strength alloys and superalloys. Most molybdenum ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cement Industry

A cement is a binder, a chemical substance used for construction that sets, hardens, and adheres to other materials to bind them together. Cement is seldom used on its own, but rather to bind sand and gravel ( aggregate) together. Cement mixed with fine aggregate produces mortar for masonry, or with sand and gravel, produces concrete. Concrete is the most widely used material in existence and is behind only water as the planet's most-consumed resource. Cements used in construction are usually inorganic, often lime- or calcium silicate-based, and are either hydraulic or less commonly non-hydraulic, depending on the ability of the cement to set in the presence of water (see hydraulic and non-hydraulic lime plaster). Hydraulic cements (e.g., Portland cement) set and become adhesive through a chemical reaction between the dry ingredients and water. The chemical reaction results in mineral hydrates that are not very water-soluble. This allows setting in wet conditions or unde ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Metal Casting

In metalworking and jewelry making, casting is a process in which a liquid metal is delivered into a mold (usually by a crucible) that contains a negative impression (i.e., a three-dimensional negative image) of the intended shape. The metal is poured into the mold through a hollow channel called a sprue. The metal and mold are then cooled, and the metal part (the ''casting'') is extracted. Casting is most often used for making complex shapes that would be difficult or uneconomical to make by other methods. Casting processes have been known for thousands of years, and have been widely used for sculpture (especially in bronze), jewelry in precious metals, and weapons and tools. Highly engineered castings are found in 90 percent of durable goods, including cars, trucks, aerospace, trains, mining and construction equipment, oil wells, appliances, pipes, hydrants, wind turbines, nuclear plants, medical devices, defense products, toys, and more. Traditional techniques include los ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |