|

EGR Valve

In internal combustion engines, exhaust gas recirculation (EGR) is a nitrogen oxide () emissions reduction technique used in petrol/gasoline, diesel engines and some hydrogen engines. EGR works by recirculating a portion of an engine's exhaust gas back to the engine cylinders. The exhaust gas displaces atmospheric air and reduces in the combustion chamber. Reducing the amount of oxygen reduces the amount of fuel that can burn in the cylinder thereby reducing peak in-cylinder temperatures. The actual amount of recirculated exhaust gas varies with the engine operating parameters. In the combustion cylinder, is produced by high-temperature mixtures of atmospheric nitrogen and oxygen, and this usually occurs at cylinder peak pressure. In a spark-ignition engine, an ancillary benefit of recirculating exhaust gases via an external EGR valve is an increase in efficiency, as charge dilution allows a larger throttle position and reduces associated pumping losses. Mazda's turbocharg ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Backpressure

Back pressure (or backpressure) is the term for a resistance to the desired flow of fluid through pipes. Obstructions or tight bends create backpressure via friction loss and pressure drop. In distributed systems in particular event-driven architecture, back pressure is a technique to regulate flow of data, ensuring that components do not become overwhelmed. Explanation A common example of backpressure is that caused by the exhaust system (consisting of the exhaust manifold, catalytic converter, muffler and connecting pipes) of an automotive four-stroke engine, which has a negative effect on engine efficiency, resulting in a decrease of power output that must be compensated by increasing fuel consumption. In a piston-ported two-stroke engine, however, the situation is more complicated, due to the need to prevent unburned fuel/air mixture from passing right through the cylinders into the exhaust. During the exhaust phase of the cycle, backpressure is even more undesir ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Piston Ring

A piston ring is a metallic split ring that is attached to the outer diameter of a piston in an internal combustion engine or steam engine. The main functions of piston rings in engines are: # Sealing the combustion chamber so that there is minimal loss of gases to the crank case. # Improving heat transfer from the piston to the cylinder wall. # Maintaining the proper quantity of the oil between the piston and the cylinder wall # Regulating engine oil consumption by scraping oil from the cylinder walls back to the sump. Most piston rings are made from cast iron or steel. Design Piston rings are designed to seal the gap between the piston and the cylinder wall. If this gap were too small, thermal expansion of the piston could mean the piston seizes in the cylinder, causing serious damage to the engine. On the other hand, a large gap would cause insufficient sealing of the piston rings against the cylinder walls, resulting in excessive blow-by (combustion gases entering th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Particulates

Particulate matter (PM) or particulates are microscopic particles of solid or liquid matter suspension (chemistry), suspended in the atmosphere of Earth, air. An ''aerosol'' is a mixture of particulates and air, as opposed to the particulate matter alone, though it is sometimes defined as a subset of aerosol terminology. Sources of particulate matter can be natural or anthropogenic hazard, anthropogenic. Particulates have impacts on climate and precipitation that adversely affect human health. Types of atmosphere, atmospheric particles include suspended particulate matter; thoracic and respirable particles; inhalable coarse particles, designated PM, which are granularity, coarse particles with a particle size, diameter of 10 micrometre, micrometers (μm) or less; fine particles, designated PM, with a diameter of 2.5 μm or less; ultrafine particles, with a diameter of 100 nm or less; and soot. Airborne particulate matter is a List of IARC Group 1 carcinogens, Group ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Spark-ignition Engine

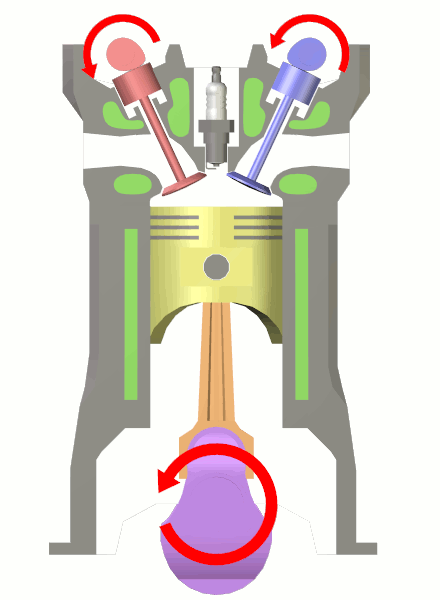

A spark-ignition engine (SI engine) is an internal combustion engine, generally a petrol engine, where the combustion process of the air-fuel mixture is ignited by a spark from a spark plug. This is in contrast to compression-ignition engines, typically diesel engines, where the heat generated from compression ratio, compression together with the injection of fuel is enough to initiate the combustion process, without needing any external spark. Fuels Spark-ignition engines are commonly referred to as "gasoline engines" in North America, and "petrol engines" in Britain and the rest of the world. Spark-ignition engines can (and increasingly are) run on fuels other than gasoline, petrol/gasoline, such as autogas (Liquefied petroleum gas, LPG), methanol, ethanol, bioethanol, compressed natural gas (CNG), hydrogen, and (in drag racing) nitromethane. Working cycle The working cycle of both spark-ignition and compression-ignition engines may be either two-stroke cycle, two-stroke or fou ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Heat Exchanger

A heat exchanger is a system used to transfer heat between a source and a working fluid. Heat exchangers are used in both cooling and heating processes. The fluids may be separated by a solid wall to prevent mixing or they may be in direct contact. They are widely used in space heating, refrigeration, air conditioning, power stations, chemical plants, Petrochemical, petrochemical plants, Oil refinery, petroleum refineries, natural-gas processing, and sewage treatment. The classic example of a heat exchanger is found in an internal combustion engine in which a circulating fluid known as engine coolant flows through radiator coils and air flows past the coils, which cools the coolant and heats the incoming air. Another example is the heat sink, which is a passive heat exchanger that transfers the heat generated by an electronic or a mechanical device to a fluid medium, often air or a liquid coolant. Flow arrangement There are three primary classifications of heat exchangers accord ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Skoda BNM EGR

Škoda means "pity" in the Czech and Slovak languages. It may also refer to: Czech brands and enterprises * Škoda Auto, automobile and previously bicycle manufacturer in Mladá Boleslav ** Škoda Motorsport, the division of Škoda Auto responsible for motorsport activities * Škoda Transportation, engineering company that manufactures rail vehicles, based in Plzeň * Škoda Works, engineering company, predecessor of Škoda Transportation * Škoda-Kauba, aircraft manufacturing subsidiary of the Škoda Works in occupied Czechoslovakia in World War II * Doosan Škoda Power, subsidiary of the Doosan Group, based in Plzeň People * Škoda (surname) * Skoda (Portuguese footballer) (born 1960) Art * ''Škoda lásky'', the original Czech title of the "Beer Barrel Polka" Other * British Rail Class 90 The British Rail Class 90 is a type of electric locomotive. They were built for mixed-traffic duties, operating from overhead lines and producing . They weigh 84.5tonnes and can ty ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Dead Centre (engineering)

In a reciprocating engine, the dead centre is the position of a piston in which it is either furthest from, or nearest to, the crankshaft. The former is known as top dead centre (TDC) while the latter is known as bottom dead centre (BDC). More generally, the dead centre is any position of a crank where the applied force is straight along its axis, meaning no turning force can be applied. Many sorts of machines are crank driven, including unicycles, bicycles, tricycles, various types of machine presses, gasoline engines, diesel engines, steam locomotives, and other steam engines. Crank-driven machines rely on the energy stored in a flywheel to overcome the dead centre, or are designed, in the case of multi-cylinder engines, so that dead centres can never exist on all cranks at the same time. A steam locomotive is an example of the latter, the connecting rods being arranged such that the dead centre for each cylinder occurs out of phase with the other one (or more) cylinders ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Throttle Plate

A throttle is a mechanism by which fluid flow is managed by construction or obstruction. An engine's power can be increased or decreased by the restriction of inlet gases (by the use of a throttle), but usually decreased. The term ''throttle'' has come to refer, informally, to any mechanism by which the power or speed of an engine is regulated, such as a car's accelerator pedal. What is often termed a ''throttle'' (in an aviation context) is also called a thrust lever, particularly for jet engine powered aircraft. For a steam locomotive, the valve which controls the steam is known as the regulator. Internal combustion engines In an internal combustion engine, the throttle is a means of controlling an engine's power by regulating the amount of fuel or air entering the engine. In a motor vehicle the control used by the driver to regulate power is sometimes called the throttle, accelerator, or gas pedal. For a gasoline engine, the throttle most commonly regulates the amount of ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Spark Ignition Engine

A spark-ignition engine (SI engine) is an internal combustion engine, generally a petrol engine, where the combustion process of the air-fuel mixture is ignited by a spark from a spark plug. This is in contrast to compression-ignition engines, typically diesel engines, where the heat generated from compression together with the injection of fuel is enough to initiate the combustion process, without needing any external spark. Fuels Spark-ignition engines are commonly referred to as "gasoline engines" in North America, and "petrol engines" in Britain and the rest of the world. Spark-ignition engines can (and increasingly are) run on fuels other than petrol/gasoline, such as autogas ( LPG), methanol, ethanol, bioethanol, compressed natural gas (CNG), hydrogen, and (in drag racing) nitromethane. Working cycle The working cycle of both spark-ignition and compression-ignition engines may be either two-stroke or four-stroke. A four-stroke spark-ignition engine is an Otto cycle engine ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Adiabatic Flame Temperature

In the study of combustion, the adiabatic flame temperature is the temperature reached by a flame under ideal conditions. It is an upper bound of the temperature that is reached in actual processes. There are two types of Adiabatic process, adiabatic flame temperature: ''constant volume'' and ''constant pressure'', depending on how the process is completed. The constant volume process, constant volume adiabatic flame temperature is the temperature that results from a complete combustion process that occurs without any Work (thermodynamics), work, heat transfer or changes in kinetic energy, kinetic or potential energy. Its temperature is higher than in the ''constant pressure'' process because no energy is utilized to change the volume of the system (i.e., generate work). Common flames In daily life, the vast majority of flames one encounters are those caused by rapid Redox, oxidation of hydrocarbons in materials such as wood, wax, fat, plastics, propane, and gasoline. The consta ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Isentropic

An isentropic process is an idealized thermodynamic process that is both adiabatic and reversible. The work transfers of the system are frictionless, and there is no net transfer of heat or matter. Such an idealized process is useful in engineering as a model of and basis of comparison for real processes. This process is idealized because reversible processes do not occur in reality; thinking of a process as both adiabatic and reversible would show that the initial and final entropies are the same, thus, the reason it is called isentropic (entropy does not change). Thermodynamic processes are named based on the effect they would have on the system (ex. isovolumetric: constant volume, isenthalpic: constant enthalpy). Even though in reality it is not necessarily possible to carry out an isentropic process, some may be approximated as such. The word "isentropic" derives from the process being one in which the entropy of the system remains unchanged. In addition to a process wh ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |