|

Structural Steel

Structural steel is steel used for making construction materials in a variety of shapes. Many structural steel shapes take the form of an elongated beam having a profile of a specific cross section (geometry), cross section. Structural steel shapes, sizes, chemical composition, mechanical properties such as strengths, storage practices, etc., are regulated by Technical standard, standards in most industrialized countries. Structural steel shapes, such as I-beams, have high Second moment of area, second moments of area, so can support a high Structural load, load without excessive Hogging and sagging, sagging. Structural shapes The shapes available are described in published standards worldwide, and specialist, proprietary cross sections are also available. *I-beam, I-beam (serif capital 'I'-shaped cross-section – in Britain these include Universal Beams (UB) and Universal Columns (UC); in Europe it includes the IPE, HE, HL, HD and other sections; in the US it includes Wide ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hot Rolling

In metalworking, rolling is a metal forming process in which metal stock is passed through one or more pairs of rolls to reduce the thickness, to make the thickness uniform, and/or to impart a desired mechanical property. The concept is similar to the rolling of dough. Rolling is classified according to the temperature of the metal rolled. If the temperature of the metal is above its recrystallization temperature, then the process is known as hot rolling. If the temperature of the metal is below its recrystallization temperature, the process is known as cold rolling. In terms of usage, hot rolling processes more tonnage than any other manufacturing process, and cold rolling processes the most tonnage out of all cold working processes... Roll stands holding pairs of rolls are grouped together into rolling mills that can quickly process metal, typically steel, into products such as structural steel (I-beams, angle stock, channel stock), bar stock, and rails. Most steel mills ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Euronorm

European Standards, sometimes called Euronorm (abbreviated EN, from the German name , "European Norm"), are technical standards which have been ratified by one of the three European Standards Organizations (ESO): European Committee for Standardization (CEN), European Committee for Electrotechnical Standardization (CENELEC), or European Telecommunications Standards Institute (ETSI). All ENs are designed and created by all standards organizations and interested parties through a transparent, open, and consensual process. European Standards are a key component of the Single European Market. They are crucial in facilitating trade and have high visibility among manufacturers inside and outside the European territory. A standard represents a model specification, a technical solution against which a market can trade. European Standards must be transposed into a national standard in all EU member states. This guarantees that a manufacturer has easier access to the market of all these Eur ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Quench

In materials science, quenching is the rapid cooling of a workpiece in water, gas, oil, polymer, air, or other fluids to obtain certain material properties. A type of heat treating, quenching prevents undesired low-temperature processes, such as phase transformations, from occurring. It does this by reducing the window of time during which these undesired reactions are both thermodynamically favorable and kinetically accessible; for instance, quenching can reduce the crystal grain size of both metallic and plastic materials, increasing their hardness. In metallurgy, quenching is most commonly used to harden steel by inducing a martensite transformation, where the steel must be rapidly cooled through its eutectoid point, the temperature at which austenite becomes unstable. Rapid cooling prevents the formation of cementite structure, instead forcibly dissolving carbon atoms in the ferrite lattice. In steel alloyed with metals such as nickel and manganese, the eutectoid tempe ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cor-ten

Weathering steel, often referred to by the genericised trademark COR-TEN steel and sometimes written without the hyphen as corten steel, is a group of steel alloys that form a stable external layer of rust that eliminates the need for painting. U.S. Steel (USS) holds the registered trademark on the name COR-TEN. The name COR-TEN refers to the two distinguishing properties of this type of steel: corrosion resistance and tensile strength. Although USS sold its discrete plate business to International Steel Group (now ArcelorMittal) in 2003, it makes COR-TEN branded material in strip mill plate and sheet forms. The original COR-TEN received the standard designation A242 (COR-TEN A) from the ASTM International standards group. Newer ASTM grades are A588 (COR-TEN B) and A606 for thin sheet. All of the alloys are in common production and use. The surface oxidation generally takes six months to develop, although surface treatments can accelerate this to as little as one hour. H ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Charpy Impact Test

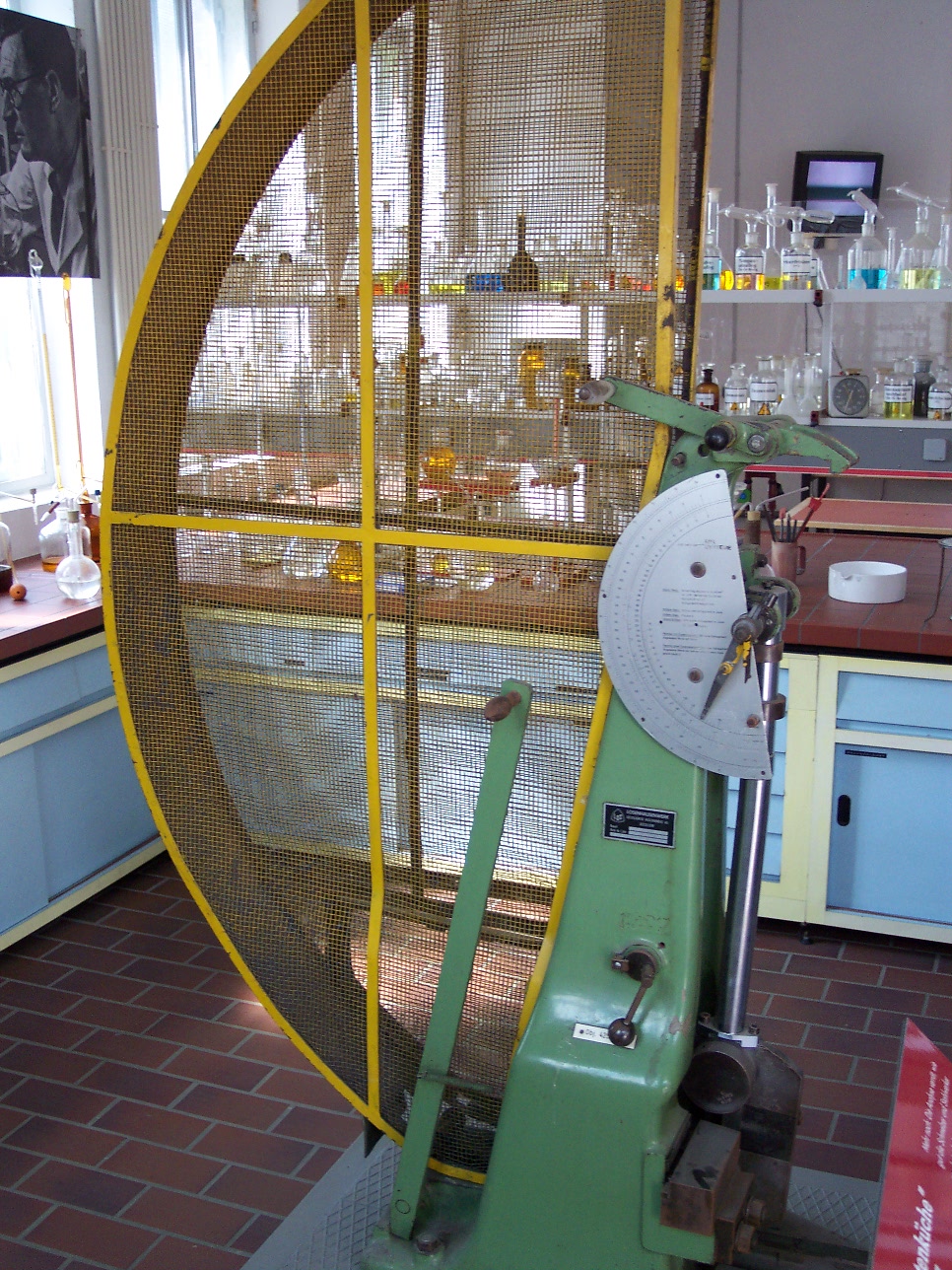

In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a material during fracture. Absorbed energy is a measure of the material's notch (engineering), notch toughness. It is widely used in industry, since it is easy to prepare and conduct and results can be obtained quickly and cheaply. A disadvantage is that some results are only comparative. The test was pivotal in understanding the fracture problems of ships during World War II. The test was developed around 1900 by S. B. Russell (1898, American) and Georges Charpy (1901, French). The test became known as the Charpy test in the early 1900s due to the technical contributions and standardization efforts by Charpy. History In 1896, S. B. Russell introduced the idea of ''residual fracture energy'' and devised a pendulum fracture test. Russell's initial tests measured un-notched samples. In 1897, Frémont intro ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Toughness

In materials science and metallurgy, toughness is the ability of a material to absorb energy and plastically deform without fracturing."Toughness" Brian Larson, editor, 2001–2011, The Collaboration for NDT Education, Iowa State University [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Megapascal

The pascal (symbol: Pa) is the unit of pressure in the International System of Units (SI). It is also used to quantify internal pressure, stress, Young's modulus, and ultimate tensile strength. The unit, named after Blaise Pascal, is an SI coherent derived unit defined as one newton per square metre (N/m2). It is also equivalent to 10 barye (10 Ba) in the CGS system. Common multiple units of the pascal are the hectopascal (1 hPa = 100 Pa), which is equal to one millibar, and the kilopascal (1 kPa = 1000 Pa), which is equal to one centibar. The unit of measurement called '' standard atmosphere (atm)'' is defined as . Meteorological observations typically report atmospheric pressure in hectopascals per the recommendation of the World Meteorological Organization, thus a standard atmosphere (atm) or typical sea-level air pressure is about 1013 hPa. Reports in the United States typically use inches of mercury or millibars (hectopascals). In Canada, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Yield Strength

In materials science and engineering, the yield point is the point on a stress–strain curve that indicates the limit of elastic behavior and the beginning of plastic behavior. Below the yield point, a material will deform elastically and will return to its original shape when the applied stress is removed. Once the yield point is passed, some fraction of the deformation will be permanent and non-reversible and is known as plastic deformation. The yield strength or yield stress is a material property and is the stress corresponding to the yield point at which the material begins to deform plastically. The yield strength is often used to determine the maximum allowable load in a mechanical component, since it represents the upper limit to forces that can be applied without producing permanent deformation. For most metals, such as aluminium and cold-worked steel, there is a gradual onset of non-linear behavior, and no precise yield point. In such a case, the offset yield p ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

EN 10025

EN 10025 - Hot rolled products of structural steels refers to a set of European standards which specify the technical delivery conditions for hot rolled products of structural steels. The standards consist of the following parts: * EN 10025-1: Part 1: General technical delivery conditions * EN 10025-2: Part 2: Technical delivery conditions for non-alloy structural steels * EN 10025-3: Part 3: Technical delivery conditions for normalized/normalized rolled weldable fine grain structural steels * EN 10025-4: Part 4: Technical delivery conditions for thermomechanical rolled weldable fine grain structural steels *EN 10025-5: Part 5: Technical delivery conditions for structural steels with improved atmospheric corrosion resistance * EN 10025-6: Part 6: Technical delivery conditions for flat products of high yield strength structural steels in the quenched and tempered condition Editions * EN 10025:2019 (current version) * EN 10025:2005 * EN 10025:1990+A1:1993 * EN 10025:1990 See ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Misnomer

A misnomer is a name that is incorrectly or unsuitably applied. Misnomers often arise because something was named long before its correct nature was known, or because an earlier form of something has been replaced by a later form to which the name no longer suitably applies. A misnomer may also be a word that is used incorrectly or misleadingly. The word "misnomer" does not mean " misunderstanding" or " popular misconception", and a number of misnomers remain in common usage — which is to say that a word being a misnomer does not necessarily make ''usage'' of the word incorrect. Sources of misnomers * An older name being retained after the thing itself has changed (e.g., tin can, mince meat pie, steamroller, tin foil, clothes iron, digital darkroom). This is essentially a metaphorical extension with the name of the older item standing for anything filling the same role. * Transference of a well-known product brand name into a genericized trademark (e.g., Xerox f ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Wrought Iron

Wrought iron is an iron alloy with a very low carbon content (less than 0.05%) in contrast to that of cast iron (2.1% to 4.5%), or 0.25 for low carbon "mild" steel. Wrought iron is manufactured by heating and melting high carbon cast iron in an open charcoal or coke hearth or furnace in a process known as puddling. The high temperatures cause the excess carbon to oxidise, the iron being stirred or puddled during the process in order to achieve this. As the carbon content reduces, the melting point of the iron increases, ultimately to a level which is higher than can be achieved by the hearth, hence the wrought iron is never fully molten and many impurities remain. The primary advantage of wrought iron over cast iron is its malleability - where cast iron is too brittle to bend or shape without breaking, wrought iron is highly malleable, and much easier to bend. Wrought iron is a semi-fused mass of iron with fibrous slag inclusions (up to 2% by weight), which give it ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |