|

Robotic Manipulators

In robotics, a manipulator is a device used to manipulate materials without direct physical contact by the operator. The applications were originally for dealing with radioactive or biohazardous materials, using robotic arms, or they were used in inaccessible places. In more recent developments they have been used in diverse range of applications including welding automation, robotic surgery and in space. It is an arm-like mechanism that consists of a series of segments, usually sliding or jointed called cross-slides, which grasp and move objects with a number of degrees of freedom. In industrial ergonomics a manipulator is a lift-assist device used to help workers lift, maneuver and place articles in process that are too heavy, too hot, too large or otherwise too difficult for a single worker to manually handle. As opposed to simply vertical lift assists (cranes, hoists, etc.) manipulators have the ability to reach in to tight spaces and remove workpieces. A good example w ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tank Container

A tank container or tanktainer is an intermodal container for the transport of liquids, gases and powders as bulk cargo. It is built to the ISO standards, making it suitable for different modes of transportation; as such, it is also called an ISO tank. Both hazardous and non-hazardous products can be transported in tank containers. A tank container is a vessel of stainless steel surrounded by an insulation and protective layer of usually polyurethane and aluminum. The vessel is in the middle of a steel frame. The frame is made according to ISO standards and is long, wide and or high. The contents of the tank range from . There are both smaller and larger tank containers, which usually have a size different from the ISO standard sizes. For example, there are some and above litre tank containers in the European swap body fleets in Europe but they are not used on international business only on intra European traffic. The trade organization ITCO estimates that as of January 1, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

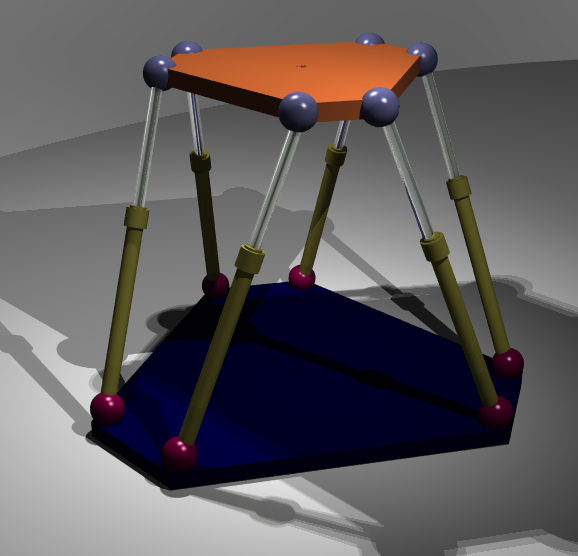

Parallel Manipulator

A parallel manipulator is a mechanical system that uses several computer-controlled serial chains to support a single platform, or end-effector. Perhaps, the best known parallel manipulator is formed from six linear actuators that support a movable base for devices such as flight simulators. This device is called a Stewart platform or the Gough-Stewart platform in recognition of the engineers who first designed and used them. Also known as parallel robots, or generalized Stewart platforms (in the Stewart platform, the actuators are paired together on both the basis and the platform), these systems are articulated robots that use similar mechanisms for the movement of either the robot on its base, or one or more manipulator arms. Their 'parallel' distinction, as opposed to a serial manipulator, is that the end effector (or 'hand') of this linkage (or 'arm') is directly connected to its base by a number of (usually three or six) separate and independent linkages working simu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Telemanipulator

A remote manipulator, also known as a telefactor, telemanipulator, or waldo (after the 1942 short story " Waldo" by Robert A. Heinlein which features a man who invents and uses such devices), is a device which, through electronic, hydraulic, or mechanical linkages, allows a hand-like mechanism to be controlled by a human operator. The purpose of such a device is usually to move or manipulate hazardous materials for reasons of safety, similar to the operation and play of a claw crane game. History In 1945, the company Central Research Laboratories was given the contract to develop a remote manipulator for the Argonne National Laboratory. The intent was to replace devices which manipulated highly radioactive materials from above a sealed chamber or hot cell, with a mechanism which operated through the side wall of the chamber, allowing a researcher to stand normally while working. The result was the Master-Slave Manipulator Mk. 8, or MSM-8, which became the iconic remote manip ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Articulated Robot

An articulated robot is a robot with rotary joints that has 6 or more Degrees of Freedom . This is one of the most commonly used robots in industry today (many examples can be found from legged robots or industrial robots). Articulated robots can range from simple 6 Degree of Freedom structures to systems with 10 or more interacting joints and materials. They are powered by a variety of means, including electric motors. Some types of robots, such as robotic arms, can be articulated or non-articulated.http://www.ssl.umd.edu/projects/rangertsx/data/spacerobotics-UNDSPST470.pdf , pg 9 Articulated robots Image:Factory Automation Robotics Palettizing Bread.jpg, Robots palletizing food at a bakery Image: Robotics Cutting Bridge Building Parts.jpg, Manufacturing of steel bridges, cutting steel Image:KUKA robot for flat glas handling.jpg, Flat-glass handling, heavy duty robot with 500 kg payload Image:Automation of foundry with robot.jpg, Automation in foundry industry, heat resi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

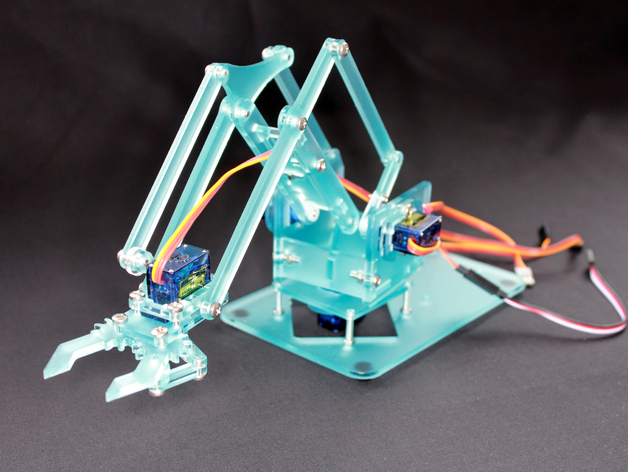

Robotic Arm

A robotic arm is a type of mechanical arm, usually programmable, with similar functions to a human arm; the arm may be the sum total of the mechanism or may be part of a more complex robot. The links of such a manipulator are connected by joints allowing either rotational motion (such as in an articulated robot) or translational (linear) displacement. The links of the manipulator can be considered to form a kinematic chain. The terminus of the kinematic chain of the manipulator is called the end effector and it is analogous to the human hand. However, the term "robotic hand" as a synonym of the robotic arm is often proscribed. Types * Cartesian robot / Gantry robot: Used for pick and place work, application of sealant, assembly operations, handling machine tools and arc welding. It is a robot whose arm has three prismatic joints, whose axes are coincident with a Cartesian coordinator. * Collaborative robot / Cobot: Cobot applications contrast with traditional industri ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Industrial Robots

An industrial robot is a robot system used for manufacturing. Industrial robots are automated, programmable and capable of movement on three or more axes. Typical applications of robots include robot welding, welding, painting, assembly, Circular economy, disassembly, Automated storage and retrieval system, pick and place for printed circuit boards, packaging and labeling, Palletizer, palletizing, product inspection, and testing; all accomplished with high endurance, speed, and precision. They can assist in material handling. In the year 2023, an estimated 4,281,585 industrial robots were in operation worldwide according to International Federation of Robotics, International Federation of Robotics (IFR). Types and features There are six types of industrial robots. Articulated robots Articulated robots are the most common industrial robots. They look like a Arm, human arm, which is why they are also called robotic arm or Manipulator (device), manipulator arm. Their articu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

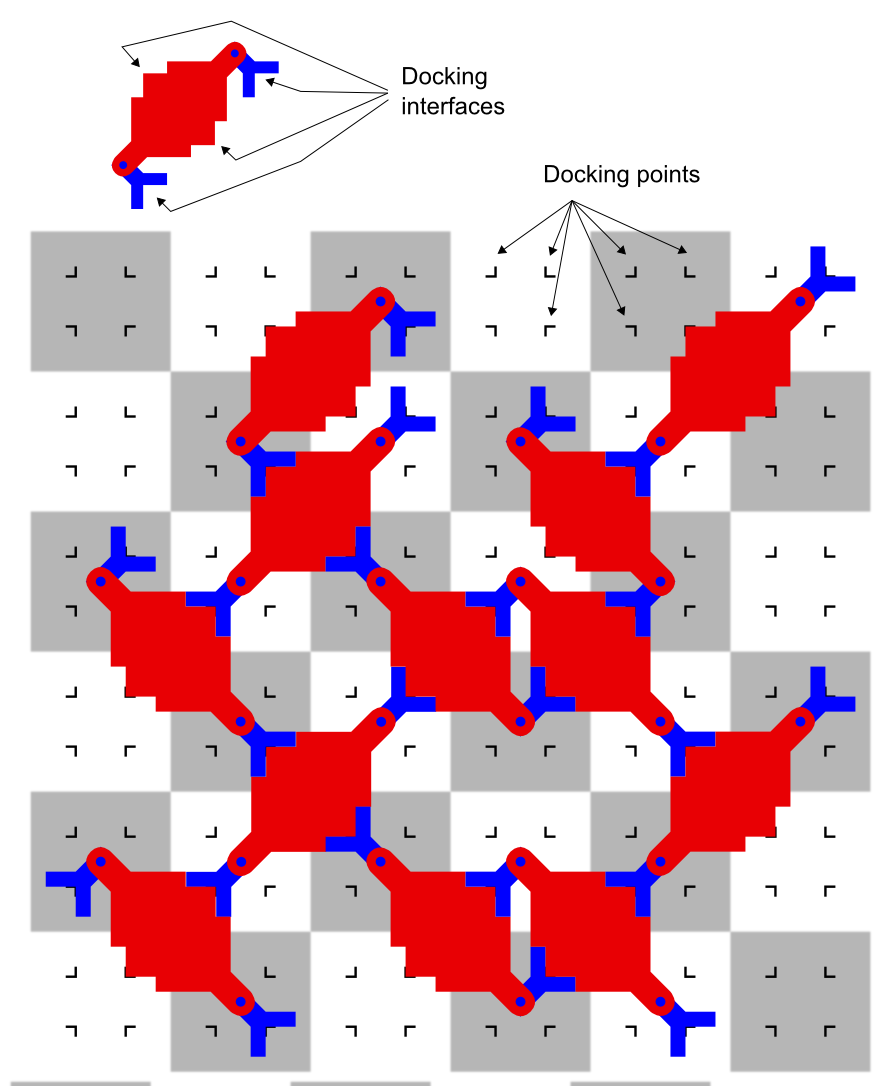

ANAT Technology

Modular self-reconfiguring robotic systems or self-reconfigurable modular robots are autonomous kinematic machines with variable morphology. Beyond conventional actuation, sensing and control typically found in fixed-morphology robots, self-reconfiguring robots are also able to deliberately change their own shape by rearranging the connectivity of their parts, in order to adapt to new circumstances, perform new tasks, or recover from damage. For example, a robot made of such components could assume a worm-like shape to move through a narrow pipe, reassemble into something with spider-like legs to cross uneven terrain, then form a third arbitrary object (like a ball or wheel that can spin itself) to move quickly over a fairly flat terrain; it can also be used for making "fixed" objects, such as walls, shelters, or buildings. In some cases this involves each module having 2 or more connectors for connecting several together. They can contain electronics, sensors, computer processo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |