|

Cimatron

Cimatron is an Israeli software company that produces computer-aided design and computer-aided manufacturing (CAD/CAM) software for manufacturing, toolmaking and computer numerical control (CNC) programming applications. The company was listed on the Nasdaq exchange under the symbol CIMT, until its 2014 acquisition by 3D Systems. Before this, the firm's major shareholder was DBSI, whose co-managing partner, Yossi Ben-Shalom, chaired the Cimatron board. Headquartered in Tel Aviv, the firm had subsidiaries in the United States, Germany, Italy, China, South Korea, India and Brazil, and resellers in over 40 countries. Its main software products, CimatronE and GibbsCAM, are used in over 40,000 installations worldwide. Its clients are largely from the automotive, aerospace, consumer electronics, toys, medical, optics and telecom industries. One of the firm's major clients is China's Haier Mould, a subsidiary of the Haier Group. History The firm was founded in 1982 as MicroCAD, relea ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Computer-aided Manufacturing

Computer-aided manufacturing (CAM) also known as computer-aided modeling or computer-aided machining is the use of software to control machine tools in the manufacturing of work pieces. This is not the only definition for CAM, but it is the most common. It may also refer to the use of a computer to assist in all operations of a manufacturing plant, including planning, Industrial management, management, transportation and storage. Its primary purpose is to create a faster production process and components and tooling with more precise dimensions and material consistency, which in some cases, uses only the required amount of raw material (thus minimizing waste), while simultaneously reducing energy consumption. CAM is now a system used in schools and lower educational purposes. CAM is a subsequent computer-aided process after computer-aided design (CAD) and sometimes computer-aided engineering (CAE), as the model generated in CAD and verified in CAE can be input into CAM software, w ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

List Of Computer-aided Manufacturing Software

This is a list of ''computer-aided manufacturing'' (CAM) software. See also *APT (programming language) *CNC machining *Computer-aided manufacturing *Comparison of computer-aided design software *G-code *List of 3D modeling software *List of 3D computer graphics software *List of 3D printing software *List of BIM software *List of computer-aided engineering software *List of CAx companies References {{Reflist * https://www.fictiv.com/articles/the-best-cad-cam-software-for-cnc Lists of software, 3d Modelling Software Computer-aided manufacturing software Computer-aided manufacturing software for Linux ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

ACIS

The 3D ACIS Modeler (ACIS) is a geometric modeling kernel developed by Spatial Corporation (formerly Spatial Technology), part of Dassault Systèmes. ACIS is used by software developers in industries such as computer-aided design, computer-aided manufacturing, computer-aided engineering, architecture, engineering and construction, coordinate-measuring machine, 3D animation, and shipbuilding. ACIS provides software developers and manufacturers the underlying 3D modeling functionality. ACIS features an object-oriented C++ architecture with 3D modelling capabilities. ACIS is used to construct applications with hybrid modeling features, since it integrates wireframe model, surface, and solid modeling functionality with both manifold and non-manifold topology, and a set of geometric operations. History As a geometric kernel, ACIS is a second generation system, coming after the first generation Romulus. There are several versions about what the word ACIS actually stands f ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Privately Held Company

A privately held company (or simply a private company) is a company whose Stock, shares and related rights or obligations are not offered for public subscription or publicly negotiated in their respective listed markets. Instead, the Private equity, company's stock is offered, owned, traded or exchanged privately, also known as "over-the-counter (finance), over-the-counter". Related terms are unlisted organisation, unquoted company and private equity. Private companies are often less well-known than their public company, publicly traded counterparts but still have major importance in the world's economy. For example, in 2008, the 441 list of largest private non-governmental companies by revenue, largest private companies in the United States accounted for $1.8 trillion in revenues and employed 6.2 million people, according to ''Forbes''. In general, all companies that are not owned by the government are classified as private enterprises. This definition encompasses both publ ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Product Lifecycle Management

In industry, product lifecycle management (PLM) is the process of managing the entire lifecycle of a product from its inception through the engineering, design, and manufacture, as well as the service and disposal of manufactured products. PLM integrates people, data, processes, and business systems and provides a product information backbone for companies and their extended enterprises. History The inspiration for the burgeoning business process now known as PLM came from American Motors Corporation (AMC). The automaker was looking for a way to speed up its product development process to compete better against its larger competitors in 1985, according to François Castaing, Vice President for Product Engineering and Development. AMC focused its R&D efforts on extending the product lifecycle of its flagship products, particularly Jeeps, because it lacked the "massive budgets of General Motors, Ford, and foreign competitors." After introducing its compact Jeep Cherokee (X ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Computer-aided Manufacturing Software

Automation describes a wide range of technologies that reduce human intervention in processes, mainly by predetermining decision criteria, subprocess relationships, and related actions, as well as embodying those predeterminations in machines. Automation has been achieved by various means including mechanical, hydraulic, pneumatic, electrical, electronic devices, and computers, usually in combination. Complicated systems, such as modern factories, airplanes, and ships typically use combinations of all of these techniques. The benefit of automation includes labor savings, reducing waste, savings in electricity costs, savings in material costs, and improvements to quality, accuracy, and precision. Automation includes the use of various equipment and control systems such as machinery, processes in factories, boilers, and heat-treating ovens, switching on telephone networks, steering, stabilization of ships, aircraft and other applications and vehicles with reduced human interve ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Electrical Discharge Machining

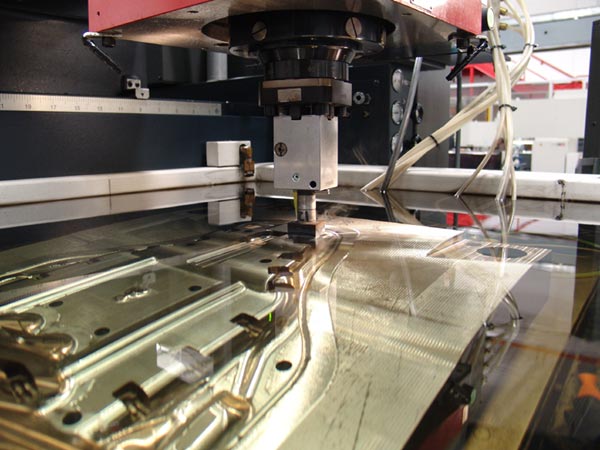

Electrical discharge machining (EDM), also known as spark machining, spark eroding, die sinking, wire burning or wire erosion, is a metal fabrication process whereby a desired shape is obtained by using electrical discharges (sparks). Material is removed from the work piece by a series of rapidly recurring current discharges between two electrodes, separated by a dielectric liquid and subject to an electric voltage. One of the electrodes is called the tool-electrode, or simply the or , while the other is called the workpiece-electrode, or . The process depends upon the tool and work piece not making physical contact. Extremely hard materials like carbides, ceramics, titanium alloys and heat treated tool steels that are very difficult to machine using conventional machining can be precisely machined by EDM. When the voltage between the two electrodes is increased, the intensity of the electric field in the volume between the electrodes becomes greater, causing electrical breakdown, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Toolpath

A machine tool is a machine for handling or machining metal or other rigid materials, usually by cutting, boring, grinding, shearing, or other forms of deformations. Machine tools employ some sort of tool that does the cutting or shaping. All machine tools have some means of constraining the workpiece and provide a guided movement of the parts of the machine. Thus, the relative movement between the workpiece and the cutting tool (which is called the toolpath) is controlled or constrained by the machine to at least some extent, rather than being entirely "offhand" or " freehand". It is a power-driven metal cutting machine which assists in managing the needed relative motion between cutting tool and the job that changes the size and shape of the job material. The precise definition of the term ''machine tool'' varies among users. While all machine tools are "machines that help people to make things", not all factory machines are machine tools. Today machine tools are typically p ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Die (manufacturing)

A die is a specialized machine tool used in manufacturing industries to cut and/or Forming (metalworking), form material to a desired shape or profile. ''Stamping (metalworking), Stamping dies'' are used with a machine press, press, as opposed to ''Draw plate, drawing dies'' (used in the manufacture of wire) and ''Die casting, casting dies'' (used in Molding (process), molding) which are not. Like molds, dies are generally customized to the item they are used to create. Products made with dies range from simple paper clips to complex pieces used in advanced technology. Continuous production, Continuous-feed laser cutting may displace the analogous die-based process in the automotive industry, among others. Die stamping Blanking and piercing are two Shearing (manufacturing), die cutting operations, and Bending (metalworking), bending is an example of a die forming operation. Die forming Forming operations work by deforming materials like sheet metal or plastic using force (Compre ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Molding (process)

Molding (American English) or moulding ( British and Commonwealth English; see spelling differences) is the process of manufacturing by shaping liquid or pliable raw material using a rigid frame called a mold or matrix. This itself may have been made using a pattern or model of the final object. A mold or mould is a hollowed-out block that is filled with a liquid or pliable material such as plastic, glass, metal, or ceramic raw material. The liquid hardens or sets inside the mold, adopting its shape. A mold is a counterpart to a cast. The very common bi-valve molding process uses two molds, one for each half of the object. Articulated molds have multiple pieces that come together to form the complete mold, and then disassemble to release the finished casting; they are expensive, but necessary when the casting shape has complex overhangs. Piece-molding uses a number of different molds, each creating a section of a complicated object. This is generally only used for larg ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

3D Printing

3D printing, or additive manufacturing, is the construction of a three-dimensional object from a CAD model or a digital 3D model. It can be done in a variety of processes in which material is deposited, joined or solidified under computer control, with the material being added together (such as plastics, liquids or powder grains being fused), typically layer by layer. In the 1980s, 3D printing techniques were considered suitable only for the production of functional or aesthetic prototypes, and a more appropriate term for it at the time was rapid prototyping. , the precision, repeatability, and material range of 3D printing have increased to the point that some 3D printing processes are considered viable as an industrial-production technology; in this context, the term ''additive manufacturing'' can be used synonymously with ''3D printing''. One of the key advantages of 3D printing is the ability to produce very complex shapes or geometries that would be otherwise infeasi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |