|

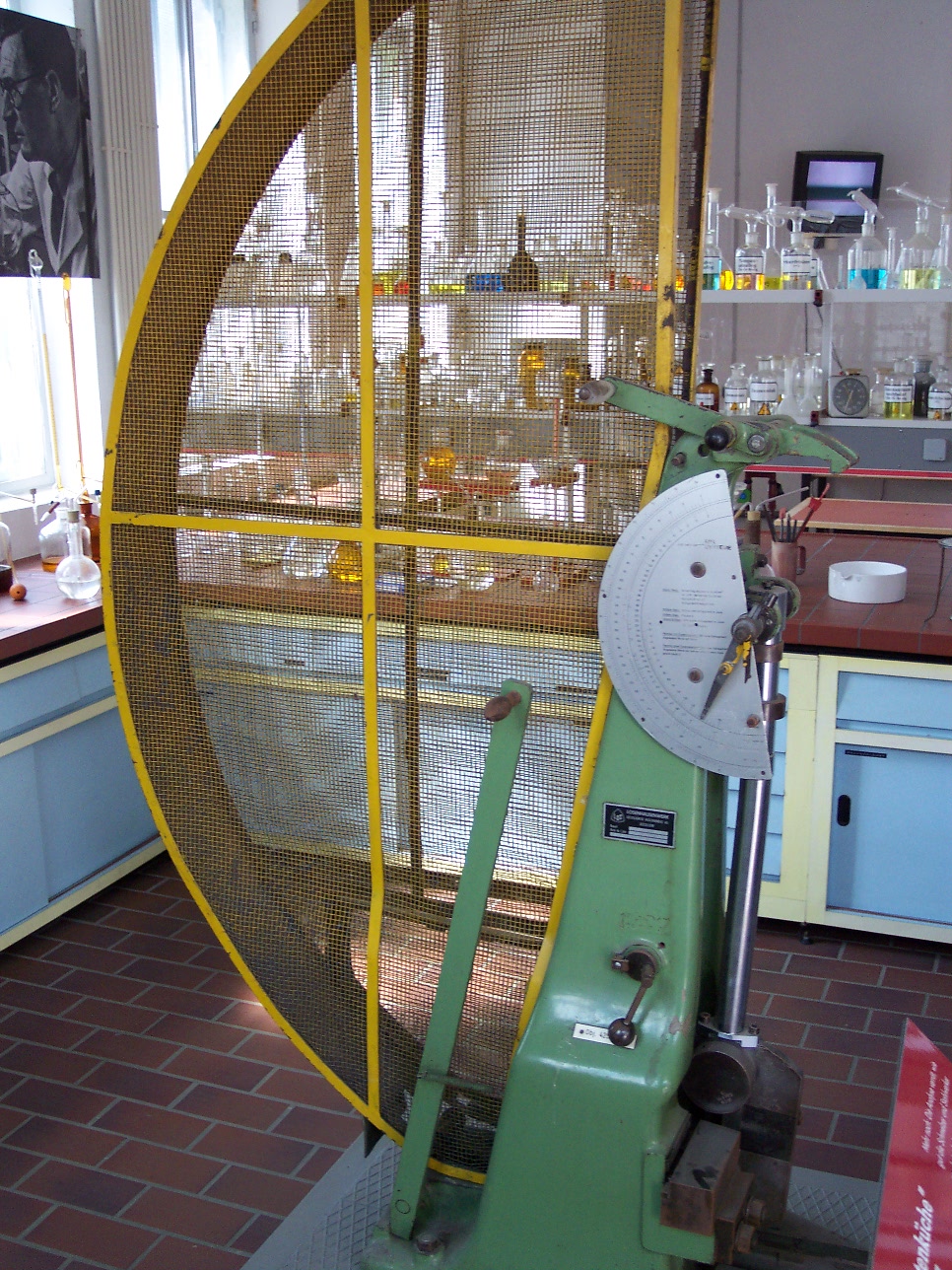

Charpy Impact Test

In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a material during fracture. Absorbed energy is a measure of the material's notch (engineering), notch toughness. It is widely used in industry, since it is easy to prepare and conduct and results can be obtained quickly and cheaply. A disadvantage is that some results are only comparative. The test was pivotal in understanding the fracture problems of ships during World War II. The test was developed around 1900 by S. B. Russell (1898, American) and Georges Charpy (1901, French). The test became known as the Charpy test in the early 1900s due to the technical contributions and standardization efforts by Charpy. History In 1896, S. B. Russell introduced the idea of ''residual fracture energy'' and devised a pendulum fracture test. Russell's initial tests measured un-notched samples. In 1897, Frémont intro ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

ASTM International

ASTM International, formerly known as American Society for Testing and Materials, is a standards organization that develops and publishes voluntary consensus technical international standards for a wide range of materials, products, systems and services. Some 12,575 apply globally. The headquarters is in West Conshohocken, Pennsylvania, about northwest of Philadelphia. It was founded in 1902 as the American Section of the International Association for Testing Materials. In addition to its traditional standards work, ASTM operates several global initiatives advancing additive manufacturing, advanced manufacturing, and emerging technologies, including the Additive Manufacturing Center of Excellence (AM CoE), the acquisition oWohlers Associatesfor market intelligence and advisory services, and the National Institute of Standards and Technology, NIST-funded Standardization Center of Excellence (SCOE). History In 1898, a group of scientists and engineers, led by chemist, industry ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Impact Force

In mechanics, an impact is when two bodies collide. During this collision, both bodies decelerate. The deceleration causes a high force or shock, applied over a short time period. A high force, over a short duration, usually causes more damage to both bodies than a lower force applied over a proportionally longer duration. At normal speeds, during a perfectly inelastic collision, an object struck by a projectile will deform, and this deformation will absorb most or all of the force of the collision. Viewed from a conservation of energy perspective, the kinetic energy of the projectile is changed into heat and sound energy, as a result of the deformations and vibrations induced in the struck object. However, these deformations and vibrations cannot occur instantaneously. A high-velocity collision (an impact) does not provide sufficient time for these deformations and vibrations to occur. Thus, the struck material behaves as if it were more brittle than it would otherwise be ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Brittle

A material is brittle if, when subjected to stress, it fractures with little elastic deformation and without significant plastic deformation. Brittle materials absorb relatively little energy prior to fracture, even those of high strength. Breaking is often accompanied by a sharp snapping sound. When used in materials science, it is generally applied to materials that fail when there is little or no plastic deformation before failure. One proof is to match the broken halves, which should fit exactly since no plastic deformation has occurred. Brittleness in different materials Polymers Mechanical characteristics of polymers can be sensitive to temperature changes near room temperatures. For example, poly(methyl methacrylate) is extremely brittle at temperature 4˚C, but experiences increased ductility with increased temperature. Amorphous polymers are polymers that can behave differently at different temperatures. They may behave like a glass at low temperatures (the gla ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Izod Impact Strength Test

The Izod impact strength test is an ASTM standard method of determining the impact resistance of materials. A pivoting arm is raised to a specific height (constant potential energy) and then released. The arm swings down hitting a notched sample, breaking the specimen. The energy absorbed by the sample is calculated from the height the arm swings to after hitting the sample. A notched sample is generally used to determine impact energy and notch sensitivity. The test is similar to the Charpy impact test but uses a different arrangement of the specimen under test. The Izod impact test differs from the Charpy impact test in that the sample is held in a cantilevered beam configuration as opposed to a three-point bending configuration. The test is named after the English engineer Edwin Gilbert Izod (1876–1946), who described it in his 1903 address to the British Association, subsequently published in ''Engineering''.Izod, Gilbert, 'Testing brittleness of steel', ''Engineering'', ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cubic Crystal System

In crystallography, the cubic (or isometric) crystal system is a crystal system where the unit cell is in the shape of a cube. This is one of the most common and simplest shapes found in crystals and minerals. There are three main varieties of these crystals: *Primitive cubic (abbreviated ''cP'' and alternatively called simple cubic) *Body-centered cubic (abbreviated ''cI'' or bcc) *Face-centered cubic (abbreviated ''cF'' or fcc) Note: the term fcc is often used in synonym for the ''cubic close-packed'' or ccp structure occurring in metals. However, fcc stands for a face-centered cubic Bravais lattice, which is not necessarily close-packed when a motif is set onto the lattice points. E.g. the diamond and the zincblende lattices are fcc but not close-packed. Each is subdivided into other variants listed below. Although the ''unit cells'' in these crystals are conventionally taken to be cubes, the primitive unit cells often are not. Bravais lattices The three Bravais latices ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Eprouvette Charpy

An is a one piece, fixed elevation mortar used by ordnance departments and armories to test the strength of gunpowder. A carefully weighed quantity of powder (charge) was placed inside the device, followed by a standard weight shot. The charge was fired and the distance the shot flew was measured and compared to the expected standard distance. were first introduced in the middle of the 1600s and went out of general use by the middle of the 19th century. were also used to test the strength of small-arms powder, starting in the second half of the 1500s. These evolved into pistol-size devices which were used until the end of the black powder Gunpowder, also commonly known as black powder to distinguish it from modern smokeless powder, is the earliest known chemical explosive. It consists of a mixture of sulfur, charcoal (which is mostly carbon), and potassium nitrate, potassium ni ... era, at the close of the 1800s. References External links Eprouvette Mortar Mort ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

ASTM

ASTM International, formerly known as American Society for Testing and Materials, is a standards organization that develops and publishes voluntary consensus technical international standards for a wide range of materials, products, systems and services. Some 12,575 apply globally. The headquarters is in West Conshohocken, Pennsylvania, about northwest of Philadelphia. It was founded in 1902 as the American Section of the International Association for Testing Materials. In addition to its traditional standards work, ASTM operates several global initiatives advancing additive manufacturing, advanced manufacturing, and emerging technologies, including the Additive Manufacturing Center of Excellence (AM CoE), the acquisition oWohlers Associatesfor market intelligence and advisory services, and the NIST-funded Standardization Center of Excellence (SCOE). History In 1898, a group of scientists and engineers, led by chemist, industry leader, and proponent of standardization Ch ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ductility

Ductility refers to the ability of a material to sustain significant plastic Deformation (engineering), deformation before fracture. Plastic deformation is the permanent distortion of a material under applied stress, as opposed to elastic deformation, which is reversible upon removing the stress. Ductility is a critical mechanical performance indicator, particularly in applications that require materials to bend, stretch, or deform in other ways without breaking. The extent of ductility can be quantitatively assessed using the percent elongation at break, given by the equation: \% \mathrm= \left ( \frac \right )\times100 where l_ is the length of the material after fracture and l_0 is the original length before testing. This formula helps in quantifying how much a material can stretch under tensile stress before failure, providing key insights into its ductile behavior. Ductility is an important consideration in engineering and manufacturing. It defines a material's suitabil ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ductile-brittle Transition Temperature

Ductility refers to the ability of a material to sustain significant plastic deformation before fracture. Plastic deformation is the permanent distortion of a material under applied stress, as opposed to elastic deformation, which is reversible upon removing the stress. Ductility is a critical mechanical performance indicator, particularly in applications that require materials to bend, stretch, or deform in other ways without breaking. The extent of ductility can be quantitatively assessed using the percent elongation at break, given by the equation: \% \mathrm= \left ( \frac \right )\times100 where l_ is the length of the material after fracture and l_0 is the original length before testing. This formula helps in quantifying how much a material can stretch under tensile stress before failure, providing key insights into its ductile behavior. Ductility is an important consideration in engineering and manufacturing. It defines a material's suitability for certain manufactur ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Yield (engineering)

In materials science and engineering, the yield point is the point on a stress–strain curve that indicates the limit of elastic behavior and the beginning of plastic behavior. Below the yield point, a material will deform elastically and will return to its original shape when the applied stress is removed. Once the yield point is passed, some fraction of the deformation will be permanent and non-reversible and is known as plastic deformation. The yield strength or yield stress is a material property and is the stress corresponding to the yield point at which the material begins to deform plastically. The yield strength is often used to determine the maximum allowable load in a mechanical component, since it represents the upper limit to forces that can be applied without producing permanent deformation. For most metals, such as aluminium and cold-worked steel, there is a gradual onset of non-linear behavior, and no precise yield point. In such a case, the offset yield p ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

International Organization For Standardization

The International Organization for Standardization (ISO ; ; ) is an independent, non-governmental, international standard development organization composed of representatives from the national standards organizations of member countries. Membership requirements are given in Article 3 of the ISO Statutes. ISO was founded on 23 February 1947, and () it has published over 25,000 international standards covering almost all aspects of technology and manufacturing. It has over 800 technical committees (TCs) and subcommittees (SCs) to take care of standards development. The organization develops and publishes international standards in technical and nontechnical fields, including everything from manufactured products and technology to food safety, transport, IT, agriculture, and healthcare. More specialized topics like electrical and electronic engineering are instead handled by the International Electrotechnical Commission.Editors of Encyclopedia Britannica. 3 June 2021.Inte ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |