|

Bisphenol-A Bis(diphenyl Phosphate)

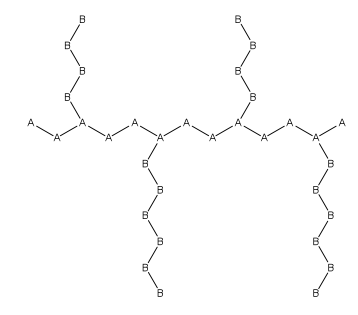

Bisphenol A diphenyl phosphate is a halogen-free flame retardant used plastics. It is used in polymer blends of engineering plastics, such as PPO/HIPS and PC/ ABS, which are commonly used to make casing for electrical items like TVs, computers and home appliances. It is formed by the transesterification of bisphenol A with triphenyl phosphate. The commercial grade material can contain oligomer In chemistry and biochemistry, an oligomer () is a molecule that consists of a few repeating units which could be derived, actually or conceptually, from smaller molecules, monomers.Quote: ''Oligomer molecule: A molecule of intermediate relativ ...s (CAS: 181028–79–5) :: References {{Reflist Phosphate esters Flame retardants ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Flame Retardant

Flame retardants are a diverse group of chemicals that are added to manufactured materials, such as plastics and textiles, and surface finishes and coatings. Flame retardants are activated by the presence of an combustion, ignition source and prevent or slow the further development of flames by a variety of different physical and chemical mechanisms. They may be added as a copolymer during the polymerisation process, or later added to the polymer at a moulding or extrusion process or (particularly for textiles) applied as a topical finish. Mineral flame retardants are typically additive, while organohalogen and organophosphorus compounds can be either reactive or additive. Classes Both reactive and additive flame retardants types can be further separated into four distinct classes: * Minerals such as aluminium hydroxide (ATH), magnesium hydroxide (MDH), huntite and hydromagnesite, various hydrates, red phosphorus, and boron compounds, mostly borates. * Organohalogen compounds. Th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Polymer Blend

In materials science, a polymer blend, or polymer mixture, is a member of a class of materials analogous to metal alloys, in which at least two polymers are blended together to create a new material with different physical properties. History During the 1940s, '50s and '60s, the commercial development of new monomers for production of new polymers seemed endless. In this period, it was discovered that the development of the new techniques for the modification of the already existing polymers, would be economically viable. The first technique of modification developed was the polymerization, in other words, the joint polymerization of more than one kind of polymer. A new polymers modification process, based on a simple mechanical mixture of two polymers first appeared when Thomas Hancock created a mixture of natural rubber with gutta-percha. This process generated a new polymer class called "polymer blends." Basic concepts Polymer blends can be broadly divided into three catego ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Engineering Plastic

Engineering plastics are a group of plastic materials that have better mechanical or thermal properties than the more widely used commodity plastics (such as polystyrene, polyvinyl chloride, polypropylene and polyethylene). Engineering plastics are more expensive than standard plastics, therefore they are produced in lower quantities and tend to be used for smaller objects or low-volume applications (such as mechanical parts), rather than for bulk and high-volume ends (like containers and packaging). Engineering plastics have a higher heat resistance than standard plastics and are continuously usable at temperatures up to about . The term usually refers to thermoplastic materials rather than thermosetting ones. Examples of engineering plastics include polyamides (PA, nylons), used for skis and ski boots; polycarbonates (PC), used in motorcycle helmets and optical discs; and poly(methyl methacrylate) (PMMA, major brand names acrylic glass and plexiglass), used e.g. for taillight ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Poly(phenylene Oxide)

Poly(''p''-phenylene oxide) (PPO), poly(''p''-phenylene ether) (PPE), poly(oxy-2,6-dimethyl-1,4-phenylene), often referred to simply as polyphenylene oxide, is a high-temperature thermoplastic with the general formula (C8H8O)n. It is rarely used in its pure form due to difficulties in processing. It is mainly used as blend with polystyrene, high impact styrene-butadiene copolymer or polyamide. PPO is a registered trademark of SABIC Innovative Plastics B.V. under which various polyphenylene ether resins are sold. History Polyphenylene ether was discovered in 1959 by Allan Hay, and was commercialized by General Electric in 1960. While it was one of the cheapest high-temperature resistant plastics, processing was difficult, while the impact and heat resistance gradually decreased with time. Mixing it with polystyrene in any ratio could compensate for the disadvantages. In the 1960s, modified PPE came into the market under the trademark Noryl. Properties PPE is an amorphous high-p ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

High Impact Polystyrene

In polymer chemistry, graft polymers are segmented copolymers with a linear backbone of one composite and randomly distributed branches of another composite. The picture labeled "graft polymer" shows how grafted chains of species B are covalently bonded to polymer species A. Although the side chains are structurally distinct from the main chain, the individual grafted chains may be homopolymers or copolymers. Graft polymers have been synthesized for many decades and are especially used as impact resistant materials, thermoplastic elastomers, compatibilizers, or emulsifiers for the preparation of stable blends or alloys. One of the better-known examples of a graft polymer is a component used in high impact polystyrene, consisting of a polystyrene backbone with polybutadiene grafted chains. General properties Graft copolymers are a branched copolymer where the components of the side chain are structurally different than that of the main chain. Graft copolymers containin ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Polycarbonate

Polycarbonates (PC) are a group of thermoplastic polymers containing carbonate ester, carbonate groups in their chemical structures. Polycarbonates used in engineering are strong, toughness, tough materials, and some grades are optically transparent. They are easily worked, injection molding, molded, and thermoforming, thermoformed. Because of these properties, polycarbonates find many applications. Polycarbonates do not have a unique resin identification code, resin identification code (RIC) and are identified as "Other", 7 on the RIC list. Products made from polycarbonate can contain the precursor monomer bisphenol A (BPA). Structure Carbonate esters have planar OC(OC)2 cores, which confer rigidity. The unique O=C bond is short (1.173 Å in the depicted example), while the C-O bonds are more ether-like (the bond distances of 1.326 Å for the example depicted). Polycarbonates received their name because they are polymers containing carbonate ester, carbonate groups (−O−( ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Acrylonitrile Butadiene Styrene

Acrylonitrile butadiene styrene (ABS) (chemical formula (C8H8)''x''·(C4H6)''y''·(C3H3N)''z'' ) is a common thermoplastic polymer. Its glass transition temperature is approximately . ABS is amorphous and therefore has no true melting point. ABS is a terpolymer made by polymerizing styrene and acrylonitrile in the presence of polybutadiene. The proportions can vary from 15% to 35% acrylonitrile, 5% to 30% butadiene and 40% to 60% styrene. The result is a long chain of polybutadiene crisscrossed with shorter chains of poly(styrene-co-acrylonitrile). The nitrile groups from neighboring chains, being polar, attract each other and bind the chains together, making ABS stronger than pure polystyrene. The acrylonitrile also contributes chemical resistance, fatigue resistance, hardness, and rigidity, while increasing the heat deflection temperature. The styrene gives the plastic a shiny, impervious surface, as well as hardness, rigidity, and improved processing ease. The polybutad ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Transesterification

Transesterification is the process of exchanging the organic functional group R″ of an ester with the organic group R' of an alcohol. These reactions are often catalyzed by the addition of an acid or base catalyst. Strong acids catalyze the reaction by donating a proton to the carbonyl group, thus making it a more potent electrophile. Bases catalyze the reaction by removing a proton from the alcohol, thus making it more nucleophilic. The reaction can also be accomplished with the help of enzymes, particularly lipases (one example is the lipase E.C.3.1.1.3). If the alcohol produced by the reaction can be separated from the reactants by distillation this will drive the equilibrium toward the products. This means that esters with larger alkoxy groups can be made from methyl or ethyl esters in high purity by heating the mixture of ester, acid/base, and large alcohol. Mechanism In the transesterification mechanism, the carbonyl carbon of the starting ester reacts to give a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bisphenol A

Bisphenol A (BPA) is a chemical compound primarily used in the manufacturing of various plastics. It is a colourless solid which is Solubility, soluble in most common organic solvents, but has very poor solubility in water. BPA is produced on an industrial scale by the condensation reaction of phenol and acetone. Global production in 2022 was estimated to be in the region of 10 million tonnes. BPA's largest single application is as a co-monomer in the production of polycarbonates, which accounts for 65–70% of all BPA production. The manufacturing of epoxy resins and vinyl ester resins account for 25–30% of BPA use. The remaining 5% is used as a major component of several high-performance plastics, and as a minor additive in polyvinyl chloride (PVC), polyurethane, thermal paper, and several other materials. It is not a plasticizer, although it is often wrongly labelled as such. The health effects of BPA have been the subject of prolonged public and scientific debate. BPA is ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Triphenyl Phosphate

Triphenyl phosphate (TPhP) is the chemical compound with the formula OP(OC6H5)3. It is the simplest aromatic organophosphate. This colourless solid is the ester (triester) of phosphoric acid and phenol. It is used as a plasticizer and a fire retardant in a wide variety of settings and products. Preparation Triphenyl phosphate is prepared by the SN2 reaction of phosphorus oxychloride and phenol. Uses Triphenyl phosphate has been used widely as a flame retardant and plasticizer. It has been used as a flame retardant for a variety of materials, including electronic equipment, PVC, hydraulic fluids, glues, in nail polishes, and casting resins. Its mechanism of action as a flame retardant is as follows: first, during thermal decomposition, phosphoric acid is formed. This reacts to form pyrophosphoric acid, which, when in its condensed phase, acts to block heat transfer. One of the most effective flame retardants for certain polymers, TPhP is only active as an additive flame retarda ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Oligomer

In chemistry and biochemistry, an oligomer () is a molecule that consists of a few repeating units which could be derived, actually or conceptually, from smaller molecules, monomers.Quote: ''Oligomer molecule: A molecule of intermediate relative molecular mass, the structure of which essentially comprises a small plurality of units derived, actually or conceptually, from molecules of lower relative molecular mass.'' The name is composed of Greek elements '' oligo-'', "a few" and '' -mer'', "parts". An adjective form is ''oligomeric''. The oligomer concept is contrasted to that of a polymer, which is usually understood to have a large number of units, possibly thousands or millions. However, there is no sharp distinction between these two concepts. One proposed criterion is whether the molecule's properties vary significantly with the removal of one or a few of the units. An oligomer with a specific number of units is referred to by the Greek prefix denoting that number, w ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bisphenol A Diphenyl Phosphate (oligomer)

Bisphenol A diphenyl phosphate is a halogen-free flame retardant used plastics. It is used in polymer blends of engineering plastics, such as PPO/HIPS and PC/ ABS, which are commonly used to make casing for electrical items like TVs, computers and home appliances. It is formed by the transesterification of bisphenol A with triphenyl phosphate. The commercial grade material can contain oligomer In chemistry and biochemistry, an oligomer () is a molecule that consists of a few repeating units which could be derived, actually or conceptually, from smaller molecules, monomers.Quote: ''Oligomer molecule: A molecule of intermediate relativ ...s (CAS: 181028–79–5) :: References {{Reflist Phosphate esters Flame retardants ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |