|

Battery Holder

A battery holder is one or more compartments or chambers for holding a battery. For dry cells, the holder must also make electrical contact with the battery terminals. For wet cells, cables are often connected to the battery terminals, as is found in automobiles or emergency lighting equipment. A battery holder is either a plastic case with the shape of the housing moulded as a compartment or compartments that accepts a battery or batteries, or a separate plastic holder that is mounted with screws, eyelets, glue, double-sided tape, or other means. Battery holders may have a lid to retain and protect the batteries or may be sealed to prevent damage to circuitry and components from battery leakage. Coiled spring wire or flat tabs that press against the battery terminals are the two most common methods of making the electrical connection inside a holder. External connections on battery holders are usually made by contacts with pins, surface mount feet, solder lugs, or wire lead ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Alkaline Battery

An alkaline battery (IEC code: L) is a type of primary battery where the electrolyte (most commonly potassium hydroxide) has a pH value above 7. Typically, these batteries derive energy from the reaction between zinc metal and manganese dioxide. Compared with zinc–carbon batteries of the Leclanché cell or zinc chloride types, alkaline batteries have a higher energy density and longer shelf life yet provide the same voltage. The alkaline battery gets its name because it has an alkaline electrolyte of potassium hydroxide (KOH) instead of the acidic ammonium chloride (NH4Cl) or zinc chloride (ZnCl2) electrolyte of the zinc–carbon batteries. Other battery systems also use alkaline electrolytes, but they use different active materials for the electrodes. alkaline batteries accounted for 80% of manufactured batteries in the US and over 10 billion individual units produced worldwide. In Japan, alkaline batteries accounted for 46% of all primary battery sales. In Switz ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Design

A design is the concept or proposal for an object, process, or system. The word ''design'' refers to something that is or has been intentionally created by a thinking agent, and is sometimes used to refer to the inherent nature of something – its design. The verb ''to design'' expresses the process of developing a design. In some cases, the direct construction of an object without an explicit prior plan may also be considered to be a design (such as in arts and crafts). A design is expected to have a purpose within a specific context, typically aiming to satisfy certain goals and constraints while taking into account aesthetic, functional and experiential considerations. Traditional examples of designs are architectural and engineering drawings, circuit diagrams, sewing patterns, and less tangible artefacts such as business process models.Dictionary meanings in the /dictionary.cambridge.org/dictionary/english/design Cambridge Dictionary of American English at /www. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cathode

A cathode is the electrode from which a conventional current leaves a polarized electrical device such as a lead-acid battery. This definition can be recalled by using the mnemonic ''CCD'' for ''Cathode Current Departs''. Conventional current describes the direction in which positive charges move. Electrons, which are the carriers of current in most electrical systems, have a negative electrical charge, so the movement of electrons is ''opposite'' to that of the conventional current flow: this means that electrons flow ''into'' the device's cathode from the external circuit. For example, the end of a household battery marked with a + (plus) is the cathode. The electrode through which conventional current flows the other way, into the device, is termed an anode. Charge flow Conventional current flows from cathode to anode outside the cell or device (with electrons moving in the opposite direction), regardless of the cell or device type and operating mode. Cathode polarity ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Anode

An anode usually is an electrode of a polarized electrical device through which conventional current enters the device. This contrasts with a cathode, which is usually an electrode of the device through which conventional current leaves the device. A common mnemonic is ACID, for "anode current into device". The direction of conventional current (the flow of positive charges) in a circuit is opposite to the direction of electron flow, so (negatively charged) electrons flow from the anode of a galvanic cell, into an outside or external circuit connected to the cell. For example, the end of a household battery marked with a "+" is the cathode (while discharging). In both a galvanic cell and an electrolytic cell, the anode is the electrode at which the oxidation reaction occurs. In a galvanic cell the anode is the wire or plate having excess negative charge as a result of the oxidation reaction. In an electrolytic cell, the anode is the wire or plate upon which excess positive charge ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Electrical Connector

Components of an electrical circuit are electrically connected if an electric current can run between them through an electrical conductor. An electrical connector is an electromechanical device used to create an electrical connection between parts of an electrical circuit, or between different electrical circuits, thereby joining them into a larger circuit. The connection may be removable (as for portable equipment), require a tool for assembly and removal, or serve as a permanent electrical joint between two points. An adapter can be used to join dissimilar connectors. Most electrical connectors have a genderi.e. the male component, called a ''plug'', connects to the female component, or ''socket''. Thousands of configurations of connectors are manufactured for power, data, and audiovisual applications. Electrical connectors can be divided into four basic categories, differentiated by their function: * ''inline'' or ''cable'' connectors permanently attached to a cable, so ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Galvanic Corrosion

Galvanic corrosion (also called bimetallic corrosion or dissimilar metal corrosion) is an electrochemical process in which one metal corrodes preferentially when it is in electrical contact with another, different metal, when both in the presence of an electrolyte. A similar galvanic reaction is exploited in single-use battery cells to generate a useful electrical voltage to power portable devices. This phenomenon is named after Italian physician Luigi Galvani (1737–1798). A similar type of corrosion caused by the presence of an external electric current is called '' electrolytic corrosion''. Overview Dissimilar metals and alloys have different electrode potentials, and when two or more come into contact in an electrolyte, one metal (that is more reactive) acts as anode and the other (that is less reactive) as cathode. The electropotential difference between the reactions at the two electrodes is the driving force for an accelerated attack on the anode metal, which disso ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Electroless Nickel Plating

Electroless Deposition, Electroless nickel-phosphorus plating, also referred to as ''E-nickel'', is a chemical engineering, chemical process that deposits an even layer of nickel-phosphorus alloy on the surface of a solid substrate, like metal or plastic. The process involves dipping the substrate in a water solution containing nickel salt (chemistry), salt and a phosphorus-containing reducing agent, usually a hypophosphite salt. It is the most common version of electroless nickel plating (EN plating) and is often referred by that name. A Electroless nickel-boron plating, similar process uses a borohydride reducing agent, yielding a nickel-boron coating instead. Unlike electroplating, processes in general do not require passing an electric current through the bath and the substrate; the redox reaction, reduction of the metal cations in solution to metallic is achieved by purely chemical means, through an autocatalysis, autocatalytic reaction. This creates an even layer of met ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Contact Resistance

Electrical contact resistance (ECR, or simply contact resistance) is resistance to the flow of electric current caused by incomplete contact of the surfaces through which the current is flowing, and by films or oxide layers on the contacting surfaces. It occurs at electrical connections such as switches, connectors, breakers, contacts, and measurement probes. Contact resistance values are typically small (in the microohm to milliohm range). Contact resistance can cause significant voltage drops and heating in circuits with high current. Because contact resistance adds to the intrinsic resistance of the conductors, it can cause significant measurement errors when exact resistance values are needed. Contact resistance may vary with temperature. It may also vary with time (most often decreasing) in a process known as resistance creep. Electrical contact resistance is also called ''interface resistance'', ''transitional resistance'', or the ''correction term''. ''Parasitic resist ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Reflow Soldering

Reflow soldering is a process in which a solder paste (a sticky mixture of powdered solder and flux (metallurgy), flux) is used to temporarily attach anywhere from one to thousands of tiny electrical components to their contact pads, after which the entire assembly is subjected to controlled heat. The solder paste reflows in a molten state, creating permanent solder joints. Heating may be accomplished by passing the assembly through a reflow oven, under an Infrared heater, infrared lamp, or (mainly for prototyping) by soldering individual joints with a hot air pencil. Reflow soldering with long industrial convection ovens is the preferred method of soldering surface mount technology (SMT) components to a printed circuit board (PCB). Each segment of the oven has a regulated temperature, according to the specific thermal requirements of each assembly. Reflow ovens meant specifically for the soldering of surface mount components may also be used for Through-hole technology, throu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

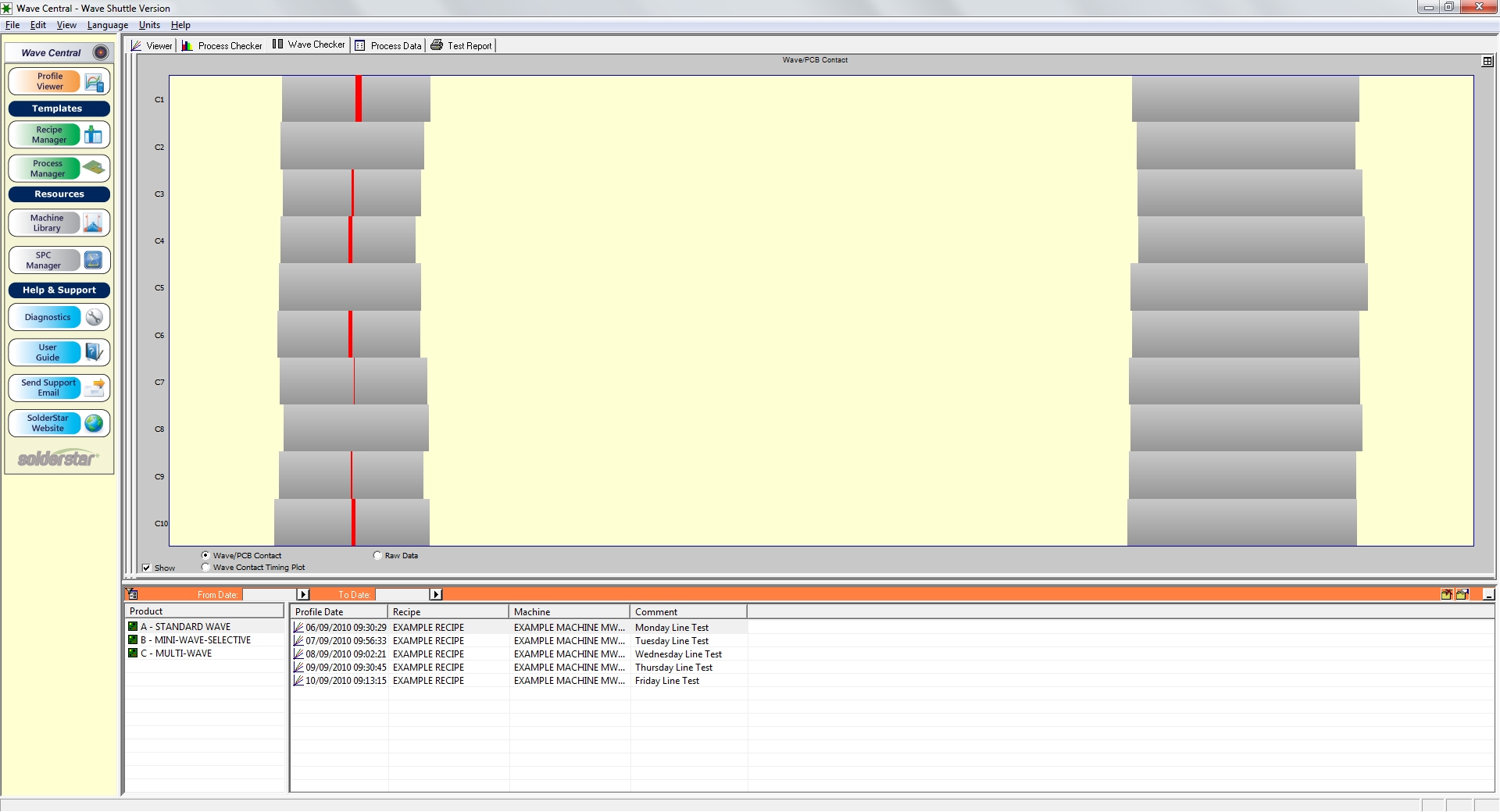

Wave Soldering

Wave soldering is a bulk soldering process used in printed circuit board manufacturing. The circuit board is passed over a pan of molten solder in which a pump produces an upwelling of solder that looks like a standing wave. As the circuit board makes contact with this wave, the components become soldered to the board. Wave soldering is used for both through-hole printed circuit assemblies, and surface mount. In the latter case, the components are glued onto the surface of a printed circuit board (PCB) by placement equipment, before being run through the molten solder wave. Wave soldering is mainly used in soldering of through hole components. As through-hole components have been largely replaced by surface mount components, wave soldering has been supplanted by reflow soldering methods in many large-scale electronics applications. However, there is still significant wave soldering where surface-mount technology (SMT) is not suitable (e.g., large power devices and high pi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |