|

AN-6530 Goggles

AN-6530 Goggles were produced during World War II as eye protection for United States Army and Navy flight crews. In 1943, the AN-6530 design served as a product modification of the USAAF B-7 goggle produced by Chas Fischer Spring Company of Brooklyn, New York. Contracts for AN-6530 goggles were awarded to Chas Fischer Spring Co. and American Optical. Construction The AN-6530's frame is nickel-plated brass and steel. Construction consists of stamped and milled pieces, soldered together. Milled brass pieces form the bridge and ferrule/strap lugs, and pieces of stamped sheet steel form the frame to hold the facepad and lenses. The ferrule / strap lugs are split lengthwise to facilitate removal and insertion of the lenses and rubber facepad. The lugs are secured closed by a salt-blued or parkerized and knurled carbon steel ferrule. The frame has vents on the upper and lower edge. The upper vents were produced in two patterns. One using a small brass tube with the inward open e ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

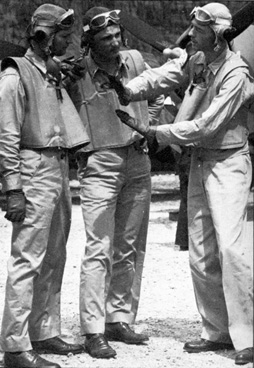

John Thach

John Smith Thach (April 19, 1905 – April 15, 1981) was a World War II Naval Aviator, air combat tactician, and United States Navy admiral. Thach developed the Thach Weave, a combat flight formation which could counter enemy fighters of superior performance, and later the big blue blanket, an aerial defense against kamikaze attacks. Early career John S. Thach was born in Pine Bluff, Arkansas, on April 19, 1905. He graduated from the United States Naval Academy in 1927 and spent two years serving in battleships, before becoming a Naval Aviator in early 1930. His USNA classmates included William Brockman, Creed Burlingame, and Eugene Lindsey. Thach spent the next decade serving as a test pilot and instructor and establishing a reputation as an expert in aerial gunnery. World War II In early 1940, Thach was placed in command of Fighting Squadron Three (VF-3). There he met a young ensign just out of flight school, Edward O'Hare, later a Medal of Honor recipient. Thach ma ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

USAAF

The United States Army Air Forces (USAAF or AAF) was the major land-based aerial warfare service component of the United States Army and ''de facto'' aerial warfare service branch of the United States during and immediately after World War II (1941–1947). It was created on 20 June 1941 as successor to the previous United States Army Air Corps and is the direct predecessor of the United States Air Force, today one of the six United States Armed Forces, armed forces of the United States. The AAF was a component of the United States Army, which on 2 March 1942 was divided functionally by executive order into three autonomous forces: the Army Ground Forces, the United States Army Services of Supply (which in 1943 became the Army Service Forces), and the Army Air Forces. Each of these forces had a commanding general who reported directly to the Chief of Staff of the United States Army, Army Chief of Staff. The AAF administered all parts of military aviation formerly distributed am ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

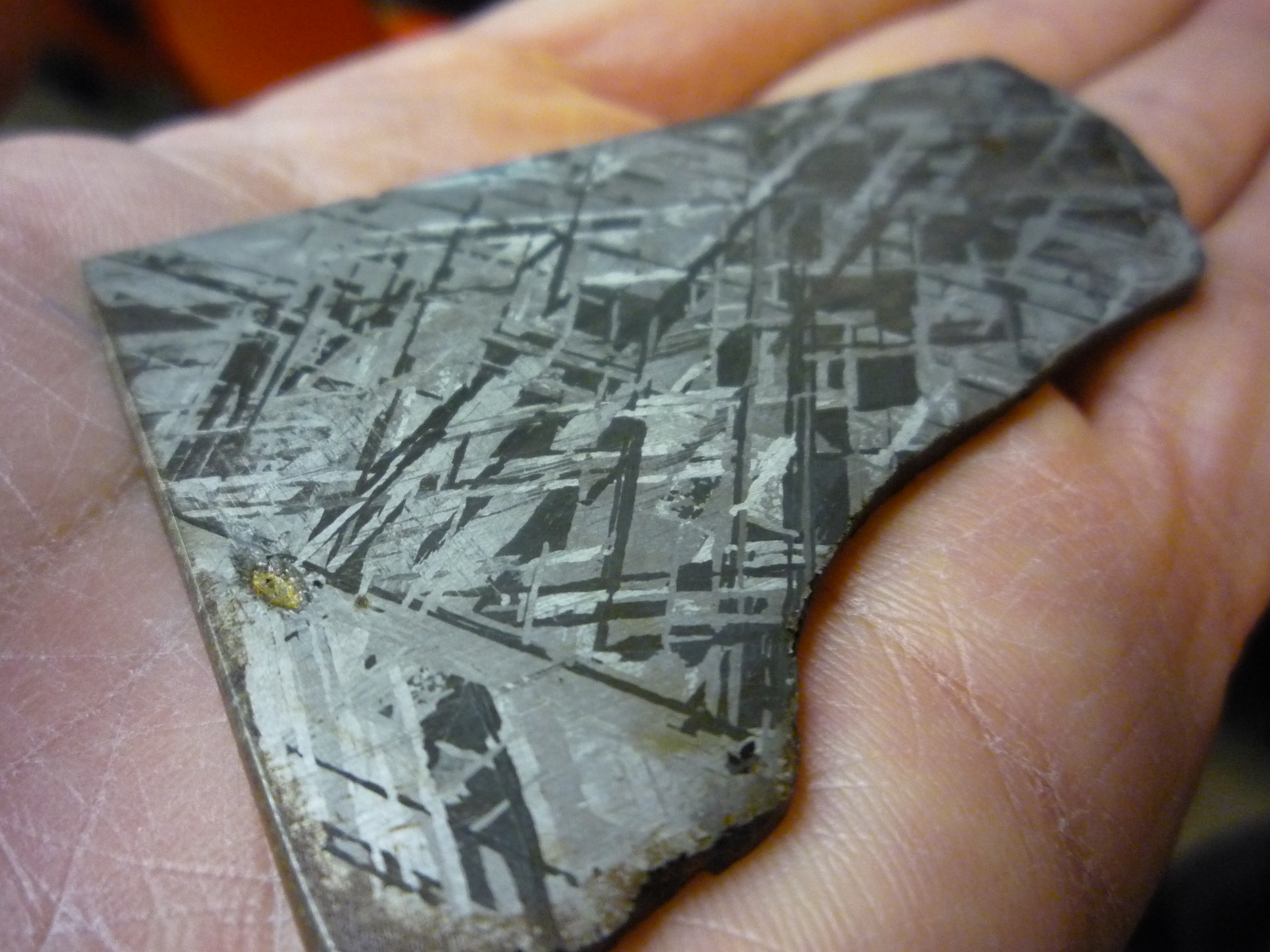

Nickel

Nickel is a chemical element; it has symbol Ni and atomic number 28. It is a silvery-white lustrous metal with a slight golden tinge. Nickel is a hard and ductile transition metal. Pure nickel is chemically reactive, but large pieces are slow to react with air under standard conditions because a passivation layer of nickel oxide forms on the surface that prevents further corrosion. Even so, pure native nickel is found in Earth's crust only in tiny amounts, usually in ultramafic rocks, and in the interiors of larger nickel–iron meteorites that were not exposed to oxygen when outside Earth's atmosphere. Meteoric nickel is found in combination with iron, a reflection of the origin of those elements as major end products of supernova nucleosynthesis. An iron–nickel mixture is thought to compose Earth's outer and inner cores. Use of nickel (as natural meteoric nickel–iron alloy) has been traced as far back as 3500 BCE. Nickel was first isolated and classifie ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Brass

Brass is an alloy of copper and zinc, in proportions which can be varied to achieve different colours and mechanical, electrical, acoustic and chemical properties, but copper typically has the larger proportion, generally copper and zinc. In use since prehistoric times, it is a substitutional alloy: atoms of the two constituents may replace each other within the same crystal structure. Brass is similar to bronze, a copper alloy that contains tin instead of zinc. Both bronze and brass may include small proportions of a range of other Chemical element, elements including arsenic, lead, phosphorus, aluminium, manganese and silicon. Historically, the distinction between the two alloys has been less consistent and clear, and increasingly museums use the more general term "list of copper alloys, copper alloy". Brass has long been a popular material for its bright gold-like appearance and is still used for drawer pulls and door handle, doorknobs. It has also been widely used to ma ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Steel

Steel is an alloy of iron and carbon that demonstrates improved mechanical properties compared to the pure form of iron. Due to steel's high Young's modulus, elastic modulus, Yield (engineering), yield strength, Fracture, fracture strength and low raw material cost, steel is one of the most commonly manufactured materials in the world. Steel is used in structures (as concrete Rebar, reinforcing rods), in Bridge, bridges, infrastructure, Tool, tools, Ship, ships, Train, trains, Car, cars, Bicycle, bicycles, Machine, machines, Home appliance, electrical appliances, furniture, and Weapon, weapons. Iron is always the main element in steel, but other elements are used to produce various grades of steel demonstrating altered material, mechanical, and microstructural properties. Stainless steels, for example, typically contain 18% chromium and exhibit improved corrosion and Redox, oxidation resistance versus its carbon steel counterpart. Under atmospheric pressures, steels generally ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Milling Machine

Milling is the process of machining using rotary cutters to remove material by advancing a cutter into a workpiece. This may be done by varying directions on one or several axes, cutter head speed, and pressure. Milling covers a wide variety of different operations and machines, on scales from small individual parts to large, heavy-duty gang milling operations. It is one of the most commonly used processes for machining custom parts to precise tolerances. Milling can be done with a wide range of machine tools. The original class of machine tools for milling was the milling machine (often called a mill). After the advent of computer numerical control (CNC) in the 1960s, milling machines evolved into ''machining centers'': milling machines augmented by automatic tool changers, tool magazines or carousels, CNC capability, coolant systems, and enclosures. Milling centers are generally classified as vertical machining centers (VMCs) or horizontal machining centers (HMCs). The integr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Stamping (metalworking)

Stamping (also known as pressing) is the process of placing flat sheet metal in either blank or coil form into a stamping press where a tool and Die (manufacturing), die surface forms the metal into a net shape. Stamping includes a variety of sheet-metal forming manufacturing processes, such as punching using a machine press or stamping press, blanking, embossing, bending, flanging, and coining. This could be a single stage operation where every stroke of the press produces the desired form on the sheet metal part, or could occur through a series of stages. The process is usually carried out on sheet metal, but can also be used on other materials, such as polystyrene. Progressive dies are commonly fed from a coil of steel, coil reel for unwinding of coil to a straightener to level the coil and then into a feeder which advances the material into the press and die at a predetermined feed length. Depending on part complexity, the number of stations in the die can be determined. St ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bluing (steel)

Bluing, sometimes spelled as blueing, is a passivation process in which steel is partially protected against rust using a black oxide coating. It is named after the blue-black appearance of the resulting protective finish. Bluing involves an electrochemical conversion coating resulting from an oxidizing chemical reaction with iron on the surface selectively forming magnetite (), the black oxide of iron. In comparison, rust, the red oxide of iron (), undergoes an extremely large volume change upon hydration; as a result, the oxide easily flakes off, causing the typical reddish rusting away of iron. Black oxide provides minimal protection against corrosion, unless also treated with a water-displacing oil to reduce wetting and galvanic action. In colloquial use, thin coatings of black oxide are often termed "gun bluing", while heavier coatings are termed "black oxide". Both refer to the same chemical process for providing true gun bluing. Overview Various processes are used ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Parkerized

Phosphate conversion coating is a chemical treatment applied to steel parts that creates a thin adhering layer of iron, zinc, or manganese phosphates to improve corrosion resistance or lubrication or as a foundation for subsequent coatings or painting. It is one of the most common types of conversion coating. The process is also called phosphate coating, phosphatization, phosphatizing, or phosphating. It is also known by the trade name Parkerizing, especially when applied to firearms and other military equipment. A phosphate coating is usually obtained by applying to the steel part a dilute solution of phosphoric acid, possibly with soluble iron, zinc, and/or manganese salts. The solution may be applied by sponging, spraying, or immersion. Phosphate conversion coatings can also be used on aluminium, zinc, cadmium, silver and tin. History The phosphatizing of firearms was discovered around 1910, when it was found that the surface of steel if changed to a phosphate acquires si ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Chamois

The chamois (; ) (''Rupicapra rupicapra'') or Alpine chamois is a species of Caprinae, goat-antelope native to the mountains in Southern Europe, from the Pyrenees, the Alps, the Apennines, the Dinarides, the Tatra Mountains, Tatra to the Carpathian Mountains, the Balkan Mountains, the Rila–Rhodope Mountains, Rhodope massif, Pindus, the northeastern mountains of Turkey, and the Caucasus. It has also been introduced to the South Island of New Zealand. Some subspecies of chamois are strictly protected in the EU under the European Habitats Directive. Description The chamois is a very small bovid. A fully grown chamois reaches a height of and measures . Males, which weigh , are slightly larger than females, which weigh . Both males and females have short, straightish horns which are hooked backwards near the tip, the horn of the male being thicker. In summer, the fur has a rich brown colour which turns to a light grey in winter. Distinct characteristics are white contrasting ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

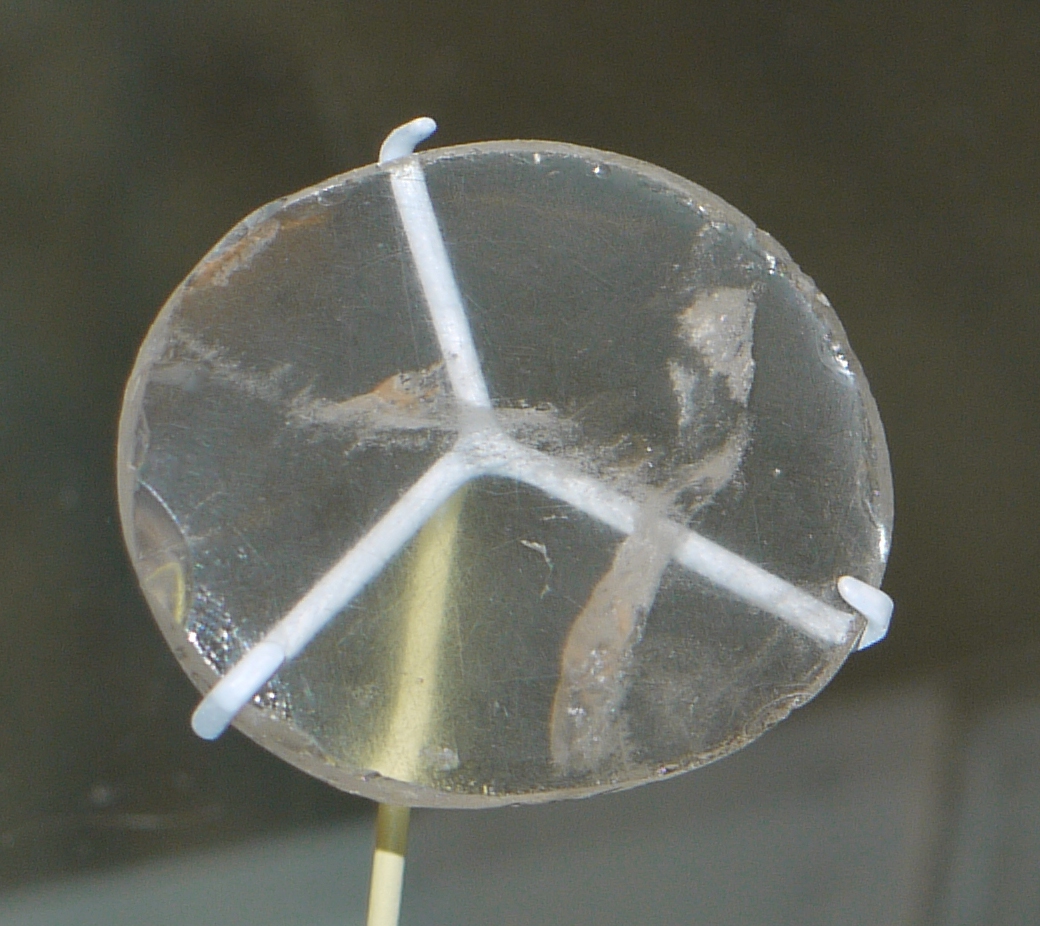

Optical Glass

Optical glass refers to a quality of glass suitable for the manufacture of optical systems such as optical lenses, Prism (geometry), prisms or mirrors. Unlike window glass or crystal, whose formula is adapted to the desired aesthetic effect, optical glass contains additives designed to modify certain optical or mechanical properties of the glass: refractive index, Dispersion (optics), dispersion, transmittance, thermal expansion and other parameters. Lenses produced for optical applications use a wide variety of materials, from silicon dioxide, silica and conventional Borosilicate glass, borosilicates to elements such as germanium and fluorite, some of which are essential for glass transparency in areas other than the visible spectrum. Various elements can be used to form glass, including silicon, boron, phosphorus, germanium and arsenic, mostly in oxide form, but also in the form of selenides, sulfides, fluorides and more. These materials give glass its characteristic non-crystall ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |