Ultrasonic welding on:

[Wikipedia]

[Google]

[Amazon]

Ultrasonic welding is an

For joining complex injection molded

For joining complex injection molded

In the electrical and computer industry ultrasonic welding is often used to join wired connections and to create connections in small, delicate circuits. Junctions of wire harnesses are often joined using ultrasonic welding.Ahmed, p. 260. Wire harnesses are large groupings of wires used to distribute electrical signals and power.

In the electrical and computer industry ultrasonic welding is often used to join wired connections and to create connections in small, delicate circuits. Junctions of wire harnesses are often joined using ultrasonic welding.Ahmed, p. 260. Wire harnesses are large groupings of wires used to distribute electrical signals and power.

"Port Sealing: An Effective Heat Sealing Solution".

''Plastic Decorating Magazine''. January/February 2013 Edition. . (Topeka, KS: Peterson Publications, Inc.). Section: Assembly: pages 36–39, covers Crawford's article. {{DEFAULTSORT:Ultrasonic Welding Ultrasound Welding Packaging machinery Plastic welding

industrial process

Industrial processes are procedures involving chemical, physical, electrical or mechanical steps to aid in the manufacturing of an item or items, usually carried out on a very large scale. Industrial processes are the key components of heavy in ...

whereby high-frequency ultrasonic acoustic vibration

Vibration is a mechanical phenomenon whereby oscillations occur about an equilibrium point. The word comes from Latin ''vibrationem'' ("shaking, brandishing"). The oscillations may be periodic, such as the motion of a pendulum—or random, su ...

s are locally applied to work pieces being held together under pressure to create a solid-state weld. It is commonly used for plastics

Plastics are a wide range of synthetic or semi-synthetic materials that use polymers as a main ingredient. Their plasticity makes it possible for plastics to be moulded, extruded or pressed into solid objects of various shapes. This adaptabi ...

and metals

A metal (from Greek μέταλλον ''métallon'', "mine, quarry, metal") is a material that, when freshly prepared, polished, or fractured, shows a lustrous appearance, and conducts electricity and heat relatively well. Metals are typical ...

, and especially for joining dissimilar materials

Material is a substance or mixture of substances that constitutes an object. Materials can be pure or impure, living or non-living matter. Materials can be classified on the basis of their physical and chemical properties, or on their geolog ...

. In ultrasonic welding, there are no connective bolts, nails, soldering materials, or adhesives necessary to bind the materials together. When used to join metals, the temperature stays well below the melting point of the involved materials, preventing any unwanted properties which may arise from high temperature exposure of the metal.

History

Practical application of ultrasonic welding for rigid plastics was completed in the 1960s. At this point only hard plastics could be welded. The patent for the ultrasonic method for welding rigid thermoplastic parts was awarded to Robert Soloff and Seymour Linsley in 1965. Soloff, the founder of Sonics & Materials Inc., was a lab manager at Branson Instruments where thin plastic films were welded into bags and tubes using ultrasonic probes. He unintentionally moved the probe close to a plastic tape dispenser and observed that the halves of the dispenser welded together. He realized that the probe did not need to be manually moved around the part, but that the ultrasonic energy could travel through and around rigid plastics and weld an entire joint. He went on to develop the first ultrasonic press. The first application of this new technology was in the toy industry. The first car made entirely out of plastic was assembled using ultrasonic welding in 1969. The automotive industry has used it regularly since the 1980s, and it is now used for a multitude of applications.Process

For joining complex injection molded

For joining complex injection molded thermoplastic

A thermoplastic, or thermosoft plastic, is any plastic polymer material that becomes pliable or moldable at a certain elevated temperature and solidifies upon cooling.

Most thermoplastics have a high molecular weight. The polymer chains associate ...

parts, ultrasonic welding equipment can be easily customized to fit the exact specifications of the parts being welded. The parts are sandwiched between a fixed shaped nest (anvil

An anvil is a metalworking tool consisting of a large block of metal (usually forged or cast steel), with a flattened top surface, upon which another object is struck (or "worked").

Anvils are as massive as practical, because the higher ...

) and a sonotrode

In ultrasonic machining, welding and mixing, a sonotrode is a tool that creates ultrasonic vibrations and applies this vibrational energy to a gas, liquid, solid or tissue.

A sonotrode usually consists of a stack of piezoelectric transducers ...

(horn) connected to a transducer, and a ~20 kHz low-amplitude acoustic vibration is emitted. (Note: Common frequencies used in ultrasonic welding of thermoplastics are 15 kHz, 20 kHz, 30 kHz, 35 kHz, 40 kHz and 70 kHz). When welding plastics, the interface of the two parts is specially designed to concentrate the melting process. One of the materials usually has a spiked or rounded energy director which contacts the second plastic part. The ultrasonic energy melts the point contact between the parts, creating a joint. Ultrasonic welding of thermoplastics causes local melting of the plastic due to absorption of vibrational energy along the joint to be welded. In metals, welding occurs due to high-pressure dispersion of surface oxides and local motion of the materials. Although there is heating, it is not enough to melt the base materials.

Ultrasonic welding can be used for both hard and soft plastics, such as semicrystalline plastics, and metals. The understanding of ultrasonic welding has increased with research and testing. The invention of more sophisticated and inexpensive equipment and increased demand for plastic and electronic components has led to a growing knowledge of the fundamental process. However, many aspects of ultrasonic welding still require more study, such as relating weld quality to process parameters. Ultrasonic welding continues to be a rapidly developing field.

Scientists from the Institute of Materials Science and Engineering (WKK) of University of Kaiserslautern, with the support from the German Research Foundation (Deutsche Forschungsgemeinschaft

The German Research Foundation (german: Deutsche Forschungsgemeinschaft ; DFG ) is a German research funding organization, which functions as a self-governing institution for the promotion of science and research in the Federal Republic of Germ ...

), have succeeded in proving that using ultrasonic welding processes can lead to highly durable bonds between light metals and carbon-fiber-reinforced polymer

Carbon fiber-reinforced polymers (American English), carbon-fibre-reinforced polymers (Commonwealth English), carbon-fiber-reinforced plastics, carbon-fiber reinforced-thermoplastic (CFRP, CRP, CFRTP), also known as carbon fiber, carbon compo ...

(CFRP) sheets.

The benefit of ultrasonic welding is that it is much faster than conventional adhesives or solvents. The drying time is very quick, and the pieces do not need to remain in a fixture for long periods of time waiting for the joint to dry or cure. The welding can easily be automated, making clean and precise joints; the site of the weld is very clean and rarely requires any touch-up work. The low thermal impact on the materials involved enables a greater number of materials to be welded together. The process is a good automated alternative to glue

Adhesive, also known as glue, cement, mucilage, or paste, is any non-metallic substance applied to one or both surfaces of two separate items that binds them together and resists their separation.

The use of adhesives offers certain advant ...

, screws

A screw and a bolt (see '' Differentiation between bolt and screw'' below) are similar types of fastener typically made of metal and characterized by a helical ridge, called a ''male thread'' (external thread). Screws and bolts are used to f ...

or snap-fit A snap-fit is an assembly method used to attach flexible parts, usually plastic, to form the final product by pushing the parts' interlocking components together. There are a number of variations in snap-fits, including cantilever, torsional and ann ...

designs. It is typically used with small parts (e.g. cell phones, consumer electronics, disposable medical tools, toys, etc.) but it can be used on parts as large as a small automotive instrument cluster. Ultrasonics can also be used to weld metals, but are typically limited to small welds of thin, malleable metals, e.g. aluminum, copper, nickel. Ultrasonics would not be used in welding the chassis of an automobile or in welding pieces of a bicycle

A bicycle, also called a pedal cycle, bike or cycle, is a human-powered or motor-powered assisted, pedal-driven, single-track vehicle, having two wheels attached to a frame, one behind the other. A is called a cyclist, or bicyclist.

B ...

together, due to the power levels required.

Components

All ultrasonic welding systems are composed of the same basic elements: * A press, usually with a pneumatic or electric drive, to assemble two parts under pressure * A nest or anvil or fixture where the parts are placed and allowing the high frequency vibration to be directed to the interfaces * An ultrasonic stack composed of a converter orpiezoelectric

Piezoelectricity (, ) is the electric charge that accumulates in certain solid materials—such as crystals, certain ceramics, and biological matter such as bone, DNA, and various proteins—in response to applied mechanical stress. The word '' ...

transducer

A transducer is a device that converts energy from one form to another. Usually a transducer converts a signal in one form of energy to a signal in another.

Transducers are often employed at the boundaries of automation, measurement, and con ...

, an optional booster and a Horn. All three elements of the stack are specifically tuned to resonate at the same exact ultrasonic frequency (Typically 15, 20, 30, 35 or 40 kHz)

** Converter: Converts the electrical signal into a mechanical vibration using piezo electric effect

** Booster: Modifies the amplitude of the vibration mechanically. It is also used in standard systems to clamp the stack in the press.

** Horn: Takes the shape of the part, also modifies the amplitude mechanically and applies the mechanical vibration to the parts to be welded.

* An electronic ultrasonic generator (US: Power supply) delivering a high power electric signal with frequency matching the resonance

Resonance describes the phenomenon of increased amplitude that occurs when the frequency of an applied periodic force (or a Fourier component of it) is equal or close to a natural frequency of the system on which it acts. When an oscil ...

frequency of the stack.

* A controller controlling the movement of the press and the delivery of the ultrasonic energy.

Applications

The applications of ultrasonic welding are extensive and are found in many industries including electrical and computer, automotive and aerospace, medical, and packaging. Whether two items can be ultrasonically welded is determined by their thickness. If they are too thick this process will not join them. This is the main obstacle in the welding of metals. However, wires, microcircuit connections, sheet metal, foils, ribbons and meshes are often joined using ultrasonic welding. Ultrasonic welding is a very popular technique for bondingthermoplastic

A thermoplastic, or thermosoft plastic, is any plastic polymer material that becomes pliable or moldable at a certain elevated temperature and solidifies upon cooling.

Most thermoplastics have a high molecular weight. The polymer chains associate ...

s. It is fast and easily automated with weld times often below one second and there is no ventilation system required to remove heat or exhaust. This type of welding is often used to build assemblies that are too small, too complex, or too delicate for more common welding techniques.

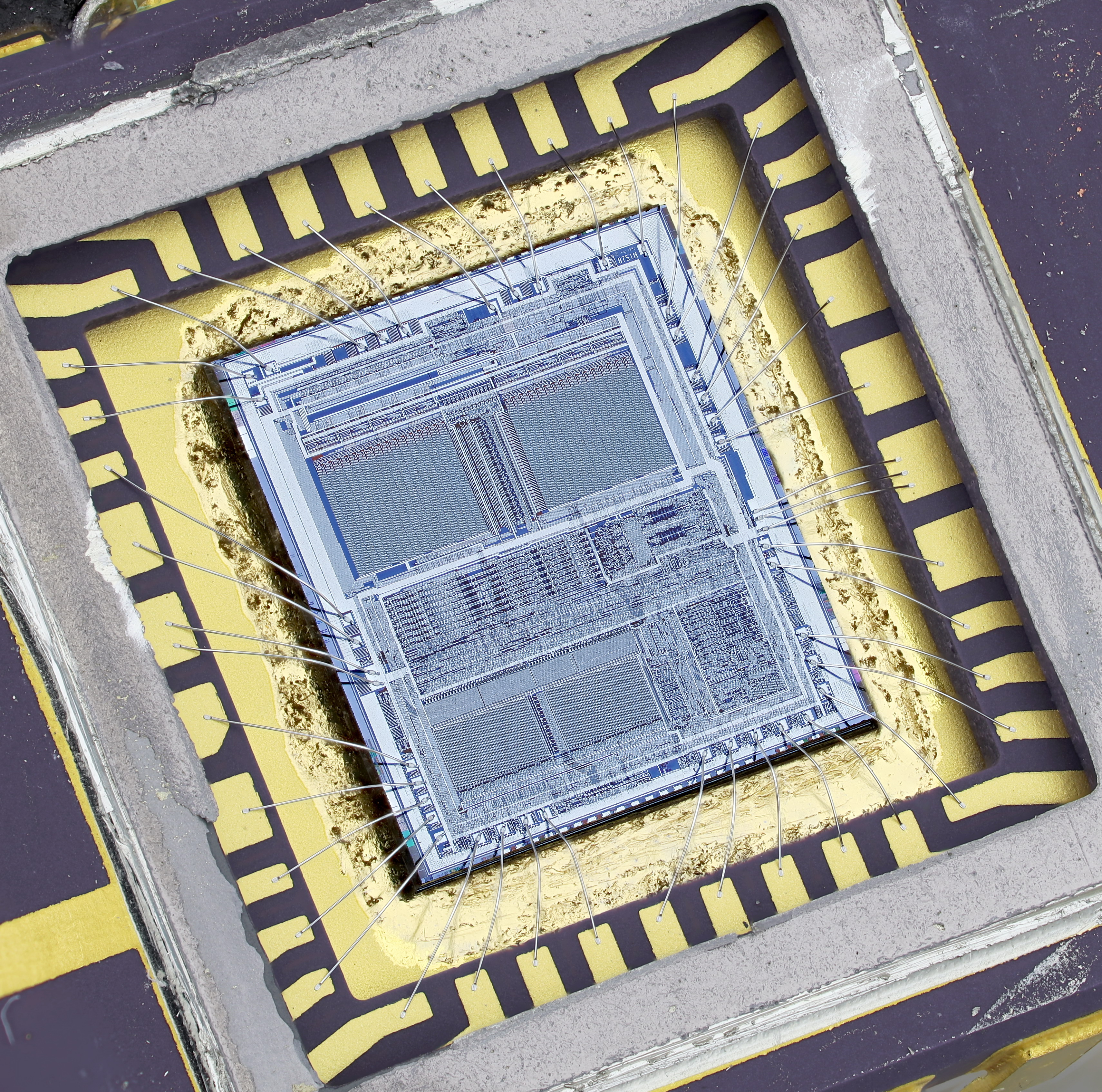

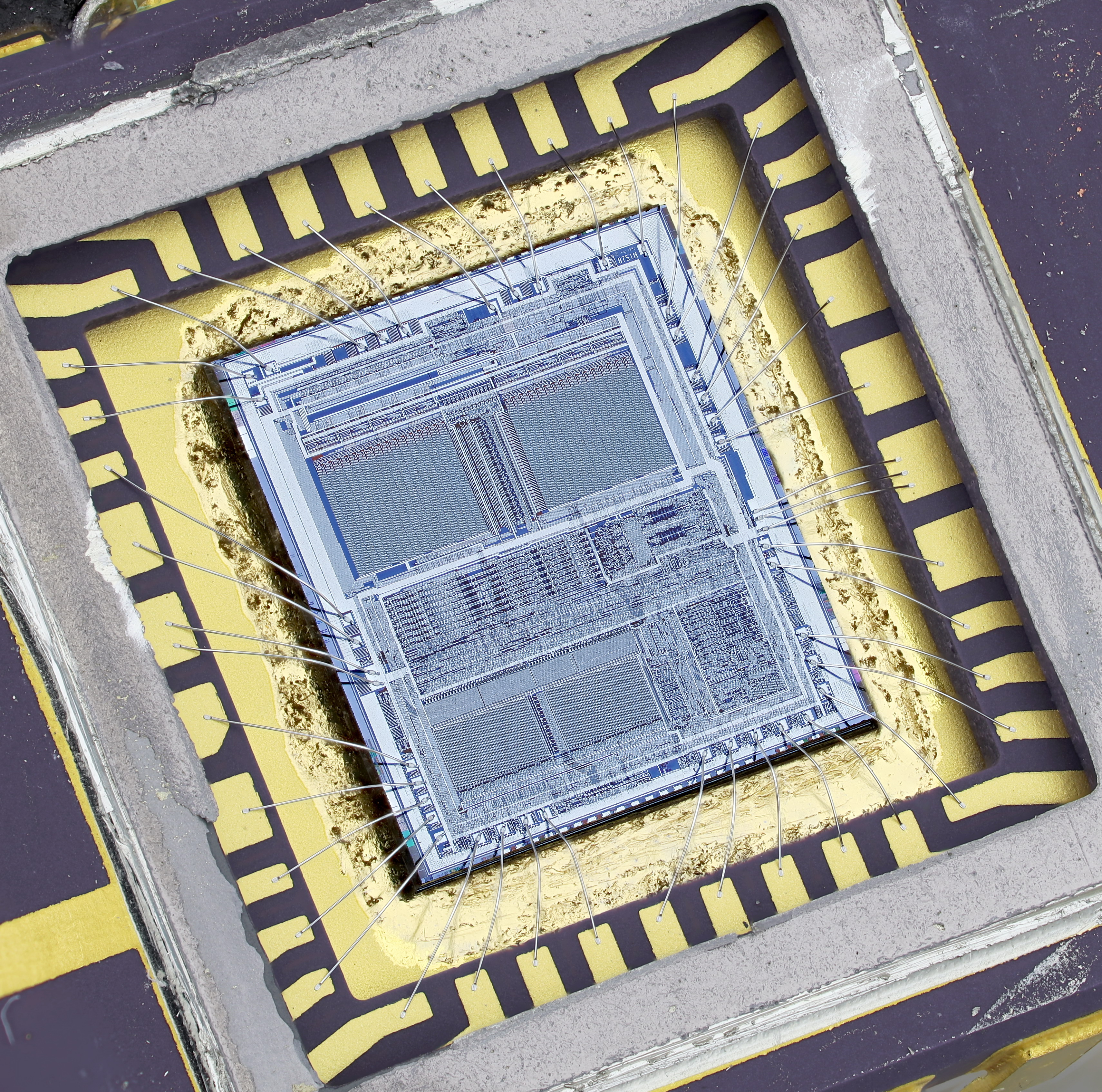

Computer and electrical industries

In the electrical and computer industry ultrasonic welding is often used to join wired connections and to create connections in small, delicate circuits. Junctions of wire harnesses are often joined using ultrasonic welding.Ahmed, p. 260. Wire harnesses are large groupings of wires used to distribute electrical signals and power.

In the electrical and computer industry ultrasonic welding is often used to join wired connections and to create connections in small, delicate circuits. Junctions of wire harnesses are often joined using ultrasonic welding.Ahmed, p. 260. Wire harnesses are large groupings of wires used to distribute electrical signals and power. Electric motor

An electric motor is an electrical machine that converts electrical energy into mechanical energy. Most electric motors operate through the interaction between the motor's magnetic field and electric current in a wire winding to generate f ...

s, field coils, transformer

A transformer is a passive component that transfers electrical energy from one electrical circuit to another circuit, or multiple circuits. A varying current in any coil of the transformer produces a varying magnetic flux in the transformer' ...

s and capacitor

A capacitor is a device that stores electrical energy in an electric field by virtue of accumulating electric charges on two close surfaces insulated from each other. It is a passive electronic component with two terminals.

The effect of ...

s may also be assembled with ultrasonic welding. It is also often preferred in the assembly of storage media such as flash drives and computer disks because of the high volumes required. Ultrasonic welding of computer disks has been found to have cycle times of less than 300 ms.

One of the areas in which ultrasonic welding is most used and where new research and experimentation is centered is microcircuits. This process is ideal for microcircuits since it creates reliable bonds without introducing impurities or thermal distortion into components. Semiconductor devices, transistor

upright=1.4, gate (G), body (B), source (S) and drain (D) terminals. The gate is separated from the body by an insulating layer (pink).

A transistor is a semiconductor device used to Electronic amplifier, amplify or electronic switch, switch ...

s and diode

A diode is a two-terminal electronic component that conducts current primarily in one direction (asymmetric conductance); it has low (ideally zero) resistance in one direction, and high (ideally infinite) resistance in the other.

A diod ...

s are often connected by thin aluminum and gold wires using ultrasonic welding.American Welding Society, ''Jefferson's Welding Encyclopedia'', p. 570. It is also used for bonding wiring and ribbons as well as entire chips to microcircuits. An example of where microcircuits are used is in medical sensors used to monitor the human heart in bypass patients.

One difference between ultrasonic welding and traditional welding is the ability of ultrasonic welding to join dissimilar materials. The assembly of battery components is a good example of where this ability is utilized. When creating battery and fuel cell

A fuel cell is an electrochemical cell that converts the chemical energy of a fuel (often hydrogen fuel, hydrogen) and an oxidizing agent (often oxygen) into electricity through a pair of redox reactions. Fuel cells are different from most bat ...

components, thin gauge copper, nickel and aluminium connections, foil layers and metal meshes are often ultrasonically welded together. Multiple layers of foil or mesh can often be applied in a single weld eliminating steps and costs.

Aerospace and automotive industries

For automobiles, ultrasonic welding tends to be used to assemble large plastic and electrical components such as instrument panels, door panels, lamps, air ducts, steering wheels, upholstery and engine components.Plastics Design Library, ''Handbook of Plastics Joining: A Practical Guide'', p. 56. As plastics have continued to replace other materials in the design and manufacture of automobiles, the assembly and joining of plastic components has increasingly become a critical issue. Some of the advantages for ultrasonic welding are low cycle times,automation

Automation describes a wide range of technologies that reduce human intervention in processes, namely by predetermining decision criteria, subprocess relationships, and related actions, as well as embodying those predeterminations in machines ...

, low capital costs, and flexibility. Ultrasonic welding does not damage surface finish because the high-frequency vibrations prevent marks from being generated, which is a crucial consideration for many car manufacturers, .

Ultrasonic welding is generally utilized in the aerospace industry when joining thin sheet gauge metals and other lightweight materials. Aluminum

Aluminium (aluminum in American and Canadian English) is a chemical element with the symbol Al and atomic number 13. Aluminium has a density lower than those of other common metals, at approximately one third that of steel. It ha ...

is a difficult metal to weld using traditional techniques because of its high thermal conductivity. However, it is one of the easier materials to weld using ultrasonic welding because it is a softer metal and thus a solid-state weld is simple to achieve. Since aluminum is so widely used in the aerospace industry, it follows that ultrasonic welding is an important manufacturing process. With the advent of new composite material

A composite material (also called a composition material or shortened to composite, which is the common name) is a material which is produced from two or more constituent materials. These constituent materials have notably dissimilar chemical or ...

s, ultrasonic welding is becoming even more prevalent. It has been used in the bonding of the popular composite material carbon fiber

Carbon fiber-reinforced polymers (American English), carbon-fibre-reinforced polymers (Commonwealth English), carbon-fiber-reinforced plastics, carbon-fiber reinforced-thermoplastic (CFRP, CRP, CFRTP), also known as carbon fiber, carbon compo ...

. Numerous studies have been done to find the optimum parameters that will produce quality welds for this material.

Medical industry

In the medical industry ultrasonic welding is often used because it does not introduce contaminants or degradation into the weld and the machines can be specialized for use inclean room

A cleanroom or clean room is an engineered space, which maintains a very low concentration of airborne particulates. It is well isolated, well-controlled from contamination, and actively cleansed. Such rooms are commonly needed for scientif ...

s. The process can also be highly automated, provides strict control over dimensional tolerances and does not interfere with the biocompatibility of parts. Therefore, it increases part quality and decreases production costs. Items such as arterial filters, anesthesia filters, blood filters, IV catheters, dialysis tubes, pipette

A pipette (sometimes spelled as pipett) is a laboratory tool commonly used in chemistry, biology and medicine to transport a measured volume of liquid, often as a media dispenser. Pipettes come in several designs for various purposes with diff ...

s, cardiometry reservoirs, blood/gas filters, face masks and IV spike/filters can all be made using ultrasonic welding. Another important application in the medical industry for ultrasonic welding is textiles. Items like hospital gowns, sterile garments, masks, transdermal patch

A transdermal patch is a medicated adhesive patch that is placed on the skin to deliver a specific dose of medication through the skin and into the bloodstream. An advantage of a transdermal drug delivery route over other types of medica ...

es and textiles for clean rooms can be sealed and sewn using ultrasonic welding. This prevents contamination and dust production and reduces the risk of infection.

Packaging industry

Ultrasonic welding is often used in packaging applications. Many common items are either created or packaged using ultrasonic welding. Sealing containers, tubes andblister pack

A blister pack is any of several types of pre-formed plastic packaging used for small consumer goods, foods, and for pharmaceuticals.

The primary component of a blister pack is a cavity or pocket made from a formable web, usually a thermofor ...

s are common applications.

Ultrasonic welding is also applied in the packaging of dangerous materials, such as explosives, fireworks and other reactive chemicals. These items tend to require hermetic seal

A hermetic seal is any type of sealing that makes a given object airtight (preventing the passage of air, oxygen, or other gases). The term originally applied to airtight glass containers, but as technology advanced it applied to a larger categor ...

ing, but cannot be subjected to high temperatures. One example is a butane lighter. This container weld must be able to withstand high pressure and stress and must be airtight to contain the butane.Grewell, p. 171. Another example is the packaging of ammunition and propellants. These packages must be able to withstand high pressure and stress to protect the consumer from the contents.

The food industry finds ultrasonic welding preferable to traditional joining techniques, because it is fast, sanitary and can produce hermetic seals. Milk and juice containers are examples of products often sealed using ultrasonic welding. The paper parts to be sealed are coated with plastic, generally polypropylene

Polypropylene (PP), also known as polypropene, is a thermoplastic polymer used in a wide variety of applications. It is produced via chain-growth polymerization from the monomer propylene.

Polypropylene

belongs to the group of polyolefins a ...

or polyethylene

Polyethylene or polythene (abbreviated PE; IUPAC name polyethene or poly(methylene)) is the most commonly produced plastic. It is a polymer, primarily used for packaging ( plastic bags, plastic films, geomembranes and containers including b ...

, and then welded together to create an airtight seal. The main obstacle to overcome in this process is the setting of the parameters. For example, if over-welding occurs, then the concentration of plastic in the weld zone may be too low and cause the seal to break. If it is under-welded, the seal is incomplete. Variations in the thicknesses of materials can cause variations in weld quality. Some other food items sealed using ultrasonic welding include candy bar wrappers, frozen food packages and beverage containers.

Safety

Hazards of ultrasonic welding include exposure to high temperatures and voltages. This equipment should be operated using the safety guidelines provided by the manufacturer to avoid injury. For instance, operators must never place hands or arms near the welding tip when the machine is activated.American Welding Society, ''Welding Handbook: Welding Science and Technology'', p. 750. Also, operators should be provided with hearing protection and safety glasses. Operators should be informed of government agency regulations for the ultrasonic welding equipment and these regulations should be enforced.American Welding Society, ''Jefferson's Welding Encyclopedia'', p. 572. Ultrasonic welding machines require routine maintenance and inspection. Panel doors, housing covers and protective guards may need to be removed for maintenance. This should be done when the power to the equipment is off and only by the trained professional servicing the machine. Sub-harmonic vibrations, which can create annoying audible noise, may be caused in larger parts near the machine due to the ultrasonic welding frequency. This noise can be damped by clamping these large parts at one or more locations. Also, high-powered welders with frequencies of 15 kHz and 20 kHz typically emit a potentially damaging high-pitched squeal in the range of human hearing. Shielding this radiating sound can be done using an acoustic enclosure.Ahmed, p. 266.See also

* Thermosonic bondingReferences

Notes

Bibliography

* American Welding Society (1997). ''Jefferson’s Welding Encyclopedia''. American Welding Society. . * American Welding Society (2001). ''Welding Handbook: Welding Science and Technology''. American Welding Society. . * Ahmed, Nasir (Ed.), (2005). ''New Developments in Advanced Welding''. Boca Raton, Florida: CRC Press LLC. . * Grewell, David A.; Benatar, Avraham; & Park, Joon B. (Eds), (2003). ''Plastics and Composites Welding Handbook''. Cincinnati, Ohio: Hanser Gardner Publications, Inc. . * Plastics Design Library (1997). ''Handbook of Plastics Joining: A Practical Guide''. Norwich, New York: Plastics Design Library. .Further reading

*Tres, Paul A., "Designing Plastic Parts for Assembly", 6th ed., 2006, * Crawford, Lance"Port Sealing: An Effective Heat Sealing Solution".

''Plastic Decorating Magazine''. January/February 2013 Edition. . (Topeka, KS: Peterson Publications, Inc.). Section: Assembly: pages 36–39, covers Crawford's article. {{DEFAULTSORT:Ultrasonic Welding Ultrasound Welding Packaging machinery Plastic welding