Thermoset polymer matrix on:

[Wikipedia]

[Google]

[Amazon]

A thermoset polymer matrix is a synthetic

Cure is characterised by expansion rather than shrinkage and uses include structural

Cure is characterised by expansion rather than shrinkage and uses include structural

This thermoset polymer type is merged into composites as a

This thermoset polymer type is merged into composites as a

Cyanate ester resin prepregs combine the high temperature stability of polyimides with the flame and fire resistance of phenolics and are used in the manufacture of aerospace structural composite components which meet fire protection regulations concerning flammability, smoke density and toxicity. Other uses include film adhesives, surfacing films and 3D printing.

Cyanate ester resin prepregs combine the high temperature stability of polyimides with the flame and fire resistance of phenolics and are used in the manufacture of aerospace structural composite components which meet fire protection regulations concerning flammability, smoke density and toxicity. Other uses include film adhesives, surfacing films and 3D printing.

Epoxy resin is used widely in numerous formulations and forms in the aircraft-aerospace industry. It is regarded as "the work-horse of modern day composites". In recent years, the epoxy formulations used in composite prepregs have been fine-tuned to improve their toughness, impact strength and moisture absorption resistance. Maximum properties have been realized for this polymer.

This is not only used in aircraft-aerospace demand. It is used in military and commercial applications and is also used in construction. Epoxy-reinforced concrete and glass-reinforced and carbon-reinforced epoxy structures are used in building and bridge structures.

Epoxy composites have the following properties:

* High-Strength Glass Fiber Reinforced

* Relative Density 1.6-2.0

* Melting temperature(°C)

* Thermoset Processing Range(°F) C:300-330,I=280-380

* Molding pressure 1-5

* Shrinkage 0.001-0.008

* Tensile strength (p.s.i.) 5,000-20,000

* Compressive strength (p.s.i.) 18,000-40,000

* Flexural Strength (p.s.i.) 8000-30,000

* Izod impact strength (ft·lb/in) 0.3-10.0

* Linear expansion (10−6 in./in./°C) 11-50

* Hardness Rockwell M100-112

* Flammability V-0

* Water absorption 24h (%) 0.04-0.20

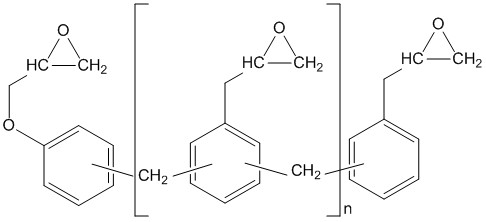

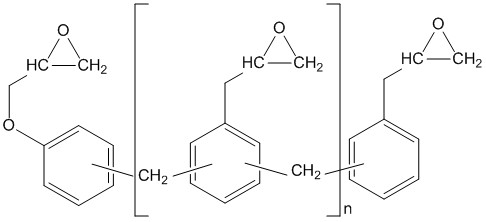

Epoxy Phenol Novolac (EPN) and Epoxy Cresol Novolac (ECN) resins made by reacting epichlorohydrin with multifunctional phenol novolac or cresol novolac resins have more reactive sites compared to DGEBF epoxy resins and on cure result in higher crosslink density thermosets. They are used in printed wire/circuit board laminating and also for electrical encapsulation, adhesive and coatings for metal where there is a need to provide protection from corrosion, erosion or chemical attack at high continuous operating temperatures.

Epoxy resin is used widely in numerous formulations and forms in the aircraft-aerospace industry. It is regarded as "the work-horse of modern day composites". In recent years, the epoxy formulations used in composite prepregs have been fine-tuned to improve their toughness, impact strength and moisture absorption resistance. Maximum properties have been realized for this polymer.

This is not only used in aircraft-aerospace demand. It is used in military and commercial applications and is also used in construction. Epoxy-reinforced concrete and glass-reinforced and carbon-reinforced epoxy structures are used in building and bridge structures.

Epoxy composites have the following properties:

* High-Strength Glass Fiber Reinforced

* Relative Density 1.6-2.0

* Melting temperature(°C)

* Thermoset Processing Range(°F) C:300-330,I=280-380

* Molding pressure 1-5

* Shrinkage 0.001-0.008

* Tensile strength (p.s.i.) 5,000-20,000

* Compressive strength (p.s.i.) 18,000-40,000

* Flexural Strength (p.s.i.) 8000-30,000

* Izod impact strength (ft·lb/in) 0.3-10.0

* Linear expansion (10−6 in./in./°C) 11-50

* Hardness Rockwell M100-112

* Flammability V-0

* Water absorption 24h (%) 0.04-0.20

Epoxy Phenol Novolac (EPN) and Epoxy Cresol Novolac (ECN) resins made by reacting epichlorohydrin with multifunctional phenol novolac or cresol novolac resins have more reactive sites compared to DGEBF epoxy resins and on cure result in higher crosslink density thermosets. They are used in printed wire/circuit board laminating and also for electrical encapsulation, adhesive and coatings for metal where there is a need to provide protection from corrosion, erosion or chemical attack at high continuous operating temperatures.

Phenolic resins, originally developed in the late 19th century and, regarded as the first truly synthetic polymer types, are often referred to as the “work-horse of thermosetting resins”. They are characterised by high bonding strength, dimensional stability and creep resistance at elevated temperatures, and frequently combined with co-curing resins such as epoxies.

General purpose molding compounds, engineering molding compounds and sheet molding compounds are the primary forms of phenolic composites. Phenolics are also used as the matrix binder with Honeycomb core. Phenolics find use in many electrical applications such as breaker boxes, brake lining materials and most recently in combination with various reinforcements in the molding of an engine block-head assembly, called the

Phenolic resins, originally developed in the late 19th century and, regarded as the first truly synthetic polymer types, are often referred to as the “work-horse of thermosetting resins”. They are characterised by high bonding strength, dimensional stability and creep resistance at elevated temperatures, and frequently combined with co-curing resins such as epoxies.

General purpose molding compounds, engineering molding compounds and sheet molding compounds are the primary forms of phenolic composites. Phenolics are also used as the matrix binder with Honeycomb core. Phenolics find use in many electrical applications such as breaker boxes, brake lining materials and most recently in combination with various reinforcements in the molding of an engine block-head assembly, called the

In the liquid state, unsaturated polyester resins may be processed by numerous methods, including Hand Layup, vacuum bag molding, and spray-up and compression molded Sheet Molding Compound (SMC). They can also be B-staged after application to chopped reinforcement and continuous reinforcement, to form pre-pregs. Solid molding compounds in the form of pellets or granules are also used in processes such as compression and transfer molding.

In the liquid state, unsaturated polyester resins may be processed by numerous methods, including Hand Layup, vacuum bag molding, and spray-up and compression molded Sheet Molding Compound (SMC). They can also be B-staged after application to chopped reinforcement and continuous reinforcement, to form pre-pregs. Solid molding compounds in the form of pellets or granules are also used in processes such as compression and transfer molding.

The cut of polyimides is , highest of all thermosets, with short term exposure capabilities of . Normal

The cut of polyimides is , highest of all thermosets, with short term exposure capabilities of . Normal

Furan resin prepolymers made from furfuryl alcohol, or by modification of

Furan resin prepolymers made from furfuryl alcohol, or by modification of

Varun Ratta: POLYIMIDES: Chemistry & structure-property relationships – literature review

(Chapter 1).

polymer

A polymer (; Greek '' poly-'', "many" + '' -mer'', "part")

is a substance or material consisting of very large molecules called macromolecules, composed of many repeating subunits. Due to their broad spectrum of properties, both synthetic a ...

reinforcement where polymers act as binder or matrix to secure in place incorporated particulates, fibres or other reinforcements. They were first developed for structural applications, such as glass-reinforced plastic

Fiberglass (American English) or fibreglass (Commonwealth English) is a common type of fiber-reinforced plastic using glass fiber. The fibers may be randomly arranged, flattened into a sheet called a chopped strand mat, or woven into glass clo ...

radar

Radar is a detection system that uses radio waves to determine the distance (''ranging''), angle, and radial velocity of objects relative to the site. It can be used to detect aircraft, Marine radar, ships, spacecraft, guided missiles, motor v ...

domes on aircraft

An aircraft is a vehicle that is able to flight, fly by gaining support from the Atmosphere of Earth, air. It counters the force of gravity by using either Buoyancy, static lift or by using the Lift (force), dynamic lift of an airfoil, or in ...

and graphite

Graphite () is a crystalline form of the element carbon. It consists of stacked layers of graphene. Graphite occurs naturally and is the most stable form of carbon under standard conditions. Synthetic and natural graphite are consumed on la ...

-epoxy

Epoxy is the family of basic components or cured end products of epoxy resins. Epoxy resins, also known as polyepoxides, are a class of reactive prepolymers and polymers which contain epoxide groups. The epoxide functional group is also co ...

payload bay doors on the Space Shuttle

The Space Shuttle is a retired, partially reusable low Earth orbital spacecraft system operated from 1981 to 2011 by the U.S. National Aeronautics and Space Administration (NASA) as part of the Space Shuttle program. Its official program n ...

.

They were first used after World War II

World War II or the Second World War, often abbreviated as WWII or WW2, was a world war that lasted from 1939 to 1945. It involved the World War II by country, vast majority of the world's countries—including all of the great power ...

, and continuing research has led to an increased range of thermoset resins, polymers or plastics, as well as engineering grade thermoplastics. They were all developed for use in the manufacture of polymer composites with enhanced and longer-term service capabilities. Thermoset polymer matrix technologies also find use in a wide diversity of non-structural industrial applications.

The foremost types of thermosetting polymers used in structural composites are benzoxazine resin

Polybenzoxazines, also called benzoxazine resins, are cured polymerization products derived from benzoxazine monomers.

Monomers

Benzoxazines are bicyclic heterocyclic compounds containing one oxygen and one nitrogen atom in a doubly unsaturated ...

s, bis-maleimide resins (BMI), cyanate ester resins, epoxy (epoxide) resins, phenolic (PF) resins, unsaturated polyester (UP) resins, polyimides, polyurethane (PUR) resins, silicones, and vinyl esters.

Benzoxazine resins

These are made by the reaction of phenols, formaldehyde and primary amines which at elevated temperatures (400 °F (200 °C)) undergo ring–opening polymerisation forming polybenzoxazine thermoset networks; when hybridised with epoxy and phenolic resins the resulting ternary systems have glass transition temperatures in excess of 490 °F (250 °C). Cure is characterised by expansion rather than shrinkage and uses include structural

Cure is characterised by expansion rather than shrinkage and uses include structural prepreg

Pre-preg is a composite material made from "pre-impregnated" fibers and a ''partially cured'' polymer matrix, such as epoxy or phenolic resin, or even thermoplastic mixed with liquid rubbers or resins. The fibers often take the form of a weave an ...

s, liquid molding and film adhesives for composite construction, bonding and repair. The high aromatic content of the high molecular weight polymers provides enhanced mechanical and flammability performance compared to epoxy and phenolic resins.

Bis-maleimides (BMI)

Formed by the condensation reaction of adiamine

A diamine is an amine with exactly two amino groups. Diamines are used as monomers to prepare polyamides, polyimides, and polyureas. The term ''diamine'' refers mostly to primary diamines, as those are the most reactive.

In terms of quantities ...

with maleic anhydride, and processed basically like epoxy resins ( cure). After an elevated post-cure (), they will exhibit superior properties. These properties are influenced by a 400-450 °F (204-232 °C) continuous use temperature and a glass transition of .  This thermoset polymer type is merged into composites as a

This thermoset polymer type is merged into composites as a prepreg

Pre-preg is a composite material made from "pre-impregnated" fibers and a ''partially cured'' polymer matrix, such as epoxy or phenolic resin, or even thermoplastic mixed with liquid rubbers or resins. The fibers often take the form of a weave an ...

matrix used in electrical printed circuit board

A printed circuit board (PCB; also printed wiring board or PWB) is a medium used in electrical and electronic engineering to connect electronic components to one another in a controlled manner. It takes the form of a laminated sandwich str ...

s, and for large scale structural aircraft

An aircraft is a vehicle that is able to flight, fly by gaining support from the Atmosphere of Earth, air. It counters the force of gravity by using either Buoyancy, static lift or by using the Lift (force), dynamic lift of an airfoil, or in ...

– aerospace

Aerospace is a term used to collectively refer to the atmosphere and outer space. Aerospace activity is very diverse, with a multitude of commercial, industrial and military applications. Aerospace engineering consists of aeronautics and ast ...

composite structures, etc. It is also used as a coating material and as the matrix of glass reinforced pipes, particularly in high temperature and chemical environments.

Cyanate ester resins

The reaction of bisphenols or multifunctional phenol novolac resins with cyanogen bromide or chloride leads to cyanate functional monomers which can be converted in a controlled manner into cyanate ester functional prepolymer resins by chain extension or copolymerization. When postcured, all residual cyanate ester functionality polymerises by cyclotrimerisation leading to tightly crosslinked polycyanurate networks with high thermal stability and glass transition temperatures up to 752 °F (400 °C) and wet heat stability up to around 400 °F (200 °C). Cyanate ester resin prepregs combine the high temperature stability of polyimides with the flame and fire resistance of phenolics and are used in the manufacture of aerospace structural composite components which meet fire protection regulations concerning flammability, smoke density and toxicity. Other uses include film adhesives, surfacing films and 3D printing.

Cyanate ester resin prepregs combine the high temperature stability of polyimides with the flame and fire resistance of phenolics and are used in the manufacture of aerospace structural composite components which meet fire protection regulations concerning flammability, smoke density and toxicity. Other uses include film adhesives, surfacing films and 3D printing.

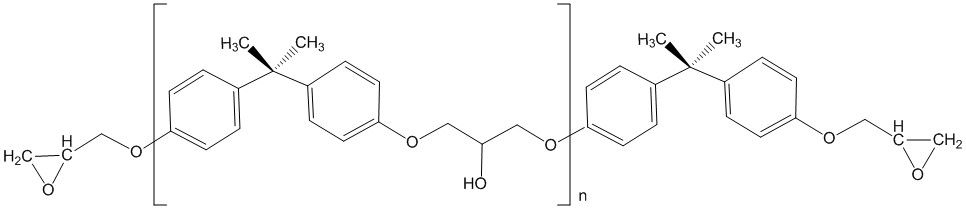

Epoxy (epoxide) resins

Epoxy

Epoxy is the family of basic components or cured end products of epoxy resins. Epoxy resins, also known as polyepoxides, are a class of reactive prepolymers and polymers which contain epoxide groups. The epoxide functional group is also co ...

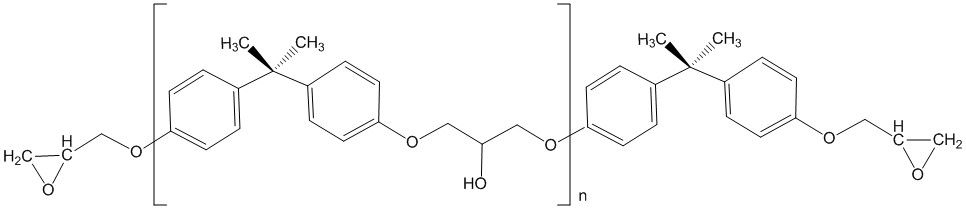

resins are thermosetting prepolymers made either by the reaction of epichlorohydrin

Epichlorohydrin (abbreviated ECH) is an organochlorine compound and an epoxide. Despite its name, it is not a halohydrin. It is a colorless liquid with a pungent, garlic-like odor, moderately soluble in water, but miscible with most polar organ ...

with hydroxyl functional aromatics, cycloaliphatics and aliphatics or amine functional aromatics, or by the oxidation of unsaturated cycloaliphatics. The diglycidyl ethers of bisphenol-A (DGEBA) and bisphenol-F (DGEBF) are the most widely used due to their characteristic high adhesion, mechanical strength, heat and corrosion resistance. Epoxide functional resins and prepolymers cure by polyaddition/copolymerisation or homopolymerisation depending on the selection of crosslinker, hardener, curing agent or catalyst as well as by the temperature. Epoxy resin is used widely in numerous formulations and forms in the aircraft-aerospace industry. It is regarded as "the work-horse of modern day composites". In recent years, the epoxy formulations used in composite prepregs have been fine-tuned to improve their toughness, impact strength and moisture absorption resistance. Maximum properties have been realized for this polymer.

This is not only used in aircraft-aerospace demand. It is used in military and commercial applications and is also used in construction. Epoxy-reinforced concrete and glass-reinforced and carbon-reinforced epoxy structures are used in building and bridge structures.

Epoxy composites have the following properties:

* High-Strength Glass Fiber Reinforced

* Relative Density 1.6-2.0

* Melting temperature(°C)

* Thermoset Processing Range(°F) C:300-330,I=280-380

* Molding pressure 1-5

* Shrinkage 0.001-0.008

* Tensile strength (p.s.i.) 5,000-20,000

* Compressive strength (p.s.i.) 18,000-40,000

* Flexural Strength (p.s.i.) 8000-30,000

* Izod impact strength (ft·lb/in) 0.3-10.0

* Linear expansion (10−6 in./in./°C) 11-50

* Hardness Rockwell M100-112

* Flammability V-0

* Water absorption 24h (%) 0.04-0.20

Epoxy Phenol Novolac (EPN) and Epoxy Cresol Novolac (ECN) resins made by reacting epichlorohydrin with multifunctional phenol novolac or cresol novolac resins have more reactive sites compared to DGEBF epoxy resins and on cure result in higher crosslink density thermosets. They are used in printed wire/circuit board laminating and also for electrical encapsulation, adhesive and coatings for metal where there is a need to provide protection from corrosion, erosion or chemical attack at high continuous operating temperatures.

Epoxy resin is used widely in numerous formulations and forms in the aircraft-aerospace industry. It is regarded as "the work-horse of modern day composites". In recent years, the epoxy formulations used in composite prepregs have been fine-tuned to improve their toughness, impact strength and moisture absorption resistance. Maximum properties have been realized for this polymer.

This is not only used in aircraft-aerospace demand. It is used in military and commercial applications and is also used in construction. Epoxy-reinforced concrete and glass-reinforced and carbon-reinforced epoxy structures are used in building and bridge structures.

Epoxy composites have the following properties:

* High-Strength Glass Fiber Reinforced

* Relative Density 1.6-2.0

* Melting temperature(°C)

* Thermoset Processing Range(°F) C:300-330,I=280-380

* Molding pressure 1-5

* Shrinkage 0.001-0.008

* Tensile strength (p.s.i.) 5,000-20,000

* Compressive strength (p.s.i.) 18,000-40,000

* Flexural Strength (p.s.i.) 8000-30,000

* Izod impact strength (ft·lb/in) 0.3-10.0

* Linear expansion (10−6 in./in./°C) 11-50

* Hardness Rockwell M100-112

* Flammability V-0

* Water absorption 24h (%) 0.04-0.20

Epoxy Phenol Novolac (EPN) and Epoxy Cresol Novolac (ECN) resins made by reacting epichlorohydrin with multifunctional phenol novolac or cresol novolac resins have more reactive sites compared to DGEBF epoxy resins and on cure result in higher crosslink density thermosets. They are used in printed wire/circuit board laminating and also for electrical encapsulation, adhesive and coatings for metal where there is a need to provide protection from corrosion, erosion or chemical attack at high continuous operating temperatures.

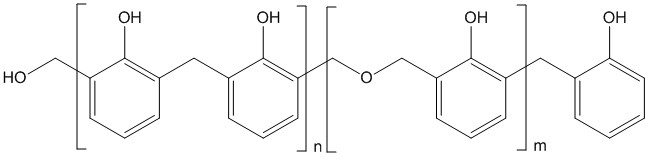

Phenolic (PF) resins

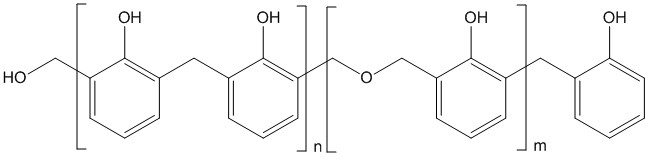

There are two types of phenolic resins - novolacs and resoles. Novolacs are made with acid catalysts and a molar ratio of formaldehyde to phenol of less than one to give methylene linked phenolic oligomers; resoles are made with alkali catalysts and a molar ratio of formaldehyde to phenol of greater than one to give phenolic oligomers with methylene and benzylic ether-linked phenol units.

Phenolic resins, originally developed in the late 19th century and, regarded as the first truly synthetic polymer types, are often referred to as the “work-horse of thermosetting resins”. They are characterised by high bonding strength, dimensional stability and creep resistance at elevated temperatures, and frequently combined with co-curing resins such as epoxies.

General purpose molding compounds, engineering molding compounds and sheet molding compounds are the primary forms of phenolic composites. Phenolics are also used as the matrix binder with Honeycomb core. Phenolics find use in many electrical applications such as breaker boxes, brake lining materials and most recently in combination with various reinforcements in the molding of an engine block-head assembly, called the

Phenolic resins, originally developed in the late 19th century and, regarded as the first truly synthetic polymer types, are often referred to as the “work-horse of thermosetting resins”. They are characterised by high bonding strength, dimensional stability and creep resistance at elevated temperatures, and frequently combined with co-curing resins such as epoxies.

General purpose molding compounds, engineering molding compounds and sheet molding compounds are the primary forms of phenolic composites. Phenolics are also used as the matrix binder with Honeycomb core. Phenolics find use in many electrical applications such as breaker boxes, brake lining materials and most recently in combination with various reinforcements in the molding of an engine block-head assembly, called the polimotor The Plastic automotive engine has its origins in the late 1970s with research and work done by Matthew (Matti) Holtzberg of Polimotor Research and his associates. Since then Holtzberg and others have done steady work in the field.

Holtzberg's earl ...

. Phenolics may be processed by the various common techniques, including compression, transfer and injection molding

Injection moulding (U.S. spelling: injection molding) is a manufacturing process for producing parts by injecting molten material into a mould, or mold. Injection moulding can be performed with a host of materials mainly including metals (for ...

.

Properties of phenolic composites have the following properties:

* High-Strength Glass Fiber Reinforced

* Relative Density 1.69-2.0

* Water Absorption 24h(%) 0.03-1.2

* Melting Temperature (◦c)

* Thermo set Processing Range (◦F) C:300-380 I:330-390

* Molding pressure I-20

* Shrinkage 0.001-0.004

* Tensile Strength (p.s.i.) 7000-18000

* Compressive Strength (p.s.i.) 16,000-70,000

* Flexural Strength (p.s.i.)12,000-60,000

* Izod Impact strength (ft-lb/in) 0.5-18.0

* Linear expansion (10−6 in./in./°C) 8-21

* Hardness Rockwell E54-101

* Flammability V-0

Polyester resins

Unsaturated polyester

Polyester is a category of polymers that contain the ester functional group in every repeat unit of their main chain. As a specific material, it most commonly refers to a type called polyethylene terephthalate (PET). Polyesters include natural ...

resins are an extremely versatile, and fairly inexpensive class of thermosetting polymer formed by the polycondensation of glycol mixtures often containing propylene glycol

Propylene glycol ( IUPAC name: propane-1,2-diol) is a viscous, colorless liquid, which is nearly odorless but possesses a faintly sweet taste. Its chemical formula is CH3CH(OH)CH2OH.

Containing two alcohol groups, it is classed as a diol. It ...

, with a dibasic acid and anhydrides usually maleic anhydride to provide backbone unsaturation needed for crosslinking, and phthalic anhydride, isophthalic acid or terephthalic acid where superior structural and corrosion resistance properties are required. Polyester resins are routinely diluted/dissolved in a vinyl functional monomer

In chemistry, a monomer ( ; '' mono-'', "one" + '' -mer'', "part") is a molecule that can react together with other monomer molecules to form a larger polymer chain or three-dimensional network in a process called polymerization.

Classification

...

such as styrene and include an inhibitor to stabilize the resin for storage purposes. Polymerisation in service is initiated by free radicals generated from ionizing radiation or by the photolytic or thermal decomposition of a radical initiator. Organic peroxide

In organic chemistry, organic peroxides are organic compounds containing the peroxide functional group (). If the R′ is hydrogen, the compounds are called hydroperoxides, which are discussed in that article. The O−O bond of peroxides easily b ...

s, such as methyl ethyl ketone peroxide and auxiliary accelerators which promote decomposition to form radicals are combined with the resin to initiate a room temperature cure.  In the liquid state, unsaturated polyester resins may be processed by numerous methods, including Hand Layup, vacuum bag molding, and spray-up and compression molded Sheet Molding Compound (SMC). They can also be B-staged after application to chopped reinforcement and continuous reinforcement, to form pre-pregs. Solid molding compounds in the form of pellets or granules are also used in processes such as compression and transfer molding.

In the liquid state, unsaturated polyester resins may be processed by numerous methods, including Hand Layup, vacuum bag molding, and spray-up and compression molded Sheet Molding Compound (SMC). They can also be B-staged after application to chopped reinforcement and continuous reinforcement, to form pre-pregs. Solid molding compounds in the form of pellets or granules are also used in processes such as compression and transfer molding.

Polyimides

There are two types of commercialpolyimide

Polyimide (sometimes abbreviated PI) is a polymer containing imide groups belonging to the class of high-performance plastics. With their high heat-resistance, polyimides enjoy diverse applications in roles demanding rugged organic materials, e. ...

s: thermosetting cross-linkable polyimides made by the condensation of aromatic diamines with aromatic dianhydride derivatives and anhydrides with unsaturated sites that facilitate addition polymerisation between preformed imide monomers and oligomers, and thermoplastic polyimides formed by the condensation reaction between aromatic diamines and aromatic dianhydrides. Thermoset polyimides are the most advanced of all thermoset polymer matrices with characteristics of high temperature physical and mechanical properties and are available commercially as resin, prepreg, stock shapes, thin sheets/films, laminates, and machined parts. Along with the high temperature properties, this thermoset polymer type must be processed at very high temperatures and relative pressure to produce optimum characteristics. With prepreg materials, to temperatures and pressures are required. The entire cure profiles are inherently long as there are a number of intermediate temperatures dwells, duration of which are dependent on part size and thickness.  The cut of polyimides is , highest of all thermosets, with short term exposure capabilities of . Normal

The cut of polyimides is , highest of all thermosets, with short term exposure capabilities of . Normal operating temperature

An operating temperature is the allowable temperature range of the local ambient environment at which an electrical or mechanical device operates. The device will operate effectively within a specified temperature range which varies based on the de ...

s range from cryogenic

In physics, cryogenics is the production and behaviour of materials at very low temperatures.

The 13th IIR International Congress of Refrigeration (held in Washington DC in 1971) endorsed a universal definition of “cryogenics” and “cr ...

to .

Polyimide composites have the following properties:

* Good mechanical properties and retention at high temperatures

* Good electrical properties

* High wear resistance

* Low creep at high temperatures

* Good compression with glass or graphite fiber reinforcement

* Good chemical resistance

* Inherently flame resistant

* Unaffected by most solvents and oils

Polyimide film possesses a unique combination of properties that make it ideal for a variety of applications in many different industries especially as excellent physical, electrical, and mechanical properties are maintained over a wide temperature range.

High-performance polyimide resin is used in electrical, wear resistant and as structural materials when combined with reinforcement for aircraft-aerospace applications, which are replacing heavier more expensive metals. High temperature processing causes some technical problems as well as higher costs compared to other polymers. Hysols PMR series is an example of this polymer.

Polyurethane (PUR) resins

Thermoset polyurethane prepolymers with carbamate (-NH-CO-O-) links are linear and elastomeric if formed by combining diisocyanates (OCN-R1-NCO) with long chain diols (HO-R2-OH), or crosslinked and rigid if formed from combinations of polyisocyanates and, polyols. They can be solid or have an open cellular structure if foamed, and are widely used for their characteristic high adhesion and resistance to fatigue. Polyurethane foam structural cores combined with glass-reinforced or graphite-reinforced composite laminates are used to make lightweight, strong, sandwich structures. All forms of the material, inclusive of flexible and rigid foams, foam moldings, solidelastomer

An elastomer is a polymer with viscoelasticity (i.e. both viscosity and Elasticity (physics), elasticity) and with weak intermolecular forces, generally low Young's modulus and high Deformation (mechanics), failure strain compared with other mate ...

ic moldings and extrudates, when combined with various reinforcement–fillers have found commercial applications in thermoset polymer matrix composites.

They differ from polyurea

Polyurea is a type of elastomer that is derived from the reaction product of an isocyanate component and a synthetic resin blend component through step-growth polymerization. The isocyanate can be aromatic or aliphatic in nature. It can be m ...

s which are thermoset elastomeric polymers with carbamide (-NH-CO-NH-) links made by combining diisocyanate monomers or prepolymers (OCN-R-NCO) with blends of long-chain amine-terminated polyether or polyester resins (H2N-RL-NH2) and short-chain diamine extenders (H2N-RS-NH2). Polyureas are characterised by near instantaneous cure, high mechanical strength and resistance to corrosion so are widely used for 1:1 volume mix ratio spray applied, abrasion resistant waterproofing protective coating and lining.

Silicone resins

Silicone resins are partly organic in nature with a backbone polymer structure made of alternatingsilicon

Silicon is a chemical element with the symbol Si and atomic number 14. It is a hard, brittle crystalline solid with a blue-grey metallic luster, and is a tetravalent metalloid and semiconductor. It is a member of group 14 in the periodic ...

and oxygen

Oxygen is the chemical element with the symbol O and atomic number 8. It is a member of the chalcogen group in the periodic table, a highly reactive nonmetal, and an oxidizing agent that readily forms oxides with most elements ...

atom

Every atom is composed of a nucleus and one or more electrons bound to the nucleus. The nucleus is made of one or more protons and a number of neutrons. Only the most common variety of hydrogen has no neutrons.

Every solid, liquid, gas, a ...

s rather than the familiar carbon

Carbon () is a chemical element with the symbol C and atomic number 6. It is nonmetallic and tetravalent—its atom making four electrons available to form covalent chemical bonds. It belongs to group 14 of the periodic table. Carbon ma ...

-to-carbon backbone characteristics of organic polymers. In addition to having at least one oxygen atom bonded to each silicon atom, silicone resins have direct bonds to carbon and therefore also known as polyorganosiloxanes. They have the general formula (R2SiO)n and the physical form (liquid, gel, elastomer or solid) and use varies with molecular weight, structure (linear, branched, caged) and nature of substituent groups (R = alkyl, aryl, H, OH, alkoxy). Aryl substituted silicone resins have greater thermal stability than alkyl substituted silicone resins when polymerised (condensation cure mechanism) at temperatures between ~300 °F (~150 °C) and ~400 °F (~200 °C). Heating above ~600 °F (~ 300 °C) converts all silicone polymers into ceramics since all organic constituents pyrolytically decompose leaving crystalline silicate polymers with the general formula (-SiO2-)n. In addition to applications as ceramic matrix composite precursors, silicone resins in the form of polysiloxane polymers made from silicone resins with pendant acrylate, vinyl ether or epoxy functionality find application as UV, electron beam and thermoset polymer matrix composites where they are characterised by their resistance to oxidation, heat and ultraviolet degradation.

Assorted other uses in the general area of composites for silicones include sealants, coating materials, and as a reusable bag material for vacuum-bag curing of composite parts.

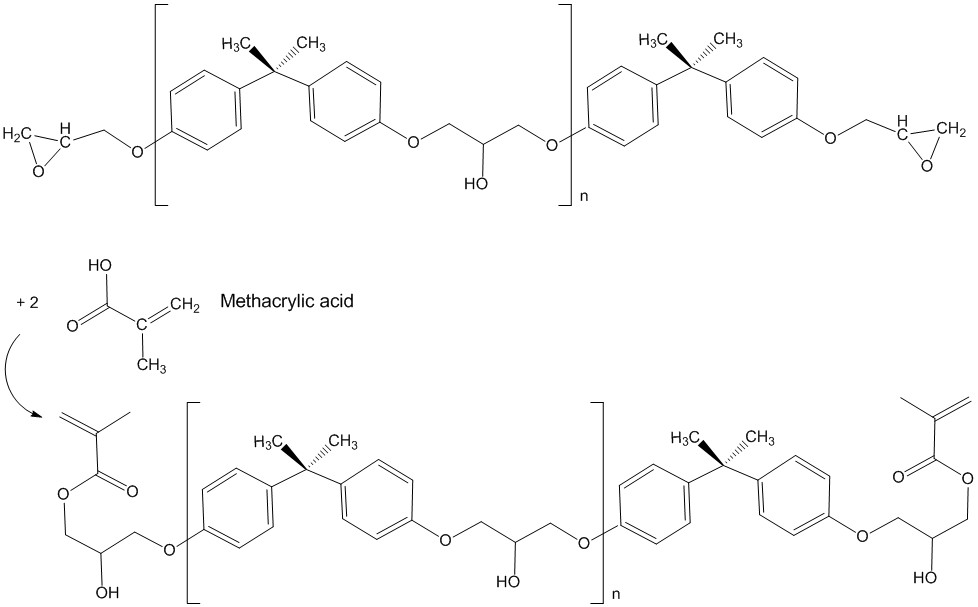

Vinyl ester resins

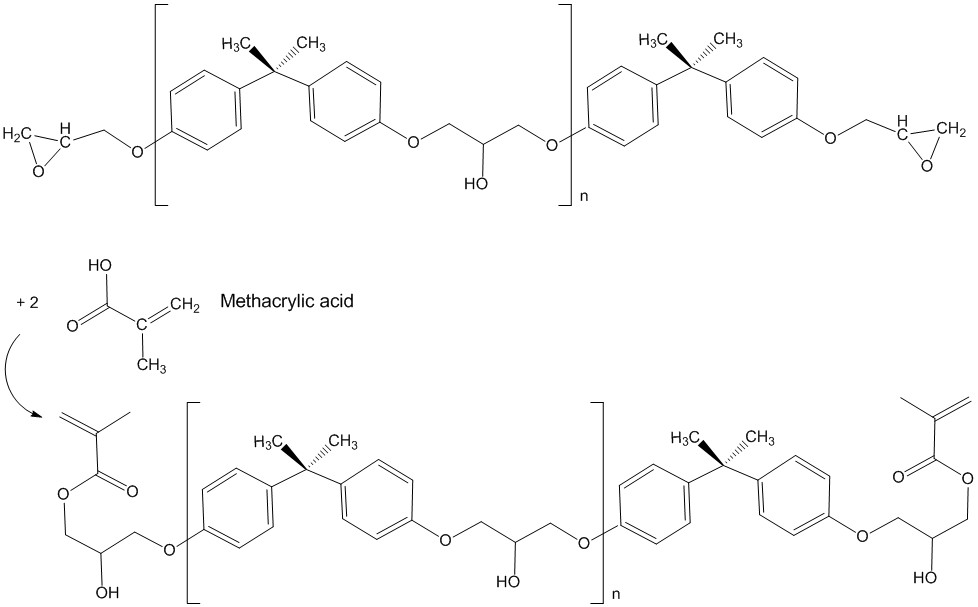

Vinyl ester resins made by addition reactions between an epoxy resin with acrylic acid derivatives, when diluted/dissolved in a vinyl functionalmonomer

In chemistry, a monomer ( ; '' mono-'', "one" + '' -mer'', "part") is a molecule that can react together with other monomer molecules to form a larger polymer chain or three-dimensional network in a process called polymerization.

Classification

...

such as styrene, polymerise. The resulting thermosets are notable for their high adhesion, heat resistance and corrosion resistance. They are stronger than polyesters and more resistant to impact than epoxies. Vinyl ester resins are used for wet lay-up laminating, SMC and BMC in the manufacture and repair of corrosion and heat resistant components ranging from pipelines, vessels and buildings to transportation, marine, military and aerospace applications.

Miscellaneous

Amino resins are another class of thermoset prepolymers formed by copolymerisation of amines or amides with an aldehyde. Urea-formaldehyde and melamine-formaldehyde resins, although not widely used in high performance structural composite applications, are characteristically used as the polymer matrix in molding and extrusion compounds where some use of fillers and reinforcements occurs. Urea-formaldehyde resins are widely used as the matrix binder in construction utility products such as particle board,wafer board

Waferboard belongs to the subset of reconstituted wood panel products called flakeboards. It is a structural material made from rectangular wood flakes of controlled length and thickness bonded together with waterproof phenolic resin under extrem ...

, and plywood

Plywood is a material manufactured from thin layers or "plies" of wood veneer that are glued together with adjacent layers having their wood grain rotated up to 90 degrees to one another. It is an engineered wood from the family of manufactured ...

, which are true particulate and laminar composite structures. Melamine-formaldehyde resins are used for plastic laminating.

Furan resin prepolymers made from furfuryl alcohol, or by modification of

Furan resin prepolymers made from furfuryl alcohol, or by modification of furfural

Furfural is an organic compound with the formula C4H3OCHO. It is a colorless liquid, although commercial samples are often brown. It has an aldehyde group attached to the 2-position of furan. It is a product of the dehydration of sugars, as occur ...

with phenol

Phenol (also called carbolic acid) is an aromatic organic compound with the molecular formula . It is a white crystalline solid that is volatile. The molecule consists of a phenyl group () bonded to a hydroxy group (). Mildly acidic, it r ...

, formaldehyde (methanal

Formaldehyde ( , ) ( systematic name methanal) is a naturally occurring organic compound with the formula and structure . The pure compound is a pungent, colourless gas that polymerises spontaneously into paraformaldehyde (refer to section ...

), urea

Urea, also known as carbamide, is an organic compound with chemical formula . This amide has two amino groups (–) joined by a carbonyl functional group (–C(=O)–). It is thus the simplest amide of carbamic acid.

Urea serves an important ...

or other extenders, are similar to amino and phenolic thermosetting resins in that cure involves polycondensation and release of water as well as heat. While they are generally cured under the influence of heat, catalysts and pressure, furan resins can also be formulated as dual-component no-bake acid-hardened systems which are characterised by high resistance to heat, acids and alkalies. Furan resins are of increasing interest for the manufacture of sustainable composites - biocomposites made from a bio-derived matrix (in this case furan resin), or biofibre reinforcement, or both.

Advantages and disadvantages

Advantages

* Well established processing and application history * Overall, better economics than thermoplastic polymers * Better high temperature properties * Good wetting and adhesion to reinforcementDisadvantages

* Resins and composite materials must be refrigerated * Moisture absorption and subsequent property degradation * Long process cycles * Reduced impact –toughness * Poor recycling capabilities * More difficult repair abilityReferences

Further reading

* * * * James M. Margolis, editor in chief, ''Engineering plastics handbook '', , McGraw-Hill, c2006 * Modern Plastic Mid-October Encyclopedia Issue, Polyimide, thermoset, p. 146.Varun Ratta: POLYIMIDES: Chemistry & structure-property relationships – literature review

(Chapter 1).

External links

*http://www.cartage.org.lb/en/themes/sciences/Chemistry/Organicchemistry/Organicindex/Polymers/Thermosetpolymers/Thermosetpolymers.htm *http://pslc.ws/macrog/lab/epoxy.htm *http://www.thefreedictionary.com/silicone+polymer *http://www.ciba.com/index/ind-index/ind-pla/ind-pla-polymersandpolymerprocessing/ind-pla-pol-polyurethane.htm *http://www.profma.com/polyimide.htm *http://www.wisegeek.com/what-is-polyester.htm {{DEFAULTSORT:Thermoset Polymer Matrices Composite materials Polymers Fibre-reinforced polymers