Railway brakes on:

[Wikipedia]

[Google]

[Amazon]

A railway brake is a type of brake used on the

A railway brake is a type of brake used on the

In the early part of the 20th century, many British railways employed vacuum brakes rather than the railway air brakes used in much of the rest of the world. The main advantage of vacuum was that the vacuum can be created by a

In the early part of the 20th century, many British railways employed vacuum brakes rather than the railway air brakes used in much of the rest of the world. The main advantage of vacuum was that the vacuum can be created by a

The higher performing EP brake uses a "main reservoir pipe" feeding air to all the brake reservoirs on the train, with the brake valves controlled electrically with a three-wire control circuit. This provides between four and seven braking levels, depending on the class of train. It also allows for faster brake application, as the electrical control signal is propagated effectively instantly to all vehicles in the train, whereas the change in air pressure which activates the brakes in a conventional system can take several seconds or tens of seconds to propagate fully to the rear of the train. This system is not however used on freight trains due to cost.

The higher performing EP brake uses a "main reservoir pipe" feeding air to all the brake reservoirs on the train, with the brake valves controlled electrically with a three-wire control circuit. This provides between four and seven braking levels, depending on the class of train. It also allows for faster brake application, as the electrical control signal is propagated effectively instantly to all vehicles in the train, whereas the change in air pressure which activates the brakes in a conventional system can take several seconds or tens of seconds to propagate fully to the rear of the train. This system is not however used on freight trains due to cost.

Image:URCengines.jpg, Loco from Uganda with small air brake hose above coupling and tap.

File:20070420-Korinthos-9106.JPG, Greece NG Air Brake

Thin hose above and tap

RailTech

{{Railway brakes Brakes History of rail transport

A railway brake is a type of brake used on the

A railway brake is a type of brake used on the cars

A car or automobile is a motor vehicle with wheels. Most definitions of ''cars'' say that they run primarily on roads, Car seat, seat one to eight people, have four wheels, and mainly transport private transport#Personal transport, people in ...

of railway

Rail transport (also known as train transport) is a means of transport that transfers passengers and goods on wheeled vehicles running on rails, which are incorporated in tracks. In contrast to road transport, where the vehicles run on a pre ...

train

In rail transport, a train (from Old French , from Latin , "to pull, to draw") is a series of connected vehicles that run along a railway track and transport people or freight. Trains are typically pulled or pushed by locomotives (often ...

s to enable deceleration, control acceleration (downhill) or to keep them immobile when parked. While the basic principle is similar to that on road vehicle usage, operational features are more complex because of the need to control multiple linked carriages and to be effective on vehicles left without a prime mover

Prime mover may refer to:

Philosophy

*Unmoved mover, a concept in Aristotle's writings

Engineering

* Prime mover (engine), motor, a machine that converts various other forms of energy (chemical, electrical, fluid pressure/flow, etc) into energy ...

. Clasp brakes are one type of brakes historically used on trains.

Early days

In the earliest days of railways, braking technology was primitive. The first trains had brakes operative on the locomotive tender and on vehicles in the train, where "porters" or, in the United States brakemen, travelling for the purpose on those vehicles operated the brakes. Some railways fitted a special deep-noted brake whistle to locomotives to indicate to the porters the necessity to apply the brakes. All the brakes at this stage of development were applied by operation of a screw and linkage to brake blocks applied to wheel treads, and these brakes could be used when vehicles were parked. In the earliest times, the porters travelled in crude shelters outside the vehicles, but "assistant guards" who travelled inside passenger vehicles, and who had access to a brake wheel at their posts, supplanted them. The braking effort achievable was limited and it was also unreliable, as the application of brakes by guards depended upon their hearing and responding quickly to a whistle for brakes. An early development was the application of a steam brake to locomotives, where boiler pressure could be applied to brake blocks on the locomotive wheels. As train speeds increased, it became essential to provide some more powerful braking system capable of instant application and release by the train operator, described as a ''continuous'' brake because it would be effective continuously along the length of the train. In the United Kingdom, theAbbots Ripton rail accident

The Abbots Ripton rail disaster occurred on 21 January 1876 at Abbots Ripton, then in the county of Huntingdonshire, England, on the Great Northern Railway main line, previously thought to be exemplary for railway safety. In the accident, the ' ...

in January 1876 was aggravated by the long stopping distances of express trains without continuous brakes, which – it became clear – in adverse conditions could considerably exceed those assumed when positioning signals. This had become apparent from the trials on railway brakes carried out at Newark in the previous year, to assist a Royal Commission then considering railway accidents. In the words of a contemporary railway official, these showed that under normal conditions it required a distance of 800 to 1200 yards to bring a train to rest when travelling at 45½ to 48½ mph, this being much below the ordinary travelling speed of the fastest express trains. Railway officials were not prepared for this result and the necessity for a great deal more brake power was at once admittedTrials conducted after Abbots Ripton reported the following (for an express train roughly matching one of those involved, like it on a 1 in 200 fall, but unlike it braking under favorable conditions) However, there was no clear technical solution to the problem, because of the necessity of achieving a reasonably uniform rate of braking effort throughout a train, and because of the necessity to add and remove vehicles from the train at frequent points on the journey. (At these dates,

unit train

A unit train, also called a block train or a trainload service, is a train in which all cars (wagons) carry the same commodity and are shipped from the same origin to the same destination, without being split up or stored en route.

They are dist ...

s were a rarity).

The chief types of solution were:

* A spring system: James Newall, carriage builder to the Lancashire and Yorkshire Railway

The Lancashire and Yorkshire Railway (L&YR) was a major British railway company before the 1923 Grouping. It was incorporated in 1847 from an amalgamation of several existing railways. It was the third-largest railway system based in northern ...

, in 1853 obtained a patent for a system whereby a rotating rod passing the length of the train was used to wind up the brake levers on each carriage against the force of conical springs carried in cylinders. The rod, mounted on the carriage roofs in rubber journals, was fitted with universal joint

A universal joint (also called a universal coupling or U-joint) is a joint or coupling connecting rigid shafts whose axes are inclined to each other. It is commonly used in shafts that transmit rotary motion. It consists of a pair of hinges ...

s and short sliding sections to allow for compression of the buffers. The brakes were controlled from one end of the train. To release the brakes the guard wound up the rod to compress the springs, whereupon they were held off by a single ratchet under his control (although in an emergency the driver could draw on a cord to release the ratchet). When the ratchet was released the springs applied the brakes. If the train divided, the brakes were not held off by the ratchet in the guard's compartment and the springs in each carriage forced the brakes onto the wheels. Excess play

Play most commonly refers to:

* Play (activity), an activity done for enjoyment

* Play (theatre), a work of drama

Play may refer also to:

Computers and technology

* Google Play, a digital content service

* Play Framework, a Java framework

* P ...

in the couplings limited the effectiveness of the device to about five carriages; additional guards and brake compartments were necessary if this number were exceeded. This apparatus was sold to a few companies and the system received recommendation from the Board of Trade. The L&Y conducted a simultaneous trial with a similar system designed by another employee, Charles Fay, but little difference was found in their effectiveness. In Fay's version, patented in 1856, the rods passed beneath the carriages and the direct spring application to each brake was given an intervening worm drive. The important "automatic" feature of Newall's system was retained but the worm drive ensured that the brakes did not act too fiercely when released. It was Fay's version of the system that the company entered for the Newark brake trials of June 1875, where a moderate performance, usually in the mid position of the eight systems on test, was achieved.

* The chain brake, in which a chain was connected continuously along the bottom of the train. When pulled tight, it activated a friction clutch that used the rotation of the wheels to tighten a brake system at that point; this system has severe limitations in length of train capable of being handled (as braking strength was considerably weaker after the third car), and of achieving good adjustment (give the slack that pin couplers required, which a fixed-length chain could not account for). In the United States, the chain brake was independently developed and patented by Lucious Stebbins of Hartford, Connecticut in 1848 and by William Loughridge of Weverton, Maryland

Weverton is an unincorporated community hamlet located in the southern tip of Washington County, Maryland, United States, near the north shore of the Potomac River. Its population is about 500. Weverton is located at the intersection of MD Route ...

in 1855. The British version was known as the Clark and Webb Brake, after John Clark, who developed it throughout the 1840s, and Francis William Webb, who perfected it in 1875. The chain brake remained in use until the 1870s in America and 1890s in the UK.

** The Heberlein brake

A Heberlein brake is a continuous railway brake used in Germany that is applied by means of a mechanical cable. Train braking is therefore initiated centrally from the locomotive using a winder. This causes the brake clips to be applied on individu ...

is a notable variation on the chain brake popular in Germany, using an overhead cable instead of an underlinked chain.

* Hydraulic brakes. Actuating pressure to apply brakes was transmitted hydraulically (as with automobile brakes). These found some favour in the UK (e.g. with the Midland and Great Eastern Railways), but water was used as the hydraulic fluid and even in the UK "Freezing possibilities told against the hydraulic brakes, though the Great Eastern Railway, which used them for a while, overcame this by the use of salt water"

* The simple vacuum system. An ejector on the locomotive created a vacuum in a continuous pipe along the train, allowing the external air pressure to operate brake cylinders on every vehicle. This system was very cheap and effective, but it had the major weakness that it became inoperative if the train became divided or if the train pipe was ruptured.

* The automatic vacuum brake. This system was similar to the simple vacuum system, except that the creation of vacuum in the train pipe exhausted vacuum reservoirs on every vehicle and ''released'' the brakes. If the driver applied the brake, his driver's brake valve admitted atmospheric air to the train pipe, and this atmospheric pressure applied the brakes against the vacuum in the vacuum reservoirs. Being an automatic brake, this system applies braking effort if the train becomes divided or if the train pipe is ruptured. Its disadvantage is that the large vacuum reservoirs were required on every vehicle, and their bulk and the rather complex mechanisms were seen as objectionable.

* The Westinghouse air brake system. In this system, air reservoirs are provided on every vehicle and the locomotive charges the train pipe with a positive air pressure, which releases the vehicle brakes and charges the air reservoirs on the vehicles. If the driver applies the brakes, his brake valve releases air from the train pipe, and triple valves at each vehicle detect the pressure loss and admit air from the air reservoirs to brake cylinders, applying the brakes. The Westinghouse system uses smaller air reservoirs and brake cylinders than the corresponding vacuum equipment, because a moderately high air pressure can be used. However, an air compressor is required to generate the compressed air and in the earlier days of railways, this required a large reciprocating steam air compressor, and this was regarded by many engineers as highly undesirable. A further drawback was the need to release the brake completely before it could be re-applied—initially there was no "graduable release" available and numerous accidents occurred while the brake power was temporarily unavailable.

Note: there are a number of variants and developments of all these systems.

The Newark trials showed the braking performance of the Westinghouse air-brakes to be distinctly superior: but for other reasons it was the vacuum system that was generally adopted on UK railways.

Later British practice

In British practice, only passenger trains were fitted with continuous brakes until about 1930; goods and mineral trains ran at slower speed and relied on the brake force from the locomotive and tender and thebrake van

Brake van and guard's van are terms used mainly in the UK, Ireland, Australia and India for a railway vehicle equipped with a hand brake which can be applied by the guard. The equivalent North American term is caboose, but a British brake van ...

—a heavy vehicle provided at the rear of the train and occupied by a guard.

Goods and mineral vehicles had hand brakes which were applied by a hand lever operated by staff on the ground. These hand brakes were used where necessary when vehicles were parked but also when trains were descending a steep gradient. The train stopped at the top of the gradient, and the guard walked forward to "pin down" the handles of the brakes, so the brakes were partially applied during the descent. Early goods vehicles had brake handles on one side only but, from about 1930, brake handles were required on both sides of good vehicles. Trains containing hand-braked vehicles were described as "unfitted": they were in use in Britain until about 1985. From about 1930, semi-fitted trains were introduced, in which goods vehicles fitted with continuous brakes were marshalled next to the locomotive, giving sufficient braking power to run at higher speeds than unfitted trains. A trial in January 1952 saw a 52-wagon, 850 ton, coal train run at an average of , compared to the usual maximum speed on the Midland main line

The Midland Main Line is a major railway line in England from London to Nottingham and Sheffield in the Midlands. It comprises the lines from London's St Pancras station via Leicester, Derby/Nottingham and Chesterfield in the East Midlands ...

of for unfitted freight trains. In 1952, 14% of open wagons, 55% of covered wagons and 80% of cattle trucks had vacuum brakes.

In the early days of diesel locomotives, a purpose-built brake tender was attached to the locomotive to increase braking effort when hauling unfitted trains. The brake tender was low, so that the driver could still see the line and signals ahead if the brake tender was propelled (pushed) ahead of the locomotive, which was often the case.

By 1878 there were over 105 patents in various countries for braking systems, most of which were not widely adopted.

Continuous brakes

As train loads, gradients and speeds increased, braking became a problem. In the late 19th century, significantly better ''continuous brakes'' started to appear. The earliest type of continuous brake was the ''chain brake'' which used a chain, running the length of the train, to operate brakes on all vehicles simultaneously. The chain brake was soon superseded by air operated or vacuum operated brakes. These brakes used hoses connecting all the wagons of a train, so the operator could apply or release the brakes with a single valve in the locomotive. These continuous brakes can be simple or automatic, the essential difference being what happens should the train break in two. With simple brakes, pressure is needed to apply the brakes, and all braking power is lost if the continuous hose is broken for any reason. Simple non-automatic brakes are thus useless when things really go wrong, as is shown with theArmagh rail disaster

The Armagh rail disaster happened on 12 June 1889 near Armagh, County Armagh, in Ireland, when a crowded Sunday school excursion train had to negotiate a steep incline; the steam locomotive was unable to complete the climb and the train stall ...

.

Automatic brakes on the other hand use the air or vacuum pressure to hold the brakes off against a reservoir carried on each vehicle, which applies the brakes if pressure/vacuum is lost in the train pipe. Automatic brakes are thus largely " fail safe", though faulty closure of hose taps can lead to accidents such as the Gare de Lyon accident.

The standard Westinghouse Air Brake has the additional enhancement of a triple valve, and local reservoirs on each wagon that enable the brakes to be applied fully with only a slight reduction in air pressure, reducing the time that it takes to release the brakes as not all pressure is voided to the atmosphere.

Non-automatic brakes still have a role on engines and first few wagons, as they can be used to control the whole train without having to apply the automatic brakes.

Types

Mechanical brake

Most tractive units, passenger coaches and some freight wagons are equipped with a hand-operated parking brake (handbrake). This acts directly (mechanically) on the vehicle's brake linkage. The activation of such a brake prevents wheel rotation independently of the pneumatic brake and is therefore suitable for securing parked wagons and coaches from unintentional movement. Only mechanical brakes can be used for this purpose, since the holding power of air brakes can decrease due to unavoidable leaks. Securing railway vehicles with compressed air brakes is only permitted for up to 60 minutes after parking. There are two types. The handbrake that can be operated on board the vehicle is used firstly to prevent it from rolling away and secondly to regulate the speed for certain shunting operations and to stop trains if the automatic brake fails. It is usually designed as a screw brake and is operated from a brakeman's platform or, in the case of passenger coaches, from inside the coach, usually from an entrance area. On UIC freight wagons, this braking weight is framed in white (white like the rest of the brake inscription, alternatively black on a white or light-coloured background). Hand brakes on tenders andtank locomotive

A tank locomotive or tank engine is a steam locomotive that carries its water in one or more on-board water tanks, instead of a more traditional tender. Most tank engines also have bunkers (or fuel tanks) to hold fuel; in a tender-tank locom ...

s are often designed as counterweight brakes.

The manually operating parking brake is only suitable for securing static railway vehicles from rolling away. It can be designed as a hand wheel or as a spring-loaded brake, the operating handles are marked in red frames on freight wagons.

A direction-dependent pawl brake is often installed in vehicles on rack railways. It only brakes when going downhill. When driving uphill, the applied ratchet brake is released by a ratchet mechanism and prevents the train from rolling backwards.

Air versus vacuum brakes

In the early part of the 20th century, many British railways employed vacuum brakes rather than the railway air brakes used in much of the rest of the world. The main advantage of vacuum was that the vacuum can be created by a

In the early part of the 20th century, many British railways employed vacuum brakes rather than the railway air brakes used in much of the rest of the world. The main advantage of vacuum was that the vacuum can be created by a steam ejector

An injector is a system of ducting and nozzles used to direct the flow of a high-pressure fluid in such a way that a lower pressure fluid is entrained in the jet and carried through a duct to a region of higher pressure. It is a fluid-dynamic ...

with no moving parts (and which could be powered by the steam of a steam locomotive), whereas an air brake system requires a noisy and complicated compressor.

However, air brakes can be made much more effective than vacuum brakes for a given size of brake cylinder. An air brake compressor is usually capable of generating a pressure of vs only for vacuum. With a vacuum system, the maximum pressure differential is atmospheric pressure ( at sea level, less at altitude). Therefore, an air brake system can use a much smaller brake cylinder than a vacuum system to generate the same braking force. This advantage of air brakes increases at high altitude, e.g. Peru and Switzerland where today vacuum brakes are used by secondary railways. The much higher effectiveness of air brakes and the demise of the steam locomotive have seen the air brake become ubiquitous; however, vacuum braking is still in use in India

India, officially the Republic of India (Hindi: ), is a country in South Asia. It is the seventh-largest country by area, the second-most populous country, and the most populous democracy in the world. Bounded by the Indian Ocean on the so ...

, Argentina

Argentina (), officially the Argentine Republic ( es, link=no, República Argentina), is a country in the southern half of South America. Argentina covers an area of , making it the second-largest country in South America after Brazil, th ...

and South Africa

South Africa, officially the Republic of South Africa (RSA), is the Southern Africa, southernmost country in Africa. It is bounded to the south by of coastline that stretch along the Atlantic Ocean, South Atlantic and Indian Oceans; to the ...

, but this will be declining in near future. See ''Jane's World Railways

''Jane's World Railways'' is a directory of railway activities worldwide. It is published annually by Jane's Information Group. Janes World Railways (JWR) provides details on railway systems and operators, manufacturers of equipment, technology ...

''.

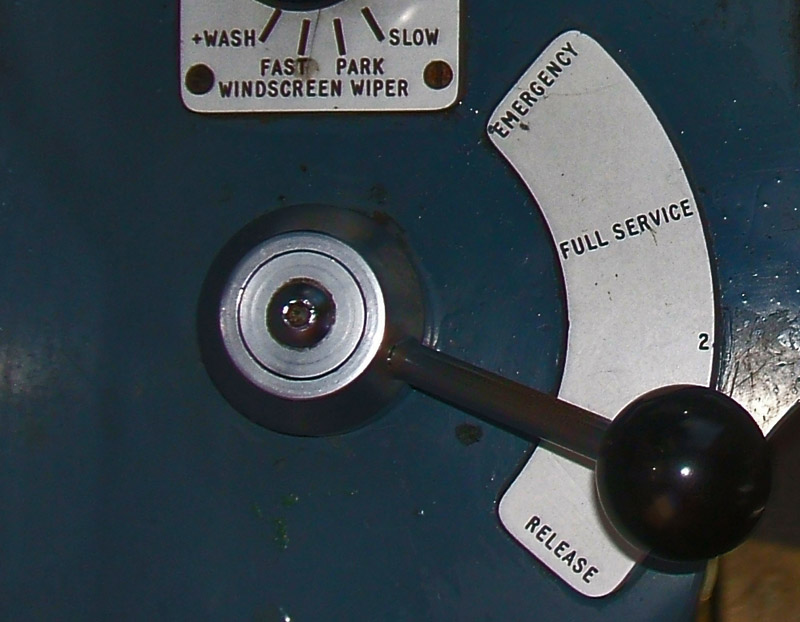

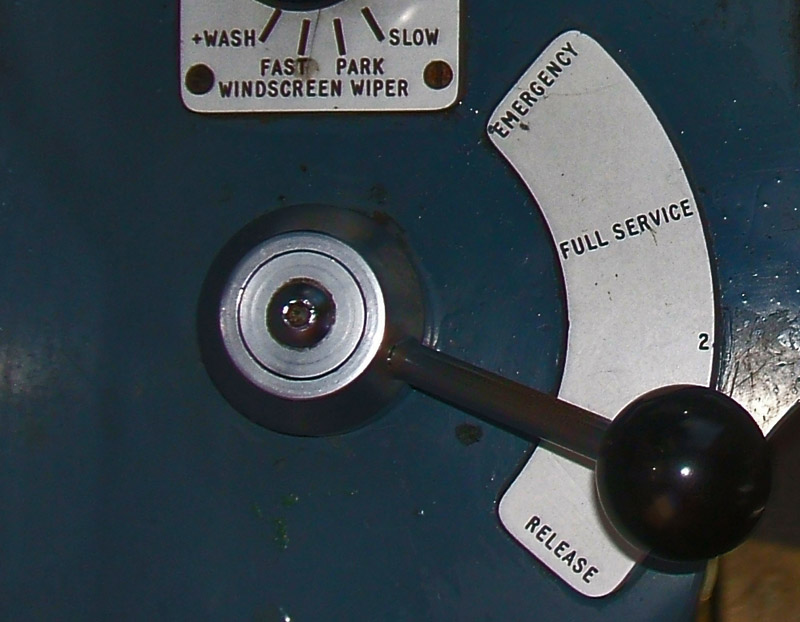

Visual differences between the two systems are shown by air brakes working off high pressure, with the air hoses at the ends of rolling stock having a small diameter; vacuum brakes work off low pressure, and the hoses at the ends of rolling stock are of a larger diameter. Air brakes at the outermost vehicles of a train are turned off using a tap. Vacuum brakes at the outermost vehicles of a train are sealed by fixed plugs ("dummies") onto which the open end of the vacuum pipe is placed. It is sealed against a rubber washer by the vacuum, with a pin to hold the pipe in place when the vacuum drops during braking.

Air brake enhancements

One enhancement of the automatic air brake is to have a second air hose (the main reservoir or main line) along the train to recharge the air reservoirs on each wagon. This air pressure can also be used to operate loading and unloading doors on wheat wagons and coal and ballast wagons. Onpassenger coaches

A passenger railroad car or passenger car ( United States), also called a passenger carriage, passenger coach ( United Kingdom and International Union of Railways), or passenger bogie ( India) is a railroad car that is designed to carry pas ...

, the main reservoir pipe is also used to supply air to operate doors and air suspension.

Electropneumatic brakes

The higher performing EP brake uses a "main reservoir pipe" feeding air to all the brake reservoirs on the train, with the brake valves controlled electrically with a three-wire control circuit. This provides between four and seven braking levels, depending on the class of train. It also allows for faster brake application, as the electrical control signal is propagated effectively instantly to all vehicles in the train, whereas the change in air pressure which activates the brakes in a conventional system can take several seconds or tens of seconds to propagate fully to the rear of the train. This system is not however used on freight trains due to cost.

The higher performing EP brake uses a "main reservoir pipe" feeding air to all the brake reservoirs on the train, with the brake valves controlled electrically with a three-wire control circuit. This provides between four and seven braking levels, depending on the class of train. It also allows for faster brake application, as the electrical control signal is propagated effectively instantly to all vehicles in the train, whereas the change in air pressure which activates the brakes in a conventional system can take several seconds or tens of seconds to propagate fully to the rear of the train. This system is not however used on freight trains due to cost.

Electronically controlled pneumatic brakes

Electronically controlled pneumatic brakes (ECP) are a development of the late 20th Century to deal with very long and heavy freight trains, and are a development of the EP brake with even higher level of control. In addition, information about the operation of the brakes on each wagon is returned to the driver's control panel. With ECP, a power and control line is installed from wagon to wagon from the front of the train to the rear. Electrical control signals are propagated effectively instantaneously, as opposed to changes in air pressure which propagate at a rather slow speed limited in practice by the resistance to air flow of the pipework, so that the brakes on all wagons can be applied simultaneously, or even from rear to front rather than from front to rear. This prevents wagons at the rear "shoving" wagons at the front, and results in reduced stopping distance and less equipment wear. There are two brands of ECP brakes available in North America, one by New York Air Brake and the other byWabtec

Wabtec Corporation (derived from Westinghouse Air Brake Technologies Corporation) is an American company formed by the merger of the Westinghouse Air Brake Company (WABCO) and MotivePower Industries Corporation in 1999. It is headquartered ...

. These two types are interchangeable.

Reversibility

Brake connections between wagons may be simplified if wagons always point the same way. An exception would be made for locomotives which are often turned onturntable

A phonograph, in its later forms also called a gramophone (as a trademark since 1887, as a generic name in the UK since 1910) or since the 1940s called a record player, or more recently a turntable, is a device for the mechanical and analogu ...

s or triangles

A triangle is a polygon with three edges and three vertices. It is one of the basic shapes in geometry. A triangle with vertices ''A'', ''B'', and ''C'' is denoted \triangle ABC.

In Euclidean geometry, any three points, when non-collinear ...

.

On the new Fortescue railway opened in 2008, wagons are operated in sets, although their direction changes at the balloon loop

A balloon loop, turning loop, or reversing loop ( North American Terminology) allows a rail vehicle or train to reverse direction without having to shunt or stop. Balloon loops can be useful for passenger trains and unit freight trains.

Bal ...

at the port. The ECP connections are on one side only and are unidirectional.

Accidents with brakes

Defective or improperly-applied brakes may lead to arunaway train

A runaway train is a type of railroad incident in which unattended rolling stock is accidentally allowed to roll onto the main line, a moving train loses enough braking power to be unable to stop in safety, or a train operates at unsafe speeds d ...

; in some instances this has caused train wreck

A train wreck, train collision, train accident or train crash is a type of disaster involving one or more trains. Train wrecks often occur as a result of miscommunication, as when a moving train meets another train on the same track; or an acci ...

s:

* Lac-Mégantic derailment, Quebec

Quebec ( ; )According to the Canadian government, ''Québec'' (with the acute accent) is the official name in Canadian French and ''Quebec'' (without the accent) is the province's official name in Canadian English is one of the thirtee ...

(2013), handbrakes were improperly set on unattended parked crude oil train, runaway tank car

A tank car ( International Union of Railways (UIC): tank wagon) is a type of railroad car (UIC: railway car) or rolling stock designed to transport liquid and gaseous commodities.

History

Timeline

The following major events occurred in ...

s rolled down a slope and derailed due to excessive speed on a curve in the centre of town, spilling of oil and causing fires which killed 47 people.

* Democratic Republic of the Congo

The Democratic Republic of the Congo (french: République démocratique du Congo (RDC), colloquially "La RDC" ), informally Congo-Kinshasa, DR Congo, the DRC, the DROC, or the Congo, and formerly and also colloquially Zaire, is a country in ...

west of Kananga (2007) - 100 killed.

* Igandu train disaster

The Igandu train disaster occurred during the early morning of June 24, 2002, in Tanzania. It is one of the worst rail accidents in African history. A passenger train with over 1,200 people on board rolled backwards down a hill into a slow movi ...

, Tanzania (2002) – runaway backwards - 281 killed.

* Tenga rail disaster, Mozambique (2002) – runaway backwards - 192 killed.

* San Bernardino train disaster, California (1989) - brakes failed on freight train which crashed into houses

* Gare de Lyon train accident, France (1988) – valve closed by mistake leading to runaway.

* Chester General rail crash, UK (1972) - brakes failed on fuel train which hit a parked DMU

* Chapel-en-le-Frith

Chapel-en-le-Frith () is a town and civil parish in the Borough of High Peak in Derbyshire, England.

It has been dubbed the "Capital of the Peak", in reference to the Peak District, historically the upperland areas between the Saxon lands (belo ...

, Great Britain (1957) – broken steam pipe made it impossible for crew to apply brakes.

* Federal Express train wreck, Union station, Washington, DC, (1953) - valve closed by badly designed bufferplate.

* Torre del Bierzo rail disaster

The Torre del Bierzo rail disaster occurred on 3 January 1944 near the village of Torre del Bierzo in the El Bierzo region of Spain's Province of León, León province when three trains collided and caught fire inside a tunnel. Although the offici ...

, Spain (1944) - brakes failed on overloaded passenger train which collided with another in a tunnel; a third train was unaware and also crashed into it.

* Saint-Michel-de-Maurienne derailment, France 1917 - runaway train on 3.3 percent grade, with air brakes on only 3 of 19 cars and on locomotive unable to keep train below authorized speed - 700 killed.

* Armagh rail disaster

The Armagh rail disaster happened on 12 June 1889 near Armagh, County Armagh, in Ireland, when a crowded Sunday school excursion train had to negotiate a steep incline; the steam locomotive was unable to complete the climb and the train stall ...

, Northern Ireland (1889) – runaway backwards led to change in law.

* Shipton-on-Cherwell train crash, Oxford (1874) - caused by fracture of a carriage wheel.

Gallery

Thin hose above and tap

See also

* Counterweight brake * Driver's brake valve * Dual brake *Dynamic brake

Dynamic braking is the use of an electric traction motor as a generator when slowing a vehicle such as an electric or diesel-electric locomotive. It is termed " rheostatic" if the generated electrical power is dissipated as heat in brake grid ...

* Eddy current brake

* Electromagnetic brake

* Emergency brake (train)

On trains, the expression emergency brake has several meanings:

* The ''maximum'' brake force available to the engine driver from the conventional braking system, usually operated by taking the brake handle to its furthest position, through a gat ...

* Gladhand connector

* Heberlein brake

A Heberlein brake is a continuous railway brake used in Germany that is applied by means of a mechanical cable. Train braking is therefore initiated centrally from the locomotive using a winder. This causes the brake clips to be applied on individu ...

* Railway air brake

A railway air brake is a railway brake power braking system with compressed air as the operating medium. Modern trains rely upon a fail-safe air brake system that is based upon a design patented by George Westinghouse on April 13, 1869. The ...

* Railway disc brake

A disc brake is a type of brake that uses the calipers to squeeze pairs of pads against a disc or a "rotor" to create friction. This action slows the rotation of a shaft, such as a vehicle axle, either to reduce its rotational speed or to hold ...

* Railway tread brake

* Regenerative brake

Regenerative braking is an energy recovery mechanism that slows down a moving vehicle or object by converting its kinetic energy into a form that can be either used immediately or stored until needed. In this mechanism, the electric traction mo ...

* Riggenbach counter-pressure brake

* Track brake

A magnetic track brake (Mg brake) is a brake for rail vehicles. It consists of brake magnets, pole shoes, a suspension, a power transmission and, in the case of mainline railroads, a track rod. When current flows through the magnet coil, the ma ...

* Vacuum brake

The vacuum brake is a braking system employed on trains and introduced in the mid-1860s. A variant, the automatic vacuum brake system, became almost universal in British train equipment and in countries influenced by British practice. Vacuum br ...

* Yaw brake

Manufacturers

* The Rane Group of Companies (Rane Brake Lining Limited),Chennai, Tamil Nadu, India *Westinghouse Air Brake Company

The Westinghouse Air Brake Company (sometimes nicknamed or abbreviated WABCO although this was also confusingly used for spinoffs) was founded on September 28, 1869 by George Westinghouse in Pittsburgh, Pennsylvania.

Earlier in the year he had i ...

(WABCO), later Wabtec

Wabtec Corporation (derived from Westinghouse Air Brake Technologies Corporation) is an American company formed by the merger of the Westinghouse Air Brake Company (WABCO) and MotivePower Industries Corporation in 1999. It is headquartered ...

, United States

* Faiveley Transport

Faiveley Transport (), formerly Faiveley, is an international manufacturer and supplier of equipment for the railway industry founded in 1919. It introduced the single-arm pantograph in 1955. The company has subsidiaries in more than 24 countr ...

, France

* Knorr-Bremse

Knorr-Bremse AG is a German manufacturer of braking systems for rail and commercial vehicles that has operated in the field for over 110 years. Other products in Group's portfolio include intelligent door systems, control components, air c ...

Rail Vehicle Systems, Germany

* Westinghouse Brake and Signal Company Ltd

The Westinghouse Brake & Signal Company Ltd was a British manufacturer of rail transport, railroad signs. Founded by George Westinghouse, it was registered as "Westinghouse Brake Company" in 1881. The company reorganised in 1920, associating with ...

(now a division of Knorr-Bremse), UK

* New York Air Brake (now a division of Knorr-Bremse), United States

* MTZ TRANSMASH, Russia

* MZT HEPOS, Macedonia(now a division of Wabtec)

* Mitsubishi Electric, Japan

* Nabtesco, Japan

* Dellner

Dellner Couplers AB is a Swedish original equipment manufacturer of train connection systems as couplers, gangway systems and dampers. The headquarter of the company is located in Vika in the Falun Municipality. Dellner is owned by the investme ...

, Sweden

* Aflink, South Africa

* Hanning & Kahl GmbH LRT trains, Hydraulic Brakes and control components, Germany

* Voith

The Voith Group is a German manufacturer of machines for the pulp and paper industry, technical equipment for hydropower plants and drive and braking systems. The family-owned company, which operates worldwide and has its headquarters in Heid ...

, Germany

* YUJIN Machinery Ltd, South Korea

References

Sources

*British Transport Commission

The British Transport Commission (BTC) was created by Clement Attlee's post-war Labour government as a part of its nationalisation programme, to oversee railways, canals and road freight transport in Great Britain (Northern Ireland had the se ...

, London (1957:142). ''Handbook for Railway Steam Locomotive Enginemen''

Further reading

* Marsh, G.H. and Sharpe, A.C. The development of railway brakes. Part 1 1730-1880 ''Railway engineering journal'' 2(1) 1973, 46–53; Part 2 1880-1940 ''Railway engineering journal'' 2(2) 1973, 32-42 * Winship, I.R. The acceptance of continuous brakes on railways in Britain '' History of technology'' 11 1986, 209–248. Covering developments from about 1850 to 1900.External links

RailTech

{{Railway brakes Brakes History of rail transport