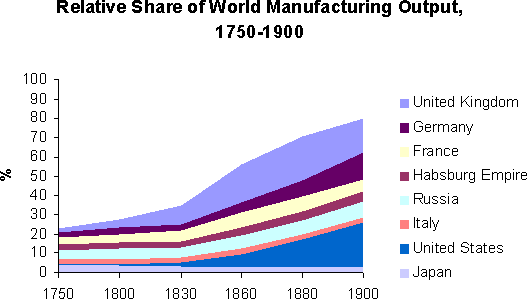

The Industrial Revolution was the transition to new manufacturing processes in Great Britain,

continental Europe, and the United States, that occurred during the period from around 1760 to about 1820–1840. This transition included going from

hand production methods to

machines, new

chemical manufacturing and

iron production processes, the increasing use of

steam power and

water power, the development of

machine tools and the rise of the

mechanized factory system

The factory system is a method of manufacturing using machinery and division of labor. Because of the high capital cost of machinery and factory buildings, factories are typically privately owned by wealthy individuals or corporations who emplo ...

. Output greatly increased, and a result was an unprecedented rise in population and in the rate of population growth.

Textiles were the dominant industry of the Industrial Revolution in terms of employment, value of output and

capital invested. The

textile industry was also the first to use modern production methods.

The Industrial Revolution began in

Great Britain

Great Britain is an island in the North Atlantic Ocean off the northwest coast of continental Europe. With an area of , it is the largest of the British Isles, the largest European island and the ninth-largest island in the world. It i ...

, and many of the

technological

Technology is the application of knowledge to reach practical goals in a specifiable and reproducible way. The word ''technology'' may also mean the product of such an endeavor. The use of technology is widely prevalent in medicine, science, ...

and

architectural innovations were of British origin. By the mid-18th century, Britain was the world's leading commercial nation, controlling a global trading empire with

colonies in North America and the Caribbean. Britain had major military and political hegemony on the

Indian subcontinent

The Indian subcontinent is a list of the physiographic regions of the world, physiographical region in United Nations geoscheme for Asia#Southern Asia, Southern Asia. It is situated on the Indian Plate, projecting southwards into the Indian O ...

; particularly with the

proto-industrialised Mughal Bengal

The Bengal Subah ( bn, সুবাহ বাংলা; fa, ), also referred to as Mughal Bengal ( bn, মোগল বাংলা), was the largest subdivision of the Mughal Empire (and later an independent state under the Nawabs of Beng ...

, through the activities of the

East India Company.

The development of trade and the rise of business were among the major causes of the Industrial Revolution.

The Industrial Revolution marked a major turning point in history. Comparable only to humanity's

adoption of agriculture with respect to material advancement, the Industrial Revolution influenced in some way almost every aspect of daily life. In particular, average income and population began to exhibit unprecedented sustained growth. Some economists have said the most important effect of the Industrial Revolution was that the

standard of living for the general population in the western world began to increase consistently for the first time in history, although others have said that it did not begin to meaningfully improve until the late 19th and 20th centuries.

was broadly stable before the Industrial Revolution and the emergence of the modern

capitalist economy,

while the Industrial Revolution began an era of per-capita

economic growth in capitalist economies.

Economic historians are in agreement that the onset of the Industrial Revolution is the most important event in

human history since the

domestication

Domestication is a sustained multi-generational relationship in which humans assume a significant degree of control over the reproduction and care of another group of organisms to secure a more predictable supply of resources from that group. ...

of animals and plants.

The precise start and end of the Industrial Revolution is still debated among historians, as is the pace of economic and

social changes.

held that the Industrial Revolution began in Britain in the 1780s and was not fully felt until the 1830s or 1840s,

while

T. S. Ashton held that it occurred roughly between 1760 and 1830.

Rapid

industrialization first began in Britain, starting with mechanized spinning in the 1780s,

with high rates of growth in steam power and iron production occurring after 1800.

Mechanized textile production spread from Great Britain to continental Europe and the United States in the early 19th century, with important centres of textiles, iron and

coal

Coal is a combustible black or brownish-black sedimentary rock, formed as rock strata called coal seams. Coal is mostly carbon with variable amounts of other elements, chiefly hydrogen, sulfur, oxygen, and nitrogen.

Coal is formed when ...

emerging

in Belgium and the United States and later textiles in France.

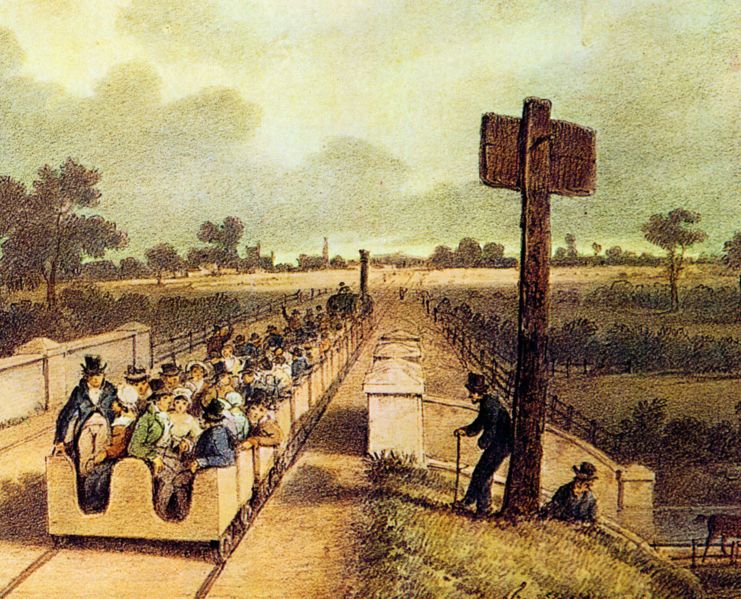

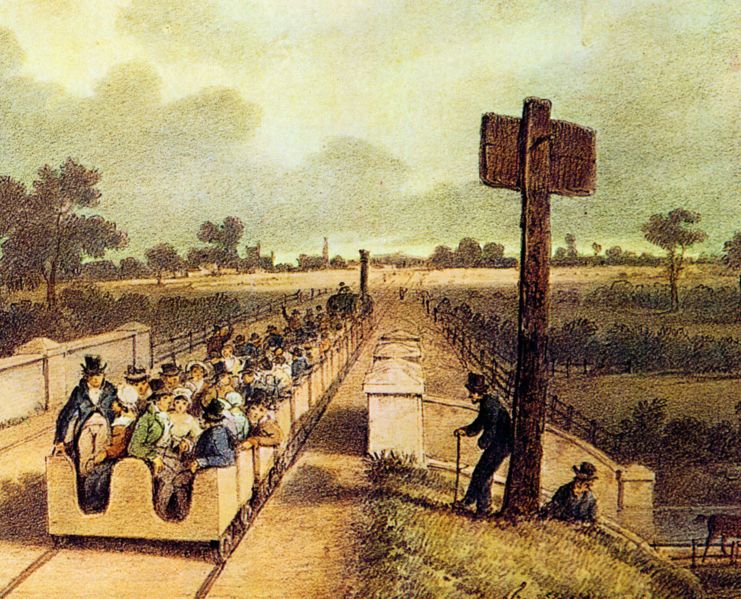

An economic recession occurred from the late 1830s to the early 1840s when the adoption of the Industrial Revolution's early innovations, such as mechanized spinning and weaving, slowed and their markets matured. Innovations developed late in the period, such as the increasing adoption of locomotives, steamboats and steamships and

hot blast iron smelting. New technologies, such as the

electrical telegraph

Electrical telegraphs were point-to-point text messaging systems, primarily used from the 1840s until the late 20th century. It was the first electrical telecommunications system and the most widely used of a number of early messaging systems ...

, widely introduced in the 1840s and 1850s, were not powerful enough to drive high rates of growth. Rapid economic growth began to occur after 1870, springing from a new group of innovations in what has been called the

Second Industrial Revolution. These innovations included new

steel making processes,

mass-production

Mass production, also known as flow production or continuous production, is the production of substantial amounts of standardized products in a constant flow, including and especially on assembly lines. Together with job production and bat ...

,

assembly line

An assembly line is a manufacturing process (often called a ''progressive assembly'') in which parts (usually interchangeable parts) are added as the semi-finished assembly moves from workstation to workstation where the parts are added in se ...

s,

electrical grid systems, the large-scale manufacture of machine tools, and the use of increasingly advanced machinery in steam-powered factories.

Etymology

The earliest recorded use of the term "Industrial Revolution" was written in July 1799 by French envoy

Louis-Guillaume Otto, announcing that France had entered the race to industrialise.

In his 1976 book ''

Keywords: A Vocabulary of Culture and Society'',

Raymond Williams states in the entry for "Industry": "The idea of a new social order based on major industrial change was clear in

Southey and

Owen, between 1811 and 1818, and was implicit as early as

Blake in the early 1790s and

Wordsworth at the turn of the

9thcentury." The term ''Industrial Revolution'' applied to technological change was becoming more common by the late 1830s, as in

Jérôme-Adolphe Blanqui's description in 1837 of ''la révolution industrielle''.

Friedrich Engels in ''

The Condition of the Working Class in England'' in 1844 spoke of "an industrial revolution, a revolution which at the same time changed the whole of civil society". However, although Engels wrote his book in the 1840s, it was not translated into English until the late 1800s, and his expression did not enter everyday language until then. Credit for popularising the term may be given to

Arnold Toynbee, whose 1881 lectures gave a detailed account of the term.

Economic historians and authors such as Mendels,

Pomeranz and Kridte argue that

proto-industrialization

Proto-industrialization is the regional development, alongside commercial agriculture, of rural handicraft production for external markets.

The term was introduced in the early 1970s by economic historians who argued that such developments in pa ...

in parts of Europe,

Islamic world,

Mughal India, and

China created the social and economic conditions that led to the Industrial Revolution, thus causing the

Great Divergence

The Great Divergence or European miracle is the socioeconomic shift in which the Western world (i.e. Western Europe and the parts of the New World where its people became the dominant populations) overcame pre-modern growth constraints and eme ...

.

Some historians, such as

John Clapham and

Nicholas Crafts

Nicholas Francis Robert Crafts CBE (born 9 March 1949 in Nottingham, England) is Professor of Economic History at thUniversity of Sussex Business School a post held from 2019. Previously he was Professor of Economics and Economic History at the ...

, have argued that the economic and social changes occurred gradually and that the term ''revolution'' is a misnomer. This is still a subject of debate among some historians.

Requirements

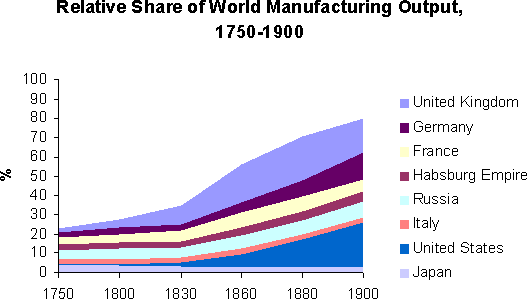

Six factors facilitated industrialization: high levels of agricultural productivity to provide excess manpower and food; a pool of managerial and entrepreneurial skills; available ports, rivers, canals, and roads to cheaply move raw materials and outputs; natural resources such as coal, iron, and waterfalls; political stability and a legal system that supported business; and financial capital available to invest. Once industrialization began in Great Britain, new factors can be added: the eagerness of British entrepreneurs to export industrial expertise and the willingness to import the process. Britain met the criteria and industrialized starting in the 18th century, and then it exported the process to western Europe (especially Belgium, France, and the German states) in the early 19th century. The United States copied the British model in the early 19th century and Japan copied the Western European models in the late 19th century.

Important technological developments

The commencement of the Industrial Revolution is closely linked to a small number of innovations,

beginning in the second half of the 18th century. By the 1830s, the following gains had been made in important technologies:

* Textiles – mechanised cotton spinning powered by steam or water increased the output of a worker by a factor of around 500. The

power loom increased the output of a worker by a factor of over 40. The

cotton gin increased productivity of removing seed from cotton by a factor of 50.

Large gains in productivity also occurred in spinning and weaving of wool and linen, but they were not as great as in cotton.

* Steam power – the efficiency of

steam engines increased so that they used between one-fifth and one-tenth as much fuel. The adaptation of stationary steam engines to rotary motion made them suitable for industrial uses.

The high-pressure engine had a high power to weight ratio, making it suitable for transportation.

Steam power underwent a rapid expansion after 1800.

* Iron making – the substitution of

coke for

charcoal greatly lowered the fuel cost of

pig iron and

wrought iron production.

Using coke also allowed larger blast furnaces, resulting in

economies of scale. The steam engine began being used to power blast air (indirectly by pumping water to a waterwheel) in the mid 1750s, enabling a large increase in iron production by overcoming the limitation of water power.

The cast iron blowing cylinder was first used in 1760. It was later improved by making it double acting, which allowed higher

blast furnace temperatures. The

puddling process produced a structural grade iron at a lower cost than the

finery forge

A finery forge is a forge used to produce wrought iron from pig iron by decarburization in a process called "fining" which involved liquifying cast iron in a fining hearth and removing carbon from the molten cast iron through oxidation. Finery ...

.

The

rolling mill

In metalworking, rolling is a metal forming process in which metal stock is passed through one or more pairs of rolls to reduce the thickness, to make the thickness uniform, and/or to impart a desired mechanical property. The concept is simil ...

was fifteen times faster than hammering wrought iron.

Hot blast

Hot blast refers to the preheating of air blown into a blast furnace or other metallurgical process. As this considerably reduced the fuel consumed, hot blast was one of the most important technologies developed during the Industrial Revolution. ...

(1828) greatly increased fuel efficiency in iron production in the following decades.

* Invention of machine tools – The first

machine tools were invented. These included the

screw cutting lathe, cylinder boring machine, and the

milling machine

Milling is the process of machining using rotary cutters to remove material by advancing a cutter into a workpiece. This may be done by varying direction on one or several axes, cutter head speed, and pressure. Milling covers a wide variety of d ...

. Machine tools made the economical manufacture of

precision metal parts possible, although it took several decades to develop effective techniques.

Textile manufacture

British textile industry statistics

In 1750 Britain imported 2.5 million pounds of raw cotton, most of which was spun and woven by cottage industry in Lancashire. The work was done by hand in workers' homes or occasionally in master weavers' shops. In 1787 raw cotton consumption was 22 million pounds, most of which was cleaned, carded, and spun on machines.

The British textile industry used 52 million pounds of cotton in 1800, which increased to 588 million pounds in 1850.

The share of value added by the cotton textile industry in Britain was 2.6% in 1760, 17% in 1801, and 22.4% in 1831. Value added by the British woollen industry was 14.1% in 1801. Cotton factories in Britain numbered approximately 900 in 1797. In 1760 approximately one-third of cotton cloth manufactured in Britain was exported, rising to two-thirds by 1800. In 1781 cotton spun amounted to 5.1 million pounds, which increased to 56 million pounds by 1800. In 1800 less than 0.1% of world cotton cloth was produced on machinery invented in Britain. In 1788 there were 50,000 spindles in Britain, rising to 7 million over the next 30 years.

Wages in

Lancashire

Lancashire ( , ; abbreviated Lancs) is the name of a historic county, ceremonial county, and non-metropolitan county in North West England. The boundaries of these three areas differ significantly.

The non-metropolitan county of Lancash ...

, a core region for cottage industry and later factory spinning and weaving, were about six times those in India in 1770 when overall

productivity

Productivity is the efficiency of production of goods or services expressed by some measure. Measurements of productivity are often expressed as a ratio of an aggregate output to a single input or an aggregate input used in a production proces ...

in Britain was about three times higher than in India.

Cotton

Parts of India, China, Central America, South America, and the Middle East have a long history of hand manufacturing

cotton

Cotton is a soft, fluffy staple fiber that grows in a boll, or protective case, around the seeds of the cotton plants of the genus '' Gossypium'' in the mallow family Malvaceae. The fiber is almost pure cellulose, and can contain minor pe ...

textiles, which became a major industry sometime after 1000 AD. In tropical and subtropical regions where it was grown, most was grown by small farmers alongside their food crops and was spun and woven in households, largely for domestic consumption. In the 15th century, China began to require households to pay part of their taxes in cotton cloth. By the 17th century, almost all Chinese wore cotton clothing. Almost everywhere cotton cloth could be used as a

medium of exchange

In economics, a medium of exchange is any item that is widely acceptable in exchange for goods and services. In modern economies, the most commonly used medium of exchange is currency.

The origin of "mediums of exchange" in human societies is ass ...

. In India, a significant amount of cotton textiles were manufactured for distant markets, often produced by professional weavers. Some merchants also owned small weaving workshops. India produced a variety of cotton cloth, some of exceptionally fine quality.

Cotton was a difficult raw material for Europe to obtain before it was grown on colonial plantations in the Americas.

The early Spanish explorers found Native Americans growing unknown species of excellent quality cotton: sea island cotton (''

Gossypium barbadense

''Gossypium barbadense'' (''gos-SIP-pee-um bar-ba-DEN-see'') is one of several species of cotton. It is in the mallow family. It has been cultivated since antiquity, but has been especially prized since a form with particularly long fibers was ...

'') and upland green seeded cotton ''

Gossypium hirsutum

''Gossypium hirsutum'', also known as upland cotton or Mexican cotton, is the most widely planted species of cotton in the world. Globally, about 90% of all cotton production is of cultivars derived from this species. In the United States, the wo ...

''. Sea island cotton grew in tropical areas and on barrier islands of Georgia and South Carolina but did poorly inland. Sea island cotton began being exported from Barbados in the 1650s. Upland green seeded cotton grew well on inland areas of the southern U.S., but was not economical because of the difficulty of removing seed, a problem solved by the

cotton gin.

A strain of cotton seed brought from Mexico to Natchez, Mississippi in 1806 became the parent genetic material for over 90% of world cotton production today; it produced

bolls that were three to four times faster to pick.

Trade and textiles

The

Age of Discovery was followed by a period of

colonialism beginning around the 16th century. Following the discovery of a trade route to India around southern Africa by the Portuguese, the Dutch established the Verenigde Oostindische Compagnie (abbr. VOC) or

Dutch East India Company

The United East India Company ( nl, Verenigde Oostindische Compagnie, the VOC) was a chartered company established on the 20th March 1602 by the States General of the Netherlands amalgamating existing companies into the first joint-stock ...

, the world's first

transnational corporation

A transnational corporation is an enterprise that is involved with the international production of goods or services, foreign investments, or income and asset management in more than one country. It sets up factories in developing countries as land ...

and the first

multinational enterprise to issue

shares of stock to the public. The British later founded the

East India Company, along with smaller companies of different nationalities which established trading posts and employed agents to engage in trade throughout the Indian Ocean region and between the Indian Ocean region and North Atlantic Europe.

One of the largest segments of this trade was in cotton textiles, which were purchased in India and sold in Southeast Asia, including the Indonesian archipelago, where spices were purchased for sale to Southeast Asia and Europe. By the mid-1760s cloth was over three-quarters of the East India Company's exports. Indian textiles were in demand in the North Atlantic region of Europe where previously only wool and linen were available; however, the number of cotton goods consumed in Western Europe was minor until the early 19th century.

Pre-mechanized European textile production

By 1600 Flemish refugees began weaving cotton cloth in English towns where cottage spinning and weaving of wool and linen was well established. They were left alone by the

guild

A guild ( ) is an association of artisans and merchants who oversee the practice of their craft/trade in a particular area. The earliest types of guild formed as organizations of tradesmen belonging to a professional association. They sometimes ...

s who did not consider cotton a threat. Earlier European attempts at cotton spinning and weaving were in 12th-century Italy and 15th-century southern Germany, but these industries eventually ended when the supply of cotton was cut off. The

Moors in Spain grew, spun, and wove cotton beginning around the 10th century.

British cloth could not compete with Indian cloth because India's labour cost was approximately one-fifth to one-sixth that of Britain's.

In 1700 and 1721 the British government passed

Calico Acts

The Calico Acts (1700, 1721) banned the import of most cotton textiles into England, followed by the restriction of sale of most cotton textiles. It was a form of economic protectionism, largely in response to India (particularly Bengal), which dom ...

to

protect the domestic woollen and linen industries from the increasing amounts of cotton fabric imported from India.

The demand for heavier fabric was met by a domestic industry based around

Lancashire

Lancashire ( , ; abbreviated Lancs) is the name of a historic county, ceremonial county, and non-metropolitan county in North West England. The boundaries of these three areas differ significantly.

The non-metropolitan county of Lancash ...

that produced

fustian, a cloth with flax

warp and cotton

weft. Flax was used for the warp because wheel-spun cotton did not have sufficient strength, but the resulting blend was not as soft as 100% cotton and was more difficult to sew.

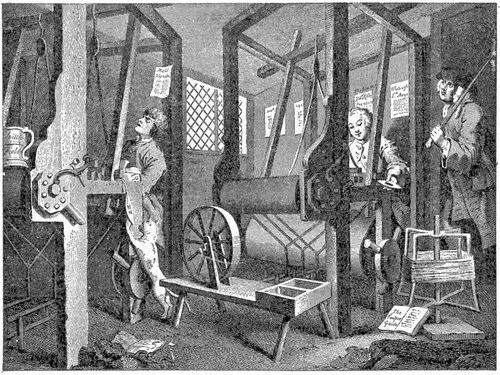

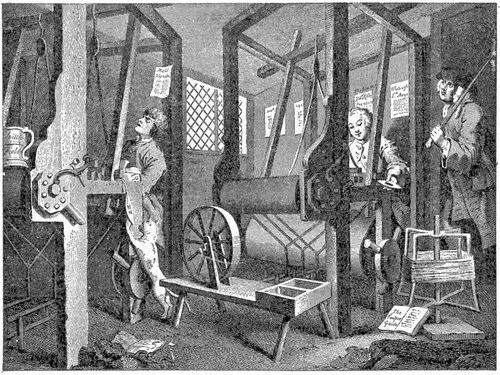

On the eve of the Industrial Revolution, spinning and weaving were done in households, for domestic consumption, and as a cottage industry under the

putting-out system

The putting-out system is a means of subcontracting work. Historically, it was also known as the workshop system and the domestic system. In putting-out, work is contracted by a central agent to subcontractors who complete the project via remote w ...

. Occasionally the work was done in the workshop of a master weaver. Under the putting-out system, home-based workers produced under contract to merchant sellers, who often supplied the raw materials. In the off-season the women, typically farmers' wives, did the spinning and the men did the weaving. Using the

spinning wheel, it took anywhere from four to eight spinners to supply one handloom weaver.

Invention of textile machinery

The

flying shuttle, patented in 1733 by

John Kay, with a number of subsequent improvements including an important one in 1747, doubled the output of a weaver, worsening the imbalance between spinning and weaving. It became widely used around Lancashire after 1760 when John's son,

Robert, invented the dropbox, which facilitated changing thread colors.

Lewis Paul

Lewis Paul (died 1759) was the original inventor of roller spinning, the basis of the water frame for spinning cotton in a cotton mill.

Life and work

Lewis Paul was of Huguenot descent. His father was physician to Lord Shaftesbury. He may hav ...

patented the roller

spinning frame

The spinning frame is an Industrial Revolution invention for spinning thread or yarn from fibres such as wool or cotton in a mechanized way. It was developed in 18th-century Britain by Richard Arkwright and John Kay.

Historical context

In 1 ...

and the flyer-and-bobbin system for drawing wool to a more even thickness. The technology was developed with the help of John Wyatt of

Birmingham. Paul and Wyatt opened a mill in Birmingham which used their new rolling machine powered by a donkey. In 1743 a factory opened in

Northampton with 50 spindles on each of five of Paul and Wyatt's machines. This operated until about 1764. A similar mill was built by

Daniel Bourn

Daniel Bourn was an English inventor, who took out a patent for a carding machine with rotating cylinders in 1748.

Though Bourn is thought likely to have had some association with Lancashire, at the time he received the patent he owned a Paul-Wy ...

in

Leominster

Leominster ( ) is a market town in Herefordshire, England, at the confluence of the River Lugg and its tributary the River Kenwater. The town is north of Hereford and south of Ludlow in Shropshire. With a population of 11,700, Leominster i ...

, but this burnt down. Both Lewis Paul and Daniel Bourn patented

carding machines in 1748. Based on two sets of rollers that travelled at different speeds, it was later used in the first

cotton spinning mill. Lewis's invention was later developed and improved by

Richard Arkwright in his

water frame

The water frame is a spinning frame that is powered by a water-wheel. Water frames in general have existed since Ancient Egypt times. Richard Arkwright, who patented the technology in 1769, designed a model for the production of cotton thread; ...

and

Samuel Crompton

Samuel Crompton (3 December 1753 – 26 June 1827) was an English inventor and pioneer of the spinning industry. Building on the work of James Hargreaves and Richard Arkwright he invented the spinning mule, a machine that revolutionised th ...

in his

spinning mule

The spinning mule is a machine used to spin cotton and other fibres. They were used extensively from the late 18th to the early 20th century in the mills of Lancashire and elsewhere. Mules were worked in pairs by a minder, with the help of tw ...

.

In 1764 in the village of Stanhill, Lancashire,

James Hargreaves

James Hargreaves ( 1720 – 22 April 1778) was an English weaver, carpenter and inventor who lived and worked in Lancashire, England. He was one of three men responsible for the mechanisation of spinning: Hargreaves is credited with inventing ...

invented the

spinning jenny

The spinning jenny is a multi- spindle spinning frame, and was one of the key developments in the industrialization of textile manufacturing during the early Industrial Revolution. It was invented in 1764 or 1765 by James Hargreaves in Sta ...

, which he patented in 1770. It was the first practical spinning frame with multiple spindles. The jenny worked in a similar manner to the spinning wheel, by first clamping down on the fibres, then by drawing them out, followed by twisting. It was a simple, wooden framed machine that only cost about £6 for a 40-spindle model in 1792, and was used mainly by home spinners. The jenny produced a lightly twisted yarn only suitable for

weft, not

warp.

The

spinning frame

The spinning frame is an Industrial Revolution invention for spinning thread or yarn from fibres such as wool or cotton in a mechanized way. It was developed in 18th-century Britain by Richard Arkwright and John Kay.

Historical context

In 1 ...

or water frame was developed by Richard Arkwright who, along with two partners, patented it in 1769. The design was partly based on a spinning machine built for Thomas High by clockmaker John Kay, who was hired by Arkwright.

For each spindle the water frame used a series of four pairs of rollers, each operating at a successively higher rotating speed, to draw out the fibre, which was then twisted by the spindle. The roller spacing was slightly longer than the fibre length.

Too close a spacing caused the fibres to break while too distant a spacing caused uneven thread. The top rollers were leather-covered and loading on the rollers was applied by a weight. The weights kept the twist from backing up before the rollers. The bottom rollers were wood and metal, with fluting along the length. The water frame was able to produce a hard, medium-count thread suitable for warp, finally allowing 100% cotton cloth to be made in Britain. A horse powered the first factory to use the spinning frame. Arkwright and his partners used water power at a factory in Cromford, Derbyshire in 1771, giving the invention its name.

Samuel Crompton

Samuel Crompton (3 December 1753 – 26 June 1827) was an English inventor and pioneer of the spinning industry. Building on the work of James Hargreaves and Richard Arkwright he invented the spinning mule, a machine that revolutionised th ...

's

Spinning Mule

The spinning mule is a machine used to spin cotton and other fibres. They were used extensively from the late 18th to the early 20th century in the mills of Lancashire and elsewhere. Mules were worked in pairs by a minder, with the help of tw ...

was introduced in 1779. Mule implies a hybrid because it was a combination of the spinning jenny and the water frame, in which the spindles were placed on a carriage, which went through an operational sequence during which the rollers stopped while the carriage moved away from the drawing roller to finish drawing out the fibres as the spindles started rotating.

Crompton's mule was able to produce finer thread than hand spinning and at a lower cost. Mule spun thread was of suitable strength to be used as a warp and finally allowed Britain to produce highly competitive yarn in large quantities.

Realising that the expiration of the Arkwright patent would greatly increase the supply of spun cotton and lead to a shortage of weavers, Edmund Cartwright developed a vertical

power loom which he patented in 1785. In 1776 he patented a two-man operated loom which was more conventional.

Cartwright built two factories; the first burned down and the second was sabotaged by his workers. Cartwright's loom design had several flaws, the most serious being thread breakage. Samuel Horrocks patented a fairly successful loom in 1813. Horock's loom was improved by Richard Roberts in 1822 and these were produced in large numbers by Roberts, Hill & Co.

The demand for cotton presented an opportunity to planters in the Southern United States, who thought upland cotton would be a profitable crop if a better way could be found to remove the seed.

Eli Whitney responded to the challenge by inventing the inexpensive

cotton gin. A man using a cotton gin could remove seed from as much upland cotton in one day as would previously, working at the rate of one pound of cotton per day, have taken a woman two months to process.

[. Reprinted by McGraw-Hill, New York and London, 1926 (); and by Lindsay Publications, Inc., Bradley, Illinois, ().]

These advances were capitalised on by

entrepreneur

Entrepreneurship is the creation or extraction of economic value. With this definition, entrepreneurship is viewed as change, generally entailing risk beyond what is normally encountered in starting a business, which may include other values t ...

s, of whom the best known is Richard Arkwright. He is credited with a list of inventions, but these were actually developed by such people as

Thomas Highs

Thomas Highs (1718–1803), of Leigh, Lancashire, was a reed-maker and manufacturer of cotton carding and spinning engines in the 1780s, during the Industrial Revolution. He is known for claiming patents on a spinning jenny (invented by Jame ...

and

John Kay; Arkwright nurtured the inventors, patented the ideas, financed the initiatives, and protected the machines. He created the

cotton mill

A cotton mill is a building that houses spinning or weaving machinery for the production of yarn or cloth from cotton, an important product during the Industrial Revolution in the development of the factory system.

Although some were driven b ...

which brought the production processes together in a factory, and he developed the use of powerfirst horsepower and then

water powerwhich made cotton manufacture a mechanised industry. Other inventors increased the efficiency of the individual steps of spinning (carding, twisting and spinning, and rolling) so that the supply of

yarn increased greatly. Before long

steam power was applied to drive textile machinery.

Manchester

Manchester () is a city in Greater Manchester, England. It had a population of 552,000 in 2021. It is bordered by the Cheshire Plain to the south, the Pennines to the north and east, and the neighbouring city of Salford to the west. The t ...

acquired the nickname

Cottonopolis during the early 19th century owing to its sprawl of textile factories.

Although mechanization dramatically decreased the cost of cotton cloth, by the mid-19th century machine-woven cloth still could not equal the quality of hand-woven Indian cloth, in part due to the fineness of thread made possible by the type of cotton used in India, which allowed high thread counts. However, the high productivity of British textile manufacturing allowed coarser grades of British cloth to undersell hand-spun and woven fabric in low-wage India, eventually destroying the industry.

Wool

The earliest European attempts at mechanized spinning were with wool; however, wool spinning proved more difficult to mechanize than cotton. Productivity improvement in wool spinning during the Industrial Revolution was significant, but far less than that of cotton.

[

]

Silk

Arguably the first highly mechanised factory was

John Lombe

John Lombe (1693 in Norwich – November 20, 1722 in Derby) was a silk spinner in the 18th century Derby, England.

Biography

Lombe was born in Norwich in approximately 1693, the son of a worsted weaver. He was a younger half-brother of Thoma ...

's

water-powered silk mill at

Derby

Derby ( ) is a city and unitary authority area in Derbyshire, England. It lies on the banks of the River Derwent in the south of Derbyshire, which is in the East Midlands Region. It was traditionally the county town of Derbyshire. Derby g ...

, operational by 1721. Lombe learned silk thread manufacturing by taking a job in Italy and acting as an industrial spy; however, because the Italian silk industry guarded its secrets closely, the state of the industry at that time is unknown. Although Lombe's factory was technically successful, the supply of raw silk from Italy was cut off to eliminate competition. In order to promote manufacturing, the Crown paid for models of Lombe's machinery which were exhibited in the

Tower of London.

Iron industry

UK iron production statistics

Bar iron was the commodity form of iron used as the raw material for making hardware goods such as nails, wire, hinges, horseshoes, wagon tires, chains, etc., as well as structural shapes. A small amount of bar iron was converted into steel.

Cast iron

Cast iron is a class of iron– carbon alloys with a carbon content more than 2%. Its usefulness derives from its relatively low melting temperature. The alloy constituents affect its color when fractured: white cast iron has carbide impur ...

was used for pots, stoves, and other items where its brittleness was tolerable. Most cast iron was refined and converted to bar iron, with substantial losses. Bar iron was also made by the

bloomery process, which was the predominant iron smelting process until the late 18th century.

In the UK in 1720, there were 20,500 tons of cast iron produced with charcoal and 400 tons with coke. In 1750 charcoal iron production was 24,500 and coke iron was 2,500 tons. In 1788 the production of charcoal cast iron was 14,000 tons while coke iron production was 54,000 tons. In 1806 charcoal cast iron production was 7,800 tons and coke cast iron was 250,000 tons.

In 1750 the UK imported 31,200 tons of bar iron and either refined from cast iron or directly produced 18,800 tons of bar iron using charcoal and 100 tons using coke. In 1796 the UK was making 125,000 tons of bar iron with coke and 6,400 tons with charcoal; imports were 38,000 tons and exports were 24,600 tons. In 1806 the UK did not import bar iron but exported 31,500 tons.

Iron process innovations

A major change in the iron industries during the Industrial Revolution was the replacement of

wood

Wood is a porous and fibrous structural tissue found in the stems and roots of trees and other woody plants. It is an organic materiala natural composite of cellulose fibers that are strong in tension and embedded in a matrix of lignin ...

and other bio-fuels with coal. For a given amount of heat, mining coal required much less labour than cutting wood and converting it to charcoal, and coal was much more abundant than wood, supplies of which were becoming scarce before the enormous increase in iron production that took place in the late 18th century.

By 1750

coke had generally replaced charcoal in the smelting of copper and lead, and was in widespread use in glass production. In the smelting and refining of iron, coal and coke produced inferior iron to that made with charcoal because of the coal's sulfur content. Low sulfur coals were known, but they still contained harmful amounts. Conversion of coal to coke only slightly reduces the sulfur content.

A minority of coals are coking.

Another factor limiting the iron industry before the Industrial Revolution was the scarcity of water power to power blast bellows. This limitation was overcome by the steam engine.

Use of coal in iron

smelting started somewhat before the Industrial Revolution, based on innovations by Sir

Clement Clerke and others from 1678, using coal

reverberatory furnace

A reverberatory furnace is a metallurgical or process furnace that isolates the material being processed from contact with the fuel, but not from contact with combustion gases. The term ''reverberation'' is used here in a generic sense of ''re ...

s known as cupolas. These were operated by the flames playing on the

ore

Ore is natural rock or sediment that contains one or more valuable minerals, typically containing metals, that can be mined, treated and sold at a profit.Encyclopædia Britannica. "Ore". Encyclopædia Britannica Online. Retrieved 7 Apr ...

and charcoal or coke mixture,

reducing the

oxide to metal. This has the advantage that impurities (such as sulphur ash) in the coal do not migrate into the metal. This technology was applied to

lead

Lead is a chemical element with the symbol Pb (from the Latin ) and atomic number 82. It is a heavy metal that is denser than most common materials. Lead is soft and malleable, and also has a relatively low melting point. When freshly cu ...

from 1678 and to

copper

Copper is a chemical element with the symbol Cu (from la, cuprum) and atomic number 29. It is a soft, malleable, and ductile metal with very high thermal and electrical conductivity. A freshly exposed surface of pure copper has a pinkis ...

from 1687. It was also applied to iron foundry work in the 1690s, but in this case the reverberatory furnace was known as an air furnace. (The

foundry cupola is a different, and later, innovation.)

By 1709

Abraham Darby made progress using coke to fuel his

blast furnaces at

Coalbrookdale. However, the coke

pig iron he made was not suitable for making wrought iron and was used mostly for the production of

cast iron

Cast iron is a class of iron– carbon alloys with a carbon content more than 2%. Its usefulness derives from its relatively low melting temperature. The alloy constituents affect its color when fractured: white cast iron has carbide impur ...

goods, such as pots and kettles. He had the advantage over his rivals in that his pots, cast by his patented process, were thinner and cheaper than theirs.

Coke pig iron was hardly used to produce

wrought iron until 1755–56, when Darby's son

Abraham Darby II

Abraham Darby, in his lifetime called Abraham Darby the Younger, referred to for convenience as Abraham Darby II (12 May 1711 – 31 March 1763) was the second man of that name in an English Quaker family that played an important role in the early ...

built furnaces at

Horsehay

Horsehay is a suburban village on the western outskirts of Dawley, which, along with several other towns and villages, now forms part of the new town of Telford in Shropshire, England. Horsehay lies in the Dawley Hamlets parish, and on the no ...

and

Ketley

Ketley is a large village and part of Telford in the borough of Telford and Wrekin and ceremonial county of Shropshire, England. It is a civil parish. Immediately to the north of Ketley is Hadley.

Residential development

East Ketley is currentl ...

where low sulfur coal was available (and not far from Coalbrookdale). These new furnaces were equipped with water-powered bellows, the water being pumped by

Newcomen steam engines. The Newcomen engines were not attached directly to the blowing cylinders because the engines alone could not produce a steady air blast. Abraham Darby III installed similar steam-pumped, water-powered blowing cylinders at the Dale Company when he took control in 1768. The Dale Company used several Newcomen engines to drain its mines and made parts for engines which it sold throughout the country.

Steam engines made the use of higher-pressure and volume blast practical; however, the leather used in bellows was expensive to replace. In 1757, ironmaster

John Wilkinson patented a hydraulic powered

blowing engine for blast furnaces.

[ Based on the works of Joseph Needham] The blowing cylinder for blast furnaces was introduced in 1760 and the first blowing cylinder made of cast iron is believed to be the one used at Carrington in 1768 that was designed by

John Smeaton.

Cast iron cylinders for use with a piston were difficult to manufacture; the cylinders had to be free of holes and had to be machined smooth and straight to remove any warping.

James Watt had great difficulty trying to have a cylinder made for his first steam engine. In 1774 John Wilkinson, who built a cast iron blowing cylinder for his ironworks, invented a precision boring machine for boring cylinders. After Wilkinson bored the first successful cylinder for a

Boulton and Watt steam engine in 1776, he was given an exclusive contract for providing cylinders.

After Watt developed a rotary steam engine in 1782, they were widely applied to blowing, hammering, rolling and slitting.

The solutions to the sulfur problem were the addition of sufficient limestone to the furnace to force sulfur into the slag and the use of low sulfur coal. The use of lime or limestone required higher furnace temperatures to form a free-flowing slag. The increased furnace temperature made possible by improved blowing also increased the capacity of blast furnaces and allowed for increased furnace height.

In addition to lower cost and greater availability, coke had other important advantages over charcoal in that it was harder and made the column of materials (iron ore, fuel, slag) flowing down the blast furnace more porous and did not crush in the much taller furnaces of the late 19th century.

As cast iron became cheaper and widely available, it began being a structural material for bridges and buildings. A famous early example was the

Iron Bridge built in 1778 with cast iron produced by

Abraham Darby III.

However, most cast iron was converted to

wrought iron.

Europe relied on the

bloomery for most of its wrought iron until the large-scale production of cast iron. Conversion of cast iron was done in a

finery forge

A finery forge is a forge used to produce wrought iron from pig iron by decarburization in a process called "fining" which involved liquifying cast iron in a fining hearth and removing carbon from the molten cast iron through oxidation. Finery ...

, as it long had been. An improved refining process known as

potting and stamping Potting and stamping is a modern name for one of the 18th-century processes for refining pig iron without the use of charcoal.

Inventors

The process was devised by Charles Wood of Lowmill, Egremont in Cumberland and his brother John Wood of We ...

was developed, but this was superseded by

Henry Cort

Henry Cort (c. 1740 – 23 May 1800) was an English ironware producer although formerly a Navy pay agent. During the Industrial Revolution in England, Cort began refining iron from pig iron to wrought iron (or bar iron) using innovative producti ...

's

puddling process. Cort developed two significant iron manufacturing processes:

rolling

Rolling is a type of motion that combines rotation (commonly, of an axially symmetric object) and translation of that object with respect to a surface (either one or the other moves), such that, if ideal conditions exist, the two are in contact ...

in 1783 and

puddling in 1784.

Puddling produced a structural grade iron at a relatively low cost.

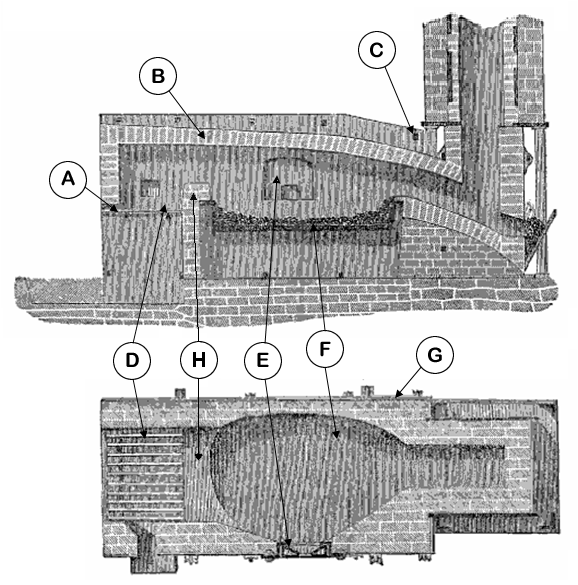

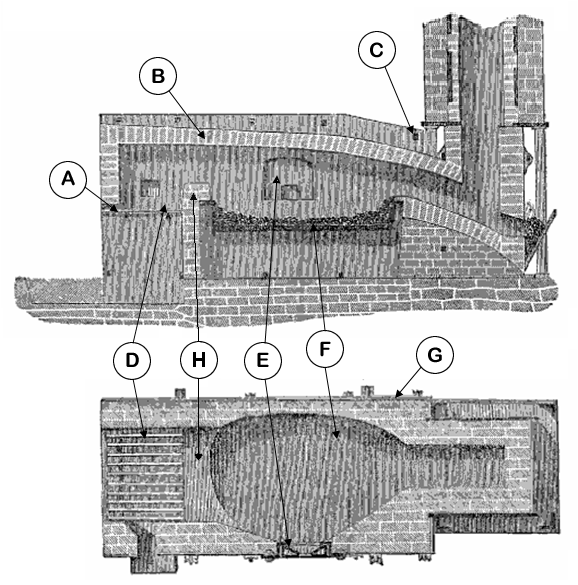

Puddling was a means of decarburizing molten pig iron by slow oxidation in a reverberatory furnace by manually stirring it with a long rod. The decarburized iron, having a higher melting point than cast iron, was raked into globs by the puddler. When the glob was large enough, the puddler would remove it. Puddling was backbreaking and extremely hot work. Few puddlers lived to be 40.

Because puddling was done in a reverberatory furnace, coal or coke could be used as fuel.

The puddling process continued to be used until the late 19th century when iron was being displaced by steel. Because puddling required human skill in sensing the iron globs, it was never successfully mechanised. Rolling was an important part of the puddling process because the grooved rollers expelled most of the molten slag and consolidated the mass of hot wrought iron. Rolling was 15 times faster at this than a

trip hammer

A trip hammer, also known as a tilt hammer or helve hammer, is a massive powered hammer. Traditional uses of trip hammers include pounding, wikt:decorticate, decorticating and polishing of grain in agriculture. In mining, trip hammers were used f ...

. A different use of rolling, which was done at lower temperatures than that for expelling slag, was in the production of iron sheets, and later structural shapes such as beams, angles, and rails.

The puddling process was improved in 1818 by Baldwyn Rogers, who replaced some of the sand lining on the reverberatory furnace bottom with iron oxide. In 1838

John Hall patented the use of roasted tap cinder (iron silicate) for the furnace bottom, greatly reducing the loss of iron through increased slag caused by a sand lined bottom. The tap cinder also tied up some phosphorus, but this was not understood at the time.

Hall's process also used iron scale or rust, which reacted with carbon in the molten iron. Hall's process, called ''wet puddling'', reduced losses of iron with the slag from almost 50% to around 8%.

Puddling became widely used after 1800. Up to that time, British iron manufacturers had used considerable amounts of iron imported from Sweden and Russia to supplement domestic supplies. Because of the increased British production, imports began to decline in 1785 and by the 1790s Britain eliminated imports and became a net exporter of bar iron.

Hot blast

Hot blast refers to the preheating of air blown into a blast furnace or other metallurgical process. As this considerably reduced the fuel consumed, hot blast was one of the most important technologies developed during the Industrial Revolution. ...

, patented by the Scottish inventor

James Beaumont Neilson in 1828, was the most important development of the 19th century for saving energy in making pig iron. By using preheated combustion air, the amount of fuel to make a unit of pig iron was reduced at first by between one-third using coke or two-thirds using coal; however, the efficiency gains continued as the technology improved. Hot blast also raised the operating temperature of furnaces, increasing their capacity. Using less coal or coke meant introducing fewer impurities into the pig iron. This meant that lower quality coal or

anthracite could be used in areas where coking coal was unavailable or too expensive; however, by the end of the 19th century transportation costs fell considerably.

Shortly before the Industrial Revolution, an improvement was made in the production of

steel, which was an expensive commodity and used only where iron would not do, such as for cutting edge tools and for springs.

Benjamin Huntsman

Benjamin Huntsman (4 June 170420 June 1776) was an English inventor and manufacturer of cast or crucible steel.

Biography

Huntsman was born the fourth child of William and Mary (née Nainby) Huntsman, a Quaker farming couple, in Epworth, Li ...

developed his

crucible steel

Crucible steel is steel made by melting pig iron (cast iron), iron, and sometimes steel, often along with sand, glass, ashes, and other fluxes, in a crucible. In ancient times steel and iron were impossible to melt using charcoal or coal fires ...

technique in the 1740s. The raw material for this was blister steel, made by the

cementation process.

The supply of cheaper iron and steel aided a number of industries, such as those making nails, hinges, wire, and other hardware items. The development of

machine tools allowed better working of iron, causing it to be increasingly used in the rapidly growing machinery and engine industries.

Steam power

The development of the

stationary steam engine was an important element of the Industrial Revolution; however, during the early period of the Industrial Revolution, most industrial power was supplied by water and wind. In Britain, by 1800 an estimated 10,000 horsepower was being supplied by steam. By 1815 steam power had grown to 210,000 hp.

The first commercially successful industrial use of steam power was due to

Thomas Savery in 1698. He constructed and patented in London a low-lift combined vacuum and pressure water pump, that generated about one

horsepower (hp) and was used in numerous waterworks and in a few mines (hence its "brand name", ''The Miner's Friend''). Savery's pump was economical in small horsepower ranges but was prone to boiler explosions in larger sizes. Savery pumps continued to be produced until the late 18th century.

The first successful piston steam engine was introduced by

Thomas Newcomen before 1712. A number of Newcomen engines were installed in Britain for draining hitherto unworkable deep mines, with the engine on the surface; these were large machines, requiring a significant amount of capital to build, and produced upwards of . They were also used to power municipal water supply pumps. They were extremely inefficient by modern standards, but when located where coal was cheap at pit heads, opened up a great expansion in coal mining by allowing mines to go deeper.

[L. T. C. Rolt and J. S. Allen, ''The Steam Engine of Thomas Newcomen'' (Landmark Publishing, Ashbourne 1997). p. 145.]

Despite their disadvantages, Newcomen engines were reliable and easy to maintain and continued to be used in the coalfields until the early decades of the 19th century. By 1729, when Newcomen died, his engines had spread (first) to Hungary in 1722, Germany, Austria, and Sweden. A total of 110 are known to have been built by 1733 when the joint patent expired, of which 14 were abroad. In the 1770s the engineer

John Smeaton built some very large examples and introduced a number of improvements. A total of 1,454 engines had been built by 1800.

A fundamental change in working principles was brought about by

Scotsman James Watt. With financial support from his business partner

Englishman

The English people are an ethnic group and nation native to England, who speak the English language, a West Germanic language, and share a common history and culture. The English identity is of Anglo-Saxon origin, when they were known in ...

Matthew Boulton, he had succeeded by 1778 in perfecting his

steam engine, which incorporated a series of radical improvements, notably the closing off of the upper part of the cylinder, thereby making the low-pressure steam drive the top of the piston instead of the atmosphere, use of a steam jacket and the celebrated separate steam condenser chamber. The separate condenser did away with the cooling water that had been injected directly into the cylinder, which cooled the cylinder and wasted steam. Likewise, the steam jacket kept steam from condensing in the cylinder, also improving efficiency. These improvements increased engine efficiency so that Boulton and Watt's engines used only 20–25% as much coal per horsepower-hour as Newcomen's. Boulton and Watt opened the

Soho Foundry

Soho Foundry is a factory created in 1775 by Matthew Boulton and James Watt and their sons Matthew Robinson Boulton and James Watt Jr. at Smethwick, West Midlands, England (), for the manufacture of steam engines. Now owned by Avery Weigh-Tr ...

for the manufacture of such engines in 1795.

By 1783 the Watt steam engine had been fully developed into a

double-acting rotative type, which meant that it could be used to directly drive the rotary machinery of a factory or mill. Both of Watt's basic engine types were commercially very successful, and by 1800, the firm

Boulton & Watt had constructed 496 engines, with 164 driving reciprocating pumps, 24 serving

blast furnaces, and 308 powering mill machinery; most of the engines generated from .

Until about 1800 the most common pattern of steam engine was the

beam engine, built as an integral part of a stone or brick engine-house, but soon various patterns of self-contained rotative engines (readily removable, but not on wheels) were developed, such as the

table engine

A table engine is a variety of stationary steam engine where the cylinder is placed on top of a table-shaped base, the legs of which stand on the baseplate which locates the crankshaft bearings. The piston rod protrudes from the top of the cylinder ...

. Around the start of the 19th century, at which time the Boulton and Watt patent expired, the Cornish engineer

Richard Trevithick

Richard Trevithick (13 April 1771 – 22 April 1833) was a British inventor and mining engineer. The son of a mining captain, and born in the mining heartland of Cornwall, Trevithick was immersed in mining and engineering from an early age. He w ...

and the American

Oliver Evans

Oliver Evans (September 13, 1755 – April 15, 1819) was an American inventor, engineer and businessman born in rural Delaware and later rooted commercially in Philadelphia. He was one of the first Americans building steam engines and an advoca ...

began to construct higher-pressure non-condensing steam engines, exhausting against the atmosphere. High pressure yielded an engine and boiler compact enough to be used on mobile road and rail

locomotives and

steam boats.

The development of

machine tools, such as the engine

lathe,

planing, milling and shaping machines powered by these engines, enabled all the metal parts of the engines to be easily and accurately cut and in turn made it possible to build larger and more powerful engines.

Small industrial power requirements continued to be provided by animal and human muscle until widespread

electrification in the early 20th century. These included

crank-powered,

treadle-powered and horse-powered workshop, and light industrial machinery.

Machine tools

Pre-industrial machinery was built by various craftsmen

millwrights built water and windmills,

carpenters made wooden framing, and smiths and turners made metal parts. Wooden components had the disadvantage of changing dimensions with temperature and humidity, and the various joints tended to rack (work loose) over time. As the Industrial Revolution progressed, machines with metal parts and frames became more common. Other important uses of metal parts were in firearms and threaded fasteners, such as machine screws, bolts, and nuts. There was also the need for precision in making parts. Precision would allow better working machinery, interchangeability of parts, and standardization of threaded fasteners.

The demand for metal parts led to the development of several

machine tools. They have their origins in the tools developed in the 18th century by makers of clocks and watches and scientific instrument makers to enable them to batch-produce small mechanisms.

Before the advent of machine tools, metal was worked manually using the basic hand tools of hammers, files, scrapers, saws, and chisels. Consequently, the use of metal machine parts was kept to a minimum. Hand methods of production were very laborious and costly and precision was difficult to achieve.

The first large precision machine tool was the cylinder

boring machine invented by

John Wilkinson in 1774. It was used for boring the large-diameter cylinders on early steam engines. Wilkinson's boring machine differed from earlier

cantilevered machines used for boring cannon in that the cutting tool was mounted on a beam that ran through the cylinder being bored and was supported outside on both ends.

The

planing machine

A planer is a type of metalworking machine tool that uses linear relative motion between the workpiece and a single-point cutting tool to cut the work piece.Parker, Dana T. ''Building Victory: Aircraft Manufacturing in the Los Angeles Area in Wo ...

, the

milling machine

Milling is the process of machining using rotary cutters to remove material by advancing a cutter into a workpiece. This may be done by varying direction on one or several axes, cutter head speed, and pressure. Milling covers a wide variety of d ...

and the

shaping machine were developed in the early decades of the 19th century. Although the milling machine was invented at this time, it was not developed as a serious workshop tool until somewhat later in the 19th century.

, who trained a school of machine tool makers early in the 19th century, was a mechanic with superior ability who had been employed at the

Royal Arsenal,

Woolwich. He worked as an apprentice in the Royal Gun Foundry of

Jan Verbruggen

Jan Verbruggen (1712 – 27 October 1781) was a Dutch master gun-founder in the Netherlands and later at the Royal Arsenal in Woolwich, London. He was also an artist.

Early life and career

He was born in 1712 in Enkhuizen in the Netherlands, so ...

. In 1774

Jan Verbruggen

Jan Verbruggen (1712 – 27 October 1781) was a Dutch master gun-founder in the Netherlands and later at the Royal Arsenal in Woolwich, London. He was also an artist.

Early life and career

He was born in 1712 in Enkhuizen in the Netherlands, so ...

had installed a

horizontal boring machine

A horizontal boring machine or horizontal boring mill is a machine tool which bores holes in a horizontal direction. There are three main types — table, planer and floor. The table type is the most common and, as it is the most versatil ...

in Woolwich which was the first industrial size

lathe in the UK. Maudslay was hired away by

Joseph Bramah for the production of high-security metal locks that required precision craftsmanship. Bramah patented a lathe that had similarities to the slide rest lathe.

Maudslay perfected the slide rest lathe, which could cut machine screws of different thread pitches by using changeable gears between the spindle and the lead screw. Before its invention screws could not be cut to any precision using various earlier lathe designs, some of which copied from a template.

The slide rest lathe was called one of history's most important inventions. Although it was not entirely Maudslay's idea, he was the first person to build a functional lathe using a combination of known innovations of the lead screw, slide rest, and change gears.

Maudslay left Bramah's employment and set up his own shop. He was engaged to build the machinery for making ships' pulley blocks for the

Royal Navy

The Royal Navy (RN) is the United Kingdom's naval warfare force. Although warships were used by English and Scottish kings from the early medieval period, the first major maritime engagements were fought in the Hundred Years' War against ...

in the

Portsmouth Block Mills

The Portsmouth Block Mills form part of the Portsmouth Dockyard at Portsmouth, Hampshire, England, and were built during the Napoleonic Wars to supply the British Royal Navy with pulley blocks. They started the age of mass-production using ...

. These machines were all-metal and were the first machines for

mass production and making components with a degree of

interchangeability

Interchangeability can refer to:

*Interchangeable parts

Interchangeable parts are parts (components) that are identical for practical purposes. They are made to specifications that ensure that they are so nearly identical that they will fit into ...

. The lessons Maudslay learned about the need for stability and precision he adapted to the development of machine tools, and in his workshops, he trained a generation of men to build on his work, such as

Richard Roberts,

Joseph Clement and

Joseph Whitworth.

James Fox

William Fox (born 19 May 1939), known professionally as James Fox, is an English actor. He appeared in several notable films of the 1960s and early 1970s, including '' King Rat'', '' The Servant'', ''Thoroughly Modern Millie'' and ''Performan ...

of

Derby

Derby ( ) is a city and unitary authority area in Derbyshire, England. It lies on the banks of the River Derwent in the south of Derbyshire, which is in the East Midlands Region. It was traditionally the county town of Derbyshire. Derby g ...

had a healthy export trade in machine tools for the first third of the century, as did

Matthew Murray

Matthew Murray (1765 – 20 February 1826) was an English steam engine and machine tool manufacturer, who designed and built the first commercially viable steam locomotive, the twin cylinder ''Salamanca'' in 1812. He was an innovative design ...

of Leeds. Roberts was a maker of high-quality machine tools and a pioneer of the use of jigs and gauges for precision workshop measurement.

The effect of machine tools during the Industrial Revolution was not that great because other than firearms, threaded fasteners, and a few other industries there were few mass-produced metal parts. The techniques to make mass-produced metal parts made with sufficient precision to be

interchangeable is largely attributed to a program of the U.S. Department of War which perfected

interchangeable parts for firearms in the early 19th century.

In the half-century following the invention of the fundamental machine tools the

machine industry

The machine industry or machinery industry is a subsector of the industry, that produces and maintains machines for consumers, the industry, and most other companies in the economy.

This machine industry traditionally belongs to the heavy indust ...

became the largest industrial sector of the U.S. economy, by value added.

[Economics 323–2: Economic History of the United States Since 1865 http://faculty.wcas.northwestern.edu/~jmokyr/Graphs-and-Tables.PDF]

Chemicals

The large-scale production of

chemicals

A chemical substance is a form of matter having constant chemical composition and characteristic properties. Some references add that chemical substance cannot be separated into its constituent elements by physical separation methods, i.e., wit ...

was an important development during the Industrial Revolution. The first of these was the production of

sulphuric acid by the

lead chamber process invented by the Englishman

John Roebuck

John Roebuck of Kinneil FRS FRSE (1718 – 17 July 1794) was an English inventor and industrialist who played an important role in the Industrial Revolution and who is known for developing the industrial-scale manufacture of sulphuric aci ...

(

James Watt's first partner) in 1746. He was able to greatly increase the scale of the manufacture by replacing the relatively expensive glass vessels formerly used with larger, less expensive chambers made of

riveted sheets of

lead

Lead is a chemical element with the symbol Pb (from the Latin ) and atomic number 82. It is a heavy metal that is denser than most common materials. Lead is soft and malleable, and also has a relatively low melting point. When freshly cu ...

. Instead of making a small amount each time, he was able to make around in each of the chambers, at least a tenfold increase.

The production of an

alkali on a large scale became an important goal as well, and

Nicolas Leblanc

Nicolas Leblanc (December 6, 1742 – January 16, 1806) was a French chemist and surgeon who discovered how to manufacture soda ash from common salt.

Earlier days

Leblanc was born in Ivoy le Pré, Cher, France on 6 December 1742. His fathe ...

succeeded in 1791 in introducing a method for the production of

sodium carbonate. The

Leblanc process was a reaction of sulfuric acid with sodium chloride to give sodium sulfate and

hydrochloric acid

Hydrochloric acid, also known as muriatic acid, is an aqueous solution of hydrogen chloride. It is a colorless solution with a distinctive pungent smell. It is classified as a strong acid

Acid strength is the tendency of an acid, symbol ...

. The

sodium sulfate was heated with

limestone

Limestone ( calcium carbonate ) is a type of carbonate sedimentary rock which is the main source of the material lime. It is composed mostly of the minerals calcite and aragonite, which are different crystal forms of . Limestone forms whe ...

(

calcium carbonate) and coal to give a mixture of sodium carbonate and

calcium sulfide

Calcium sulfide is the chemical compound with the formula Ca S. This white material crystallizes in cubes like rock salt. CaS has been studied as a component in a process that would recycle gypsum, a product of flue-gas desulfurization. Like m ...

. Adding water separated the soluble sodium carbonate from the calcium sulfide. The process produced a large amount of pollution (the hydrochloric acid was initially vented to the air, and calcium sulfide was a useless waste product). Nonetheless, this synthetic

soda ash

Sodium carbonate, , (also known as washing soda, soda ash and soda crystals) is the inorganic compound with the formula Na2CO3 and its various hydrates. All forms are white, odourless, water-soluble salts that yield moderately alkaline solutions ...

proved economical compared to that from burning specific plants (

barilla

''Barilla'' refers to several species of salt-tolerant (halophyte) plants that, until the 19th century, were the primary source of soda ash and hence of sodium carbonate. The word "barilla" was also used directly to refer to the soda ash obtained ...

) or from

kelp

Kelps are large brown algae seaweeds that make up the order Laminariales. There are about 30 different genera. Despite its appearance, kelp is not a plant - it is a heterokont, a completely unrelated group of organisms.

Kelp grows in "underwa ...

, which were the previously dominant sources of soda ash,

and also to

potash (

potassium carbonate

Potassium carbonate is the inorganic compound with the formula K2 CO3. It is a white salt, which is soluble in water. It is deliquescent, often appearing as a damp or wet solid. Potassium carbonate is mainly used in the production of soap and gl ...

) produced from hardwood ashes.

These two chemicals were very important because they enabled the introduction of a host of other inventions, replacing many small-scale operations with more cost-effective and controllable processes. Sodium carbonate had many uses in the glass, textile, soap, and

paper

Paper is a thin sheet material produced by mechanically or chemically processing cellulose fibres derived from wood, rags, grasses or other vegetable sources in water, draining the water through fine mesh leaving the fibre evenly distrib ...

industries. Early uses for sulfuric acid included pickling (removing rust from) iron and steel, and for

bleaching cloth.

The development of bleaching powder (

calcium hypochlorite) by Scottish chemist

Charles Tennant

Charles Tennant (3 May 1768 – 1 October 1838) was a Scottish chemist and industrialist. He discovered bleaching powder and founded an industrial dynasty.

Biography

Charles Tennant was born at Laigh Corton, Alloway, Ayrshire, the sixth of thi ...

in about 1800, based on the discoveries of French chemist

Claude Louis Berthollet

Claude Louis Berthollet (, 9 December 1748 – 6 November 1822) was a Savoyard-French chemist who became vice president of the French Senate in 1804. He is known for his scientific contributions to theory of chemical equilibria via the mecha ...

, revolutionised the

bleaching processes in the textile industry by dramatically reducing the time required (from months to days) for the traditional process then in use, which required repeated exposure to the sun in bleach fields after soaking the textiles with alkali or sour milk. Tennant's factory at St Rollox, North

Glasgow, became the largest chemical plant in the world.

After 1860 the focus on chemical innovation was in

dyestuffs, and Germany took world leadership, building a strong chemical industry. Aspiring chemists flocked to German universities in the 1860–1914 era to learn the latest techniques. British scientists by contrast, lacked research universities and did not train advanced students; instead, the practice was to hire German-trained chemists.

Cement

In 1824

Joseph Aspdin, a British

bricklayer turned builder, patented a chemical process for making

portland cement which was an important advance in the building trades. This process involves

sintering a mixture of

clay

Clay is a type of fine-grained natural soil material containing clay minerals (hydrous aluminium phyllosilicates, e.g. kaolin, Al2 Si2 O5( OH)4).

Clays develop plasticity when wet, due to a molecular film of water surrounding the clay par ...

and

limestone

Limestone ( calcium carbonate ) is a type of carbonate sedimentary rock which is the main source of the material lime. It is composed mostly of the minerals calcite and aragonite, which are different crystal forms of . Limestone forms whe ...

to about , then

grinding

Grind is the cross-sectional shape of a blade.

Grind, grinds, or grinding may also refer to:

Grinding action

* Grinding (abrasive cutting), a method of crafting

* Grinding (dance), suggestive club dancing

* Grinding (video gaming), repetitive and ...

it into a fine powder which is then mixed with water, sand and

gravel to produce

concrete

Concrete is a composite material composed of fine and coarse aggregate bonded together with a fluid cement (cement paste) that hardens (cures) over time. Concrete is the second-most-used substance in the world after water, and is the most wid ...

. Portland cement was used by the famous English engineer

Marc Isambard Brunel

Sir Marc Isambard Brunel (, ; 25 April 1769 – 12 December 1849) was a French-British engineer who is most famous for the work he did in Britain. He constructed the Thames Tunnel and was the father of Isambard Kingdom Brunel.

Born in Franc ...

several years later when constructing the

Thames Tunnel

The Thames Tunnel is a tunnel beneath the River Thames in London, connecting Rotherhithe and Wapping. It measures 35 feet (11 m) wide by 20 feet (6 m) high and is 1,300 feet (396 m) long, running at a depth of ...

.

Cement was used on a large scale in the construction of the

London sewerage system

The London sewer system is part of the water infrastructure serving London, England. The modern system was developed during the late 19th century, and as London has grown the system has been expanded. It is currently owned and operated by Thames ...

a generation later.

Gas lighting

Another major industry of the later Industrial Revolution was

gas lighting

Gas lighting is the production of artificial light from combustion of a gaseous fuel, such as hydrogen, methane, carbon monoxide, propane, butane, acetylene, ethylene, coal gas (town gas) or natural gas. The light is produced either directly ...

. Though others made a similar innovation elsewhere, the large-scale introduction of this was the work of

William Murdoch, an employee of Boulton & Watt, the

Birmingham steam engine pioneers. The process consisted of the large-scale gasification of coal in furnaces, the purification of the gas (removal of sulphur, ammonia, and heavy hydrocarbons), and its storage and distribution. The first gas lighting utilities were established in London between 1812 and 1820. They soon became one of the major consumers of coal in the UK. Gas lighting affected social and industrial organisation because it allowed factories and stores to remain open longer than with tallow candles or oil. Its introduction allowed nightlife to flourish in cities and towns as interiors and streets could be lighted on a larger scale than before.

Glass making

Glass was made in ancient Greece and Rome. A new method of producing glass, known as the

cylinder process, was developed in Europe during the early 19th century. In 1832 this process was used by the

Chance Brothers

Chance Brothers and Company was a glassworks originally based in Spon Lane, Smethwick, West Midlands (formerly in Staffordshire), in England. It was a leading glass manufacturer and a pioneer of British glassmaking technology.

The Chance fam ...

to create sheet glass. They became the leading producers of window and plate glass. This advancement allowed for larger panes of glass to be created without interruption, thus freeing up the space planning in interiors as well as the fenestration of buildings.

The Crystal Palace is the supreme example of the use of sheet glass in a new and innovative structure.

Paper machine

A machine for making a continuous sheet of paper on a loop of wire fabric was patented in 1798 by Nicholas Louis Robert who worked for

Saint-Léger Didot family in France. The paper machine is known as a Fourdrinier after the financiers, brothers Sealy and

Henry Fourdrinier

Henry Fourdrinier (11 February 1766 – 3 September 1854) was a British paper-making entrepreneur.

He was born in 1766, the son of paper maker and stationer Henry Fourdrinier, and grandson of the engraver Paul Fourdrinier, 1698–1758, sometimes ...

, who were

stationers in London. Although greatly improved and with many variations, the Fourdrinier machine is the predominant means of paper production today.

The method of

continuous production demonstrated by the paper machine influenced the development of continuous rolling of iron and later steel and other

continuous production processes.

Agriculture

The

British Agricultural Revolution is considered one of the causes of the Industrial Revolution because improved agricultural productivity freed up workers to work in other sectors of the economy.

[

] In contrast, per-capita food supply in Europe was stagnant or declining and did not improve in some parts of Europe until the late 18th century.

Industrial technologies that affected farming included the

seed drill

A seed drill is a device used in agriculture that sows seeds for crops by positioning them in the soil and burying them to a specific depth while being dragged by a tractor. This ensures that seeds will be distributed evenly.

The seed drill sow ...

, the

Dutch plough, which contained iron parts, and the threshing machine.

The English lawyer

Jethro Tull invented an improved seed drill in 1701. It was a mechanical seeder that distributed seeds evenly across a plot of land and planted them at the correct depth. This was important because the yield of seeds harvested to seeds planted at that time was around four or five. Tull's seed drill was very expensive and not very reliable and therefore did not have much of an effect. Good quality seed drills were not produced until the mid 18th century.

Joseph Foljambe's ''Rotherham

plough'' of 1730 was the first commercially successful iron plough.

The

threshing machine, invented by the Scottish engineer

Andrew Meikle

Andrew Meikle (5 May 1719 – 27 November 1811) was a Scottish mechanical engineer credited with inventing the threshing machine, a device used to remove the outer husks from grains of wheat. He also had a hand in assisting Firbeck in the inve ...

in 1784, displaced hand threshing with a

flail

A flail is an agriculture, agricultural tool used for threshing, the process of separating cereal, grains from their husks.

It is usually made from two or more large sticks attached by a short chain; one stick is held and swung, causing the othe ...

, a laborious job that took about one-quarter of agricultural labour.

It took several decades to diffuse and was the final straw for many farm labourers, who faced near starvation, leading to the 1830 agricultural rebellion of the

Swing Riots.