Concrete on:

[Wikipedia]

[Google]

[Amazon]

Concrete is a

Concrete is a

concrete hydration

that hardens over several hours to form a hard matrix that binds the materials together into a durable stone-like material that has many uses. This time allows concrete to not only be cast in forms but also to have a variety of tooled processes preformed. The hydration process is exothermic, which means ambient temperature plays a significant role in how long it takes concrete to set. Often, additives (such as pozzolans or superplasticizers) are included in the mixture to improve the physical properties of the wet mix, delay or accelerate the curing time, or otherwise change the finished material. Most concrete is poured with reinforcing materials (such as rebar) embedded to provide

In the Ancient Egyptian and later

In the Ancient Egyptian and later

Perhaps the greatest step forward in the modern use of concrete was

Perhaps the greatest step forward in the modern use of concrete was

Aggregates consist of large chunks of material in a concrete mix, generally a coarse gravel or crushed rocks such as

Aggregates consist of large chunks of material in a concrete mix, generally a coarse gravel or crushed rocks such as

Portland cement is the most common type of cement in general usage. It is a basic ingredient of concrete, mortar, and many plasters. British masonry worker Joseph Aspdin patented Portland cement in 1824. It was named because of the similarity of its color to Portland limestone, quarried from the English

Portland cement is the most common type of cement in general usage. It is a basic ingredient of concrete, mortar, and many plasters. British masonry worker Joseph Aspdin patented Portland cement in 1824. It was named because of the similarity of its color to Portland limestone, quarried from the English

Fine and coarse aggregates make up the bulk of a concrete mixture.

Fine and coarse aggregates make up the bulk of a concrete mixture.

Concrete is a

Concrete is a composite material

A composite material (also called a composition material or shortened to composite, which is the common name) is a material which is produced from two or more constituent materials. These constituent materials have notably dissimilar chemical or ...

composed of fine and coarse aggregate

Aggregate or aggregates may refer to:

Computing and mathematics

* collection of objects that are bound together by a root entity, otherwise known as an aggregate root. The aggregate root guarantees the consistency of changes being made within the ...

bonded together with a fluid cement

A cement is a binder, a chemical substance used for construction that sets, hardens, and adheres to other materials to bind them together. Cement is seldom used on its own, but rather to bind sand and gravel (aggregate) together. Cement mixe ...

(cement paste) that hardens (cures) over time. Concrete is the second-most-used substance in the world after water

Water (chemical formula ) is an inorganic, transparent, tasteless, odorless, and nearly colorless chemical substance, which is the main constituent of Earth's hydrosphere and the fluids of all known living organisms (in which it acts as ...

, and is the most widely used building material. Its usage worldwide, ton for ton, is twice that of steel, wood, plastics, and aluminum combined. Globally, the ready-mix concrete industry, the largest segment of the concrete market, is projected to exceed $600 billion in revenue by 2025. This widespread use results in a number of environmental impacts. Most notably, the production process for cement produces large volumes of greenhouse gas emissions

Greenhouse gas emissions from human activities strengthen the greenhouse effect, contributing to climate change. Most is carbon dioxide from burning fossil fuels: coal, oil, and natural gas. The largest emitters include coal in China and ...

, leading to net 8% of global emissions. Other environmental concerns include widespread illegal sand mining, impacts on the surrounding environment such as increased surface runoff or urban heat island effect, and potential public health implications from toxic ingredients. Significant research and development is being done to try to reduce the emissions or make concrete a source of carbon sequestration, and increase recycled and secondary raw materials content into the mix to achieve a circular economy. Concrete is expected to be a key material for structures resilient to climate disasters, as well as a solution to mitigate the pollution of other industries, capturing wastes such as coal fly ash

Fly ash, flue ash, coal ash, or pulverised fuel ash (in the UK) plurale tantum: coal combustion residuals (CCRs)is a coal combustion product that is composed of the particulates (fine particles of burned fuel) that are driven out of coal-fired b ...

or bauxite tailings and residue.

When aggregate is mixed with dry Portland cement

Portland cement is the most common type of cement in general use around the world as a basic ingredient of concrete, mortar, stucco, and non-specialty grout. It was developed from other types of hydraulic lime in England in the early 19t ...

and water

Water (chemical formula ) is an inorganic, transparent, tasteless, odorless, and nearly colorless chemical substance, which is the main constituent of Earth's hydrosphere and the fluids of all known living organisms (in which it acts as ...

, the mixture forms a fluid slurry that is easily poured and molded into shape. The cement reacts with the water through a process calleconcrete hydration

that hardens over several hours to form a hard matrix that binds the materials together into a durable stone-like material that has many uses. This time allows concrete to not only be cast in forms but also to have a variety of tooled processes preformed. The hydration process is exothermic, which means ambient temperature plays a significant role in how long it takes concrete to set. Often, additives (such as pozzolans or superplasticizers) are included in the mixture to improve the physical properties of the wet mix, delay or accelerate the curing time, or otherwise change the finished material. Most concrete is poured with reinforcing materials (such as rebar) embedded to provide

tensile strength

Ultimate tensile strength (UTS), often shortened to tensile strength (TS), ultimate strength, or F_\text within equations, is the maximum stress that a material can withstand while being stretched or pulled before breaking. In brittle materials ...

, yielding reinforced concrete.

In the past, lime based cement binders, such as lime putty, were often used but sometimes with other hydraulic cements, (water resistant) such as a calcium aluminate cement or with Portland cement to form Portland cement concrete (named for its visual resemblance to Portland stone). Many other non-cementitious types of concrete exist with other methods of binding aggregate together, including asphalt concrete with a bitumen binder, which is frequently used for road surfaces, and polymer concrete

Polymer concrete, also known as Epoxy Granite, is a type of concrete that uses a polymer to replace lime-type cements as a binder. In some cases the polymer is used in addition to Portland cement to form Polymer Cement Concrete (PCC) or Polymer M ...

s that use polymers as a binder. Concrete is distinct from mortar. Whereas concrete is itself a building material, mortar is a bonding agent that typically holds bricks, tiles and other masonry units together.

Etymology

The word concrete comes from the Latin word "''concretus''" (meaning compact or condensed), the perfect passive participle of "''concrescere''", from "''con''-" (together) and "''crescere''" (to grow).History

Ancient times

Mayan concrete at the ruins ofUxmal

Uxmal (Yucatec Maya: ''Óoxmáal'' ) is an ancient Maya city of the classical period located in present-day Mexico. It is considered one of the most important archaeological sites of Maya culture, along with Palenque, Chichen Itza and Calakmul ...

(850-925 A.D.) is referenced in ''Incidents of Travel in the Yucatán'' by John L. Stephens. "The roof is flat and had been covered with cement". "The floors were cement, in some places hard, but, by long exposure, broken, and now crumbling under the feet." "But throughout the wall was solid, and consisting of large stones imbedded in mortar, almost as hard as rock."

Small-scale production of concrete-like materials was pioneered by the Nabatean traders who occupied and controlled a series of oases and developed a small empire in the regions of southern Syria and northern Jordan from the 4th century BC. They discovered the advantages of hydraulic lime, with some self-cementing properties, by 700 BC. They built kilns to supply mortar for the construction of rubble masonry

Rubble stone is rough, uneven building stone not laid in regular courses. It may fill the core of a wall which is faced with unit masonry such as brick or ashlar. Analogously, some medieval cathedral walls are outer shells of ashlar with an inn ...

houses, concrete floors, and underground waterproof cisterns. They kept the cisterns secret as these enabled the Nabataeans to thrive in the desert. Some of these structures survive to this day.

Classical era

Roman

Roman or Romans most often refers to:

* Rome, the capital city of Italy

* Ancient Rome, Roman civilization from 8th century BC to 5th century AD

*Roman people, the people of ancient Rome

*''Epistle to the Romans'', shortened to ''Romans'', a lett ...

eras, builders discovered that adding volcanic ash

Volcanic ash consists of fragments of rock, mineral crystals, and volcanic glass, created during volcanic eruptions and measuring less than 2 mm (0.079 inches) in diameter. The term volcanic ash is also often loosely used to refer ...

to the mix allowed it to set underwater.

Concrete floors were found in the royal palace of Tiryns, Greece, which dates roughly to 1400–1200 BC. Lime mortars were used in Greece, Crete, and Cyprus in 800 BC. The Assyria

Assyria ( Neo-Assyrian cuneiform: , romanized: ''māt Aššur''; syc, ܐܬܘܪ, ʾāthor) was a major ancient Mesopotamian civilization which existed as a city-state at times controlling regional territories in the indigenous lands of the A ...

n Jerwan Aqueduct (688 BC) made use of waterproof concrete. Concrete was used for construction in many ancient structures.

The Romans used concrete extensively from 300 BC to 476 AD. During the Roman Empire, Roman concrete (or '' opus caementicium'') was made from quicklime, pozzolana

Pozzolana or pozzuolana ( , ), also known as pozzolanic ash ( la, pulvis puteolanus), is a natural siliceous or siliceous- aluminous material which reacts with calcium hydroxide in the presence of water at room temperature (cf. pozzolanic react ...

and an aggregate of pumice. Its widespread use in many Roman structures, a key event in the history of architecture

The history of architecture traces the changes in architecture through various traditions, regions, overarching stylistic trends, and dates. The beginnings of all these traditions is thought to be humans satisfying the very basic need of shelt ...

termed the Roman architectural revolution, freed Roman construction from the restrictions of stone and brick materials. It enabled revolutionary new designs in terms of both structural complexity and dimension. The Colosseum

The Colosseum ( ; it, Colosseo ) is an oval amphitheatre in the centre of the city of Rome, Italy, just east of the Roman Forum. It is the largest ancient amphitheatre ever built, and is still the largest standing amphitheatre in the world ...

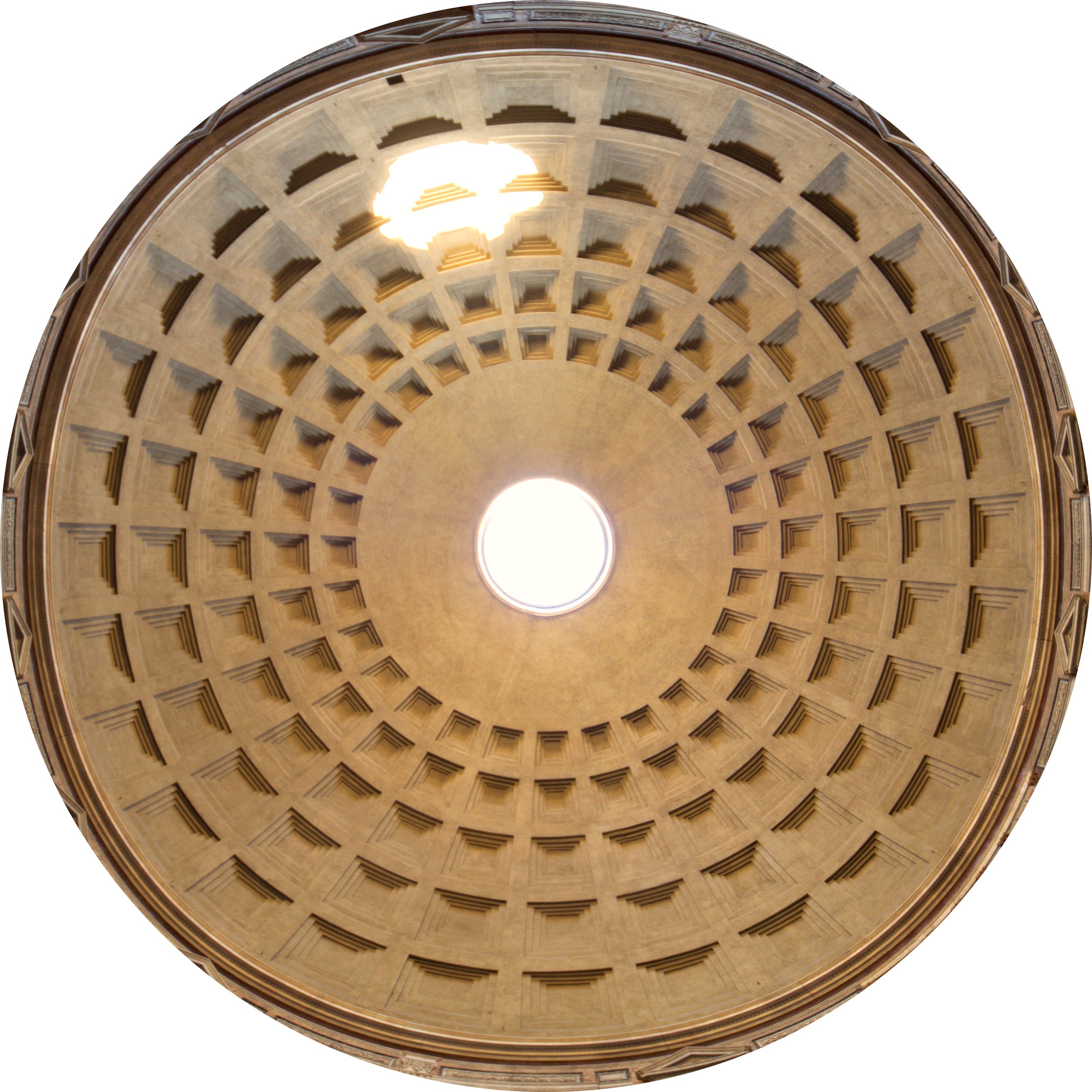

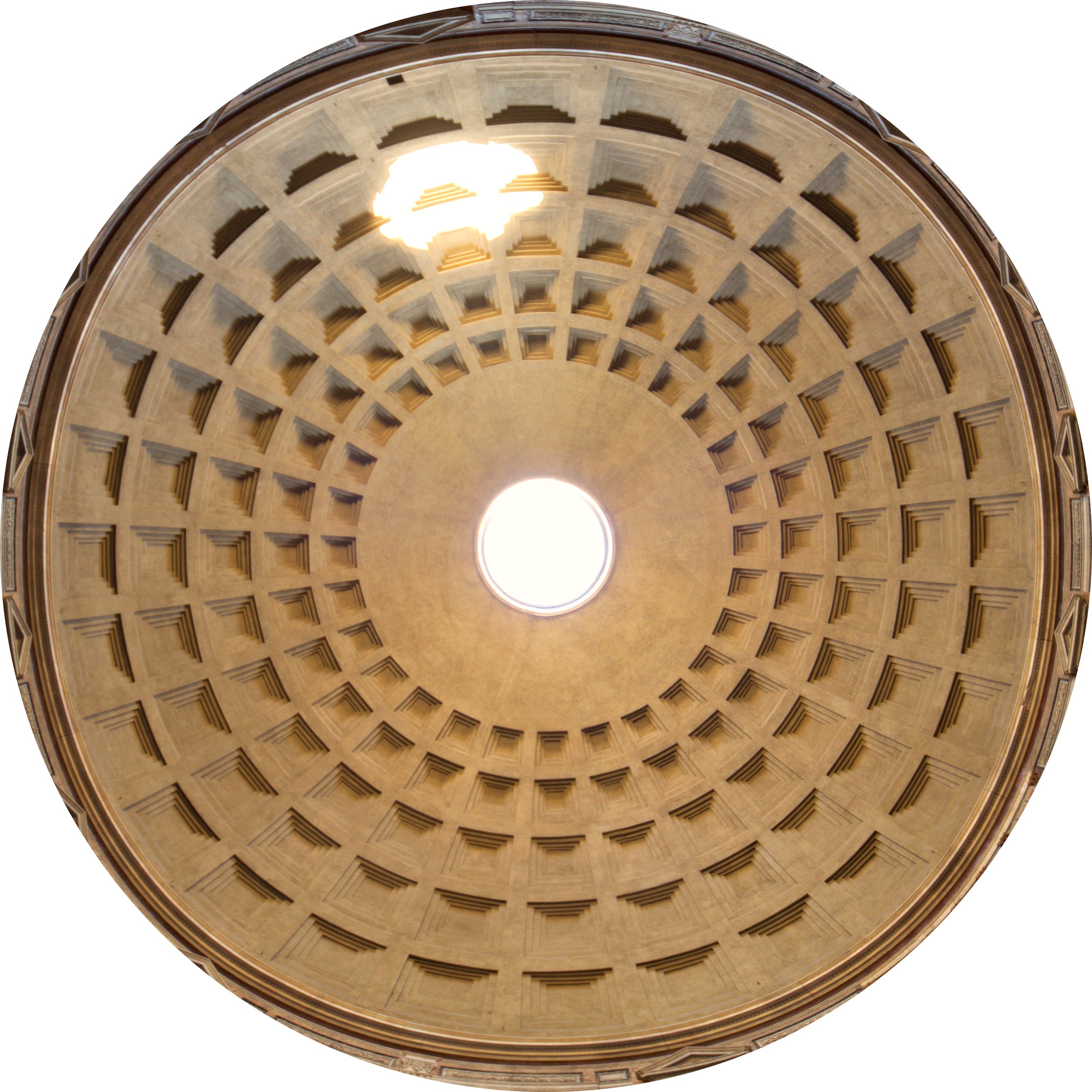

in Rome was built largely of concrete, and the Pantheon

Pantheon may refer to:

* Pantheon (religion), a set of gods belonging to a particular religion or tradition, and a temple or sacred building

Arts and entertainment Comics

*Pantheon (Marvel Comics), a fictional organization

* ''Pantheon'' (Lone St ...

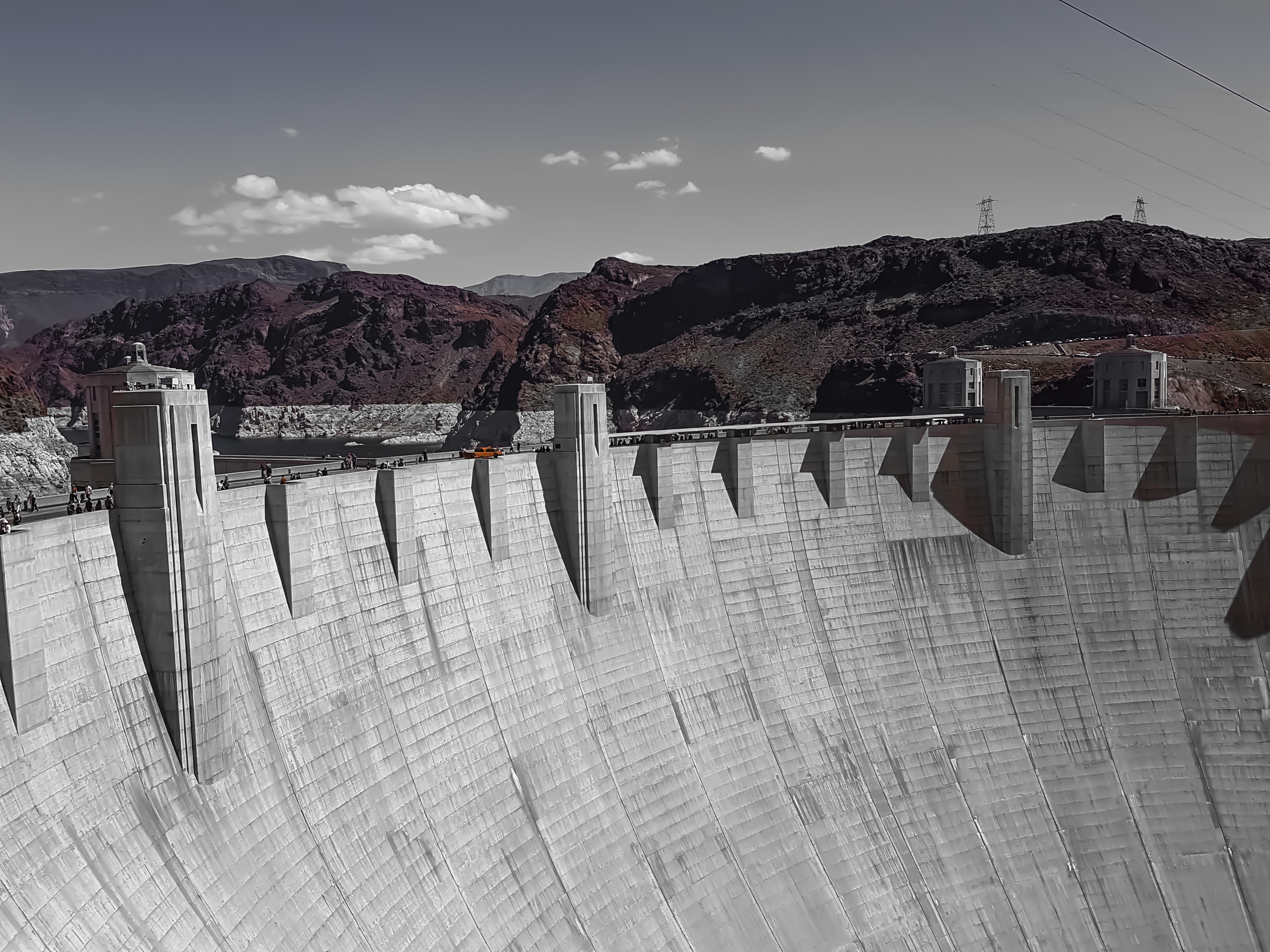

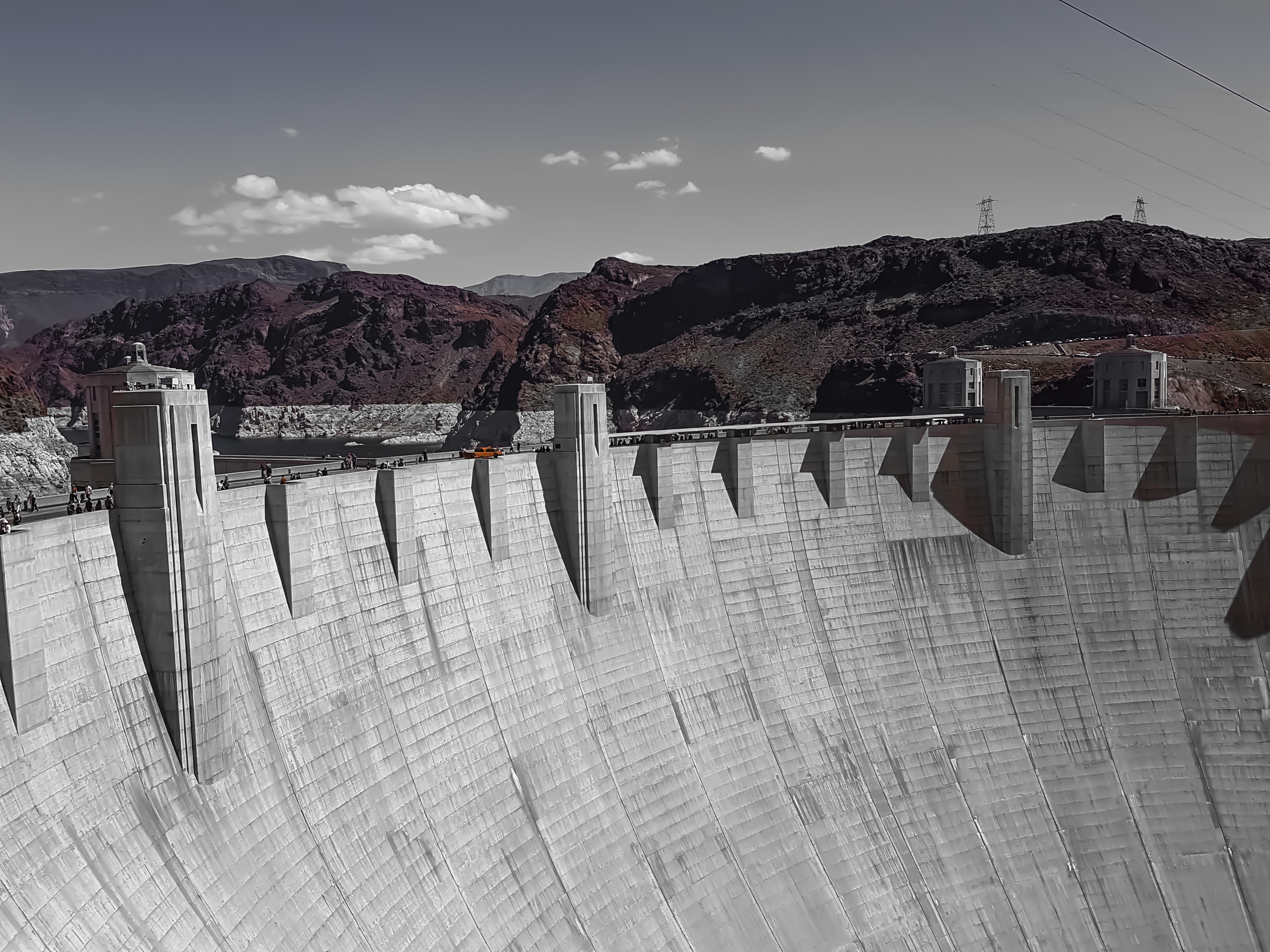

has the world's largest unreinforced concrete dome.

Concrete, as the Romans knew it, was a new and revolutionary material. Laid in the shape of arches, vaults andModern tests show that ''opus caementicium'' had as much compressive strength as modern Portland-cement concrete (ca. ). However, due to the absence of reinforcement, itsdomes A dome () is an architectural element similar to the hollow upper half of a sphere. There is significant overlap with the term cupola, which may also refer to a dome or a structure on top of a dome. The precise definition of a dome has been a m ..., it quickly hardened into a rigid mass, free from many of the internal thrusts and strains that troubled the builders of similar structures in stone or brick.

tensile strength

Ultimate tensile strength (UTS), often shortened to tensile strength (TS), ultimate strength, or F_\text within equations, is the maximum stress that a material can withstand while being stretched or pulled before breaking. In brittle materials ...

was far lower than modern reinforced concrete, and its mode of application also differed:

Modern structural concrete differs from Roman concrete in two important details. First, its mix consistency is fluid and homogeneous, allowing it to be poured into forms rather than requiring hand-layering together with the placement of aggregate, which, in Roman practice, often consisted of rubble. Second, integral reinforcing steel gives modern concrete assemblies great strength in tension, whereas Roman concrete could depend only upon the strength of the concrete bonding to resist tension.The long-term durability of Roman concrete structures has been found to be due to its use of pyroclastic (volcanic) rock and ash, whereby the crystallization of strätlingite (a specific and complex calcium aluminosilicate hydrate) and the coalescence of this and similar calcium–aluminum-silicate–hydrate cementing binders helped give the concrete a greater degree of fracture resistance even in seismically active environments. Roman concrete is significantly more resistant to erosion by seawater than modern concrete; it used pyroclastic materials which react with seawater to form Al- tobermorite crystals over time. The widespread use of concrete in many Roman structures ensured that many survive to the present day. The

Baths of Caracalla

, alternate_name = it, Terme di Caracalla

, image = File:Baths of Caracalla, facing Caldarium.jpg

, caption = The baths as viewed from the south-west. The caldarium would have been in the front of the image

, coordinates = ...

in Rome are just one example. Many Roman aqueducts and bridges, such as the magnificent Pont du Gard

The Pont du Gard is an ancient Roman aqueduct bridge built in the first century AD to carry water over to the Roman colony of ''Nemausus'' ( Nîmes). It crosses the river Gardon near the town of Vers-Pont-du-Gard in southern France. The Po ...

in southern France, have masonry cladding on a concrete core, as does the dome of the Pantheon

Pantheon may refer to:

* Pantheon (religion), a set of gods belonging to a particular religion or tradition, and a temple or sacred building

Arts and entertainment Comics

*Pantheon (Marvel Comics), a fictional organization

* ''Pantheon'' (Lone St ...

.

After the Roman Empire collapsed, use of concrete became rare until the technology was redeveloped in the mid-18th century. Worldwide, concrete has overtaken steel in tonnage of material used.

Middle Ages

After the Roman Empire, the use of burned lime and pozzolana was greatly reduced. Low kiln temperatures in the burning of lime, lack of pozzolana, and poor mixing all contributed to a decline in the quality of concrete and mortar. From the 11th century, the increased use of stone in church and castle construction led to an increased demand for mortar. Quality began to improve in the 12th century through better grinding and sieving. Medieval lime mortars and concretes were non-hydraulic and were used for binding masonry, "hearting" (bindingrubble masonry

Rubble stone is rough, uneven building stone not laid in regular courses. It may fill the core of a wall which is faced with unit masonry such as brick or ashlar. Analogously, some medieval cathedral walls are outer shells of ashlar with an inn ...

cores) and foundations. Bartholomaeus Anglicus Bartholomaeus Anglicus (before 1203–1272), also known as Bartholomew the Englishman and Berthelet, was an early 13th-century Scholastic of Paris, a member of the Franciscan order. He was the author of the compendium ''De proprietatibus rerum' ...

in his ''De proprietatibus rerum'' (1240) describes the making of mortar. In an English translation from 1397, it reads "lyme ... is a stone brent; by medlynge thereof with sonde and water sement is made". From the 14th century, the quality of mortar was again excellent, but only from the 17th century was pozzolana commonly added.

The '' Canal du Midi'' was built using concrete in 1670.

Industrial era

Perhaps the greatest step forward in the modern use of concrete was

Perhaps the greatest step forward in the modern use of concrete was Smeaton's Tower

Smeaton's Tower is a memorial to civil engineer John Smeaton, designer of the third and most notable Eddystone Lighthouse. A major step forward in lighthouse design, Smeaton's structure was in use from 1759 to 1877, until erosion of the ledge i ...

, built by British engineer John Smeaton

John Smeaton (8 June 1724 – 28 October 1792) was a British civil engineer responsible for the design of bridges, canals, harbours and lighthouses. He was also a capable mechanical engineer and an eminent physicist. Smeaton was the fi ...

in Devon, England, between 1756 and 1759. This third Eddystone Lighthouse

The Eddystone Lighthouse is a lighthouse that is located on the dangerous Eddystone Rocks, south of Rame Head in Cornwall, England. The rocks are submerged below the surface of the sea and are composed of Precambrian gneiss. View at 1:50000 ...

pioneered the use of hydraulic lime in concrete, using pebbles and powdered brick as aggregate.

A method for producing Portland cement

Portland cement is the most common type of cement in general use around the world as a basic ingredient of concrete, mortar, stucco, and non-specialty grout. It was developed from other types of hydraulic lime in England in the early 19t ...

was developed in England and patented by Joseph Aspdin in 1824. Aspdin chose the name for its similarity to Portland stone, which was quarried on the Isle of Portland

An isle is an island, land surrounded by water. The term is very common in British English. However, there is no clear agreement on what makes an island an isle or its difference, so they are considered synonyms.

Isle may refer to:

Geography

* Is ...

in Dorset, England. His son William continued developments into the 1840s, earning him recognition for the development of "modern" Portland cement.

Reinforced concrete was invented in 1849 by Joseph Monier. and the first reinforced concrete house was built by François Coignet

François Coignet (10 February 1814 – 30 October 1888) was a French industrialist and a pioneer in the development of reinforced concrete as the first person to use iron-reinforced concrete to construct buildings.Day, p. 284

Biography

Coign ...

in 1853.

The first concrete reinforced bridge was designed and built by Joseph Monier in 1875.

Composition

Concrete is an artificial composite material, comprising a matrix of cementitious binder (typicallyPortland cement

Portland cement is the most common type of cement in general use around the world as a basic ingredient of concrete, mortar, stucco, and non-specialty grout. It was developed from other types of hydraulic lime in England in the early 19t ...

paste or asphalt

Asphalt, also known as bitumen (, ), is a sticky, black, highly viscous liquid or semi-solid form of petroleum. It may be found in natural deposits or may be a refined product, and is classed as a pitch. Before the 20th century, the term ...

) and a dispersed phase or "filler" of aggregate

Aggregate or aggregates may refer to:

Computing and mathematics

* collection of objects that are bound together by a root entity, otherwise known as an aggregate root. The aggregate root guarantees the consistency of changes being made within the ...

(typically a rocky material, loose stones, and sand). The binder "glues" the filler together to form a synthetic conglomerate. Many types of concrete are available, determined by the formulations of binders and the types of aggregate used to suit the application of the engineered material. These variables determine strength and density, as well as chemical and thermal resistance of the finished product.

Aggregates consist of large chunks of material in a concrete mix, generally a coarse gravel or crushed rocks such as

Aggregates consist of large chunks of material in a concrete mix, generally a coarse gravel or crushed rocks such as limestone

Limestone ( calcium carbonate ) is a type of carbonate sedimentary rock which is the main source of the material lime. It is composed mostly of the minerals calcite and aragonite, which are different crystal forms of . Limestone forms w ...

, or granite

Granite () is a coarse-grained ( phaneritic) intrusive igneous rock composed mostly of quartz, alkali feldspar, and plagioclase. It forms from magma with a high content of silica and alkali metal oxides that slowly cools and solidifies un ...

, along with finer materials such as sand

Sand is a granular material composed of finely divided mineral particles. Sand has various compositions but is defined by its grain size. Sand grains are smaller than gravel and coarser than silt. Sand can also refer to a textural class ...

.

Cement paste, most commonly made of Portland cement, is the most prevalent kind of concrete binder. For cementitious binders, water

Water (chemical formula ) is an inorganic, transparent, tasteless, odorless, and nearly colorless chemical substance, which is the main constituent of Earth's hydrosphere and the fluids of all known living organisms (in which it acts as ...

is mixed with the dry cement powder and aggregate, which produces a semi-liquid slurry (paste) that can be shaped, typically by pouring it into a form. The concrete solidifies and hardens through a chemical process called hydration Hydration may refer to:

* Hydrate, a substance that contains water

* Hydration enthalpy, energy released through hydrating a substance

* Hydration reaction, a chemical addition reaction where a hydroxyl group and proton are added to a compound

* ...

. The water reacts with the cement, which bonds the other components together, creating a robust, stone-like material. Other cementitious materials, such as fly ash and slag cement, are sometimes added—either pre-blended with the cement or directly as a concrete component—and become a part of the binder for the aggregate. Fly ash and slag can enhance some properties of concrete such as fresh properties and durability. Alternatively, other materials can also be used as a concrete binder: the most prevalent substitute is asphalt

Asphalt, also known as bitumen (, ), is a sticky, black, highly viscous liquid or semi-solid form of petroleum. It may be found in natural deposits or may be a refined product, and is classed as a pitch. Before the 20th century, the term ...

, which is used as the binder in asphalt concrete.

Admixtures are added to modify the cure rate or properties of the material. Mineral admixtures use recycled materials as concrete ingredients. Conspicuous materials include fly ash, a by-product of coal-fired power plants

Coal is a combustible black or brownish-black sedimentary rock, formed as rock strata called coal seams. Coal is mostly carbon with variable amounts of other elements, chiefly hydrogen, sulfur, oxygen, and nitrogen.

Coal is formed when dead ...

; ground granulated blast furnace slag, a by-product of steelmaking; and silica fume, a by-product of industrial electric arc furnaces.

Structures employing Portland cement concrete usually include steel reinforcement

Rebar (short for reinforcing bar), known when massed as reinforcing steel or reinforcement steel, is a steel bar used as a tension device in reinforced concrete and reinforced masonry structures to strengthen and aid the concrete under tension. ...

because this type of concrete can be formulated with high compressive strength, but always has lower tensile strength

Ultimate tensile strength (UTS), often shortened to tensile strength (TS), ultimate strength, or F_\text within equations, is the maximum stress that a material can withstand while being stretched or pulled before breaking. In brittle materials ...

. Therefore, it is usually reinforced with materials that are strong in tension, typically steel

Steel is an alloy made up of iron with added carbon to improve its strength and fracture resistance compared to other forms of iron. Many other elements may be present or added. Stainless steels that are corrosion- and oxidation-resistan ...

rebar.

The '' mix design'' depends on the type of structure being built, how the concrete is mixed and delivered, and how it is placed to form the structure.

Cement

Isle of Portland

An isle is an island, land surrounded by water. The term is very common in British English. However, there is no clear agreement on what makes an island an isle or its difference, so they are considered synonyms.

Isle may refer to:

Geography

* Is ...

and used extensively in London architecture. It consists of a mixture of calcium silicates ( alite, belite

Belite is an industrial mineral important in Portland cement manufacture. Its main constituent is dicalcium silicate, Ca2SiO4, sometimes formulated as 2 CaO · SiO2 (C2S in cement chemist notation).

Etymology

The name was given by Törnebohm in ...

), aluminates and ferrites—compounds which combine calcium, silicon, aluminum and iron in forms which will react with water. Portland cement and similar materials are made by heating limestone

Limestone ( calcium carbonate ) is a type of carbonate sedimentary rock which is the main source of the material lime. It is composed mostly of the minerals calcite and aragonite, which are different crystal forms of . Limestone forms w ...

(a source of calcium) with clay or shale (a source of silicon, aluminum and iron) and grinding this product (called ''clinker

Clinker may refer to:

*Clinker (boat building), construction method for wooden boats

*Clinker (waste), waste from industrial processes

*Clinker (cement), a kilned then quenched cement product

* ''Clinkers'' (album), a 1978 album by saxophonist St ...

'') with a source of sulfate (most commonly gypsum

Gypsum is a soft sulfate mineral composed of calcium sulfate dihydrate, with the chemical formula . It is widely mined and is used as a fertilizer and as the main constituent in many forms of plaster, blackboard or sidewalk chalk, and drywa ...

).

In modern cement kilns, many advanced features are used to lower the fuel consumption per ton of clinker produced. Cement kilns are extremely large, complex, and inherently dusty industrial installations, and have emissions which must be controlled. Of the various ingredients used to produce a given quantity of concrete, the cement is the most energetically expensive. Even complex and efficient kilns require 3.3 to 3.6 gigajoules of energy to produce a ton of clinker and then grind it into cement. Many kilns can be fueled with difficult-to-dispose-of wastes, the most common being used tires. The extremely high temperatures and long periods of time at those temperatures allows cement kilns to efficiently and completely burn even difficult-to-use fuels.

Water

Combiningwater

Water (chemical formula ) is an inorganic, transparent, tasteless, odorless, and nearly colorless chemical substance, which is the main constituent of Earth's hydrosphere and the fluids of all known living organisms (in which it acts as ...

with a cementitious material forms a cement paste by the process of hydration. The cement paste glues the aggregate together, fills voids within it, and makes it flow more freely.

As stated by Abrams' law Abrams' law (also called Abrams' water-cement ratio law) is a concept in civil engineering. The law states the strength of a concrete mix is inversely related to the mass ratio of water to cement. As the water content increases, the strength of co ...

, a lower water-to-cement ratio yields a stronger, more durable concrete, whereas more water gives a freer-flowing concrete with a higher slump. Impure water used to make concrete can cause problems when setting or in causing premature failure of the structure.

Portland cement consists of five major compounds of calcium silicates and alumninates ranging from 5 to 50% in weight, which all undergo hydration to contribute to final material's strength. Thus, the hydration of cement involves many reactions, often occurring at the same time. As the reactions proceed, the products of the cement hydration process gradually bond together the individual sand and gravel particles and other components of the concrete to form a solid mass.

Hydration of tricalcium silicate

: Cement chemist notation: C3S + H → C-S-H + CH + heat :Standard notation: Ca3SiO5 + H2O → (CaO)·(SiO2)·(H2O)(gel) + Ca(OH)2 :Balanced: 2Ca3SiO5 + 7H2O → 3(CaO)·2(SiO2)·4(H2O)(gel) + 3Ca(OH)2 (approximately; the exact ratios of the CaO, SiO2 and H2O in C-S-H can vary) Due to the nature of the chemical bonds created in these reactions and the final characteristics of the particles formed, the process of cement hydration is considered irreversible, which makes methods of cement recycling prohibitive.Aggregates

Sand

Sand is a granular material composed of finely divided mineral particles. Sand has various compositions but is defined by its grain size. Sand grains are smaller than gravel and coarser than silt. Sand can also refer to a textural class ...

, natural gravel, and crushed stone

Crushed stone or angular rock is a form of construction aggregate, typically produced by mining a suitable rock deposit and breaking the removed rock down to the desired size using crushers. It is distinct from naturally occurring gravel, which ...

are used mainly for this purpose. Recycled aggregates (from construction, demolition, and excavation waste) are increasingly used as partial replacements for natural aggregates, while a number of manufactured aggregates, including air-cooled blast furnace slag and bottom ash are also permitted.

The size distribution of the aggregate determines how much binder is required. Aggregate with a very even size distribution has the biggest gaps whereas adding aggregate with smaller particles tends to fill these gaps. The binder must fill the gaps between the aggregate as well as paste the surfaces of the aggregate together, and is typically the most expensive component. Thus, variation in sizes of the aggregate reduces the cost of concrete. The aggregate is nearly always stronger than the binder, so its use does not negatively affect the strength of the concrete.

Redistribution of aggregates after compaction often creates non-homogeneity due to the influence of vibration. This can lead to strength gradients.

Decorative stones such as quartzite, small river stones or crushed glass are sometimes added to the surface of concrete for a decorative "exposed aggregate" finish, popular among landscape designers.

Admixtures

Admixtures are materials in the form of powder or fluids that are added to the concrete to give it certain characteristics not obtainable with plain concrete mixes. Admixtures are defined as additions "made as the concrete mix is being prepared". The most common admixtures are retarders and accelerators. In normal use, admixture dosages are less than 5% by mass of cement and are added to the concrete at the time of batching/mixing. (See below.) The common types of admixtures are as follows: * Accelerators speed up the hydration (hardening) of the concrete. Typical materials used are calcium chloride, calcium nitrate and sodium nitrate. However, use of chlorides may cause corrosion in steel reinforcing and is prohibited in some countries, so that nitrates may be favored, even though they are less effective than the chloride salt. Accelerating admixtures are especially useful for modifying the properties of concrete in cold weather. * Air entraining agents add and entrain tiny air bubbles in the concrete, which reduces damage during freeze-thaw cycles, increasingdurability

Durability is the ability of a physical product to remain functional, without requiring excessive maintenance or repair, when faced with the challenges of normal operation over its design lifetime. There are several measures of durability in us ...

. However, entrained air entails a tradeoff with strength, as each 1% of air may decrease compressive strength by 5%. If too much air becomes trapped in the concrete as a result of the mixing process, defoamers can be used to encourage the air bubble to agglomerate, rise to the surface of the wet concrete and then disperse.

* Bonding agents are used to create a bond between old and new concrete (typically a type of polymer) with wide temperature tolerance and corrosion resistance.

* Corrosion inhibitors are used to minimize the corrosion of steel and steel bars in concrete.

* Crystalline admixtures are typically added during batching of the concrete to lower permeability. The reaction takes place when exposed to water and un-hydrated cement particles to form insoluble needle-shaped crystals, which fill capillary pores and micro-cracks in the concrete to block pathways for water and waterborne contaminates. Concrete with crystalline admixture can expect to self-seal as constant exposure to water will continuously initiate crystallization to ensure permanent waterproof protection.

* Pigments can be used to change the color of concrete, for aesthetics.

* Plasticizers increase the workability of plastic, or "fresh", concrete, allowing it to be placed more easily, with less consolidating effort. A typical plasticizer is lignosulfonate. Plasticizers can be used to reduce the water content of a concrete while maintaining workability and are sometimes called water-reducers due to this use. Such treatment improves its strength and durability characteristics.

* Superplasticizers (also called high-range water-reducers) are a class of plasticizers that have fewer deleterious effects and can be used to increase workability more than is practical with traditional plasticizers. Superplasticizers are used to increase compressive strength. It increases the workability

{{Short pages monitor

*

*

*

*

*

Advantage and Disadvantage of Concrete

* {{Authority control Building materials Masonry Pavements Sculpture materials Composite materials Heterogeneous chemical mixtures Roofing materials

References

External links

*Advantage and Disadvantage of Concrete

* {{Authority control Building materials Masonry Pavements Sculpture materials Composite materials Heterogeneous chemical mixtures Roofing materials