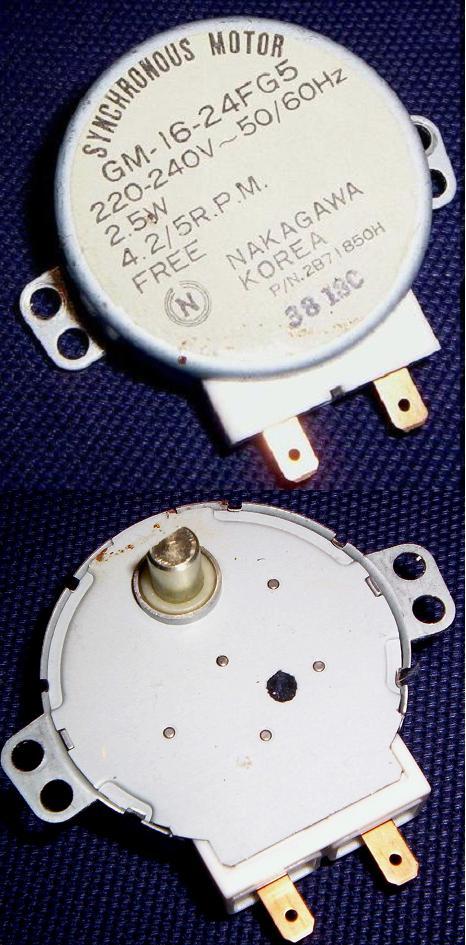

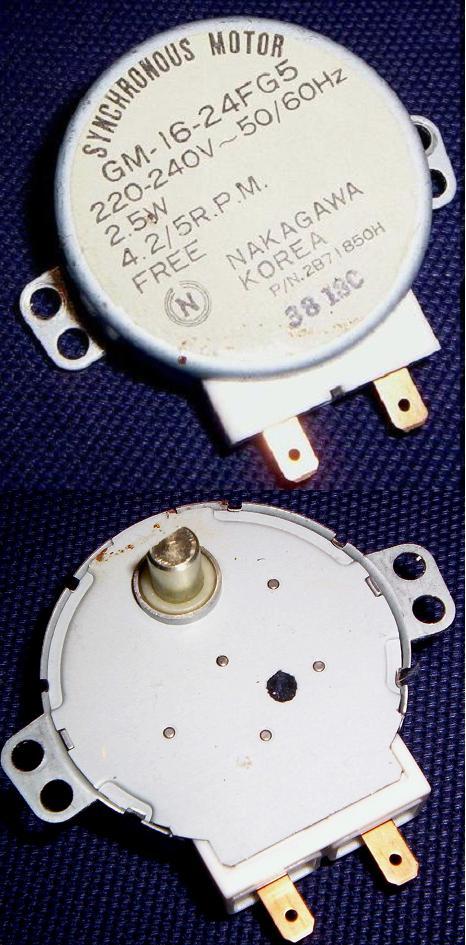

Synchronous motor on:

[Wikipedia]

[Google]

[Amazon]

A synchronous electric motor is an AC electric motor in which, at steady state,

the rotation of the shaft is synchronized with the frequency of the supply current; the rotation period is exactly equal to an integral number of AC cycles. Synchronous motors contain multiphase AC

A synchronous electric motor is an AC electric motor in which, at steady state,

the rotation of the shaft is synchronized with the frequency of the supply current; the rotation period is exactly equal to an integral number of AC cycles. Synchronous motors contain multiphase AC

In non-excited motors, the rotor is made of steel. At synchronous speed it rotates in step with the rotating magnetic field of the stator, so it has an almost-constant magnetic field through it. The external stator field magnetizes the rotor, inducing the magnetic poles needed to turn it. The rotor is made of a high-

In non-excited motors, the rotor is made of steel. At synchronous speed it rotates in step with the rotating magnetic field of the stator, so it has an almost-constant magnetic field through it. The external stator field magnetizes the rotor, inducing the magnetic poles needed to turn it. The rotor is made of a high-

Usually made in larger sizes (larger than about 1 horsepower or 1 kilowatt) these motors require direct current (DC) supplied to the rotor for excitation. This is most straightforwardly supplied through

Usually made in larger sizes (larger than about 1 horsepower or 1 kilowatt) these motors require direct current (DC) supplied to the rotor for excitation. This is most straightforwardly supplied through

in RPM, by: : and in rad·s−1, by: : where: * is the

The principal components of a synchronous motor are the stator and the rotor. The stator of synchronous motor and stator of induction motor are similar in construction. With the wound-rotor synchronous doubly fed electric machine as the exception, the stator frame contains ''wrapper plate''.

''Circumferential ribs'' and ''keybars'' are attached to the wrapper plate. To carry the weight of the machine, ''frame mounts'' and ''footings'' are required. When the field winding is excited by DC excitation, brushes and slip rings are required to connect to the excitation supply. The field winding can also be excited by a brushless exciter. Cylindrical, round rotors, (also known as non salient pole rotor) are used for up to six poles. In some machines or when a large number of poles are needed, a salient pole rotor is used. The construction of synchronous motor is similar to that of a synchronous

The principal components of a synchronous motor are the stator and the rotor. The stator of synchronous motor and stator of induction motor are similar in construction. With the wound-rotor synchronous doubly fed electric machine as the exception, the stator frame contains ''wrapper plate''.

''Circumferential ribs'' and ''keybars'' are attached to the wrapper plate. To carry the weight of the machine, ''frame mounts'' and ''footings'' are required. When the field winding is excited by DC excitation, brushes and slip rings are required to connect to the excitation supply. The field winding can also be excited by a brushless exciter. Cylindrical, round rotors, (also known as non salient pole rotor) are used for up to six poles. In some machines or when a large number of poles are needed, a salient pole rotor is used. The construction of synchronous motor is similar to that of a synchronous

The operation of a synchronous motor is due to the interaction of the magnetic fields of the stator and the rotor. Its stator winding, which consists of a 3 phase winding, is provided with a 3 phase supply, and the rotor is provided with a DC supply. The 3 phase stator winding carrying 3 phase currents produces 3 phase rotating magnetic flux (and therefore a rotating magnetic field). The rotor locks in with the rotating magnetic field and rotates along with it. Once the rotor field locks in with the rotating magnetic field, the motor is said to be in synchronization. A single-phase (or two-phase derived from single phase) stator winding is possible, but in this case the direction of rotation is not defined and the machine may start in either direction unless prevented from doing so by the starting arrangements.

Once the motor is in operation, the speed of the motor is dependent only on the supply frequency. When the motor load is increased beyond the breakdown load, the motor falls out of synchronization and the field winding no longer follows the rotating magnetic field. Since the motor cannot produce (synchronous) torque if it falls out of synchronization, practical synchronous motors have a partial or complete squirrel-cage damper (amortisseur) winding to stabilize operation and facilitate starting. Because this winding is smaller than that of an equivalent induction motor and can overheat on long operation, and because large slip-frequency voltages are induced in the rotor excitation winding, synchronous motor protection devices sense this condition and interrupt the power supply (out of step protection).IEEE Standard 141-1993 ''Recommended Practice for Electric Power Distribution for Industrial Plants'' pages 227-230

The operation of a synchronous motor is due to the interaction of the magnetic fields of the stator and the rotor. Its stator winding, which consists of a 3 phase winding, is provided with a 3 phase supply, and the rotor is provided with a DC supply. The 3 phase stator winding carrying 3 phase currents produces 3 phase rotating magnetic flux (and therefore a rotating magnetic field). The rotor locks in with the rotating magnetic field and rotates along with it. Once the rotor field locks in with the rotating magnetic field, the motor is said to be in synchronization. A single-phase (or two-phase derived from single phase) stator winding is possible, but in this case the direction of rotation is not defined and the machine may start in either direction unless prevented from doing so by the starting arrangements.

Once the motor is in operation, the speed of the motor is dependent only on the supply frequency. When the motor load is increased beyond the breakdown load, the motor falls out of synchronization and the field winding no longer follows the rotating magnetic field. Since the motor cannot produce (synchronous) torque if it falls out of synchronization, practical synchronous motors have a partial or complete squirrel-cage damper (amortisseur) winding to stabilize operation and facilitate starting. Because this winding is smaller than that of an equivalent induction motor and can overheat on long operation, and because large slip-frequency voltages are induced in the rotor excitation winding, synchronous motor protection devices sense this condition and interrupt the power supply (out of step protection).IEEE Standard 141-1993 ''Recommended Practice for Electric Power Distribution for Industrial Plants'' pages 227-230

By varying the excitation of a synchronous motor, it can be made to operate at lagging, leading and unity power factor. Excitation at which the power factor is unity is termed ''normal excitation voltage''.

The magnitude of current at this excitation is minimum. Excitation voltage more than normal excitation is called over excitation voltage, excitation voltage less than normal excitation is called under excitation. When the motor is over excited, the back emf will be greater than the motor terminal voltage. This causes a demagnetizing effect due to armature reaction.

The V curve of a synchronous machine shows armature current as a function of field current. With increasing field current armature current at first decreases, then reaches a minimum, then increases. The minimum point is also the point at which power factor is unity.

This ability to selectively control power factor can be exploited for power factor correction of the power system to which the motor is connected. Since most power systems of any significant size have a net lagging power factor, the presence of overexcited synchronous motors moves the system's net power factor closer to unity, improving efficiency. Such power-factor correction is usually a side effect of motors already present in the system to provide mechanical work, although motors can be run without mechanical load simply to provide power-factor correction. In large industrial plants such as factories the interaction between synchronous motors and other, lagging, loads may be an explicit consideration in the plant's electrical design.

By varying the excitation of a synchronous motor, it can be made to operate at lagging, leading and unity power factor. Excitation at which the power factor is unity is termed ''normal excitation voltage''.

The magnitude of current at this excitation is minimum. Excitation voltage more than normal excitation is called over excitation voltage, excitation voltage less than normal excitation is called under excitation. When the motor is over excited, the back emf will be greater than the motor terminal voltage. This causes a demagnetizing effect due to armature reaction.

The V curve of a synchronous machine shows armature current as a function of field current. With increasing field current armature current at first decreases, then reaches a minimum, then increases. The minimum point is also the point at which power factor is unity.

This ability to selectively control power factor can be exploited for power factor correction of the power system to which the motor is connected. Since most power systems of any significant size have a net lagging power factor, the presence of overexcited synchronous motors moves the system's net power factor closer to unity, improving efficiency. Such power-factor correction is usually a side effect of motors already present in the system to provide mechanical work, although motors can be run without mechanical load simply to provide power-factor correction. In large industrial plants such as factories the interaction between synchronous motors and other, lagging, loads may be an explicit consideration in the plant's electrical design.

Synchronous motor animation

{{Authority control Electric motors Synchronous machines

A synchronous electric motor is an AC electric motor in which, at steady state,

the rotation of the shaft is synchronized with the frequency of the supply current; the rotation period is exactly equal to an integral number of AC cycles. Synchronous motors contain multiphase AC

A synchronous electric motor is an AC electric motor in which, at steady state,

the rotation of the shaft is synchronized with the frequency of the supply current; the rotation period is exactly equal to an integral number of AC cycles. Synchronous motors contain multiphase AC electromagnet

An electromagnet is a type of magnet in which the magnetic field is produced by an electric current. Electromagnets usually consist of wire wound into a coil. A current through the wire creates a magnetic field which is concentrated in ...

s on the stator

The stator is the stationary part of a rotary system, found in electric generators, electric motors, sirens, mud motors or biological rotors. Energy flows through a stator to or from the rotating component of the system. In an electric m ...

of the motor that create a magnetic field

A magnetic field is a vector field that describes the magnetic influence on moving electric charges, electric currents, and magnetic materials. A moving charge in a magnetic field experiences a force perpendicular to its own velocity and to ...

which rotates in time with the oscillations of the line current. The rotor

Rotor may refer to:

Science and technology

Engineering

* Rotor (electric), the non-stationary part of an alternator or electric motor, operating with a stationary element so called the stator

*Helicopter rotor, the rotary wing(s) of a rotorcraft ...

with permanent magnets or electromagnets turns in step with the stator field at the same rate and as a result, provides the second synchronized rotating magnet field of any AC motor. A synchronous motor is termed ''doubly fed'' if it is supplied with independently excited multiphase AC electromagnets on both the rotor and stator.

The synchronous motor and the induction motor

An induction motor or asynchronous motor is an AC electric motor in which the electric current in the rotor needed to produce torque is obtained by electromagnetic induction from the magnetic field of the stator winding. An induction motor ...

are the most widely used types of AC motors. The difference between the two types is that the synchronous motor rotates at a rate locked to the line frequency since it does not rely on current induction to produce the rotor's magnetic field. By contrast, the induction motor requires '' slip'': the rotor must rotate slightly slower than the AC alternations in order to induce current in the rotor winding. Small synchronous motors are used in timing applications such as in synchronous clocks, timer

A timer is a specialized type of clock used for measuring specific time intervals.

Timers can be categorized into two main types.

The word "timer" is usually reserved for devices that counts down from a specified time interval, while devices th ...

s in appliances, tape recorder

An audio tape recorder, also known as a tape deck, tape player or tape machine or simply a tape recorder, is a sound recording and reproduction device that records and plays back sounds usually using magnetic tape for storage. In its present ...

s and precision servomechanism

In control engineering a servomechanism, usually shortened to servo, is an automatic device that uses error-sensing negative feedback to correct the action of a mechanism. On displacement-controlled applications, it usually includes a built-in ...

s in which the motor must operate at a precise speed; speed accuracy is that of the power line frequency, which is carefully controlled in large interconnected grid systems.

Synchronous motors are available in self-excited sub-fractional horsepower sizes to high power industrial sizes. In the fractional horsepower range, most synchronous motors are used where precise constant speed is required. These machines are commonly used in analog electric clocks, timers and other devices where correct time is required.

In higher power industrial sizes, the synchronous motor provides two important functions. First, it is a highly efficient means of converting AC energy to work. Second, it can operate at leading or unity power factor

In electrical engineering, the power factor of an AC power system is defined as the ratio of the ''real power'' absorbed by the load to the '' apparent power'' flowing in the circuit. Real power is the average of the instantaneous product of v ...

and thereby provide power-factor correction.

Type

Synchronous motors fall under the more general category of ''synchronous machines'' which also includes the synchronous generator. Generator action will be observed if the field poles are "driven ahead of the resultant air-gap flux by the forward motion of the prime mover". Motor action will be observed if the field poles are "dragged behind the resultant air-gap flux by the retardingtorque

In physics and mechanics, torque is the rotational equivalent of linear force. It is also referred to as the moment of force (also abbreviated to moment). It represents the capability of a force to produce change in the rotational motion of th ...

of a shaft load".

There are two major types of synchronous motors depending on how the rotor is magnetized: ''non-excited'' and ''direct-current excited''.

Non-excited motors

In non-excited motors, the rotor is made of steel. At synchronous speed it rotates in step with the rotating magnetic field of the stator, so it has an almost-constant magnetic field through it. The external stator field magnetizes the rotor, inducing the magnetic poles needed to turn it. The rotor is made of a high-

In non-excited motors, the rotor is made of steel. At synchronous speed it rotates in step with the rotating magnetic field of the stator, so it has an almost-constant magnetic field through it. The external stator field magnetizes the rotor, inducing the magnetic poles needed to turn it. The rotor is made of a high-retentivity

Remanence or remanent magnetization or residual magnetism is the magnetization left behind in a ferromagnetic material (such as iron) after an external magnetic field is removed. Colloquially, when a magnet is "magnetized", it has remanence. ...

steel such as cobalt

Cobalt is a chemical element with the symbol Co and atomic number 27. As with nickel, cobalt is found in the Earth's crust only in a chemically combined form, save for small deposits found in alloys of natural meteoric iron. The free element, p ...

steel. These are manufactured in permanent magnet

A magnet is a material or object that produces a magnetic field. This magnetic field is invisible but is responsible for the most notable property of a magnet: a force that pulls on other ferromagnetic materials, such as iron, steel, nicke ...

, reluctance and hysteresis

Hysteresis is the dependence of the state of a system on its history. For example, a magnet may have more than one possible magnetic moment in a given magnetic field, depending on how the field changed in the past. Plots of a single component of ...

designs:William Yeadon (ed.), ''Handbook of Small Electric Motors'', McGraw-Hill 2001 , Chapter 12 "Synchronous Machines"

Reluctance motors

These have a rotor consisting of a solid steel casting with projecting (salient) toothed poles. Typically there are fewer rotor than stator poles to minimize torque ripple and to prevent the poles from all aligning simultaneously—a position that cannot generate torque. The size of the air gap in the magnetic circuit and thus the reluctance is minimum when the poles are aligned with the (rotating) magnetic field of the stator, and increases with the angle between them. This creates a torque pulling the rotor into alignment with the nearest pole of the stator field. Thus at synchronous speed the rotor is "locked" to the rotating stator field. This cannot start the motor, so the rotor poles usually have squirrel-cage windings embedded in them, to provide torque below synchronous speed. The machine starts as an induction motor until it approaches synchronous speed, when the rotor "pulls in" and locks to the rotating stator field. Reluctance motor designs have ratings that range from fractional horsepower (a few watts) to about . Very small reluctance motors have lowtorque

In physics and mechanics, torque is the rotational equivalent of linear force. It is also referred to as the moment of force (also abbreviated to moment). It represents the capability of a force to produce change in the rotational motion of th ...

, and are generally used for instrumentation applications. Moderate torque, multi-horsepower motors use squirrel cage construction with toothed rotors. When used with an adjustable frequency power supply, all motors in the drive system can be controlled at exactly the same speed. The power supply frequency determines motor operating speed.

Hysteresis motors

These have a solid smooth cylindrical rotor, cast of a highcoercivity

Coercivity, also called the magnetic coercivity, coercive field or coercive force, is a measure of the ability of a ferromagnetic material to withstand an external magnetic field without becoming demagnetized. Coercivity is usually measured in ...

magnetically "hard" cobalt steel. This material has a wide hysteresis loop (high coercivity

Coercivity, also called the magnetic coercivity, coercive field or coercive force, is a measure of the ability of a ferromagnetic material to withstand an external magnetic field without becoming demagnetized. Coercivity is usually measured in ...

), meaning once it is magnetized in a given direction, it requires a large reverse magnetic field to reverse the magnetization. The rotating stator field causes each small volume of the rotor to experience a reversing magnetic field. Because of hysteresis the phase of the magnetization lags behind the phase of the applied field. The result of this is that the axis of the magnetic field induced in the rotor lags behind the axis of the stator field by a constant angle δ, producing a torque as the rotor tries to "catch up" with the stator field. As long as the rotor is below synchronous speed, each particle of the rotor experiences a reversing magnetic field at the "slip" frequency which drives it around its hysteresis loop, causing the rotor field to lag and create torque. There is a 2-pole low reluctance bar structure in the rotor. As the rotor approaches synchronous speed and slip goes to zero, this magnetizes and aligns with the stator field, causing the rotor to "lock" to the rotating stator field.

A major advantage of the hysteresis motor is that since the lag angle δ is independent of speed, it develops constant torque from startup to synchronous speed. Therefore, it is self-starting and doesn't need an induction winding to start it, although many designs do have a squirrel-cage conductive winding structure embedded in the rotor to provide extra torque at start-up.

Hysteresis motors are manufactured in sub-fractional horsepower ratings, primarily as servomotors and timing motors. More expensive than the reluctance type, hysteresis motors are used where precise constant speed is required.

Permanent-magnet motors

A permanent-magnet synchronous motor (PMSM) usespermanent magnet

A magnet is a material or object that produces a magnetic field. This magnetic field is invisible but is responsible for the most notable property of a magnet: a force that pulls on other ferromagnetic materials, such as iron, steel, nickel ...

s embedded in the steel rotor to create a constant magnetic field. The stator carries windings connected to an AC supply to produce a rotating magnetic field (as in an asynchronous motor). At synchronous speed the rotor poles lock to the rotating magnetic field. Permanent magnet synchronous motors are similar to brushless DC motors. Neodymium magnets are the most commonly used magnets in these motors. Although in the last few years, due to rapid fluctuation in the prices of neodymium magnets, a lot of research has been looking at ferrite magnets as an alternative. Due to the inherent characteristics of the currently available ferrite magnets, the design of the magnetic circuit

A magnetic circuit is made up of one or more closed loop paths containing a magnetic flux. The flux is usually generated by permanent magnets or electromagnets and confined to the path by magnetic cores consisting of ferromagnetic materials lik ...

of these machines needs to be able to concentrate the magnetic flux, one of the most common strategies is the use of spoke type rotors. Currently, the new machines that use ferrite magnets have lower power density and torque density, when compared with machines that use neodymium magnets.

Permanent magnet motors have been used as gearless elevator motors since 2000.

Most PMSMs require a variable-frequency drive

A variable-frequency drive (VFD) is a type of motor drive used in electro-mechanical drive systems to control AC motor speed and torque by varying motor input frequency and, depending on topology, to control associated voltage or current va ...

to start. However, some incorporate a squirrel cage in the rotor for starting—these are known as line-start or self-starting PMSMs. These are typically used as higher-efficiency replacements for induction motors (owing to the lack of slip), but need to be specified carefully for the application to ensure that synchronous speed is reached and that the system can withstand the torque ripple during starting.

Permanent magnet synchronous motors are mainly controlled using direct torque control Direct torque control (DTC) is one method used in variable-frequency drives to control the torque (and thus finally the speed) of three-phase AC electric motors. This involves calculating an estimate of the motor's magnetic flux and torque b ...

and field oriented control. However, these methods suffer from relatively high torque and stator flux ripples. Predictive control and neural network controllers are recently developed to cope with these issues.

DC-excited motors

Usually made in larger sizes (larger than about 1 horsepower or 1 kilowatt) these motors require direct current (DC) supplied to the rotor for excitation. This is most straightforwardly supplied through

Usually made in larger sizes (larger than about 1 horsepower or 1 kilowatt) these motors require direct current (DC) supplied to the rotor for excitation. This is most straightforwardly supplied through slip ring

A slip ring is an electromechanical device that allows the transmission of power and electrical signals from a stationary to a rotating structure. A slip ring can be used in any electromechanical system that requires rotation while transmitting ...

s, but a brushless AC induction and rectifier arrangement may also be used. The direct current may be supplied from a separate DC source or from a DC generator directly connected to the motor shaft.

Control techniques

A permanent magnet synchronous motor and reluctance motor requires a control system for operating ( VFD orservo drive

A servo drive is an electronic amplifier used to power electric servomechanisms.

A servo drive monitors the feedback signal from the servomechanism and continually adjusts for deviation from expected behavior.

Function

A servo drive receives a c ...

).

There are a large number of control methods for PMSM, which is selected depending on the construction of the electric motor and the scope.

Control methods can be divided into:

Sinusoidal

* Scalar

* Vector ( FOC, DTC)

Trapezoidal

* Open loop

* Closed loop (with and without Hall sensor)

Synchronous speed

The synchronous speed of a synchronous motor is given:in RPM, by: : and in rad·s−1, by: : where: * is the

frequency

Frequency is the number of occurrences of a repeating event per unit of time. It is also occasionally referred to as ''temporal frequency'' for clarity, and is distinct from ''angular frequency''. Frequency is measured in hertz (Hz) which is eq ...

of the AC supply current in Hz,

* is the number of magnetic poles

Poles,, ; singular masculine: ''Polak'', singular feminine: ''Polka'' or Polish people, are a West Slavic nation and ethnic group, who share a common history, culture, the Polish language and are identified with the country of Poland in ...

,

* is the number of pole pairs (rarely, ''planes of commutation''), .

Examples

Asingle-phase

In electrical engineering, single-phase electric power (abbreviated 1φ) is the distribution of alternating current electric power using a system in which all the voltages of the supply vary in unison. Single-phase distribution is used when loa ...

, 4-pole (2-pole-pair) synchronous motor is operating at an AC supply frequency of 50 Hz. The number of pole-pairs is 2, so

the synchronous speed is:

:

A three-phase

Three-phase electric power (abbreviated 3φ) is a common type of alternating current used in electricity generation, transmission, and distribution. It is a type of polyphase system employing three wires (or four including an optional neutral ...

, 12-pole (6-pole-pair) synchronous motor is operating at an AC supply frequency of 60 Hz. The number of pole-pairs is 6, so the synchronous speed is:

:

The number of magnetic poles, , is equal to the number of coil groups per phase. To determine the number of coil groups per phase in a 3-phase motor, count the number of coils, divide by the number of phases, which is 3. The coils may span several slots in the stator core, making it tedious to count them. For a 3-phase motor, if you count a total of 12 coil groups, it has 4 magnetic poles. For a 12-pole 3-phase machine, there will be 36 coils. The number of magnetic poles in the rotor is equal to the number of magnetic poles in the stator.

Construction

The principal components of a synchronous motor are the stator and the rotor. The stator of synchronous motor and stator of induction motor are similar in construction. With the wound-rotor synchronous doubly fed electric machine as the exception, the stator frame contains ''wrapper plate''.

''Circumferential ribs'' and ''keybars'' are attached to the wrapper plate. To carry the weight of the machine, ''frame mounts'' and ''footings'' are required. When the field winding is excited by DC excitation, brushes and slip rings are required to connect to the excitation supply. The field winding can also be excited by a brushless exciter. Cylindrical, round rotors, (also known as non salient pole rotor) are used for up to six poles. In some machines or when a large number of poles are needed, a salient pole rotor is used. The construction of synchronous motor is similar to that of a synchronous

The principal components of a synchronous motor are the stator and the rotor. The stator of synchronous motor and stator of induction motor are similar in construction. With the wound-rotor synchronous doubly fed electric machine as the exception, the stator frame contains ''wrapper plate''.

''Circumferential ribs'' and ''keybars'' are attached to the wrapper plate. To carry the weight of the machine, ''frame mounts'' and ''footings'' are required. When the field winding is excited by DC excitation, brushes and slip rings are required to connect to the excitation supply. The field winding can also be excited by a brushless exciter. Cylindrical, round rotors, (also known as non salient pole rotor) are used for up to six poles. In some machines or when a large number of poles are needed, a salient pole rotor is used. The construction of synchronous motor is similar to that of a synchronous alternator

An alternator is an electrical generator that converts mechanical energy to electrical energy in the form of alternating current. For reasons of cost and simplicity, most alternators use a rotating magnetic field with a stationary armature.Gor ...

. Most of the synchronous motors construction uses the stationary armature and rotating field winding. This type of construction as an advantage than DC motor

A DC motor is any of a class of rotary electrical motors that converts direct current (DC) electrical energy into mechanical energy. The most common types rely on the forces produced by induced magnetic fields due to flowing current in the coil ...

type where the armature used is of rotating type.

Operation

The operation of a synchronous motor is due to the interaction of the magnetic fields of the stator and the rotor. Its stator winding, which consists of a 3 phase winding, is provided with a 3 phase supply, and the rotor is provided with a DC supply. The 3 phase stator winding carrying 3 phase currents produces 3 phase rotating magnetic flux (and therefore a rotating magnetic field). The rotor locks in with the rotating magnetic field and rotates along with it. Once the rotor field locks in with the rotating magnetic field, the motor is said to be in synchronization. A single-phase (or two-phase derived from single phase) stator winding is possible, but in this case the direction of rotation is not defined and the machine may start in either direction unless prevented from doing so by the starting arrangements.

Once the motor is in operation, the speed of the motor is dependent only on the supply frequency. When the motor load is increased beyond the breakdown load, the motor falls out of synchronization and the field winding no longer follows the rotating magnetic field. Since the motor cannot produce (synchronous) torque if it falls out of synchronization, practical synchronous motors have a partial or complete squirrel-cage damper (amortisseur) winding to stabilize operation and facilitate starting. Because this winding is smaller than that of an equivalent induction motor and can overheat on long operation, and because large slip-frequency voltages are induced in the rotor excitation winding, synchronous motor protection devices sense this condition and interrupt the power supply (out of step protection).IEEE Standard 141-1993 ''Recommended Practice for Electric Power Distribution for Industrial Plants'' pages 227-230

The operation of a synchronous motor is due to the interaction of the magnetic fields of the stator and the rotor. Its stator winding, which consists of a 3 phase winding, is provided with a 3 phase supply, and the rotor is provided with a DC supply. The 3 phase stator winding carrying 3 phase currents produces 3 phase rotating magnetic flux (and therefore a rotating magnetic field). The rotor locks in with the rotating magnetic field and rotates along with it. Once the rotor field locks in with the rotating magnetic field, the motor is said to be in synchronization. A single-phase (or two-phase derived from single phase) stator winding is possible, but in this case the direction of rotation is not defined and the machine may start in either direction unless prevented from doing so by the starting arrangements.

Once the motor is in operation, the speed of the motor is dependent only on the supply frequency. When the motor load is increased beyond the breakdown load, the motor falls out of synchronization and the field winding no longer follows the rotating magnetic field. Since the motor cannot produce (synchronous) torque if it falls out of synchronization, practical synchronous motors have a partial or complete squirrel-cage damper (amortisseur) winding to stabilize operation and facilitate starting. Because this winding is smaller than that of an equivalent induction motor and can overheat on long operation, and because large slip-frequency voltages are induced in the rotor excitation winding, synchronous motor protection devices sense this condition and interrupt the power supply (out of step protection).IEEE Standard 141-1993 ''Recommended Practice for Electric Power Distribution for Industrial Plants'' pages 227-230

Starting methods

Above a certain size, synchronous motors are not self-starting motors. This property is due to the inertia of the rotor; it cannot instantly follow the rotation of the magnetic field of the stator. Since a synchronous motor produces no inherent average torque at standstill, it cannot accelerate to synchronous speed without some supplemental mechanism. Large motors operating on commercial power frequency include a squirrel-cage induction winding which provides sufficient torque for acceleration and which also serves to damp oscillations in motor speed in operation. Once the rotor nears the synchronous speed, the field winding is excited, and the motor pulls into synchronization. Very large motor systems may include a "pony" motor that accelerates the unloaded synchronous machine before load is applied. Motors that are electronically controlled can be accelerated from zero speed by changing the frequency of the stator current. Very small synchronous motors are commonly used in line-powered electric mechanical clocks or timers that use the power line frequency to run the gear mechanism at the correct speed. Such small synchronous motors are able to start without assistance if themoment of inertia

The moment of inertia, otherwise known as the mass moment of inertia, angular mass, second moment of mass, or most accurately, rotational inertia, of a rigid body is a quantity that determines the torque needed for a desired angular accele ...

of the rotor and its mechanical load is sufficiently small ecause the motorwill be accelerated from slip speed up to synchronous speed during an accelerating half cycle of the reluctance torque." Single-phase

In electrical engineering, single-phase electric power (abbreviated 1φ) is the distribution of alternating current electric power using a system in which all the voltages of the supply vary in unison. Single-phase distribution is used when loa ...

synchronous motors such as in electric wall clocks can freely rotate in either direction unlike a shaded-pole type. See Shaded-pole synchronous motor for how consistent starting direction is obtained.

The operational economics is an important parameter to address different motor starting methods. Accordingly, the excitation of the rotor is a possible way to solve the motor starting issue. In addition, modern proposed starting methods for large synchronous machines include repetitive polarity inversion of the rotor poles during startup.

Applications, special properties, and advantages

Use as synchronous condenser

Steady state stability limit

: where, : is the torque : is the torque angle : is the maximum torque here, : When load is applied, torque angle increases. When = 90° the torque will be maximum. If load is applied further then the motor will lose its synchronism, since motor torque will be less than load torque. The maximum load torque that can be applied to a motor without losing its synchronism is called steady state stability limit of a synchronous motor.Other

Synchronous motors are especially useful in applications requiring precise speed or position control: * Speed is independent of the load over the operating range of the motor. * Speed and position may be accurately controlled using open loop controls (e.g. stepper motors). * Low-power applications include positioning machines, where high precision is required, androbot

A robot is a machine—especially one programmable by a computer—capable of carrying out a complex series of actions automatically. A robot can be guided by an external control device, or the control may be embedded within. Robots may be ...

actuators.

* They will hold their position when a DC current is applied to both the stator and the rotor windings.

* A clock driven by a synchronous motor is in principle as accurate as the line frequency of its power source. (Although small frequency drifts will occur over any given several hours, grid operators actively adjust line frequency in later periods to compensate, thereby keeping motor-driven clocks accurate; see '' Utility frequency#Stability''.)

* Record player turntables

* Increased efficiency in low-speed applications (e.g. ball mill

A ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering. It works on the principle of impact and attrition: size reduction is done ...

s).

Subtypes

* AC Polyphase synchronous motors * Stepper motor (may be synchronous or not) * Synchronous brushless wound-rotor doubly-fed electric machineSee also

* Clock drive * Doubly fed electric machine * Short circuit ratioReferences

External links

Synchronous motor animation

{{Authority control Electric motors Synchronous machines