Spray nozzle on:

[Wikipedia]

[Google]

[Amazon]

A spray nozzle is a device that facilitates the dispersion of a liquid by the formation of a

A spray nozzle is a device that facilitates the dispersion of a liquid by the formation of a

File:Plain orifice nozzle.png, alt=Plain orifice spray nozzle, Plain orifice spray nozzle

File:Flat fan nozzle.png, alt=Flat fan spray nozzle, Flat fan spray pattern spray nozzle

File:Impg nozzle.png, Surface impingement spray nozzle

File:spiral impingement nozzle.png, Spiral spray nozzle

File:swirl nozzle.png, Pressure swirl spray nozzle

File:Spillback Nozzle.jpg, Spillback Nozzle

File:Compound nozzle.png, alt=Compound spray nozzle, Compound pressure swirl spray nozzle with wide pattern

File:IMTF wiki.png, Internal mix two-fluid spray nozzle

File:EM TF wiki.png, External mix two-fluid spray nozzle

File:Laval Nozzle.JPG, TwinFluid Nozzle

Experiment of The Month , Millersville University

{{DEFAULTSORT:Spray Nozzle Nozzles Articles containing video clips

A spray nozzle is a device that facilitates the dispersion of a liquid by the formation of a

A spray nozzle is a device that facilitates the dispersion of a liquid by the formation of a spray

Spray or spraying commonly refer to:

* Spray (liquid drop)

** Aerosol spray

** Blood spray

** Hair spray

** Nasal spray

** Pepper spray

** PAVA spray

** Road spray or tire spray, road debris kicked up from a vehicle tire

** Sea spray, refers to ...

. The production of a spray requires the fragmentation of liquid structures, such as liquid sheets or ligaments, into droplets, often by using kinetic energy to overcome the cost of creating additional surface area. A wide variety of spray nozzles exist, that make use of one or multiple liquid breakup mechanisms, which can be divided into three categories: liquid sheet breakup, jets and capillary waves. Spray nozzles are of great importance for many applications

Application may refer to:

Mathematics and computing

* Application software, computer software designed to help the user to perform specific tasks

** Application layer, an abstraction layer that specifies protocols and interface methods used in a c ...

, where the spray nozzle is designed to have the right spray characteristics.

Spray nozzles can have one or more outlets; a multiple outlet nozzle is known as a compound nozzle. Multiple outlets on nozzles are present on spray balls, which have been used in the brewing industry for many years for cleaning casks and kegs. Spray nozzles range from heavy duty industrial uses to light duty spray cans or spray bottle

A bottle is a narrow-necked container made of an impermeable material (such as glass, plastic or aluminium) in various shapes and sizes that stores and transports liquids. Its mouth, at the bottling line, can be sealed with an internal s ...

s.

Single-fluid nozzles

Single-fluid or hydraulic spray nozzles utilize the kinetic energy imparted to the liquid to break it up into droplets. This most widely used type of spray nozzle is more energy efficient at producing surface area than most other types. As the fluid pressure increases, the flow through the nozzle increases, and the drop size decreases. Many configurations of single fluid nozzles are used depending on the spray characteristics desired.Plain-orifice

The simplest single fluid nozzle is a plain orifice nozzle as shown in the diagram. This nozzle often produces little if any atomization, but directs the stream of liquid. If the pressure drop is high, at least , the material is often finely atomized, as in a diesel injector. At lower pressures, this type of nozzle is often used for tank cleaning, either as a fixed position compound spray nozzle or as a rotary nozzle.Shaped-orifice

The shaped orifice uses a semi spherical shaped inlet and a ''V'' notched outlet to cause the flow to spread out on the axis of the V notch. A flat fan spray results which is useful for many spray applications, such as spray painting.Surface-impingement single-fluid

A surface impingement nozzle causes a stream of liquid to impinge on a surface resulting in a sheet of liquid that breaks up into small drops. This flat fan spray pattern nozzle is used in many applications ranging from applying agriculturalherbicides

Herbicides (, ), also commonly known as weedkillers, are substances used to control undesired plants, also known as weeds.EPA. February 201Pesticides Industry. Sales and Usage 2006 and 2007: Market Estimates. Summary in press releasMain page fo ...

to row o painting.

The impingement surface can be formed in a spiral to yield a spiral shaped sheet approximating a full cone spray pattern or a hollow-cone spray pattern.

The spiral design generally produces a smaller drop size than pressure swirl type nozzle design, for a given pressure and flow rate. This design is clog resistant due to the large free passage.

Common applications include gas scrubbing applications (e.g., flue-gas desulfurization

Flue-gas desulfurization (FGD) is a set of technologies used to remove sulfur dioxide () from exhaust flue gases of fossil-fuel power plants, and from the emissions of other sulfur oxide emitting processes such as waste incineration.

Methods

...

where the smaller droplets often offer superior performance) and fire fighting (where the mix of droplet densities allow spray penetration through strong thermal currents).

Pressure-swirl single-fluid

Pressure-swirl spray nozzles are high-performance (small drop size) devices with one configuration shown. The stationary core induces a rotary fluid motion which causes the swirling of the fluid in the swirl chamber. A film is discharged from the perimeter of the outlet orifice producing a characteristic hollow cone spray pattern. Air or other surrounding gas is drawn inside the swirl chamber to form an air core within the swirling liquid. Many configurations of fluid inlets are used to produce this hollow cone pattern depending on the nozzle capacity and materials of construction. The uses of this nozzle include evaporative cooling and spray drying.Solid-cone single-fluid

One of the configurations of the solid cone spray nozzle is shown in a schematic diagram. A swirling liquid motion is induced with the vane structure, however; the discharge flow fills the entire outlet orifice. For the same capacity and pressure drop, a full cone nozzle will produce a larger drop size than a hollow cone nozzle. The coverage is the desired feature for such a nozzle, which is often used for applications to distribute fluid over an area.Compound

A compound nozzle is a type of nozzle in which several individual single or two fluid nozzles are incorporated into one nozzle body, as shown below. This allows design control of drop size and spray coverage angle.Two-fluid nozzles

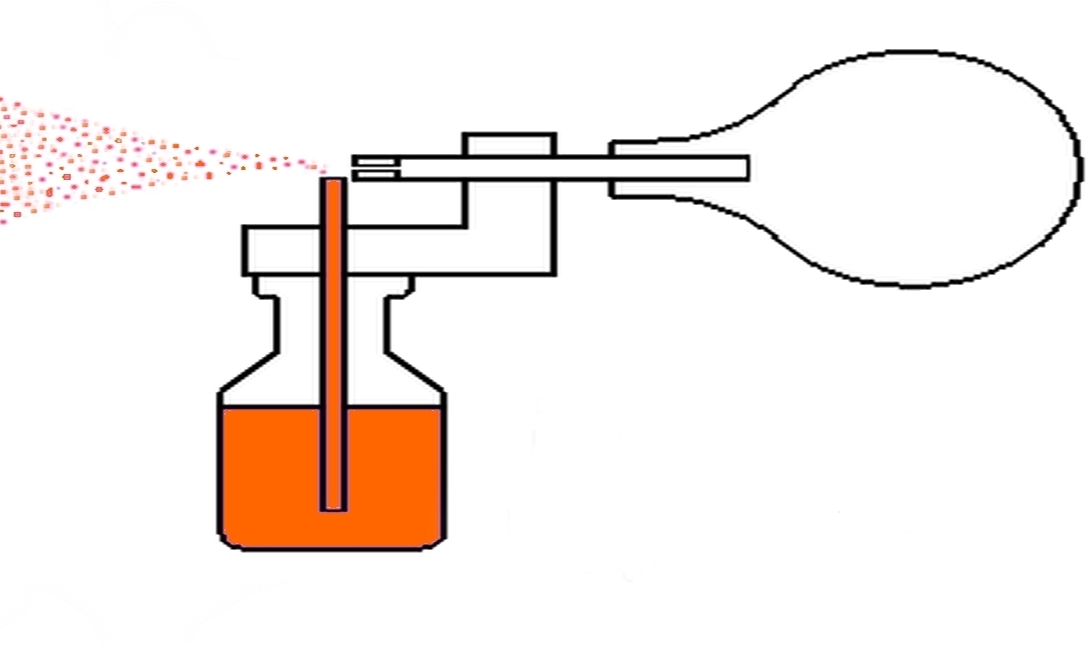

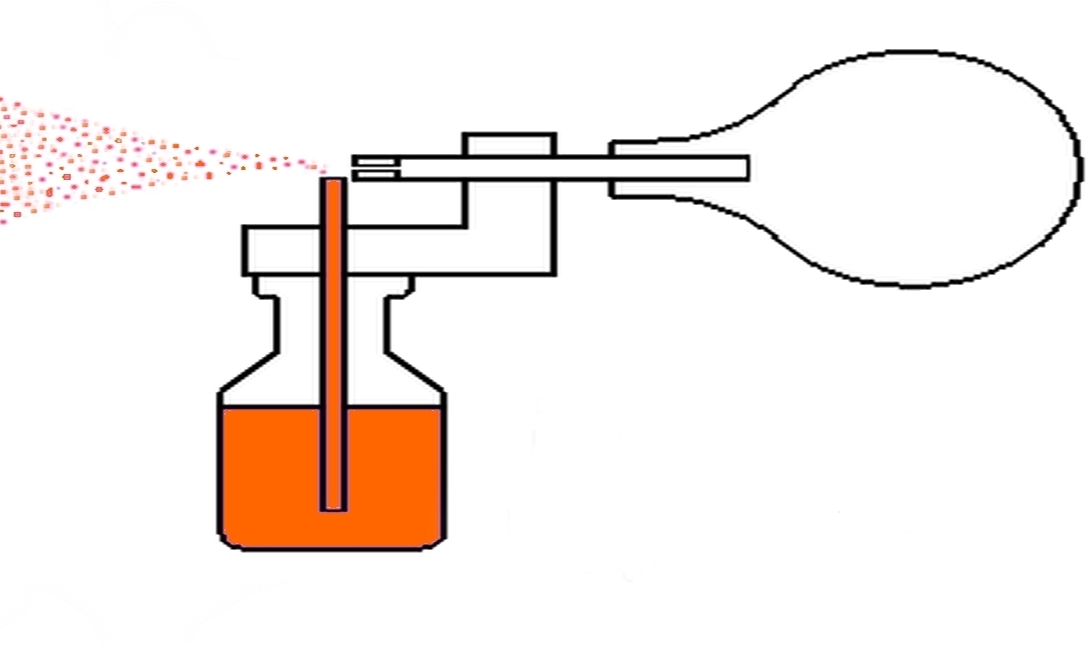

Two-fluid nozzles atomize by causing the interaction of high velocity gas and liquid. Compressed air is most often used as the atomizing gas, but sometimes steam or other gases are used. The many varied designs of two-fluid nozzles can be grouped into internal mix or external mix depending on the mixing point of the gas and liquid streams relative to the nozzle face.Internal-mix two-fluid

Internal mix nozzles contact fluids inside the nozzle; one configuration is shown in the figure above. Shearing between high velocity gas and low velocity liquid disintegrates the liquid stream into droplets, producing a high velocity spray. This type of nozzle tends to use less atomizing gas than an external mix atomizer and is better suited to higher viscosity streams. Many compound internal-mix nozzles are commercially used; e.g., for fuel oil atomization.External-mix two-fluid

External mix nozzles contacts fluids outside the nozzle as shown in the schematic diagram. This type of spray nozzle may require more atomizing air and a higher atomizing air pressure drop because the mixing and atomization of liquid takes place outside the nozzle. The liquid pressure drop is lower for this type of nozzle, sometimes drawing liquid into the nozzle due to the suction caused by the atomizing air nozzles (siphon nozzle). If the liquid to be atomized contains solids an external mix atomizer may be preferred. This spray may be shaped to produce different spray patterns. A flat pattern is formed with additional air ports to flatten or reshape the circular spray cross-section discharge.Control of two-fluid

Many applications use two-fluid nozzles to achieve a controlled small drop size over a range of operation. Each nozzle has a performance curve, and the liquid and gas flow rates determine the drop size. Excessive drop size can lead to catastrophic equipment failure or may have an adverse effect on the process or product. For example, the gas conditioning tower in a cement plant often utilizes evaporative cooling caused by water atomized by two-fluid nozzles into the dust laden gas. If drops do not completely evaporate and strike a vessel wall dust will accumulate, resulting in the potential for flow restriction in the outlet duct, disrupting the plant operation.Rotary atomizers

Rotary atomizers use a high speed rotating disk, cup or wheel to discharge liquid at high speed to the perimeter, forming a hollow cone spray. The rotational speed controls the drop size. Spray drying and spray painting are the most important and common uses of this technology. They can also be automatic.Ultrasonic atomizers

This type of spray nozzle utilizes high frequency (20–180 kHz) vibration to produce narrow drop-size distribution and low velocity spray from a liquid. The vibration of a piezoelectric crystal causes capillary waves on the nozzle surface liquid film. An Ultrasonic nozzle can be key to high transfer efficiency and process stability as they are very hard to clog. They are particularly useful in medical device coatings for their reliability.Electrostatic

Electrostatic charging of sprays is very useful for high transfer efficiency. Examples are the industrial spraying of coatings (paint) and applying lubricant oils. The charging is at high voltage (20–40 kV) but low current.Performance factors

Liquid properties

Almost all drop size data supplied by nozzle manufacturers are based on spraying water under laboratory conditions, . The effect of liquid properties should be understood and accounted for when selecting a nozzle for a process that is drop size sensitive.Temperature

Liquid temperature changes do not directly affect nozzle performance, but can affect viscosity, surface tension, and specific gravity, which can then influence spray nozzle performance.Specific gravity

Specific gravity

Relative density, or specific gravity, is the ratio of the density (mass of a unit volume) of a substance to the density of a given reference material. Specific gravity for liquids is nearly always measured with respect to water at its dens ...

is the ratio of the mass of a given volume of liquid to the mass of the same volume of water. In spraying, the main effect of the specific gravity Sg of a liquid other than water is on the capacity of the spray nozzle. All vendor-supplied performance data for nozzles are based on spraying water. To determine the volumetric flowrate Q, of a liquid other than water the following equation should be used.

:

Viscosity

Dynamicviscosity

The viscosity of a fluid is a measure of its resistance to deformation at a given rate. For liquids, it corresponds to the informal concept of "thickness": for example, syrup has a higher viscosity than water.

Viscosity quantifies the int ...

is defined as the property of a liquid that resists change in the shape or arrangement of its elements during flow. Liquid viscosity primarily affects spray pattern formation and drop size. Liquids with a high viscosity require a higher minimum pressure to begin spray pattern formation and yield narrower spray angles compared to water.

Surface tension

Thesurface tension

Surface tension is the tendency of liquid surfaces at rest to shrink into the minimum surface area possible. Surface tension is what allows objects with a higher density than water such as razor blades and insects (e.g. water striders) t ...

of a liquid tends to assume the smallest possible size, acting as a membrane under tension. Any portion of the liquid surface exerts a tension upon adjacent portions or upon other objects that it contacts. This force is in the plane of the surface, and its amount per unit of length is surface tension. The value for water is about at . The main effects of surface tension are on minimum operating pressure, spray angle, and drop size. Surface tension is more apparent at low operating pressures. A higher surface tension reduces the spray angle, particularly on hollow cone nozzles. Low surface tensions can allow nozzles to be operated at lower pressures.

Nozzle wear

Nozzle wear is indicated by an increase in nozzle capacity and by a change in the spray pattern, in which the distribution (uniformity of spray pattern) deteriorates and increases drop size. Choice of a wear-resistant material of construction increases nozzle life. Because many single fluid nozzles are used to meter flows, worn nozzles result in excessive liquid usage.Material of construction

The material of construction is selected based on the fluid properties of the liquid that is to be sprayed and the environment surrounding the nozzle. Spray nozzles are most commonly fabricated from metals, such asbrass

Brass is an alloy of copper (Cu) and zinc (Zn), in proportions which can be varied to achieve different mechanical, electrical, and chemical properties. It is a substitutional alloy: atoms of the two constituents may replace each other wi ...

, Stainless steel

Stainless steel is an alloy of iron that is resistant to rusting and corrosion. It contains at least 11% chromium and may contain elements such as carbon, other nonmetals and metals to obtain other desired properties. Stainless steel's r ...

, and nickel alloys

This is a list of named alloys grouped alphabetically by base metal. Within these headings, the alloys are also grouped alphabetically. Some of the main alloying elements are optionally listed after the alloy names.

Alloys by base metal

Alumini ...

, but plastics such as PTFE

Polytetrafluoroethylene (PTFE) is a synthetic fluoropolymer of tetrafluoroethylene that has numerous applications. It is one of the best-known and widely applied PFAS. The commonly known brand name of PTFE-based composition is Teflon by Chem ...

and PVC and ceramics ( alumina and silicon carbide

Silicon carbide (SiC), also known as carborundum (), is a hard chemical compound containing silicon and carbon. A semiconductor, it occurs in nature as the extremely rare mineral moissanite, but has been mass-produced as a powder and crystal s ...

) are also used. Several factors must be considered, including erosive wear, chemical attack, and the effects of high temperature.

Applications

Automotive coating: automotive coating demands droplet from size uniformly deposited on substrate. Applications of spray technology are more pronounced during the course of base and clear coatings process which are encompassed as the last stages in automotive coating. Among others rotary bells mounted on robots and hvlp (high volume, low pressure) sprayers are widely used to paint car bodywork during manufacture.See also

*Aerosol spray

Aerosol spray is a type of dispensing system which creates an aerosol mist of liquid particles. It comprises a can or bottle that contains a payload, and a propellant under pressure. When the container's valve is opened, the payload is forced out ...

* Flit gun

* Dehumidifier

A dehumidifier is an air conditioning device which reduces and maintains the level of humidity in the air. This is done usually for health or thermal comfort reasons, or to eliminate musty odor and to prevent the growth of mildew by extractin ...

* Humidifier

* Nozzle

A nozzle is a device designed to control the direction or characteristics of a fluid flow (specially to increase velocity) as it exits (or enters) an enclosed chamber or pipe.

A nozzle is often a pipe or tube of varying cross sectional area, ...

* Nebulizer

In medicine, a nebulizer (American English) or nebuliser (British English) is a drug delivery device used to administer medication in the form of a mist inhaled into the lungs. Nebulizers are commonly used for the treatment of asthma, cystic fibro ...

* Pesticide application

* Institute for Liquid Atomization and Spray Systems (ILASS)

* Spray bottle

A spray bottle is a bottle that can squirt, spray or mist fluids.

History

While spray bottles existed long before the middle of the 20th century, they used a rubber bulb which was squeezed to produce the spray; the quickly-moving air siphone ...

References

External links

Experiment of The Month , Millersville University

{{DEFAULTSORT:Spray Nozzle Nozzles Articles containing video clips