Slip factor on:

[Wikipedia]

[Google]

[Amazon]

In

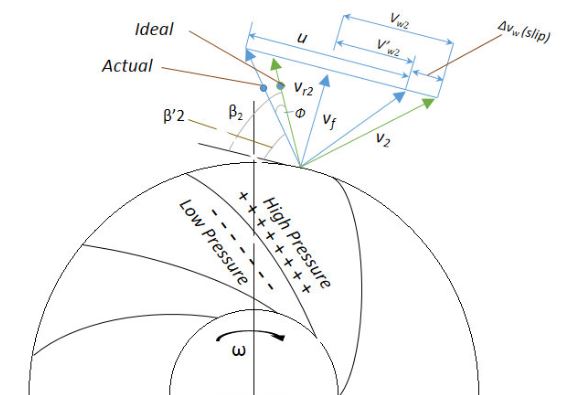

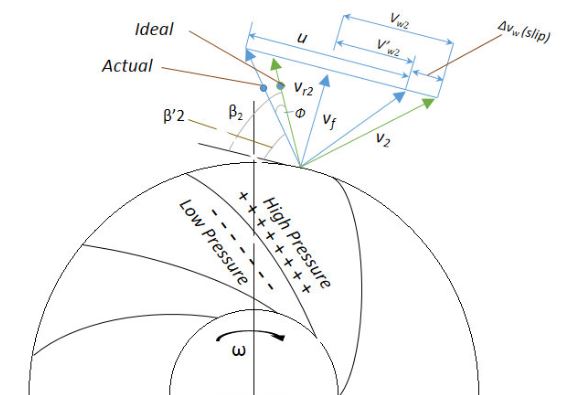

Mathematically, the Slip factor denoted by 'σ' is defined as the ratio of the actual & ideal values of the whirl velocity components at the exit of the impeller. The ideal values can be calculated using an analytical approach while the actual values should be observed experimentally.

:

where,

:V'w2 : Actual Whirl Velocity Component ,

:Vw2 : Ideal Whirl Velocity Component

Usually,σ varies from 0-1 with an average ranging from 0.8-0.9.

The Slip Velocity is given as:

VS = Vw2 - V'w2 = Vw2(1-σ)

The Whirl Velocity is given as:

V'w2 = σ Vw2

Mathematically, the Slip factor denoted by 'σ' is defined as the ratio of the actual & ideal values of the whirl velocity components at the exit of the impeller. The ideal values can be calculated using an analytical approach while the actual values should be observed experimentally.

:

where,

:V'w2 : Actual Whirl Velocity Component ,

:Vw2 : Ideal Whirl Velocity Component

Usually,σ varies from 0-1 with an average ranging from 0.8-0.9.

The Slip Velocity is given as:

VS = Vw2 - V'w2 = Vw2(1-σ)

The Whirl Velocity is given as:

V'w2 = σ Vw2

Slip Factor being a function of mass flow rate because of back eddy

Fluid Machine - FKM

Analysis and Validation of a Unified Slip Factor Model for Impellers at Design and off-Design Conditions

# ttp://nptel.iitm.ac.in/courses/Webcourse-contents/IIT-KANPUR/machine/ui/Course_home-8.htm Fluid Machinery - NPTEL

Experimental and Analytical Investigations of Slip Factor In Radial Tipped Centrifugal Fan

Gas compressors Pumps

turbomachinery

Turbomachinery, in mechanical engineering, describes machines that transfer energy between a rotor and a fluid, including both turbines and compressors. While a turbine transfers energy from a fluid to a rotor, a compressor transfers energy from ...

, the slip factor is a measure of the fluid slip in the impeller

An impeller or impellor is a rotor used to increase the pressure and flow of a fluid. It is the opposite of a turbine, which extracts energy from, and reduces the pressure of, a flowing fluid.

In pumps

An impeller is a rotating componen ...

of a compressor or a turbine, mostly a centrifugal machine. Fluid slip is the deviation in the angle at which the fluid leaves the impeller from the impeller's blade/vane angle. Being quite small in axial impellers (inlet and outlet flow in the same direction), slip is a very important phenomenon in radial impellers and is useful in determining the accurate estimation of work input or the energy transfer

In physics, energy (from Ancient Greek: ἐνέργεια, ''enérgeia'', “activity”) is the quantitative property that is transferred to a body or to a physical system, recognizable in the performance of work and in the form of heat ...

between the impeller and the fluid, rise in pressure and the velocity triangle In turbomachinery, a velocity triangle or a velocity diagram is a triangle representing the various components of velocities of the working fluid in a turbomachine. Velocity triangles may be drawn for both the inlet and outlet sections of any turbo ...

s at the impeller exit.

A simple explanation for the fluid slip can be given as: Consider an impeller with ''z'' number of blades rotating at angular velocity ω. A difference in pressure and velocity during the course of clockwise flow through the impeller passage can be observed between the trailing and leading faces of the impeller blades. High pressure and low velocity are observed at the leading face of the impeller's blade as compared to lower pressure with high velocity at the trailing face of the blade. This results in circulation in the direction of ω around the impeller blade which prevents the air from acquiring the whirl velocity equivalent to impeller speed with non-uniform velocity distribution at any radius.

This phenomenon reduces the output whirl velocity

Velocity is the directional speed of an object in motion as an indication of its rate of change in position as observed from a particular frame of reference and as measured by a particular standard of time (e.g. northbound). Velocity i ...

, which is a measure of the net power output from a turbine or a compressor. Hence, the slip factor accommodates for a slip loss which affects the net power developed which increases with increasing flow-rate.

Factors accounting for slip factor

* Relativeeddy

Eddie or Eddy may refer to:

Science and technology

*Eddy (fluid dynamics), the swirling of a fluid and the reverse current created when the fluid flows past an obstacle

* Eddie (text editor), a text editor originally for BeOS and now ported to Lin ...

.

* Back eddy.

* Impeller design or geometry

# Mean blade loading.

# Thickness of blade.

# Finite number of blades.

* Fluid entry conditions.

* Working fluid's viscosity

The viscosity of a fluid is a measure of its resistance to deformation at a given rate. For liquids, it corresponds to the informal concept of "thickness": for example, syrup has a higher viscosity than water.

Viscosity quantifies the inte ...

.

* Effect of boundary layer

In physics and fluid mechanics, a boundary layer is the thin layer of fluid in the immediate vicinity of a bounding surface formed by the fluid flowing along the surface. The fluid's interaction with the wall induces a no-slip boundary cond ...

growth.

* Flow separation.

* Friction forces on the walls of flow packages.

* Boundary layer blockage.

Mathematical Formulae for Slip factor

Mathematically, the Slip factor denoted by 'σ' is defined as the ratio of the actual & ideal values of the whirl velocity components at the exit of the impeller. The ideal values can be calculated using an analytical approach while the actual values should be observed experimentally.

:

where,

:V'w2 : Actual Whirl Velocity Component ,

:Vw2 : Ideal Whirl Velocity Component

Usually,σ varies from 0-1 with an average ranging from 0.8-0.9.

The Slip Velocity is given as:

VS = Vw2 - V'w2 = Vw2(1-σ)

The Whirl Velocity is given as:

V'w2 = σ Vw2

Mathematically, the Slip factor denoted by 'σ' is defined as the ratio of the actual & ideal values of the whirl velocity components at the exit of the impeller. The ideal values can be calculated using an analytical approach while the actual values should be observed experimentally.

:

where,

:V'w2 : Actual Whirl Velocity Component ,

:Vw2 : Ideal Whirl Velocity Component

Usually,σ varies from 0-1 with an average ranging from 0.8-0.9.

The Slip Velocity is given as:

VS = Vw2 - V'w2 = Vw2(1-σ)

The Whirl Velocity is given as:

V'w2 = σ Vw2

Slip Factor correlations

* Stodola's Equation: According to Stodola, it is the relative eddy that fills the entire exit session of the impeller passage. For a given flow geometry, the slip factor increases with the increase in the number of impeller blades, thus, accounts for one of the important parameter for losses. : :where, z = number of blades and S.L. Dixon (1978), Fluid Mechanics, Thermodynamics of Turbomachinery. Pergamon Press, Third Edition. :For Radial tip, β2 = 900 ∴ : Theoretically, In order to get the perfect ideal flow guidance, one can infinitesimally increase the number of thin vanes so that the flow should leave the impeller at an exact vane angle. : However, later experiments proved that beyond a particular value, a further increase in number of blades results in reduction of slip factor due to increase in blockage area. * Stanitz's Equation: Stanitz found the slip velocity does not depend upon the blade exit angle and hence, gave the following equation. : :where, z = number of blades, :β2 varies from 450 to 900. :For radial tip: β2 = 900 ∴ * Balje's formula: An approximate formula given by Balje for radial-tipped (β2=900) blade impellers: : :where, z = number of blades , n = The above explained models clearly states that the Slip factor is solely a function of geometry of Impeller. However, later studies proved that Slip factor depends on other factors as well namely 'mass flow rate',viscosity etc..See also

* * *Notes

* It is found that the downfall in blade angle towards the impeller exit results in increment of slip factor with increasing flow rate and vice versa.Slip Factor being a function of mass flow rate because of back eddy

References

#Flow simulation in radial pump impellers and evaluation of slip factor (July, 2015), http://pia.sagepub.com/content/early/2015/07/08/0957650915594953.full.pdf?ijkey=pW8QmRIKoDzyXzO&keytype=finite. # Seppo A. Korpela (2011), Principles of Turbomachinery. John Wiley & Sons, Inc. . # S.L. Dixon (1998), Fluid Mechanics And Thermodynamics of Turbomachinery. Elsevier Butterworth-Heinemann, Inc. . # Rama Gorla, Aijaz Khan, Turbomachinery:Design and Theory. Marcel Dekker, Inc. {{ISBN, 0-8247-0980-2.Fluid Machine - FKM

Analysis and Validation of a Unified Slip Factor Model for Impellers at Design and off-Design Conditions

# ttp://nptel.iitm.ac.in/courses/Webcourse-contents/IIT-KANPUR/machine/ui/Course_home-8.htm Fluid Machinery - NPTEL

Experimental and Analytical Investigations of Slip Factor In Radial Tipped Centrifugal Fan

Gas compressors Pumps