Slag2 on:

[Wikipedia]

[Google]

[Amazon]

The general term slag may be a

The general term slag may be a  Due to the large demand for ferrous, ferralloy, and non-ferrous materials, slag production has increased throughout the years despite recycling (most notably in the iron and

Due to the large demand for ferrous, ferralloy, and non-ferrous materials, slag production has increased throughout the years despite recycling (most notably in the iron and

In nature, iron, copper, lead,

In nature, iron, copper, lead,

There are three types of slag:

There are three types of slag:

Based on a case study at the Hopewell National Historical Site in Berks and

Based on a case study at the Hopewell National Historical Site in Berks and

Slags are transported along with slag tailings to "slag dumps", where they are exposed to weathering, with the possibility of leaching of toxic elements and hyperalkaline runoffs into the soil and water, endangering the local ecological communities. Leaching concerns are typically around non-ferrous or base metal slags, which tend to have higher concentrations of toxic elements. However, ferrous and ferroalloy slags may also have them, which raises concerns about highly weathered slag dumps and upcycled materials.

Dissolution of slags can produce highly

Slags are transported along with slag tailings to "slag dumps", where they are exposed to weathering, with the possibility of leaching of toxic elements and hyperalkaline runoffs into the soil and water, endangering the local ecological communities. Leaching concerns are typically around non-ferrous or base metal slags, which tend to have higher concentrations of toxic elements. However, ferrous and ferroalloy slags may also have them, which raises concerns about highly weathered slag dumps and upcycled materials.

Dissolution of slags can produce highly

Types of Slag

Electric Arc Furnace (EAF) Slag

US EPA {{Authority control Amorphous solids Materials with minor glass phase Steelmaking Smelting Metallurgical by-products Articles containing video clips

The general term slag may be a

The general term slag may be a by-product

A by-product or byproduct is a secondary product derived from a production process, manufacturing process or chemical reaction; it is not the primary product or service being produced.

A by-product can be useful and marketable or it can be cons ...

or co-product of smelting

Smelting is a process of applying heat and a chemical reducing agent to an ore to extract a desired base metal product. It is a form of extractive metallurgy that is used to obtain many metals such as iron-making, iron, copper extraction, copper ...

(pyrometallurgical

Pyrometallurgy is a branch of extractive metallurgy. It consists of the thermal treatment of minerals and metallurgical ores and concentrates to bring about physical and chemical transformations in the materials to enable recovery of valuable ...

) ore

Ore is natural rock or sediment that contains one or more valuable minerals, typically including metals, concentrated above background levels, and that is economically viable to mine and process. The grade of ore refers to the concentration ...

s and recycled metals depending on the type of material being produced. Slag is mainly a mixture of metal oxide

An oxide () is a chemical compound containing at least one oxygen atom and one other element in its chemical formula. "Oxide" itself is the dianion (anion bearing a net charge of −2) of oxygen, an O2− ion with oxygen in the oxidation st ...

s and silicon dioxide

Silicon dioxide, also known as silica, is an oxide of silicon with the chemical formula , commonly found in nature as quartz. In many parts of the world, silica is the major constituent of sand. Silica is one of the most complex and abundan ...

. Broadly, it can be classified as ferrous

In chemistry, iron(II) refers to the chemical element, element iron in its +2 oxidation number, oxidation state. The adjective ''ferrous'' or the prefix ''ferro-'' is often used to specify such compounds, as in ''ferrous chloride'' for iron(II ...

(co-products of processing iron and steel), ferroalloy

Ferroalloy refers to various alloys of iron with a high proportion of one or more other elements such as manganese (Mn), aluminium (Al), or silicon (Si). They are used in the production of steels and alloys. The alloys impart distinctive qualitie ...

(a by-product of ferroalloy production) or non-ferrous/base metal

A base metal is a common and inexpensive metal, as opposed to a precious metal such as gold or silver. In numismatics, coins often derived their value from the precious metal content; however, base metals have also been used in coins in the past ...

s (by-products of recovering non-ferrous materials like copper

Copper is a chemical element; it has symbol Cu (from Latin ) and atomic number 29. It is a soft, malleable, and ductile metal with very high thermal and electrical conductivity. A freshly exposed surface of pure copper has a pinkish-orang ...

, nickel

Nickel is a chemical element; it has symbol Ni and atomic number 28. It is a silvery-white lustrous metal with a slight golden tinge. Nickel is a hard and ductile transition metal. Pure nickel is chemically reactive, but large pieces are slo ...

, zinc

Zinc is a chemical element; it has symbol Zn and atomic number 30. It is a slightly brittle metal at room temperature and has a shiny-greyish appearance when oxidation is removed. It is the first element in group 12 (IIB) of the periodic tabl ...

and phosphorus

Phosphorus is a chemical element; it has Chemical symbol, symbol P and atomic number 15. All elemental forms of phosphorus are highly Reactivity (chemistry), reactive and are therefore never found in nature. They can nevertheless be prepared ar ...

). Within these general categories, slags can be further categorized by their precursor and processing conditions (e.g., blast furnace

A blast furnace is a type of metallurgical furnace used for smelting to produce industrial metals, generally pig iron, but also others such as lead or copper. ''Blast'' refers to the combustion air being supplied above atmospheric pressure.

In a ...

slags, air-cooled blast furnace slag, granulated blast furnace slag, basic oxygen furnace

Basic oxygen steelmaking (BOS, BOP, BOF, or OSM), also known as Linz-Donawitz steelmaking or the oxygen converter process,Brock and Elzinga, p. 50. is a method of primary steelmaking in which carbon-rich molten pig iron is made into steel. Blowi ...

slag, and electric arc furnace

An electric arc furnace (EAF) is a Industrial furnace, furnace that heats material by means of an electric arc.

Industrial arc furnaces range in size from small units of approximately one-tonne capacity (used in foundry, foundries for producin ...

slag). Slag generated from the EAF process can contain toxic metals, which can be hazardous to human and environmental health.

Due to the large demand for ferrous, ferralloy, and non-ferrous materials, slag production has increased throughout the years despite recycling (most notably in the iron and

Due to the large demand for ferrous, ferralloy, and non-ferrous materials, slag production has increased throughout the years despite recycling (most notably in the iron and steelmaking

Steelmaking is the process of producing steel from iron ore and/or scrap. Steel has been made for millennia, and was commercialized on a massive scale in the 1850s and 1860s, using the Bessemer process, Bessemer and open hearth furnace, Siemens-M ...

industries) and upcycling

Upcycling, also known as creative reuse, is the process of transforming by-products, waste materials, useless, or unwanted products into new materials or products perceived to be of greater quality, such as artistic value or environmental value ...

efforts. The World Steel Association

World Steel Association, abbreviated as worldsteel, is the international industry association for the iron and steel sector. The association is one of the largest and most dynamic industry associations in the world, with members in every major s ...

(WSA) estimates that 600 kg of co-materials (co-products and by-products)(about 90 wt%

In chemistry, the mass fraction of a substance within a mixture is the ratio w_i (alternatively denoted Y_i) of the mass m_i of that substance to the total mass m_\text of the mixture. Expressed as a formula, the mass fraction is:

: w_i = \frac ...

is slags) are generated per tonne

The tonne ( or ; symbol: t) is a unit of mass equal to 1,000 kilograms. It is a non-SI unit accepted for use with SI. It is also referred to as a metric ton in the United States to distinguish it from the non-metric units of the s ...

of steel produced.

Composition

Slag is usually a mixture of metaloxide

An oxide () is a chemical compound containing at least one oxygen atom and one other element in its chemical formula. "Oxide" itself is the dianion (anion bearing a net charge of −2) of oxygen, an O2− ion with oxygen in the oxidation st ...

s and silicon dioxide

Silicon dioxide, also known as silica, is an oxide of silicon with the chemical formula , commonly found in nature as quartz. In many parts of the world, silica is the major constituent of sand. Silica is one of the most complex and abundan ...

. However, slags can contain metal sulfide

Sulfide (also sulphide in British English) is an inorganic anion of sulfur with the chemical formula S2− or a compound containing one or more S2− ions. Solutions of sulfide salts are corrosive. ''Sulfide'' also refers to large families o ...

s and elemental metals. It is important to note, the oxide form may or may not be present once the molten slag solidifies and forms amorphous and crystalline components.

The major components of these slags include the oxides of calcium

Calcium is a chemical element; it has symbol Ca and atomic number 20. As an alkaline earth metal, calcium is a reactive metal that forms a dark oxide-nitride layer when exposed to air. Its physical and chemical properties are most similar to it ...

, magnesium

Magnesium is a chemical element; it has Symbol (chemistry), symbol Mg and atomic number 12. It is a shiny gray metal having a low density, low melting point and high chemical reactivity. Like the other alkaline earth metals (group 2 ...

, silicon

Silicon is a chemical element; it has symbol Si and atomic number 14. It is a hard, brittle crystalline solid with a blue-grey metallic lustre, and is a tetravalent metalloid (sometimes considered a non-metal) and semiconductor. It is a membe ...

, iron, and aluminium, with lesser amounts of manganese

Manganese is a chemical element; it has Symbol (chemistry), symbol Mn and atomic number 25. It is a hard, brittle, silvery metal, often found in minerals in combination with iron. Manganese was first isolated in the 1770s. It is a transition m ...

, phosphorus

Phosphorus is a chemical element; it has Chemical symbol, symbol P and atomic number 15. All elemental forms of phosphorus are highly Reactivity (chemistry), reactive and are therefore never found in nature. They can nevertheless be prepared ar ...

, and others depending on the specifics of the raw materials used. Furthermore, slag can be classified based on the abundance of iron among other major components.

Ore smelting

In nature, iron, copper, lead,

In nature, iron, copper, lead, nickel

Nickel is a chemical element; it has symbol Ni and atomic number 28. It is a silvery-white lustrous metal with a slight golden tinge. Nickel is a hard and ductile transition metal. Pure nickel is chemically reactive, but large pieces are slo ...

, and other metals are found in impure states called ores

Ore is natural Rock (geology), rock or sediment that contains one or more valuable minerals, typically including metals, concentrated above background levels, and that is economically viable to mine and process. The grade of ore refers to the ...

, often oxidized

Redox ( , , reduction–oxidation or oxidation–reduction) is a type of chemical reaction in which the oxidation states of the reactants change. Oxidation is the loss of electrons or an increase in the oxidation state, while reduction is ...

and mixed in with silicate

A silicate is any member of a family of polyatomic anions consisting of silicon and oxygen, usually with the general formula , where . The family includes orthosilicate (), metasilicate (), and pyrosilicate (, ). The name is also used ...

s of other metals. During smelting, when the ore is exposed to high temperatures, these impurities are separated from the molten metal and can be removed. Slag is the collection of compounds that are removed. In many smelting processes, oxides are introduced to control the slag chemistry, assisting in the removal of impurities and protecting the furnace refractory

In materials science, a refractory (or refractory material) is a material that is resistant to decomposition by heat or chemical attack and that retains its strength and rigidity at high temperatures. They are inorganic, non-metallic compound ...

lining from excessive wear. In this case, the slag is termed ''synthetic''. A good example is steelmaking slag: quicklime

Calcium oxide (formula: Ca O), commonly known as quicklime or burnt lime, is a widely used chemical compound. It is a white, caustic, alkaline, crystalline solid at room temperature. The broadly used term '' lime'' connotes calcium-containin ...

(CaO) and magnesite

Magnesite is a mineral with the chemical formula ( magnesium carbonate). Iron, manganese, cobalt, and nickel may occur as admixtures, but only in small amounts.

Occurrence

Magnesite occurs as veins in and an alteration product of ultramafic r ...

(MgCO3) are introduced for refractory protection, neutralizing the alumina

Aluminium oxide (or aluminium(III) oxide) is a chemical compound of aluminium and oxygen with the chemical formula . It is the most commonly occurring of several aluminium oxides, and specifically identified as aluminium oxide. It is commonly ...

and silica

Silicon dioxide, also known as silica, is an oxide of silicon with the chemical formula , commonly found in nature as quartz. In many parts of the world, silica is the major constituent of sand. Silica is one of the most complex and abundant f ...

separated from the metal, and assisting in the removal of sulfur and phosphorus from the steel.

As a co-product of steelmaking

Steelmaking is the process of producing steel from iron ore and/or scrap. Steel has been made for millennia, and was commercialized on a massive scale in the 1850s and 1860s, using the Bessemer process, Bessemer and open hearth furnace, Siemens-M ...

, slag is typically produced either through the blast furnace

A blast furnace is a type of metallurgical furnace used for smelting to produce industrial metals, generally pig iron, but also others such as lead or copper. ''Blast'' refers to the combustion air being supplied above atmospheric pressure.

In a ...

– oxygen converter route or the electric arc furnace

An electric arc furnace (EAF) is a Industrial furnace, furnace that heats material by means of an electric arc.

Industrial arc furnaces range in size from small units of approximately one-tonne capacity (used in foundry, foundries for producin ...

– ladle furnace route. To flux the silica produced during steelmaking, limestone

Limestone is a type of carbonate rock, carbonate sedimentary rock which is the main source of the material Lime (material), lime. It is composed mostly of the minerals calcite and aragonite, which are different Polymorphism (materials science) ...

and/or dolomite are added, as well as other types of slag conditioners such as calcium aluminate or fluorspar

Fluorite (also called fluorspar) is the mineral form of calcium fluoride, CaF2. It belongs to the halide minerals. It crystallizes in isometric cubic habit, although octahedral and more complex isometric forms are not uncommon.

The Mohs scal ...

.

Classifications

There are three types of slag:

There are three types of slag: ferrous

In chemistry, iron(II) refers to the chemical element, element iron in its +2 oxidation number, oxidation state. The adjective ''ferrous'' or the prefix ''ferro-'' is often used to specify such compounds, as in ''ferrous chloride'' for iron(II ...

, ferroalloy

Ferroalloy refers to various alloys of iron with a high proportion of one or more other elements such as manganese (Mn), aluminium (Al), or silicon (Si). They are used in the production of steels and alloys. The alloys impart distinctive qualitie ...

, non-ferrous slags, which are produced through different smelting processes.

Ferrous slag

Ferrous slags are produced in different stages of the iron and steelmaking processes resulting in varying physiochemical properties. Additionally, the rate of cooling of the slag material affects its degree ofcrystallinity

Crystallinity refers to the degree of structural order in a solid. In a crystal, the atoms or molecules are arranged in a regular, periodic manner. The degree of crystallinity has a large influence on hardness, density, transparency and diffusi ...

further diversifying its range of properties. For example, slow cooled blast furnace slags (or air-cooled slags) tend to have more crystalline phases than quenched blast furnace slags ( ground granulated blast furnace slags) making it denser and better suited as an aggregate. It may also have higher free calcium oxide

Calcium oxide (formula: Ca O), commonly known as quicklime or burnt lime, is a widely used chemical compound. It is a white, caustic, alkaline, crystalline solid at room temperature. The broadly used term '' lime'' connotes calcium-containing ...

and magnesium oxide content, which are often converted to its hydrated forms if excessive volume expansions are not desired. On the other hand, water quenched blast furnace slags have greater amorphous

In condensed matter physics and materials science, an amorphous solid (or non-crystalline solid) is a solid that lacks the long-range order that is a characteristic of a crystal. The terms "glass" and "glassy solid" are sometimes used synonymousl ...

phases giving it latent hydraulic properties (as discovered by Emil Langen in 1862) similar to Portland cement

Portland cement is the most common type of cement in general use around the world as a basic ingredient of concrete, mortar (masonry), mortar, stucco, and non-specialty grout. It was developed from other types of hydraulic lime in England in th ...

.

During the process of smelting iron, ferrous slag is created, but dominated by calcium and silicon compositions. Through this process, ferrous slag can be broken down into blast furnace slag (produced from iron oxides of molten iron), then steel slag (forms when steel scrap and molten iron combined). The major phases of ferrous slag contain calcium-rich olivine

The mineral olivine () is a magnesium iron Silicate minerals, silicate with the chemical formula . It is a type of Nesosilicates, nesosilicate or orthosilicate. The primary component of the Earth's upper mantle (Earth), upper mantle, it is a com ...

-group silicates and melilite

Melilite refers to a mineral of the melilite group. Minerals of the group are solid solutions of several endmembers, the most important of which are gehlenite and åkermanite. A generalized formula for common melilite is ( Ca, Na)2( Al, Mg ...

-group silicates.

Slag from steel mill

A steel mill or steelworks is an industrial plant for the manufacture of steel. It may be an integrated steel works carrying out all steps of steelmaking from smelting iron ore to rolled product, but may also be a plant where steel semi-fini ...

s in ferrous smelting is designed to minimize iron loss, which gives out the significant amount of iron, following by oxides of calcium

Calcium is a chemical element; it has symbol Ca and atomic number 20. As an alkaline earth metal, calcium is a reactive metal that forms a dark oxide-nitride layer when exposed to air. Its physical and chemical properties are most similar to it ...

, silicon

Silicon is a chemical element; it has symbol Si and atomic number 14. It is a hard, brittle crystalline solid with a blue-grey metallic lustre, and is a tetravalent metalloid (sometimes considered a non-metal) and semiconductor. It is a membe ...

, magnesium

Magnesium is a chemical element; it has Symbol (chemistry), symbol Mg and atomic number 12. It is a shiny gray metal having a low density, low melting point and high chemical reactivity. Like the other alkaline earth metals (group 2 ...

, and aluminium. As the slag is cooled down by water, several chemical reactions from a temperature of around (such as oxidization) take place within the slag. Based on a case study at the Hopewell National Historical Site in Berks and

Based on a case study at the Hopewell National Historical Site in Berks and Chester

Chester is a cathedral city in Cheshire, England, on the River Dee, Wales, River Dee, close to the England–Wales border. With a built-up area population of 92,760 in 2021, it is the most populous settlement in the borough of Cheshire West an ...

counties, Pennsylvania

Pennsylvania, officially the Commonwealth of Pennsylvania, is a U.S. state, state spanning the Mid-Atlantic (United States), Mid-Atlantic, Northeastern United States, Northeastern, Appalachian, and Great Lakes region, Great Lakes regions o ...

, US, ferrous slag usually contains lower concentration of various types of trace element

__NOTOC__

A trace element is a chemical element of a minute quantity, a trace amount, especially used in referring to a micronutrient, but is also used to refer to minor elements in the composition of a rock, or other chemical substance.

In nutr ...

s than non-ferrous slag. However, some of them, such as arsenic

Arsenic is a chemical element; it has Symbol (chemistry), symbol As and atomic number 33. It is a metalloid and one of the pnictogens, and therefore shares many properties with its group 15 neighbors phosphorus and antimony. Arsenic is not ...

(As), iron, and manganese

Manganese is a chemical element; it has Symbol (chemistry), symbol Mn and atomic number 25. It is a hard, brittle, silvery metal, often found in minerals in combination with iron. Manganese was first isolated in the 1770s. It is a transition m ...

, can accumulate in groundwater

Groundwater is the water present beneath Earth's surface in rock and Pore space in soil, soil pore spaces and in the fractures of stratum, rock formations. About 30 percent of all readily available fresh water in the world is groundwater. A unit ...

and surface water

Surface water is water located on top of land, forming terrestrial (surrounding by land on all sides) waterbodies, and may also be referred to as ''blue water'', opposed to the seawater and waterbodies like the ocean.

The vast majority of surfac ...

to levels that can exceed environmental guidelines.

Non-ferrous slag

Non-ferrous slag is produced from non-ferrous metals of natural ores. Non-ferrous slag can be characterized into copper, lead, andzinc

Zinc is a chemical element; it has symbol Zn and atomic number 30. It is a slightly brittle metal at room temperature and has a shiny-greyish appearance when oxidation is removed. It is the first element in group 12 (IIB) of the periodic tabl ...

slags due to the ores' compositions, and they have more potential to impact the environment negatively than ferrous slag. The smelting of copper, lead and bauxite

Bauxite () is a sedimentary rock with a relatively high aluminium content. It is the world's main source of aluminium and gallium. Bauxite consists mostly of the aluminium minerals gibbsite (), boehmite (γ-AlO(OH)), and diaspore (α-AlO(OH) ...

in non-ferrous smelting, for instance, is designed to remove the iron and silica that often occurs with those ores, and separates them as iron-silicate-based slags.

Copper slag, the waste product of smelting copper ores, was studied in an abandoned Penn Mine in California, US. For six to eight months per year, this region is flooded and becomes a reservoir for drinking water

Drinking water or potable water is water that is safe for ingestion, either when drunk directly in liquid form or consumed indirectly through food preparation. It is often (but not always) supplied through taps, in which case it is also calle ...

and irrigation

Irrigation (also referred to as watering of plants) is the practice of applying controlled amounts of water to land to help grow crops, landscape plants, and lawns. Irrigation has been a key aspect of agriculture for over 5,000 years and has bee ...

. Samples collected from the reservoir showed the higher concentration of cadmium

Cadmium is a chemical element; it has chemical symbol, symbol Cd and atomic number 48. This soft, silvery-white metal is chemically similar to the two other stable metals in group 12 element, group 12, zinc and mercury (element), mercury. Like z ...

(Cd) and lead (Pb) that exceeded regulatory guidelines.

Applications

Slags can serve other purposes, such as assisting in thetemperature control

Temperature control is a process in which change of temperature of a space (and objects collectively there within), or of a substance, is measured or otherwise detected, and the passage of heat energy into or out of the space or substance is ad ...

of the smelting, and minimizing any re-oxidation of the final liquid metal product before the molten metal is removed from the furnace and used to make solid metal. In some smelting processes, such as ilmenite

Ilmenite is a titanium-iron oxide mineral with the idealized formula . It is a weakly magnetic black or steel-gray solid. Ilmenite is the most important ore of titanium and the main source of titanium dioxide, which is used in paints, printi ...

smelting to produce titanium dioxide

Titanium dioxide, also known as titanium(IV) oxide or titania , is the inorganic compound derived from titanium with the chemical formula . When used as a pigment, it is called titanium white, Pigment White 6 (PW6), or Colour Index Internationa ...

, the slag can be the valuable product.

Ancient uses

During theBronze Age

The Bronze Age () was a historical period characterised principally by the use of bronze tools and the development of complex urban societies, as well as the adoption of writing in some areas. The Bronze Age is the middle principal period of ...

of the Mediterranean

The Mediterranean Sea ( ) is a sea connected to the Atlantic Ocean, surrounded by the Mediterranean basin and almost completely enclosed by land: on the east by the Levant in West Asia, on the north by Anatolia in West Asia and Southern ...

area there were a vast number of differential metallurgical processes in use. A slag by-product of such workings was a colorful, glassy material found on the surfaces of slag from ancient copper foundries. It was primarily blue or green and was formerly chipped away and melted down to make glassware products and jewelry. It was also ground into powder to add to glazes for use in ceramics. Some of the earliest such uses for the by-products of slag have been found in ancient Egypt

Egypt ( , ), officially the Arab Republic of Egypt, is a country spanning the Northeast Africa, northeast corner of Africa and Western Asia, southwest corner of Asia via the Sinai Peninsula. It is bordered by the Mediterranean Sea to northe ...

.

Historically, the re-smelting of iron ore slag was common practice, as improved smelting techniques permitted greater iron yields—in some cases exceeding that which was originally achieved. During the early 20th century, iron ore slag was also ground to a powder and used to make agate glass, also known as slag glass.

Modern uses

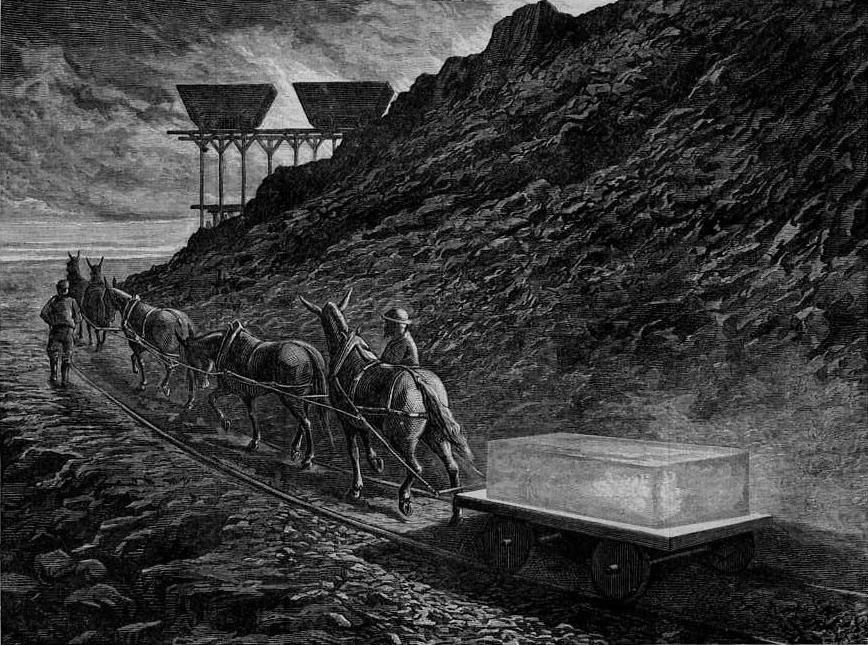

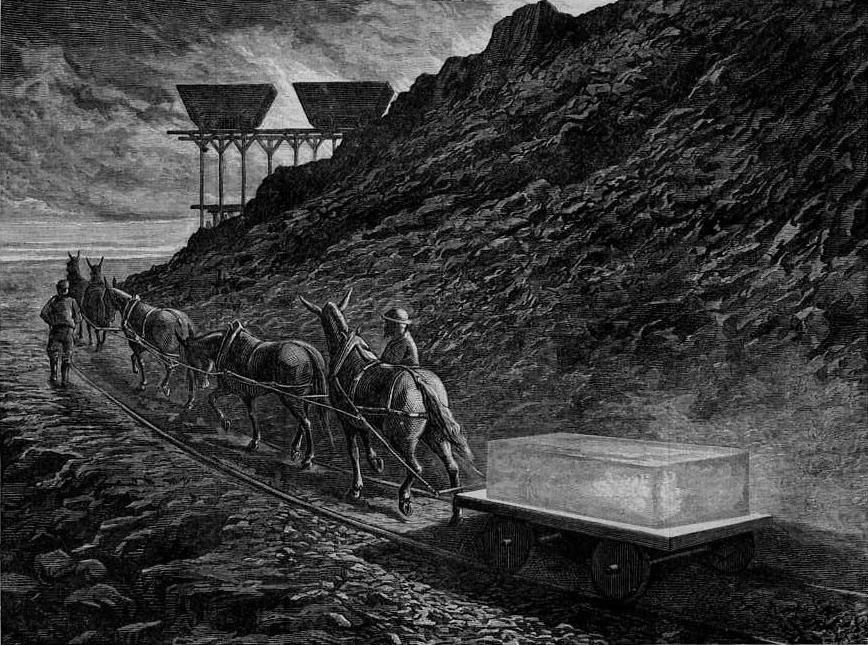

Construction

Use of slags in theconstruction industry

Construction are processes involved in delivering buildings, infrastructure, industrial facilities, and associated activities through to the end of their life. It typically starts with planning, financing, and design that continues until the ...

dates back to the 1800s, where blast furnace slags were used to build roads

A road is a thoroughfare used primarily for movement of traffic. Roads differ from streets, whose primary use is local access. They also differ from stroads, which combine the features of streets and roads. Most modern roads are paved.

The ...

and railroad ballast. During this time, it was also used as an aggregate and had begun being integrated into the cement industry as a geopolymer.

Today, ground granulated blast furnace slags are used in combination with Portland cement

Portland cement is the most common type of cement in general use around the world as a basic ingredient of concrete, mortar (masonry), mortar, stucco, and non-specialty grout. It was developed from other types of hydraulic lime in England in th ...

to create " slag cement". Granulated blast furnace slags react with portlandite (), which is formed during cement hydration, via the pozzolanic reaction

The pozzolanic activity is a measure for the degree of reaction over time or the reaction rate between a pozzolan and Ca2+ or calcium hydroxide (Ca(OH)2) in the presence of water. The rate of the pozzolanic reaction is dependent on the intrinsic ...

to produce cementitious properties that primarily contribute to the later strength gain of concrete. This leads to concrete with reduced permeability and better durability. Careful consideration of the slag type used is required, as the high calcium oxide and magnesium oxide content can lead to excessive volume expansion and cracking in concrete.

These hydraulic properties have also been used for soil stabilization in roads and railroad constructions.

Granulated blast furnace slag is used in the manufacture of high-performance concretes, especially those used in the construction of bridges and coastal features, where its low permeability and greater resistance to chlorides and sulfates can help to reduce corrosive action and deterioration of the structure.

Slag can also be used to create fibers used as an insulation material called '' slag wool''.

Slag is also used as aggregate in asphalt concrete

Asphalt concrete (commonly called asphalt, blacktop, or pavement in North America, and Tarmacadam, tarmac or bitumen macadam in the United Kingdom and the Republic of Ireland) is a composite material commonly used to surface road surface, roads ...

for paving roads. A 2022 study in Finland found that road surfaces containing ferrochrome slag release a highly abrasive dust that has caused car parts to wear at significantly greater than normal rates.

Wastewater treatment and agriculture

Dissolution of slags generate alkalinity that can be used to precipitate out metals, sulfates, and excess nutrients (nitrogen and phosphorus) in wastewater treatment. Similarly, ferrous slags have been used as soil conditioners to re-balancesoil pH

Soil pH is a measure of the acidity or basicity (alkalinity) of a soil. Soil pH is a key characteristic that can be used to make informative analysis both qualitative and quantitatively regarding soil characteristics. pH is defined as the neg ...

and fertilizer

A fertilizer or fertiliser is any material of natural or synthetic origin that is applied to soil or to plant tissues to supply plant nutrients. Fertilizers may be distinct from liming materials or other non-nutrient soil amendments. Man ...

s as sources of calcium and magnesium.

Because of the slowly released phosphate content in phosphorus

Phosphorus is a chemical element; it has Chemical symbol, symbol P and atomic number 15. All elemental forms of phosphorus are highly Reactivity (chemistry), reactive and are therefore never found in nature. They can nevertheless be prepared ar ...

-containing slag, and because of its liming effect, it is valued as fertilizer in gardens and farms in steel making areas. However, the most important application is construction.

Emerging applications

Slags have one of the highest carbonation potential among the industrial alkaline waste due their high calcium oxide and magnesium oxide content, inspiring further studies to test its feasibility in capture and storage ( CCS) methods (e.g., direct aqueous sequestration, dry gas-solid carbonation among others). Across these CCS methods, slags can be transformed into precipitated calcium carbonates to be used in the plastic, and concrete industries and leached for metals to be used in the electronic industries. However, high physical and chemical variability across different types of slags results in performance and yield inconsistencies. Moreover,stoichiometric

Stoichiometry () is the relationships between the masses of reactants and products before, during, and following chemical reactions.

Stoichiometry is based on the law of conservation of mass; the total mass of reactants must equal the total m ...

-based calculation of the carbonation potential can lead to overestimation that can further obfuscate the material's true potential. To this end, some have proposed performing a series of experiments testing the reactivity of a specific slag material (i.e., dissolution) or using the topological constraint theory (TCT) to account for its complex chemical network.

Health and environmental effect

Slags are transported along with slag tailings to "slag dumps", where they are exposed to weathering, with the possibility of leaching of toxic elements and hyperalkaline runoffs into the soil and water, endangering the local ecological communities. Leaching concerns are typically around non-ferrous or base metal slags, which tend to have higher concentrations of toxic elements. However, ferrous and ferroalloy slags may also have them, which raises concerns about highly weathered slag dumps and upcycled materials.

Dissolution of slags can produce highly

Slags are transported along with slag tailings to "slag dumps", where they are exposed to weathering, with the possibility of leaching of toxic elements and hyperalkaline runoffs into the soil and water, endangering the local ecological communities. Leaching concerns are typically around non-ferrous or base metal slags, which tend to have higher concentrations of toxic elements. However, ferrous and ferroalloy slags may also have them, which raises concerns about highly weathered slag dumps and upcycled materials.

Dissolution of slags can produce highly alkaline

In chemistry, an alkali (; from the Arabic word , ) is a basic salt of an alkali metal or an alkaline earth metal. An alkali can also be defined as a base that dissolves in water. A solution of a soluble base has a pH greater than 7.0. The ...

groundwater

Groundwater is the water present beneath Earth's surface in rock and Pore space in soil, soil pore spaces and in the fractures of stratum, rock formations. About 30 percent of all readily available fresh water in the world is groundwater. A unit ...

with pH values above 12. The calcium silicate

Calcium silicate can refer to several silicates of calcium including:

*CaO·SiO2, wollastonite (CaSiO3)

*2CaO·SiO2, larnite (Ca2SiO4)

*3CaO·SiO2, alite or (Ca3SiO5)

*3CaO·2SiO2, (Ca3Si2O7).

This article focuses on Ca2SiO4, also known as calci ...

s (CaSiO4) in slags react with water to produce calcium hydroxide

Calcium hydroxide (traditionally called slaked lime) is an inorganic compound with the chemical formula Ca( OH)2. It is a colorless crystal or white powder and is produced when quicklime ( calcium oxide) is mixed with water. Annually, approxim ...

ions that leads to a higher concentration of hydroxide

Hydroxide is a diatomic anion with chemical formula OH−. It consists of an oxygen and hydrogen atom held together by a single covalent bond, and carries a negative electric charge. It is an important but usually minor constituent of water. It ...

(OH-) in ground water

Groundwater is the water present beneath Earth's surface in rock and soil pore spaces and in the fractures of rock formations. About 30 percent of all readily available fresh water in the world is groundwater. A unit of rock or an unconsolidat ...

. This alkalinity

Alkalinity (from ) is the capacity of water to resist Freshwater acidification, acidification. It should not be confused with base (chemistry), basicity, which is an absolute measurement on the pH scale. Alkalinity is the strength of a buffer s ...

promotes the mineralization of dissolved (from the atmosphere) to produce calcite

Calcite is a Carbonate minerals, carbonate mineral and the most stable Polymorphism (materials science), polymorph of calcium carbonate (CaCO3). It is a very common mineral, particularly as a component of limestone. Calcite defines hardness 3 on ...

(CaCO3), which can accumulate to as thick as 20 cm. This can also lead to the dissolution of other metals in slag, such as iron (Fe), manganese

Manganese is a chemical element; it has Symbol (chemistry), symbol Mn and atomic number 25. It is a hard, brittle, silvery metal, often found in minerals in combination with iron. Manganese was first isolated in the 1770s. It is a transition m ...

(Mn), nickel

Nickel is a chemical element; it has symbol Ni and atomic number 28. It is a silvery-white lustrous metal with a slight golden tinge. Nickel is a hard and ductile transition metal. Pure nickel is chemically reactive, but large pieces are slo ...

(Ni), and molybdenum

Molybdenum is a chemical element; it has Symbol (chemistry), symbol Mo (from Neo-Latin ''molybdaenum'') and atomic number 42. The name derived from Ancient Greek ', meaning lead, since its ores were confused with lead ores. Molybdenum minerals hav ...

(Mo), which become insoluble in water and mobile as particulate matter

Particulate matter (PM) or particulates are microscopic particles of solid or liquid matter suspended in the air. An ''aerosol'' is a mixture of particulates and air, as opposed to the particulate matter alone, though it is sometimes defin ...

. The most effective method to detoxify alkaline ground water discharge is air sparging Air sparging, also known as ''in situ'' air stripping and ''in situ'' volatilization is an ''in situ'' remediation technique, used for the treatment of saturated soils and groundwater contaminated by volatile organic compounds (VOCs) like petroleum ...

.

Fine slags and slag dusts generated from milling

Milling may refer to:

* Milling (minting), forming narrow ridges around the edge of a coin

* Milling (grinding), breaking solid materials into smaller pieces by grinding, crushing, or cutting in a mill

* Milling (machining), a process of using ro ...

slags to be recycled into the smelting process or upcycled in a different industry (e.g. construction) can be carried by the wind, affecting a larger ecosystem. It can be ingested and inhaled, posing a direct health risk

A health risk assessment (also referred to as a health risk appraisal and health & well-being assessment) is a questionnaire about a person's medical history, demographic characteristics and lifestyle. It is one of the most widely used screening ...

to the communities near the plants

Plants are the eukaryotes that form the kingdom Plantae; they are predominantly photosynthetic. This means that they obtain their energy from sunlight, using chloroplasts derived from endosymbiosis with cyanobacteria to produce sugars f ...

, mines, disposal sites, etc.

See also

* Calcium cycle *Circular economy

A circular economy (also referred to as circularity or CE) is a model of resource Production (economics), production and Resource consumption, consumption in any economy that involves sharing, leasing, Reuse, reusing, repairing, refurbishing, and ...

* Clinker (waste)

Clinker is a generic name given to waste from industrial processes, particularly those that involve smelting metals, welding, burning fossil fuels and use of a blacksmith's forge, which commonly causes a large buildup of clinker around the tuyere ...

* Dross

Dross is a mass of solid impurities floating on a molten metal or dispersed in the metal, such as in wrought iron. It forms on the surface of low- melting-point metals such as tin, lead, zinc or aluminium or alloys by oxidation of the metal. Fo ...

* Fly ash

Coal combustion products (CCPs), also called coal combustion wastes (CCWs) or coal combustion residuals (CCRs), are byproducts of burning coal. They are categorized in four groups, each based on physical and chemical forms derived from coal combust ...

* Ground granulated blast furnace slag

* Heavy metals

upright=1.2, Crystals of lead.html" ;"title="osmium, a heavy metal nearly twice as dense as lead">osmium, a heavy metal nearly twice as dense as lead

Heavy metals is a controversial and ambiguous term for metallic elements with relatively h ...

* Mill scale

Mill scale, often shortened to just scale, is the flaky surface of hot rolled steel, consisting of the mixed iron oxides iron(II) oxide (, wüstite), iron(III) oxide (, hematite), and iron(II,III) oxide (, magnetite).

Mill scale is formed on t ...

* Pozzolan

Pozzolans are a broad class of siliceous and aluminous materials which, in themselves, possess little or no cementitious value but which will, in finely divided form and in the presence of water, react chemically with calcium hydroxide (Ca(OH)2 ...

* Slag (welding)

Welding slag is a form of slag, or glass, vitreous material produced as a byproduct of some arc welding processes, most specifically shielded metal arc welding (also known as stick welding), submerged arc welding, and flux-cored arc welding. Slag i ...

* Spoil tip

A spoil tip (also called a boney pile, culm bank, gob pile, waste tip or bing) is a pile built of accumulated ''spoil'' – waste material removed during mining. Spoil tips are not formed of slag, but in some areas, such as England and Wales, ...

* Tailings

In mining, tailings or tails are the materials left over after the process of separating the valuable fraction from the uneconomic fraction (gangue) of an ore. Tailings are different from overburden, which is the waste rock or other material ...

References

Further reading

* * *External links

Types of Slag

Electric Arc Furnace (EAF) Slag

US EPA {{Authority control Amorphous solids Materials with minor glass phase Steelmaking Smelting Metallurgical by-products Articles containing video clips